Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

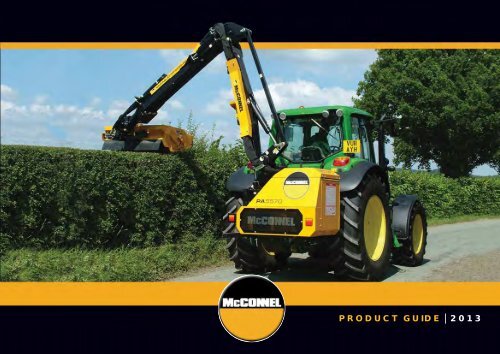

PRODUCT GUIDE 2013

Power Arms<br />

11 Series<br />

29 machines<br />

8 new models<br />

Rotary Mowers<br />

9 Series<br />

14 machines<br />

3 new models<br />

Flail Mowers<br />

7 Series<br />

21 machines<br />

6 new models<br />

Cultivation<br />

7 Series<br />

14 machines<br />

3 new models<br />

Robocut<br />

1 Series<br />

1 machine<br />

5 new attachments

Introduction<br />

Welcome to the 2013 <strong>McConnel</strong> <strong>Product</strong> <strong>Guide</strong><br />

As the world’s leading manufacturer of reach arm, green maintenance and cultivation technology, <strong>McConnel</strong> has been setting new standards for<br />

innovation, quality, and precision engineering for more than 75 years.<br />

We continue to develop next-generation machinery - constantly refining our world-famous range of Power Arms with the latest technology and<br />

introducing exciting new products such as Robocut our all-terrain remote control mower and Revolution the most advanced reach arm control system<br />

ever created.<br />

<strong>McConnel</strong> is proud to fly the flag for the United Kingdom as one of Britain’s truly successful manufacturing companies, and despite the recession, we<br />

are going from strength to strength with record sales and exports to more than 40 different countries.<br />

We have ambitious plans for the future and are making a huge investment to expand and improve our capacity and further improve the quality of our<br />

products. We’re also investing in people offering scholarships and apprenticeships to the next generation of technicians, designers and engineers.<br />

The 2013 <strong>McConnel</strong> <strong>Product</strong> <strong>Guide</strong> showcases this comprehensive range of hedge cutting, mowing, and cultivation equipment and I hope it will prove<br />

invaluable in helping you find the perfect machine to meet your needs.<br />

Christian Davies<br />

General Manager<br />

INTRODUCTION<br />

3

4<br />

Contents<br />

›››<br />

NEW<br />

NEW PA5155<br />

Page Description<br />

3 Welcome<br />

4 Contents<br />

6 Hedge and Verge Mowers Introduction<br />

8 Hedge and Verge Mower Reach Dimensions<br />

10 Fitting A Power Arm<br />

12 Swingtrim<br />

14 PA3430 / PA4330<br />

16 PA3530<br />

18 PA4745<br />

20 PA5155 / PA5455<br />

22 PA5360 / PA5860<br />

24 PA5570 / PA6070<br />

26 PA6570T / PA7070T<br />

28 PA6085 / PA6585<br />

30 PA6585T / PA7085T / PA8085T<br />

›››<br />

NEW<br />

NEW PA5360<br />

PA6570T<br />

Page Description Page Description<br />

32 PA8085TT<br />

59 Angle Float Kit<br />

34 PA5600 / PA6400<br />

60 Orbitor Head Bracket<br />

36 PA6500T<br />

61 Parallel Arm Geometry<br />

38 PA7700T / PA8000T<br />

61 Power Slew<br />

40 PA6400MM<br />

62 Hy Reach Geometry<br />

42 PA8000MM<br />

64 Safety Breakaway<br />

44 PA5054 VERSI<br />

65 Variable Forward Reach<br />

46 PA5565 VERSI<br />

66 Telescopic Dipper Arm<br />

48 Custom Built Power Arms<br />

67 Midcut Pack<br />

50 Control Systems<br />

68 Flailhead Overview<br />

52 REVOLUTION Control<br />

70 Rotor Options<br />

54 EDS - Easy Drive System<br />

71 Flail Options<br />

56 Power Arm Features<br />

72 Flailhead Roller Options<br />

57 Rotor Control Options<br />

74 Flailhead Front Hoods<br />

58 Lift Float Kit<br />

75 Flailhead Drive Options<br />

›››

›››<br />

SR Mower<br />

Page Description<br />

76 TwinCut Flailheads<br />

78 PA Attachments Introduction<br />

79 Ditch and Grip Cleaner<br />

80 Swingtrim Cutter Bar<br />

81 Sheartrim SD<br />

82 Sheartrim MD<br />

83 Shreartrim HD<br />

84 Multisaw 1600<br />

85 Multisaw 2000 / 2400<br />

87 Fine Cut Rotary Head<br />

90 Rotary Head MD / HD<br />

88 PA Accessories<br />

90 Barrier Mower<br />

94 Rotary & Flail Mowers Introduction<br />

96 Roller Mower Series<br />

›››<br />

NEW<br />

NEW Discaerator 4000<br />

Page Description<br />

98 SE Series<br />

100 PT Series<br />

102 Topper 9<br />

104 CY2000<br />

106 SR420<br />

108 SR460<br />

110 SR620<br />

112 SR820<br />

114 Flexwing Features<br />

116 Flexwing Applications<br />

118 Magnum Series<br />

120 Magnum Elite Series<br />

122 Magnum Euro Series<br />

124 Magnum Euro Open<br />

126 Magnum Elite Offset<br />

›››<br />

NEW<br />

NEW ROBOCUT<br />

Page Description<br />

128 Merlin Xtreme<br />

130 Merlin Xtreme Offset<br />

132 Cultivation, Grassland Introduction<br />

134 Pasturator<br />

136 Grassland Shakaerator<br />

138 Vibratilth - Compact<br />

140 Shakaerator 3000<br />

142 Shakaerator 5000<br />

144 Discaerator 3000<br />

146 Discaerator 4000, 5000, 6000<br />

148 Shakaerator Feature<br />

150 Rollers Features and Applications<br />

152 Robocut<br />

170 Robocut Attachments<br />

CONTENTS<br />

5

6<br />

Hedge & Verge Mowers<br />

<strong>McConnel</strong>’s Power Arm hedge and<br />

grass cutters represent the most<br />

comprehensive range of three point<br />

linkage-mounted and bracket-mounted<br />

machines available to suit your tractor<br />

and conditions on the market today.<br />

From the outset <strong>McConnel</strong> has always been<br />

highly regarded by farmers and contractors<br />

when it comes to the maintenance of hedges<br />

and grassland.<br />

Today the <strong>McConnel</strong> name is synonymous<br />

with quality, durability and reliability<br />

throughout the world in manufacturing costeffective<br />

equipment specifically for<br />

maintaining hedgerows, verges and ditches,<br />

forestry, parks and sports grounds.<br />

The benefit of more than 75 years<br />

experience in developing tractor-mounted<br />

attachments in hedge and grass cutting,<br />

offers our customer the widest choice<br />

from the market leader.

