Download the 2009 CR Review PDF 6.73MB - Tesco PLC

Download the 2009 CR Review PDF 6.73MB - Tesco PLC

Download the 2009 CR Review PDF 6.73MB - Tesco PLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

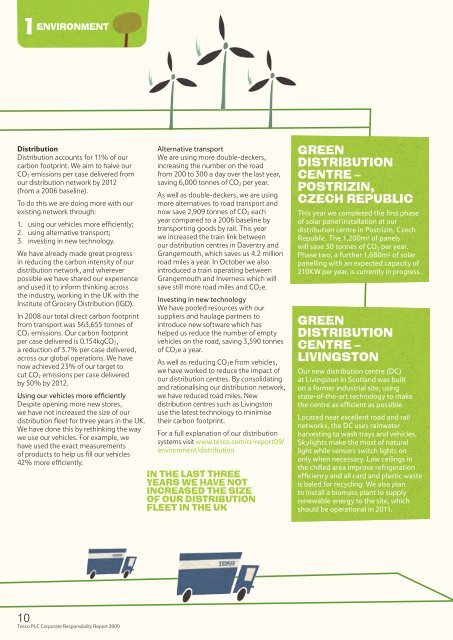

1 EnviRonMEnt<br />

Distribution<br />

Distribution accounts for 11% of our<br />

carbon footprint. We aim to halve our<br />

CO2 emissions per case delivered from<br />

our distribution network by 2012<br />

(from a 2006 baseline).<br />

To do this we are doing more with our<br />

existing network through:<br />

1. using our vehicles more efficiently;<br />

2. using alternative transport;<br />

3. investing in new technology.<br />

We have already made great progress<br />

in reducing <strong>the</strong> carbon intensity of our<br />

distribution network, and wherever<br />

possible we have shared our experience<br />

and used it to inform thinking across<br />

<strong>the</strong> industry, working in <strong>the</strong> UK with <strong>the</strong><br />

Institute of Grocery Distribution (IGD).<br />

In 2008 our total direct carbon footprint<br />

from transport was 563,655 tonnes of<br />

CO2 emissions. Our carbon footprint<br />

per case delivered is 0.154kgCO2,<br />

a reduction of 3.7% per case delivered,<br />

across our global operations. We have<br />

now achieved 23% of our target to<br />

cut CO2 emissions per case delivered<br />

by 50% by 2012.<br />

Using our vehicles more efficiently<br />

Despite opening more new stores,<br />

we have not increased <strong>the</strong> size of our<br />

distribution fleet for three years in <strong>the</strong> UK.<br />

We have done this by rethinking <strong>the</strong> way<br />

we use our vehicles. For example, we<br />

have used <strong>the</strong> exact measurements<br />

of products to help us fill our vehicles<br />

42% more efficiently.<br />

10<br />

<strong>Tesco</strong> <strong>PLC</strong> Corporate Responsibility Report <strong>2009</strong><br />

Alternative transport<br />

We are using more double-deckers,<br />

increasing <strong>the</strong> number on <strong>the</strong> road<br />

from 200 to 300 a day over <strong>the</strong> last year,<br />

saving 6,000 tonnes of CO2 per year.<br />

As well as double-deckers, we are using<br />

more alternatives to road transport and<br />

now save 2,909 tonnes of CO2 each<br />

year compared to a 2006 baseline by<br />

transporting goods by rail. This year<br />

we increased <strong>the</strong> train link between<br />

our distribution centres in Daventry and<br />

Grangemouth, which saves us 4.2 million<br />

road miles a year. In October we also<br />

introduced a train operating between<br />

Grangemouth and Inverness which will<br />

save still more road miles and CO2e.<br />

Investing in new technology<br />

We have pooled resources with our<br />

suppliers and haulage partners to<br />

introduce new software which has<br />

helped us reduce <strong>the</strong> number of empty<br />

vehicles on <strong>the</strong> road, saving 3,590 tonnes<br />

of CO2e a year.<br />

As well as reducing CO2e from vehicles,<br />

we have worked to reduce <strong>the</strong> impact of<br />

our distribution centres. By consolidating<br />

and rationalising our distribution network,<br />

we have reduced road miles. New<br />

distribution centres such as Livingston<br />

use <strong>the</strong> latest technology to minimise<br />

<strong>the</strong>ir carbon footprint.<br />

For a full explanation of our distribution<br />

systems visit www.tesco.com/cr-report09/<br />

environment/distribution<br />

in thE Last thREE<br />

YEaRs WE havE not<br />

incREasEd thE sizE<br />

of ouR distRibution<br />

fLEEt in thE uK<br />

GREEn<br />

distRibution<br />

cEntRE –<br />

PostRizin,<br />

czEch REPubLic<br />

This year we completed <strong>the</strong> first phase<br />

of solar panel installation at our<br />

distribution centre in Postrizin, Czech<br />

Republic. The 1,200m 2 of panels<br />

will save 30 tonnes of CO 2 per year.<br />

Phase two, a fur<strong>the</strong>r 1,680m 2 of solar<br />

panelling with an expected capacity of<br />

210KW per year, is currently in progress.<br />

GREEn<br />

distRibution<br />

cEntRE –<br />

LivinGston<br />

Our new distribution centre (DC)<br />

at Livingston in Scotland was built<br />

on a former industrial site, using<br />

state-of-<strong>the</strong>-art technology to make<br />

<strong>the</strong> centre as efficient as possible.<br />

Located near excellent road and rail<br />

networks, <strong>the</strong> DC uses rainwater<br />

harvesting to wash trays and vehicles.<br />

Skylights make <strong>the</strong> most of natural<br />

light while sensors switch lights on<br />

only when necessary. Low ceilings in<br />

<strong>the</strong> chilled area improve refrigeration<br />

efficiency and all card and plastic waste<br />

is baled for recycling. We also plan<br />

to install a biomass plant to supply<br />

renewable energy to <strong>the</strong> site, which<br />

should be operational in 2011.