Future Requirements of Agricultural Machines for Mechanizing ...

Future Requirements of Agricultural Machines for Mechanizing ...

Future Requirements of Agricultural Machines for Mechanizing ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

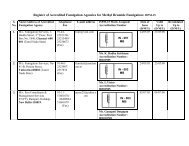

Table 10. Dehuskers, Shellers and Decorticators Developed under NARS<br />

are specialized carts and trollies developed <strong>for</strong><br />

movement <strong>of</strong> men in rural areas but not popular yet.<br />

2.1.12 Dehusking, Shelling and Decortication:<br />

Dehusking, shelling and decortication are important on<br />

-farm value adding primary processing to make the<br />

produce more presentable to the buyer, and help in<br />

reducing transport, handling and storage costs be<strong>for</strong>e<br />

further processing and utilization. Maize cobs need to<br />

be dehusked and shelled to get grain <strong>for</strong> marketing,<br />

processing and use. Coconut, arecanut are dehusked<br />

dried be<strong>for</strong>e bringing in the market. Groundnut, castor,<br />

almonds etc need to be decorticated to get the kennels.<br />

Low cost manual and power operated dehuskers, shellers<br />

and decorticators have been developed (Table 10). For<br />

minor oilseeds like cucumber seeds, neem, mango,<br />

kusum etc. decorticators have been developed or adapted<br />

but yet to be fully commercialized.<br />

2.1.13 Cleaning and Grading: Separation under<br />

natural air stream, cleaning with cleaning basket (‘Supa’)<br />

and sieving with manual sieve and manual grading have<br />

been in vogue to remove chaff and <strong>for</strong>eign matter and<br />

quality improvement through grading using sieve in case<br />

<strong>of</strong> foodgrains and oilseeds. In case <strong>of</strong> F&V manual<br />

washing and grading are generally practiced. Improved<br />

◆ 184 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

Particulars Manual Coconut Tubular Maize Manual TNAU Arecanut TNAU Groundnut<br />

Dehusker Sheller Groundnut Dehusker Decorticator<br />

Developed at CPCRI, Kasargod CIAE, Bhopal CIAE, Bhopal TNAU, Coimbatore TNAU, Coimbatore<br />

Specifications<br />

*Type Manual, piercing Manual Oscillating shoe- Power operated Power operated<br />

type concave, manual rotor-concave Osci-drumbatch<br />

continuous concave,<br />

continuous<br />

*Dimension, mm 680x275x1980 72x65 250x500x1100 1560x660x1600 1320x450x1380<br />

*Weight, kg — — — — 195<br />

Test Results<br />

*Suitability Coconut Maize Groundnut, castor Dried arecanut Groundnut<br />

*Capacity 150 nuts/h 15-20 kg/h 40-45 kg/h pods 100 kg/h 260 kg/h<br />

*Labour 1 1 2 1 2<br />

*Power Manual Manual Manual 1 hp motor 1 hp motor<br />

*Shefling (eff %) 100 100 100 — 95-8<br />

Economics<br />

*Capital cost, Rs 3,000 25 800 15,000 15,000<br />

*Unit cost, Rs/q 15 30 50 20 10<br />

*Working capital, Rs 500-1000 Negligible 2000-3000 5000-8000 5000-7000<br />

*RI% 40-45 100 or more 50-60 40-50 30-40<br />

*Pay back period, y 2-3, @ 150 d/y 10-12 days 1.5-2.0 y 2-2.5 y 2.5-3.0 @ 150 d/y<br />

<strong>of</strong> operation @30-40 d/y @150 d/y<br />

Stage <strong>of</strong> exploitation Commercial Commercial Commercial Yet to be Commercial<br />

commercialized<br />

Source <strong>of</strong> availability CPCRI, Kasargod 1. CIAE, Bhopal 1. CIAE, Bhopal TNAU, TNAU,<br />

2. MP Agro-Ind., 2. MP Agro-Ind., Coimbatore Coimbatore<br />

Bhopal Bhopal<br />

3. M/s Bindu 3. M/s Bindu Agro-<br />

Agro-Ind., Bhopal Ind., Bhopal<br />

winnowing fans, winnowers, pre-cleaners, cleaners and<br />

graders both manual and power operated have been<br />

developed and adopted, commercialized and used <strong>for</strong><br />

foodgrain and oilseeds, seed. Power operated washers,<br />

graders and packaging lines have been developed <strong>for</strong><br />

F&V and many <strong>of</strong> them commercialized but not popular<br />

yet. Seed cleaners and graders achieving very high<br />

degree <strong>of</strong> efficiencies (over 98%) are commercially<br />

manufactured and in use. Table 11 and 12 present some<br />

<strong>of</strong> the cleaners and graders developed under Indian<br />

NARS.<br />

2.1.14 Drying and Dryers: Drying under sun or<br />

shade where hot dry air conditions prevail is a common<br />

traditional method <strong>of</strong> drying <strong>of</strong> foodgrains, fruit and<br />

vegetables and many other commodities to extend their<br />

shelf life <strong>for</strong> their safe storage <strong>for</strong> <strong>of</strong>f season use and<br />

have value added products <strong>for</strong> additional income.<br />

However under unfavourable condition <strong>of</strong> hot, humid<br />

and overcast or rainy weather drying gets too slow so<br />

much so that be<strong>for</strong>e drying is accomplished molds and<br />

fungi develop contaminating and spoiling the material.<br />

To overcome this handicap different kind <strong>of</strong> drying<br />

methods and dryers have been developed but not in use<br />

except <strong>for</strong> the milling units or home level solar dryers.