Compact Power Arms<br />

pg 12 Swingtrim<br />

pg 14 PA3430 / PA4330 pg 16 PA3530<br />

Min 15hp Max Reach 3.5m<br />

Agriculural Power Arms<br />

Min 35hp Max Reach 3.4m / 4.3m<br />

Min 35hp Max Reach 3.7m<br />

pg 18 PA4745<br />

pg 20 PA5155 / PA5455 pg 22 PA5360 / PA5860<br />

Min 50hp Max Reach 4.7m<br />

Contractor Power Arms<br />

Min 60hp Max Reach 5.1m / 5.4m<br />

Min 65hp Max Reach 5.3m / 5.8m<br />

pg 24 PA5570 / PA6070 pg 26 PA6570T / PA7070T pg 28 PA6085 / PA6585 pg 30 PA6585T / PA7085T / PA8085T pg 32 PA8085TT<br />

pg 38 PA5600 / PA6400<br />

Min 70hp Max Reach 5.5m / 6.0m<br />

Contractor Power Arms<br />

PA6500T<br />

Min 75hp Max Reach 6.5m<br />

Min 75hp Max Reach 6.5m / 7.0m<br />

pg 40 pg 42 PA7700T / PA8000T<br />

Min75hp Max Reach 7.7m / 8.0m<br />

Min 85hp Max Reach 6.0m / 6.5m<br />

Min 85hp Max Reach 6.5m / 7.0m / 8.0m<br />

Min 130hp Max Reach 8.0m<br />

Min75hp Max Reach 5.6m / 6.4m<br />

pg 34 PA6400MM<br />

pg 36 PA8000MM<br />

pg 44 PA5054 VERSI pg 46 PA5565 VERSI<br />

Min 75hp Max Reach 6.4m<br />

Min 130hp Max Reach 8.0m<br />

Min 75hp Max Reach 5.0m<br />

Min 75hp Max Reach 5.5m<br />

HEDGE & VERGE MOWERS<br />

7

Linkage - Mounted<br />

8<br />

Hedge & Verge Mowers<br />

Timeline<br />

Bracket - Mounted<br />

1975 1980 1985 1990 1995 2000<br />

PA27 - 2.7m<br />

PA31 - 3.1m<br />

2005<br />

2010<br />

PA90 - 3.8m PA32 - 3.4m<br />

PA35FM - 3.7m<br />

PA91 - 3.8m<br />

PA41 - 4.3m<br />

PA45 - 4.5m<br />

PA470 - 4.7m<br />

PA47 - 4.7m<br />

PA48 - 4.8m<br />

PA22 - 3.7m<br />

PA32 - 2.7m<br />

PA92 - 4.0m<br />

PA93 - 4.6m<br />

PA92L - 4.5m<br />

PA92 - 4.9m<br />

PA50 - 5.0m<br />

PA25 - 4.25m<br />

PA93 - 5.0m<br />

PA35 - 4.6m<br />

PA500 - 5.2m<br />

PA94 - 4.6m<br />

PA500 - 5.2m<br />

PA93E - 4.6m<br />

PA52FM - 5.0m<br />

PA500E - 5.2m<br />

PA52 - 5.2m<br />

PA53 - 5.3m<br />

PA9058 - 5.8m<br />

PA590 - 5.9m<br />

PA550 - 5.51m<br />

1975 1980 1985 1990 1995 2000 2005 2010<br />

PA650 - 6.51m<br />

PA600 PA6085 - 6.0m<br />

PA44 - 3.75m<br />

PA44C Cable - 4.37m<br />

Hy Reach Hi Fy - 4.03m<br />

PA5600 - 5.6m<br />

Hy Reach Super E - 4.8m<br />

PA6585 - 6.5m<br />

Hy Reach Cable<br />

Hy Reach Super E<br />

PA6400 - 6.4m<br />

Hy Reach Super VE<br />

PA6585T - 6.5m<br />

Hy Reach Extra - 4.8m<br />

PA6500T - 6.5m<br />

PA96E - 4.8m<br />

PA7085T - 7.0m<br />

Hy Reach Xl Long Reach<br />

PA2050 - 5.2m<br />

PA7700T - 7.7m<br />

Hy Reach XLE<br />

PA2050 - 5.2m<br />

PA8000T - 8.0m<br />

PA8085T - 8.0m<br />

Hy Reach Extra Plus - 5.85m<br />

PA2050M - 5.2m<br />

PA97E - 5.85m<br />

PA5000M - 5.6m<br />

PA2050T - 6.1m<br />

PA5000T - 6.5m<br />

PA2060 - 5.5m PA2060 - 6.0m<br />

PA6000 - 6.4m<br />

PA2080 - 5.5m PA2060M - 6.0m<br />

PA6000M - 6.4m<br />

PA2070 - 6.35m PA2070T - 6.98m<br />

PA7000T - 7.7m<br />

PA8000TT - 8.0m<br />

PA6400MM (ECON) - 6.4m<br />

PA8085TT - 8.0m<br />

PA8000MM - 8.0m<br />

PA180 DC - 5.5m<br />

PA5054 VERSI - 5.0m<br />

PA5565 VERSI - 5.5m<br />

PA59 - 5.9m<br />

PA55 - 5.5m<br />

PA60 - 6.0m<br />

PA65T - 6.5m<br />

PA70T - 7.0m<br />

PA3430 - 3.4m<br />

PA3530 - 3.7m<br />

PA4330 - 4.3m<br />

PA58 - 5.8m<br />

PA4745 - 4.7m<br />

PA5155 - 5.1m<br />

PA5455 - 5.4m<br />

PA5360 - 5.3m<br />

PA5860 - 5.8m<br />

PA5570 - 5.5m<br />

PA6070 - 6.0m<br />

PA6570T - 6.5m<br />

PA7070T - 7.0m<br />

PA6085 - 6.0m

Hedge & Verge Mowers<br />

Reach Dimensions<br />

Power Arm Reach Dimensions<br />

Machine<br />

A=Max Reach<br />

Head Horizontal<br />

B=Max Reach<br />

Head Verticle<br />

C=Max Height<br />

Head Horizontal<br />

D=Max Height<br />

Head Verticle<br />

Swingtrim 3.5m / 11’ 5” 2.2m / 7’ 2” 3.1m / 10 ’2” 4.6m / 14 ’9” 1.2m / 3’ 9” 1.1m / 3’ 6”<br />

PA3430 3.4m / 11’ 2” 3.0m / 9’ 10” 3.0m / 9’ 10” 3.8m / 12’ 6” 1.4m / 4’ 7” 1.6m / 5’ 3”<br />

PA4330 4.3m / 14’ 1” 4.0m / 13’ 0” 4.1m / 13’ 5” 4.2m / 13’ 8” 1.8m / 4’ 10” 1.7m / 5’ 6”<br />

PA3530 3.7m / 10’ 0” 3.3m / 10’ 10” 3.0m / 9’ 10” 3.8m / 12’ 6” 1.4m / 4’ 7” 1.6m / 5’ 3”<br />

PA4745 4.7m / 15’ 5” 4.1m / 13’ 4” 4.0m / 13’ 0” 5.4m / 17’ 10” 2.2m / 7’ 3” 2.2m / 7’ 3”<br />

PA5155 5.1m / 16’ 9” 4.5m / 14’ 6” 4.9m / 16’ 2” 6.4m / 20’ 10” 2.4m / 7’ 10” 2.4m / 7’ 10”<br />

PA5455 5.4m / 17’ 9” 4.5m / 14’ 6” 4.9m / 16’ 2” 6.4m / 20’ 10” 2.4m / 7’ 10” 2.4m / 7’ 10”<br />

PA5360 5.3m / 17’ 5” 4.7m / 15’ 5” 4.9m / 16’ 2” 6.4m / 20’ 10” 2.4m / 7’ 10” 2.4m / 7’ 10”<br />

PA5860 5.8m / 19’ 0” 4.7m / 15’ 5” 5.3m / 17’ 5” 6.3m / 20’ 8” 2.6m / 8’ 6” 2.4m / 7’ 10”<br />

PA5570 5.5m / 18’ 0” 4.9m / 16’ 0” 5.9m / 17’ 0” 6.7m / 21’ 11” 2.7m / 8’ 8”<br />

PA6070 6.0m / 19’ 8” 5.4m / 17’ 10” 5.7m / 18’ 7” 7.2m / 23’ 6” 3.0m / 9’ 8”<br />

