OPERATORS MANUAL - Westerbeke

OPERATORS MANUAL - Westerbeke

OPERATORS MANUAL - Westerbeke

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

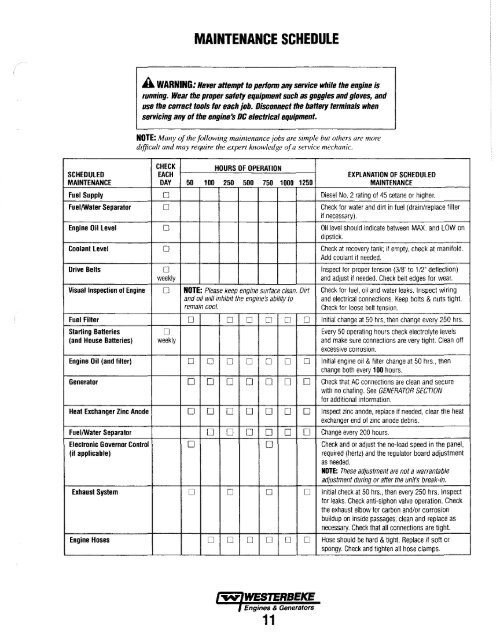

SCHEDULED<br />

MAINTENANCE<br />

Fuel Supply<br />

Fuel/Waler Separalor<br />

Engine Oil Level<br />

Coolant Level<br />

Drive Bells<br />

MAINTENANCE SCHEDULE<br />

A WARNING: Never attempt to perform any service while the engine is<br />

running. Wear the proper safety equipment such as goggles and gloves, and<br />

use the correct tools for each job. Disconnect the battery terminals when<br />

servicing any of the engine's DC electrical equipment.<br />

NOTE: Many of the following maintenance jobs are simple but others are more<br />

difficult and may require the expert know/edge of a service mechanic.<br />

CHECK HOURS OF OPERATION<br />

EACH EXPLANATION OF SCHEDULED<br />

DAY 50 100 250 500 750 1000 1250 MAINTENANCE<br />

0 Diesel No.2 rating of 45 cetane or higher.<br />

0 Check for water and dirt in fuel (drain/replace filter<br />

if necessary).<br />

0 Oil level should indicate between MAX. and LOW on<br />

dipstick.<br />

0 Check at recovery tank; if empty, check at manifold.<br />

Add coolant if needed.<br />

0 Inspect for proper tension (3/8" to 1/2" deflection)<br />

weekly and adjust if needed. Check belt edges for wear.<br />

Visual Inspection 01 Engine 0 NOTE: Please keep engine surtace clean. Dirt Check for fuel, oil and water leaks. Inspect wiring<br />

and oil will inhibit the engines ability to and electrical connections. Keep bolts & nuts tight.<br />

remain GOO/. Check for loose belt tension.<br />

Fuel Filter 0 0 0 0 0 0 Initial change at 50 hrs, then change every 250 hrs.<br />

Starting Balleries 0 Every 50 operating hours check electrolyte levels<br />

(and House Balleries) weekly and make sure connections are very tight. Clean off<br />

excessive corrosion.<br />

Engine Oil (and filler) 0 0 0 0 0 0 0 Initial engine oil & filter change at 50 hrs., then<br />

change both every 100 hours.<br />

Generator 0 0 0 0 0 0 0 Check that AC connections are clean and secure<br />

with no chafing. See GENERATOR SECTION<br />

for additional information.<br />

Heat Exchanger Zinc Anode 0 0 0 0 0 0 0 Inspect zinc anode, replace if needed, clear the heat<br />

exchanger end of zinc anode debris.<br />

Fuel/Waler Separator 0 0 0 0 0 0 Change every 200 hours.<br />

Electronic Governor Control 0 0 Check and or adjust the no-load speed in the panel,<br />

(if applicable) required (hertz) and the regulator board adjustment<br />

as needed.<br />

NOTE: These adjustment are not a warrantable<br />

adjustment during or after the units break-in.<br />

Exhaust System 0 0 0 0 Initial check at 50 hrs., then every 250 hrs. Inspect<br />

lor leaks. Check anti-Siphon valve operation. Check<br />

the exhaust elbow for carbon and/or corrosion<br />

buildup on inside passages; clean and replace as<br />

necessary. Check that all connections are tight.<br />

Engine Hoses 0 0 0 0 0 0 Hose should be hard & tight. Replace if soft or<br />

spongy. Check and tighten all hose clamps.<br />

Engines & Generators<br />

11