E=Max Depth<br />

Verticle Head Depth 45O F=Siding Width<br />

Verticle Head Depth 45O 2.4m / 7’ 10”<br />

2.5m / 8’ 2”<br />

PA6570T 6.5m / 21’ 4” 5.9m / 19’ 4” 6.1m / 19’ 9” 7.1m / 23’ 2” 3.3m / 10’ 8” 2.6m / 8’ 4”<br />

PA7070T 7.0m / 23’ 0” 5.9m / 19’ 4” 6.1m / 19’ 9” 7.1m / 23’ 2” 3.3m / 10’ 8” 2.6m / 8’ 4”<br />

PA6085 6.0m / 18’ 1” 5.9m / 19’ 4” 6.1m / 19’ 9” 7.1m / 23’ 2” 4.5m / 14’ 9” 2.1m / 9’ 6”<br />

PA6585 6.5m / 21’ 4” 6.0m / 18’ 1” 5.4m / 17’ 8” 6.8m / 22’ 4” 3.0m / 9’ 10” 2.6m / 8’ 6”<br />

PA6585T 6.5m / 21’ 4” 6.0m / 18’ 1” 5.4m / 17’ 8” 6.8m / 22’ 4” 3.0m / 9’ 10” 2.6m / 8’ 6”<br />

PA7085T 7.0m / 23’ 0” 5.9m / 19’ 4” 6.1m / 19’ 9” 7.1m / 23’ 2” 3.3m / 10’ 8” 2.6m / 8’ 4”<br />

PA8085T 8.0m / 26’ 3” 7.7m / 25’ 3 6.9m / 22’ 6” 7.9m / 25’ 9” 4.1m / 13’ 5” 2.6m / 8’ 6”<br />

PA8085TT 8.0m / 26’ 3” 7.7m / 25’ 3” 6.9m / 22’ 6” 7.9m / 25’ 9” 4.1m / 13’ 5” 2.6m / 8’ 6”<br />

PA5600 6.5m / 21’ 4” 6.0m / 18’ 1” 5.4m / 17’ 8” 6.8m / 22’ 4” 3.0m / 9’ 10” 2.6m / 8’ 6”<br />

PA6400 6.5m / 21’ 4” 6.0m / 18’ 1” 5.4m / 17’ 8” 6.8m / 22’ 4” 3.0m / 9’ 10” 2.6m / 8’ 6”<br />

PA6500T 7.0m / 23’ 0” 5.9m / 19’ 4” 6.1m / 19’ 9” 7.1m / 23’ 2” 3.3m / 10’ 8” 2.6m / 8’ 4”<br />

PA7700T 8.0m / 26’ 3” 7.7m / 25’ 3 6.9m / 22’ 6” 7.9m / 25’ 9” 4.1m / 13’ 5” 2.6m / 8’ 6”<br />

PA8000T 8.0m / 26’ 3” 7.7m / 25’ 3” 6.9m / 22’ 6” 7.9m / 25’ 9” 4.1m / 13’ 5” 2.6m / 8’ 6”<br />

PA6400MM 6.4m / 21’ 0” 6.2m / 20’ 3” 3.5m / 11’ 5” 5.0m / 16’ 4” 3.0m / 10’ 00” 2.8m / 9’ 2”<br />

PA8000MM 8.0m / 26’ 3” 7.7m / 25’ 3” 5.6m / 18’ 4” 6.8m / 22’ 4” 4.1m / 13’ 5” 3.0m / 9’ 10”<br />

PA5054 VERSI 5.0m / 16’ 5” 5.0m / 16’ 5” 3.8m / 12’ 5” 5.2m / 17’ 1” 2.5m / 8’ 2” 2.5m / 8’ 2”<br />

PA5565 VERSI 5.5m / 19’ 8” 5.0m / 16’ 5” 5.6m / 18’ 4” 6.8m / 22’ 4” 4.5m / 14’ 9” 2.9m / 9’ 6”<br />

D<br />

C<br />

E<br />

A<br />

B<br />

F<br />

HEDGE & VERGE MOWER REACH DIMENSIONS<br />

9

10<br />

Fitting a<br />

Power Arm

Fitting a Three Point or a Five Point Linkage Power Arm<br />

Three Point Linkage Five Point Linkage<br />

A Frame Linkage<br />

1. Attach lower<br />

1. Fit latch<br />

Power Arms fitted with A-frames for three point linkage<br />

links<br />

assemblies to<br />

tractor<br />

Swingtrim PA5155 PA6070<br />

PA3430 PA5455 PA6570T<br />

PA4330 PA5360 PA7070T<br />

PA3530 PA5860 PA6085<br />

PA4745 PA5570 PA5054 VERSI<br />

2. Attach yoke<br />

to tractor, then<br />

fit top link.<br />

3. Raise hydraulic<br />

arms to engage legs of<br />

yoke with hedgecutter<br />

frame, slide along until<br />

adjustable stops are<br />

reached and secure.<br />

To remove: Ensure flailhead is to the rear and<br />

resting on the ground. Extend parking stands<br />

and withdraw latch locking pins, raise hydraulics<br />

and remove top link. Pull cords to release<br />

latches and lower machine onto parking stands.<br />

If desired, remove latch assemblies from tractor.<br />

Note: Illustration purposes only.<br />

Please refer to Operators manual for fitting<br />

details.<br />

2. Attach lower<br />

links to floating<br />

pins.<br />

3. Lift machinery<br />

until mounting<br />

arms engage in<br />

latches, insert<br />

locking pins.<br />

4. Continue<br />

lifting machine<br />

until frame is<br />

level, then<br />

attach top link.<br />

5. Lower linkage arms until the<br />

weight of the PA is evenly distributed<br />

across the top<br />

link, linkage arms<br />

& axle brackets.<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Sub-Frame Conversion Kit<br />

Power Arms that can be upgraded to axle mounting<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

PA5360<br />

PA5860<br />

PA5570<br />

PA6070<br />

PA6570T<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

PA7070T<br />

PA6085<br />

Axle Mounted<br />

Power Arms fitted with five-point axle mounting as standard<br />

›››<br />

›››<br />

›››<br />

›››<br />

PA6585<br />

PA6585T<br />

PA7085T<br />

PA8085T<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

PA8085TT<br />

PA5565 VERSI<br />

FITTING A POWER ARM<br />

11

12<br />

Swingtrim<br />

3.5m (11’ 6”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

3.2m or 3.5m reach ( 1.2m or 1.5m<br />

cutter bar options)<br />

Dual cutting (L.H. and R.H. cutting)<br />

Low power requirement<br />

Three-point linkage-mounting system<br />

Operator-friendly<br />

Choice of control systems<br />

Front-mounting option<br />

Eliminates white finger<br />

Optional pump and tank kit<br />

Markets<br />

Horticultural/Landscape<br />

Groundcare/Amenity<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

550kg minimum tractor weight<br />

15hp minimum tractor horsepower

Tractor Requirements<br />

Minimum Horse Power Requirements<br />

Machine Specification<br />

15hp Minimum Tractor Weight 550kg<br />

Maximum Reach 3.5m (11’6”) Power Arm Horsepower<br />

15hp<br />

Machine Weight*<br />

Hydraulics<br />

192kg Oil tank Capacity<br />

N/A<br />

Gear Semi Independent<br />

Method of Attachment<br />

o Gear Totally Independent<br />

o<br />

3-Point Linkage-Mounted<br />

Controls<br />

n 5-Point Axle Bracket-Mounted<br />

—<br />

Cable Control<br />

o Xtra Touch Control - Mini (XTC - Mini) o<br />

Switchbox — Xtra Touch Control<br />

—<br />

Monolever<br />

Machine Equipment<br />

— REVOLUTION Control + EDS (Optional) —<br />

Parallel Arm Geometry<br />

— Telescopic Dipper Arm<br />

—<br />

Midcut Pack or VFR — Angle Float Kit - Standard On Electric Models —<br />

Lift Float Kit — Easy Drive System (EDS)<br />

—<br />

Oil Cooler — Power Slew<br />

—<br />

Safety Breakaway - Mechanical<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

n<br />

—<br />

—<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control -(Not Dual Rotation - Cutterbar Controls)<br />

Window Guards<br />

n<br />

o<br />

n<br />

Cushioned Top Link — Debris Blower<br />

—<br />

Front Mounting Build o Orbitor Head Kit<br />

—<br />

Front Flap Kit — Flailhead Skid Kit<br />

—<br />

Hydraulic Roller<br />

— Flailhead Cushioned Grass Mowing Roller —<br />

Power Arm Attachments<br />

1.20m Swingtrim Cutter Bar<br />

o 1.50m Omega Flailhead - DD or BD —<br />

1.50m Swingtrim Cutter Bar o 1.60m Multicut Flailhead - DD or BD —<br />

1.50m Sheartrim Cutter Bar - SD — 1.60m Omega Flailhead - DD or BD —<br />

1.60m Sheartrim Cutter Bar - MD — 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD — 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD — 1.20m Rotary Head - MD - 1 Rotor —<br />

2.20m Sheartrim Cutter Bar - HD — 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD — 1.40m Multisaw 1400<br />

o<br />

1.20m Supercut Flailhead - DD — 1.60m Multisaw 1600<br />

—<br />

1.20m Multicut Flailhead - DD or BD — 2.00m Multisaw 2000<br />

—<br />

1.20m Omega Flailhead - DD or BD — 2.40m Multisaw 2400<br />

—<br />

1.50m Multicut Flailhead - DD or BD — 0.70m Ditch and Grip Cleaner<br />

—<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

4<br />

8<br />

Cable<br />

Monolever<br />

XTC<br />

C<br />

B<br />

A<br />

8<br />

4<br />

8 8<br />

Choice of Controls<br />

D E<br />

For illustration purposes only<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 3.5m<br />

(11’6”)<br />

B 2.2m<br />

(7’3”)<br />

C<br />

1.7m<br />

(5’7”)<br />

D 3.1m<br />

(10’2”)<br />

E<br />

4.6m<br />

(15’1”)<br />

›››<br />

›››<br />

›››<br />

Coniferous Hedges<br />

Multisaw option<br />

Front Mount Option<br />

SWINGTRIM<br />

13

14<br />

PA3430<br />

3.4m (11’ 2”) reach<br />

PA4330<br />

4.3m (14’ 1”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

3.4m and 4.3m reach<br />

Left hand or right hand build option<br />

Low power requirement<br />

Three-point linkage-mounting system<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

High-performance hydraulic system<br />

Storage support legs<br />

Operator-friendly<br />

Choice of control systems<br />

Choice of attachments<br />

Front-mounted build option<br />

Markets<br />

Horticultural/Landscape<br />

Groundcare/Amenity<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

1300kg minimum tractor weight<br />

35hp minimum tractor horsepower<br />

See PA3430 in action at:<br />

www.mcconnel.com/videos/

Tractor Requirements PA3430 PA4330<br />

PA3430 PA4330<br />

Min Horse Power Requirements 35hp 45hp Minimum Tractor Weight 1300kg 2000kg<br />

Machine Specification<br />

Maximum Reach 3.4m (11’2”) 4.3m (14’1”) Power Arm Horsepower<br />

30hp 30hp<br />

Machine Weight*<br />

Hydraulics<br />

400kg 523kg Oil tank Capacity<br />

80ltr 80ltr<br />

Gear Semi Independent o Gear Totally Independent<br />

o<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

n 5-Point Axle Bracket-Mounted<br />

—<br />

Cable Control<br />

o Xtra Touch Control - Mini (XTC - Mini) o<br />

Switchbox o Xtra Touch Control<br />

—<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) —<br />

Parallel Arm Geometry<br />

Midcut Pack or VFR<br />

n<br />

—<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

—<br />

o<br />

Lift Float Kit o Easy Drive System (EDS)<br />

—<br />

Oil Cooler — Power Slew<br />

—<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

n<br />

—<br />

—<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

n<br />

o<br />

n<br />

Cushioned Top Link — Debris Blower<br />

—<br />

Front Mounting Build<br />

Front Flap Kit<br />

o<br />

n<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

—<br />

o<br />

Hydraulic Roller<br />

Power Arm Attachments<br />

— Flailhead Cushioned Grass Mowing Roller —<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD —<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD —<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD —<br />

1.60m Sheartrim Cutter Bar - MD — 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD — 1.20m Rotary Head - FC - 2 Rotor o<br />

1.40m Sheartrim Cutter Bar - HD — 1.20m Rotary Head - MD - 1 Rotor —<br />

2.20m Sheartrim Cutter Bar - HD — 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD o 1.60m Multisaw 1600<br />

o<br />

1.20m Supercut Flailhead - DD — 2.00m Multisaw 2000<br />

—<br />

1.20m Multicut Flailhead - DD or BD — 2.40m Multisaw 2400<br />

—<br />

1.20m Omega Flailhead - DD or BD — 0.70m Ditch and Grip Cleaner<br />

—<br />

1.50m Multicut Flailhead - DD or BD —<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions PA3430<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

4<br />

4<br />

E<br />

D<br />

Cable<br />

Monolever<br />

XTC<br />

For illustration purposes only<br />

C<br />

4<br />

4<br />

8 8<br />

Choice of Controls<br />

B<br />

A<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 3.4m<br />

(11’2”)<br />

B 3.0m<br />

(9’10”)<br />

C<br />

2.0m<br />

(6’’7”)<br />

D 3.3m<br />

(10’10”)<br />

E<br />

4.3m<br />

(14’1”)<br />

›››<br />

›››<br />

›››<br />

Hedge Cutting<br />

Versa tile<br />

Front-Mounted<br />

POWER ARM 3430 & 4330<br />

15

16<br />

PA3530 Skid Steer / Utility Loader Series<br />

3.7m (12’ 0”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

3.7m reach<br />

Left hand or right hand build option<br />

Low power requirement<br />

Front-mounted<br />

Three-point linkage-mounting system<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

High-performance hydraulic system<br />

Folding flat arms for transport<br />

Storage support legs<br />

Operator-friendly<br />

Choice of control systems<br />

Choice of attachments<br />

Markets<br />

Horticultural/Landscape<br />

Groundcare/Amenity<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

1300kg minimum tractor weight<br />

35 hp minimum tractor horsepower

Tractor Requirements<br />

Minimum Horse Power Requirements<br />

Machine Specification<br />

35hp Minimum Tractor Weight 1300kg<br />

Maximum Reach 3.7m (12’0”) Power Arm Horsepower<br />

30hp<br />

Machine Weight*<br />

Hydraulics<br />

400kg Oil tank Capacity<br />

55 ltr<br />

Gear Semi Independent<br />

Method of Attachment<br />

o Gear Totally Independent<br />

o<br />

3-Point Linkage-Mounted<br />

Controls<br />

o DIN Plate-Mounted<br />

o<br />

Cable Control<br />

o Xtra Touch Control - Mini (XTC - Mini) o<br />

Switchbox o Xtra Touch Control<br />

—<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) —<br />

Parallel Arm Geometry<br />

Midcut Pack or VFR<br />

n<br />

—<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

—<br />

o<br />

Lift Float Kit o Easy Drive System (EDS)<br />

—<br />

Oil Cooler — Power Slew<br />

—<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

n<br />

—<br />

—<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

n<br />

o<br />

n<br />

Cushioned Top Link — Debris Blower<br />

—<br />

Front Mounting Build<br />

Front Flap Kit<br />

n<br />

n<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

—<br />

o<br />

Hydraulic Roller<br />

— Flailhead Cushioned Grass Mowing Roller —<br />

Power Arm Attachments<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD —<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD —<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD —<br />

1.60m Sheartrim Cutter Bar - MD — 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD — 1.20m Rotary Head - FC - 2 Rotor o<br />

1.40m Sheartrim Cutter Bar - HD — 1.20m Rotary Head - MD - 1 Rotor —<br />

2.20m Sheartrim Cutter Bar - HD — 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD o 1.60m Multisaw 1600<br />

o<br />

1.20m Supercut Flailhead - DD — 2.00m Multisaw 2000<br />

—<br />

1.20m Multicut Flailhead - DD or BD — 2.40m Multisaw 2400<br />

—<br />

1.20m Omega Flailhead - DD or BD — 0.70m Ditch and Grip Cleaner<br />

—<br />

1.50m Multicut Flailhead - DD or BD —<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

4<br />

4<br />

E<br />

D<br />

Cable<br />

Monolever<br />

XTC<br />

For illustration purposes only<br />

C<br />

4<br />

4<br />

8 8<br />

Choice of Controls<br />

B<br />

A<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 3.7m<br />

(12’)<br />

B 3.3m<br />

(10’10”)<br />

C<br />

2.0m<br />

(6’6”)<br />

D 3.0m<br />

(9’10”)<br />

E<br />

3.8m<br />

(12’6”)<br />

›››<br />

›››<br />

›››<br />

Verge Cutting<br />

Utility Vehicle Mounting<br />

Verge Mowing<br />

POWER ARM 3530<br />

17

18<br />

PA4745<br />

4.7m (15’ 5”) reach<br />

NEW<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

4.7m reach<br />

Left hand or right hand build option<br />

Three-point linkage-mounting system<br />

Parallel arm geometry<br />

Mechanical safety breakaway<br />

45hp high-performance hydraulic<br />

system<br />

Storage support legs<br />

Operator-friendly<br />

Choice of control systems<br />

Choice of attachments<br />

Markets<br />

Agricultural<br />

Governmental<br />

Amenity<br />

Tractor Requirements<br />

2500kg minimum tractor weight<br />

50hp minimum tractor horsepower

Tractor Requirements<br />

Minimum Horse Power Requirements<br />

Machine Specification<br />

50hp Minimum Tractor Weight 2500kg<br />

Maximum Reach 4.7m (15’5”) Power Arm Horsepower<br />

45hp<br />

Machine Weight*<br />

Hydraulics<br />

633kg Oil Tank Capacity<br />

180 ltr<br />

Gear Semi Independent<br />

Method of Attachment<br />

o Gear Totally Independent<br />

o<br />

3-Point Linkage-Mounted<br />

Controls<br />

n 5-Point Axle Bracket-Mounted<br />

—<br />

Cable Control<br />

o Xtra Touch Control - Mini (XTC - Mini) o<br />

Switchbox o Xtra Touch Control<br />

—<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) —<br />

Parallel Arm Geometry<br />

Midcut Pack<br />

n<br />

o<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Option On Electric Models only<br />

—<br />

o<br />

Lift Float Kit o Easy Drive System (EDS)<br />

—<br />

Oil Cooler<br />

Safety Breakaway - Mechanical<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build<br />

Front Flap Kit<br />

o<br />

o<br />

o<br />

o<br />

n<br />

—<br />

n<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

—<br />

n<br />

o<br />

n<br />

o<br />

o<br />

o<br />

Hydraulic Roller<br />

— Flailhead Cushioned Grass Mowing Roller —<br />

Power Arm Attachments<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD —<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD —<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD —<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor o<br />

1.40m Sheartrim Cutter Bar - HD — 1.20m Rotary Head - MD - 1 Rotor —<br />

2.20m Sheartrim Cutter Bar - HD — 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

o<br />

1.20m Supercut Flailhead - DD o 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD — 2.40m Multisaw 2400<br />

—<br />

1.20m Omega Flailhead - DD or BD — 0.70m Ditch and Grip Cleaner<br />

—<br />

1.50m Multicut Flailhead - DD or BD —<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

4<br />

4<br />

E<br />

D<br />

Cable<br />

Monolever<br />

XTC<br />

For illustration purposes only<br />

C<br />

4<br />

4<br />

8 8<br />

Choice of Controls<br />

B<br />

A<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 4.7m<br />

(15’5”)<br />

B 4.1m<br />

(13’5”)<br />

C<br />

3.0m<br />

(9’10”)<br />

D 4.0m<br />

(13’1”)<br />

E<br />

5.4m<br />

(17’9”)<br />

›››<br />

›››<br />

›››<br />

Verge Mowing<br />

Right Hand Build Option<br />

Verge Mowing<br />

POWER ARM 4745<br />

19

20<br />

PA5155<br />

5.1m (16’ 9”) reach<br />

NEW<br />

PA5455<br />

5.4m (17’ 8”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

5.1m and 5.4m reach<br />

Left or right hand build option<br />

Three-point linkage mounting system<br />

Parallel arm geometry<br />

Hy-reach arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

54hp hydraulics<br />

Storage support legs<br />

Operator-friendly<br />

Choice of control systems<br />

Choice of attachments<br />

Markets<br />

Agricultural<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

3000kg minimum tractor weight<br />

60hp minimum tractor horsepower

Tractor Requirements PA5155 PA5455<br />

PA5155 PA5455<br />

Min Horse Power Requirements 60hp 60hp Minimum Tractor Weight 3000kg 3000kg<br />

Machine Specification<br />

Maximum Reach 5.1m (16’9”) 5.4m (17’8”) Power Arm Horsepower<br />

54hp 54hp<br />

Machine Weight*<br />

Hydraulics<br />

881kg 895kg Oil tank Capacity<br />

180ltr 180ltr<br />

Gear Semi Independent o Gear Totally Independent<br />

o<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

n 5-Point Axle Bracket-Mounted<br />

—<br />

Cable Control<br />

o Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox o Xtra Touch Control<br />

o<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) —<br />

Parallel Arm Geometry<br />

Midcut Pack<br />

n<br />

o<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

—<br />

o<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

o<br />

o<br />

n<br />

n<br />

o<br />

—<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

—<br />

n<br />

n<br />

o<br />

n<br />

o<br />

Front Mounting Build<br />

Front Flap Kit<br />

Hydraulic Roller<br />

Power Arm Attachments<br />

—<br />

n<br />

o<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

o<br />

o<br />

o<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD —<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD —<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor o<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor —<br />

2.20m Sheartrim Cutter Bar - HD o 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

o<br />

1.20m Supercut Flailhead - DD o 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD o 2.40m Multisaw 2400<br />

o<br />

1.20m Omega Flailhead - DD or BD o 0.70m Ditch and Grip Cleaner<br />

o<br />

1.50m Multicut Flailhead - DD or BD<br />

o<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

4<br />

4<br />

E<br />

D<br />

Cable<br />

Monolever<br />

XTC<br />

For illustration purposes only<br />

C<br />

4<br />

8<br />

4 8<br />

Choice of Controls<br />

B<br />

A<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 5.1m<br />

(16’5”)<br />

B 4.5m<br />

(14’9”)<br />

C<br />

3.0m<br />

(9’10”)<br />

D 4.5m<br />

(14’9”)<br />

E<br />

6.0m<br />

(19’8”)<br />

›››<br />

›››<br />

›››<br />

Verge Mowing<br />

Verge Mowing<br />

Highway Maintenance<br />

POWER ARM 5155 & 5455<br />

21

22<br />

PA5360<br />

5.3m (17’ 4”) reach<br />

NEW<br />

PA5860<br />

5.8m (19’ 0”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

5.3m and 5.8m reach<br />

Left hand or right hand build option<br />

Three-point linkage-mounting<br />

Axle-mounting option<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

60hp high-performance hydraulic<br />

system<br />

Tapered, seam welded arms<br />

Hy-reach arm geometry<br />

Storage support legs<br />

Road lighting kit<br />

Operator-friendly<br />

Choice of control systems<br />

Choice of attachments<br />

Front mount option (PA5360 FM only)<br />

Markets<br />

Agricultural<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

3500kg minimum tractor weight<br />

65hp minimum tractor horsepower

Tractor Requirements PA5360 PA5860<br />

PA5360 PA5860<br />

Min Horse Power Requirements 65hp 65hp Minimum Tractor Weight 3500kg 3500kg<br />

Machine Specification<br />

Maximum Reach 5.3m (17’4”) 5.8m (19’0”) Power Arm Horsepower<br />

60hp 60hp<br />

Machine Weight*<br />

Hydraulics<br />

1010kg 1062kg Oil Tank Capacity<br />

180ltr 180ltr<br />

Gear Semi Independent — Gear Totally Independent<br />

n<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

n 5-Point Axle Bracket-Mounted<br />

o<br />

Cable Control<br />

o Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox o Xtra Touch Control<br />

o<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) o<br />

Parallel Arm Geometry<br />

Midcut Pack or VFR<br />

n<br />

o<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

—<br />

o<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build (PA53 only)<br />

Front Flap Kit<br />

Hydraulic Roller<br />

Power Arm Attachments<br />

o<br />

o<br />

n<br />

n<br />

o<br />

n<br />

o<br />

n<br />

o<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

o<br />

n<br />

n<br />

o<br />

n<br />

o<br />

o<br />

o<br />

o<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD o<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD o<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD ** o<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor o<br />

2.20m Sheartrim Cutter Bar - HD o 1.50m Rotary Head - HD - 1 Rotor ** o<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

—<br />

1.20m Supercut Flailhead - DD o 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD o 2.40m Multisaw 2400<br />

o<br />

1.20m Omega Flailhead - DD or BD o 0.70m Ditch and Grip Cleaner<br />

o<br />

1.50m Multicut Flailhead - DD or BD<br />

o<br />

n<br />

Standard Equipment o<br />

Optional Equipment —<br />

Not Available<br />

* depending on machine specification excluding attachment and oil ** PA5360 ONLY<br />

›››<br />

Reach Dimensions<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

4<br />

4<br />

Cable<br />

Monolever<br />

XTC<br />

B<br />

A<br />

C<br />

4<br />

8<br />

4 4<br />

Choice of Controls<br />

D E<br />

For illustration purposes only<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 5.3m<br />

(17’5”)<br />

B 4.7m<br />

(15’5”)<br />

C<br />

3.7m<br />

(12’2”)<br />

D 4.8m<br />

(15’9”)<br />

E<br />

6.3m<br />

(20’8”)<br />

›››<br />

›››<br />

›››<br />

Hedge Cutting<br />

Verge Mowing<br />

Verge Mowing<br />

POWER ARM 5360 & 5860<br />

23

24<br />

PA5570<br />

5.5m (18’ 0”) reach<br />

PA6070<br />

6.0m (19’ 8”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

5.5m and 6.0m reach<br />

Left hand or right hand build option<br />

Choice of three-point or five-point<br />

axle-mounting<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

70hp high-performance hydraulic<br />

system<br />

Tapered, seam welded arms<br />

Hy-reach arm geometry<br />

SoftStart Rotor Engagement (Electric<br />

rotor control only)<br />

High capacity oil cooler<br />

LED Road lighting kit<br />

Integrated Debris Blower option<br />

Choice of control systems<br />

Choice of attachments<br />

Markets<br />

Agricultural<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

3500kg minimum tractor weight<br />

70hp minimum tractor horsepower

Tractor Requirements PA5570 PA6070<br />

PA5570 PA6070<br />

Min Horse Power Requirements<br />

Machine Specification<br />

70hp<br />

3500kg<br />

Maximum Reach 5.5m (18’0”) 6.0m (19’8”) Power Arm Horsepower<br />

70hp 70hp<br />

Machine Weight*<br />

Hydraulics<br />

1102kg 1380kg Oil tank Capacity<br />

180ltr 180ltr<br />

Gear Semi Independent — Gear Totally Independent<br />

n<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

o 5-Point Axle Bracket-Mounted<br />

o<br />

Cable Control<br />

— Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox o Xtra Touch Control<br />

o<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) o<br />

Parallel Arm Geometry<br />

Midcut Pack or VFR<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build<br />

Front Flap Kit<br />

Hydraulic Roller<br />

Power Arm Attachments<br />

n<br />

o<br />

o<br />

n<br />

n<br />

n<br />

o<br />

n<br />

—<br />

n<br />

o<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

—<br />

n<br />

o<br />

n<br />

n<br />

o<br />

n<br />

o<br />

o<br />

o<br />

o<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD o<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD o<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD o<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor o<br />

2.20m Sheartrim Cutter Bar - HD o 1.50m Rotary Head - HD - 1 Rotor o<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

—<br />

1.20m Supercut Flailhead - DD — 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD o 2.40m Multisaw 2400<br />

o<br />

1.20m Omega Flailhead - DD or BD o 0.70m Ditch and Grip Cleaner<br />

o<br />

1.50m Multicut Flailhead - DD or BD<br />

70hp Minimum Tractor Weight 3500kg<br />

o<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions PA6070<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

8<br />

4<br />

Cable<br />

Monolever<br />

XTC<br />

B<br />

A<br />

C<br />

4<br />

8<br />

4 4<br />

Choice of Controls<br />

D E<br />

For illustration purposes only<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 6.0m<br />

(19’8”)<br />

B 5.4m<br />

(17’9”)<br />

C<br />

4.2m<br />

(13’9”)<br />

D 5.7m<br />

(18’8”)<br />

E<br />

7.2m<br />

(23’7”)<br />

›››<br />

›››<br />

›››<br />

Hedge Cutting<br />

Orbitor Head Option<br />

VFR Arm Set Option<br />

POWER ARM 5570 & 6070<br />

25

26<br />

PA6570T<br />

6.5m (21’ 4”) reach<br />

PA7070T<br />

7.0m (23’ 0”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

6.5m and 7.0m reach<br />

Left hand or right hand build option<br />

Choice of three-point or five-point axlemounting<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

70hp high-performance hydraulic system<br />

Tapered, seam welded arms<br />

Telescopic dipper arm<br />

Hy-reach arm geometry<br />

SoftStart Rotor Engagement (Electric<br />

rotor control only)<br />

High capacity oil cooler<br />

LED Road lighting kit<br />

Integrated Debris Blower option<br />

Choice of control systems<br />

Markets<br />

Agricultural<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

4000kg minimum tractor<br />

weight<br />

75hp minimum tractor<br />

horsepower

Tractor Requirements PA6570T PA7070T<br />

PA6570T PA7070T<br />

Min Horse Power Requirements 75hp 75hp Minimum Tractor Weight 4000kg 4000kg<br />

Machine Specification<br />

Maximum Reach 6.5m (21’4”) 7.0m (23’0”) Power Arm Horsepower<br />

70hp 70hp<br />

Machine Weight*<br />

Hydraulics<br />

1214kg 1272kg Oil tank Capacity<br />

180ltr 180ltr<br />

Gear Semi Independent — Gear Totally Independent<br />

n<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

o 5-Point Axle Bracket-Mounted<br />

o<br />

Cable Control<br />

— Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox o Xtra Touch Control<br />

o<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) o<br />

Parallel Arm Geometry<br />

Midcut Pack or VFR<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build<br />

Front Flap Kit<br />

Hydraulic Roller<br />

Power Arm Attachments<br />

n<br />

—<br />

o<br />

n<br />

n<br />

n<br />

o<br />

n<br />

—<br />

n<br />

o<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

n<br />

n<br />

o<br />

n<br />

n<br />

o<br />

n<br />

o<br />

o<br />

o<br />

o<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD —<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD —<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor o<br />

2.20m Sheartrim Cutter Bar - HD o 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

—<br />

1.20m Supercut Flailhead - DD — 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD o 2.40m Multisaw 2400<br />

o<br />

1.20m Omega Flailhead - DD or BD o 0.70m Ditch and Grip Cleaner<br />

o<br />

1.50m Multicut Flailhead - DD or BD<br />

o<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions PA6570T<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

8<br />

4<br />

Cable<br />

Monolever<br />

XTC<br />

Choice of Controls<br />

B<br />

A<br />

C<br />

4<br />

8<br />

4 4<br />

D E<br />

For illustration purposes only<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 6.5m<br />

(21’4”)<br />

B 5.9m<br />

(19’4”)<br />

C<br />

4.7m<br />

(15’5”)<br />

D 6.0m<br />

(19’8”)<br />

E<br />

7.1m<br />

(23’4”)<br />

›››<br />

›››<br />

›››<br />

Hedge Cutting<br />

Orbitor Head Option<br />

Hedge Cutting<br />

POWER ARM 6570T & 7070T<br />

27

28<br />

PA6085<br />

6.0m (19’ 8”) reach<br />

PA6585<br />

6.5m (21’ 4”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

6.0m and 6.5m reach<br />

Left hand or right hand build option<br />

Choice of three-point or five-point axlemounting<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

85hp high-performance hydraulic system<br />

Tapered, seam welded arms<br />

Hy-reach arm geometry<br />

SoftStart Rotor Engagement<br />

High capacity oil cooler<br />

LED Road lighting kit<br />

Operator-friendly<br />

Integrated Debris Blower option<br />

Markets<br />

Professional<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

4000kg minimum tractor weight<br />

85hp minimum tractor horsepower<br />

See PA6085 in action at:<br />

www.mcconnel.com/videos/

Tractor Requirements PA6085 PA6585<br />

PA6085 PA6585<br />

Min Horse Power Requirements 85hp 85hp Minimum Tractor Weight 4000kg 4000kg<br />

Machine Specification<br />

Maximum Reach 6.0m (19’8”) 6.5m (21’4”) Power Arm Horsepower<br />

85hp 85hp<br />

Machine Weight*<br />

Hydraulics<br />

1340kg 1500kg Oil tank Capacity<br />

225ltr 225ltr<br />

Gear Semi Independent — Gear Totally Independent<br />

n<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

o 5-Point Axle Bracket-Mounted<br />

o<br />

Cable Control<br />

— Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox — Xtra Touch Control<br />

o<br />

Monolever<br />

Machine Equipment<br />

— REVOLUTION Control + EDS (Optional) o<br />

Parallel Arm Geometry<br />

Midcut Pack or VFR<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build<br />

Front Flap Kit<br />

Hydraulic Roller<br />

Power Arm Attachments<br />

n<br />

o<br />

o<br />

n<br />

n<br />

n<br />

o<br />

n<br />

—<br />

n<br />

o<br />

Telescopic Dipper Arm (PA6585T only)<br />

Angle Float Kit - Standard On Electric Models<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

—<br />

n<br />

o<br />

n<br />

—<br />

n<br />

n<br />

o<br />

o<br />

o<br />

o<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD o<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD o<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD o<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor o<br />

2.20m Sheartrim Cutter Bar - HD o 1.50m Rotary Head - HD - 1 Rotor o<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

—<br />

1.20m Supercut Flailhead - DD — 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD o 2.40m Multisaw 2400<br />

o<br />

1.20m Omega Flailhead - DD or BD o 0.70m Ditch and Grip Cleaner<br />

o<br />

1.50m Multicut Flailhead - DD or BD<br />

o<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Reach Dimensions PA6585T<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

8<br />

8<br />

Cable<br />

Monolever<br />

XTC<br />

B<br />

A<br />

C<br />

8<br />

8<br />

4 4<br />

Choice of Controls<br />

D E<br />

For illustration purposes only<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 6.5m<br />

(21’4”)<br />

B 6.0m<br />

(19’8”)<br />

C<br />

5.4m<br />

(17’9”)<br />

D 6.8m<br />

(22’4”)<br />

E<br />

6.5m<br />

(21’4”)<br />

›››<br />

›››<br />

›››<br />

Hedge Cutting<br />

VFR Arm Set Option<br />

Hedge Cutting<br />

POWER ARM 6085 & 6585<br />

29

30<br />

PA6585T<br />

6.5m (21’ 4”) reach<br />

PA7085T<br />

7.0m (23’ 0”) reach<br />

PA8085T<br />

8.0m (26’ 3”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

6.5m, 7.0m and 8.0m reach<br />

Left hand or right hand build option<br />

Five-point axle-mounting<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

85hp high-performance hydraulic system<br />

Tapered, seam welded arms<br />

Hy-reach arm geometry<br />

SoftStart Rotor Engagement<br />

High capacity oil cooler<br />

LED Road lighting kit<br />

Integrated Debris Blower option<br />

Telescopic dipper arm<br />

Markets<br />

Agricultural<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

4000kg minimum tractor weight<br />

85hp minimum tractor horsepower

Tractor PA6585T PA7085T PA8085T<br />

PA6585T PA6585T PA7085T PA8085T<br />

Horse Power Requirements 85hp 85hp 85hp Minimum Tractor Weight 4000kg 5000kg 5500kg<br />

Machine Specification<br />

Maximum Reach 6.5m (21’4”) 7.0m (23’0”) 8.0m (26’3”) Power Arm Horsepower 85hp 85hp 85hp<br />

Machine Weight*<br />

Hydraulics<br />

1650kg 1700kg 1800kg Oil tank Capacity 225ltr 225ltr 225ltr<br />

Gear Semi Independent — Gear Totally Independent<br />

n<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

— 5-Point Axle Bracket-Mounted<br />

n<br />

Cable Control<br />

— Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox — Xtra Touch Control<br />

o<br />

Monolever<br />

Machine Equipment<br />

— REVOLUTION Control + EDS (Optional) o<br />

Parallel Arm Geometry<br />

Midcut Pack<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build<br />

Front Flap Kit<br />

Hydraulic Power Roller Arm Attachments<br />

n<br />

o<br />

o<br />

n<br />

n<br />

n<br />

o<br />

n<br />

—<br />

n<br />

o<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

n<br />

n<br />

o<br />

n<br />

—<br />

n<br />

n<br />

o<br />

o<br />

o<br />

o<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD —<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD —<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor o<br />

2.20m Sheartrim Cutter Bar - HD o 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

—<br />

1.20m Supercut Flailhead - DD — 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD o 2.40m Multisaw 2400<br />

o<br />

1.20m Omega Flailhead - DD or BD o 0.70m Ditch and Grip Cleaner<br />

o<br />

1.50m Multicut Flailhead - DD or BD<br />

o<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification and attachment<br />

›››<br />

Reach Dimensions PA6585T<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

8<br />

8<br />

Cable<br />

Monolever<br />

XTC<br />

B<br />

A<br />

C<br />

8<br />

8<br />

4 4<br />

Choice of Controls<br />

D E<br />

For illustration purposes only<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 6.5m<br />

(21’4”)<br />

B 6.0m<br />

(19’8”)<br />

C<br />

5.4m<br />

(17’9”)<br />

D 6.8m<br />

(22’4”)<br />

E<br />

6.5m<br />

(21’4”)<br />

›››<br />

›››<br />

›››<br />

High-Performance Hydraulics<br />

Hedge Cutting<br />

Hedge Cutting<br />

POWER ARM 6585T, 7085T & 8085T<br />

31

32<br />

PA8085TT<br />

8.0m (26’ 3”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

8.0m reach<br />

Left hand or right hand build option<br />

Five-point axle-mounting<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

85hp high-performance hydraulic<br />

system<br />

Tapered, seam welded arms<br />

Twin telescopic dipper arm<br />

Hy-reach arm geometry<br />

SoftStart Rotor Engagement<br />

Storage support legs<br />

High capacity oil cooler<br />

Road lighting kit<br />

Operator-friendly<br />

Choice of attachments<br />

Markets<br />

Professional<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

5500kg minimum tractor weight<br />

130hp minimum tractor horsepower

Tractor Requirements<br />

Minimum Horse Power Requirements<br />

Machine Specification<br />

130hp Minimum Tractor Weight 5500kg<br />

Maximum Reach 8.0m (26’3”) Power Arm Horsepower<br />

85hp<br />

Machine Weight with Flailhead (exc.oil)*<br />

Hydraulics<br />

2072kg Oil tank Capacity<br />

225 ltr<br />

Gear Semi Independent<br />

Method of Attachment<br />

— 85hp Totally Independent<br />

n<br />

3-Point Linkage-Mounted<br />

Controls<br />

— 5-Point Axle Bracket-Mounted<br />

n<br />

Cable Control<br />

— Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox — Xtra Touch Control<br />

—<br />

Monolever<br />

Machine Equipment<br />

— REVOLUTION Control + EDS (Optional) n<br />

Parallel Arm Geometry<br />

n Telescopic Dipper Arm<br />

n<br />

Midcut Pack or VFR — Angle Float Kit - Standard On Electric Models —<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build<br />

Front Flap Kit<br />

Hydraulic Roller<br />

—<br />

n<br />

n<br />

n<br />

o<br />

n<br />

—<br />

n<br />

o<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

n<br />

n<br />

—<br />

n<br />

n<br />

o<br />

o<br />

o<br />

o<br />

Power Arm Attachments<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD o<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD o<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD —<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor o<br />

2.20m Sheartrim Cutter Bar - HD o 1.50m Rotary Head - HD - 1 Rotor —<br />

1.00m Compact Supercut Flailhead - GDD — 1.60m Multisaw 1600<br />

—<br />

1.20m Supercut Flailhead - DD — 2.00m Multisaw 2000<br />

o<br />

1.20m Multicut Flailhead - DD or BD o 2.40m Multisaw 2400<br />

o<br />

1.20m Omega Flailhead - DD or BD o 0.70m Ditch and Grip Cleaner<br />

o<br />

1.50m Multicut Flailhead - DD or BD<br />

o<br />

Standard Equipment n<br />

Optional Equipment o<br />

Not Available —<br />

* depending on machine specification excluding attachment and oil<br />

›››<br />

Control Options<br />

The boxes that are ticked indicate the<br />

control options available for this Power Arm<br />

Reach Dimensions<br />

8<br />

8<br />

›››<br />

Cable<br />

Monolever<br />

XTC<br />

B<br />

A<br />

C<br />

8<br />

8<br />

8 4<br />

Choice of Controls<br />

D E<br />

For illustration purposes only<br />

Switchbox<br />

XTC - Mini<br />

REVOLUTION<br />

A 8.0m<br />

(26’3”)<br />

B 7.7m<br />

(25’3”)<br />

C<br />

5.8m<br />

(19’0”)<br />

D 6.9m<br />

(22’8”)<br />

E<br />

7.9m<br />

(25’11”)<br />

›››<br />

›››<br />

›››<br />

Hedge Cutting<br />

Hedge Cutting<br />

Water Course Maintenance<br />

POWER ARM 8085TT<br />

33

34<br />

PA5600<br />

5.6m (18’ 4”) reach<br />

CLASSIC<br />

PA6400<br />

6.4m (21’ 0 ”) reach<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Machine Features<br />

5.6m and 6.4m reach<br />

Left hand or right hand build option<br />

Five-point axle-mounting<br />

Parallel arm geometry<br />

Hydraulic safety breakaway<br />

Power Slew<br />

Choice of hydraulic systems (65hp<br />

gear or 77hp piston option)<br />

Tapered, seam welded arms<br />

Hy-reach arm geometry<br />

Storage support legs<br />

High capacity oil cooler<br />

Road lighting kit<br />

Directional warning arrow (magnetic)<br />

Operator friendly<br />

Choice of control systems<br />

Choice of attachments<br />

›››<br />

›››<br />

›››<br />

›››<br />

›››<br />

Markets<br />

Professional<br />

Governmental<br />

Contractors<br />

Tractor Requirements<br />

4000kg minimum tractor<br />

weight<br />

75hp minimum tractor<br />

horse power

Tractor Requirements PA5600 PA6400<br />

PA5600 PA6400<br />

Min Horse Power Requirements 75hp 75hp Minimum Tractor Weight 4000kg 4000kg<br />

Machine Specification<br />

Maximum Reach 5.6m (18’4”) 6.4m (21’) Power Arm Horsepower<br />

65/77hp 65/77hp<br />

Machine Weight*<br />

Hydraulics<br />

1500kg 15985kg Oil tank Capacity<br />

225 ltr 225 ltr<br />

Gear Semi Independent — Gear Totally Independent<br />

o<br />

Piston Hydraulics<br />

o<br />

Method of Attachment<br />

3-Point Linkage-Mounted<br />

Controls<br />

— 5-Point Axle Bracket-Mounted<br />

n<br />

Cable Control<br />

— Xtra Touch Control - Mini (XTC - Mini)<br />

—<br />

Switchbox o Xtra Touch Control<br />

o<br />

Monolever<br />

Machine Equipment<br />

o REVOLUTION Control + EDS (Optional) o<br />

Parallel Arm Geometry<br />

Midcut Pack or VFR<br />

Lift Float Kit<br />

Oil Cooler<br />

Safety Breakaway - Hydraulic<br />

Road Lighting Kit<br />

Warning Arrow - Magnetic<br />

Cushioned Top Link<br />

Front Mounting Build<br />

Front Flap Kit<br />

Hydraulic Roller<br />

n<br />

o<br />

o<br />

n<br />

n<br />

n<br />

n<br />

n<br />

—<br />

n<br />

o<br />

Telescopic Dipper Arm<br />

Angle Float Kit - Standard On Electric Models<br />

Easy Drive System (EDS)<br />

Power Slew<br />

Cable Rotor Control - Dual Rotation (Ti only)<br />

Electric Rotor Control - Dual Rotation (Ti only)<br />

Window Guards<br />

Debris Blower<br />

Orbitor Head Kit<br />

Flailhead Skid Kit<br />

Flailhead Cushioned Grass Mowing Roller<br />

—<br />

n<br />

o<br />

n<br />

—<br />

n<br />

n<br />

o<br />

o<br />

o<br />

o<br />

Power Arm Attachments<br />

1.20m Swingtrim Cutter Bar<br />

— 1.50m Omega Flailhead - DD or BD o<br />

1.50m Swingtrim Cutter Bar — 1.60m Multicut Flailhead - DD or BD o<br />

1.50m Sheartrim Cutter Bar - SD o 1.60m Omega Flailhead - DD or BD o<br />

1.60m Sheartrim Cutter Bar - MD o 2.00m Multicut Flailhead - DD or BD o<br />

2.00m Sheartrim Cutter Bar - MD o 1.20m Rotary Head - FC - 2 Rotor —<br />

1.40m Sheartrim Cutter Bar - HD o 1.20m Rotary Head - MD - 1 Rotor o<br />