Future Requirements of Agricultural Machines for Mechanizing ...

Future Requirements of Agricultural Machines for Mechanizing ...

Future Requirements of Agricultural Machines for Mechanizing ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

1. INTRODUCTION<br />

<strong>Future</strong> <strong>Requirements</strong> <strong>of</strong> <strong>Agricultural</strong> <strong>Machines</strong> <strong>for</strong><br />

<strong>Mechanizing</strong> Agriculture<br />

Anwar Alam<br />

Dy. Director General (Agril. Engg.), Indian Council <strong>of</strong> <strong>Agricultural</strong> Research, New Delhi<br />

ABSTRACT<br />

<strong>Agricultural</strong> mechanization refers to interjection <strong>of</strong> improved tools, implements<br />

and machines between farm workers and materials handled by them. Independent<br />

India ushered in a process <strong>of</strong> agricultural mechanization and revival <strong>of</strong> rural agroprocessing<br />

which got acceleration during post-Green Revolution period. Irrigation<br />

pump sets, power threshers, tractors, power tillers and matching implements,<br />

including <strong>for</strong> 65Million draft animals have became popular. Seed and seed-cumfertilizer<br />

drills, planters, mechanical rice transplanters, vertical conveyor reapers,<br />

and combines soon followed. In the recent past, Zero-till Drill and Raise Bed Planters<br />

have found good acceptance from the farmers. Currently mechanization is in<br />

increasing demand. Farmers and policy makers and developmental agencies now<br />

realise that <strong>for</strong> increasing production and productivity at reduced unit cost <strong>of</strong><br />

production, free <strong>of</strong> arduous labour, agricultural mechanization is essential. It is<br />

brought in centre stage with globalization <strong>of</strong> world markets. Introduction <strong>of</strong> electromechanical<br />

power units supplementing and substituting traditional animate sources<br />

<strong>of</strong> farm power is going to continue. For achieving desired intensity <strong>of</strong> cropping<br />

average farm power requirement <strong>of</strong> 2 kW/ha is considered essential, currently it is<br />

1.15kW/ha. Shifts in agriculture leading to crop diversification towards horticulture,<br />

animal husbandry fishery, <strong>for</strong>estry and on-farm agro-processing are going to bring<br />

in greater degree <strong>of</strong> mechanization. India dominated by small and marginal land<br />

holdings may not have same trend <strong>of</strong> mechanization as the developed world but it is<br />

going to grow close to it with its own variant as labour wages go up and WTO<br />

Competition compels us to keep reducing unit costs <strong>of</strong> production, processing,<br />

packaging, and retail and situations demanding provision <strong>of</strong> custom servicing,<br />

custom agro-processing and acceptable standards <strong>of</strong> living.<br />

Mechanization refers to interjection <strong>of</strong> machinery<br />

between men and materials handled by them. In<br />

agriculture materials are soil, water, environment, seed,<br />

fertilizer, pesticides, growth regulators, irrigation,<br />

agricultural produce and by-products such as foodgrains,<br />

oilseeds, fruits and vegetables, cotton, sugarcane, jute<br />

& kenaf and other cash crops, milk, meat, eggs and fish<br />

etc. There is scope <strong>of</strong> mechanisation in every unit<br />

operation <strong>of</strong> production agriculture, post-harvest and<br />

agro-processing, and rural living. Mechanisation has<br />

varied connotations. While in the developed world it<br />

tends to be synonymous to automation but in developing<br />

countries, like India, mechanisation means any improved<br />

tool, implement, machinery or structure that assists in<br />

enhancement <strong>of</strong> workers’ output, multiplies the human<br />

◆ 175 ◆<br />

ef<strong>for</strong>t, supplements or substitutes human labour that is<br />

enabling and removing, avoids drudgery or stresses that<br />

adversely affect human mental faculties leading to errors,<br />

imprecision and hazards and eventually loss <strong>of</strong><br />

efficiency. It also means automation and controls that<br />

assure quality, hygiene. <strong>Agricultural</strong> mechanisation in<br />

a limited sense relates to production agriculture.<br />

1.1 Status at Independence<br />

At the time <strong>of</strong> independence in 1947, Indian<br />

agriculture used mostly bullock drawn ploughs, wooden<br />

pegtooth harrows, wooden planks <strong>for</strong> pulverisation<br />

compaction and smoothening, bullockcarts, and<br />

handtools such as Khurpi, crobar, spade, hoe, sickle,<br />

axe, chopper/Dau etc. Some philonthrops, facilitated by<br />

colonial masters, were trying to introduce western soil<br />

inversion plough like Meston plough, a 15 cm size long

eam bullock drawn plough. The only mass<br />

manufactured items were spades, pickaxe, crobars, and<br />

watering buckets manufactured by Tatas. Traditional<br />

equipments in use were made by local craftsmen, using<br />

locally available materials with little standardization,<br />

where quality depends on the craftsmanship.<br />

1.2 Important Land Marks<br />

1.2.1 Colonial India had witnessed many droughts<br />

and famines and some <strong>of</strong> them very devastating.<br />

Founding fathers <strong>of</strong> modern India took upon themselves<br />

a responsibility to avoid famines. To this effect they<br />

accorded high priority to agriculture and allied activities.<br />

<strong>Agricultural</strong> education, research and development<br />

infrastructure were strengthened. State <strong>Agricultural</strong><br />

Universities on the pattern <strong>of</strong> American Land Grand<br />

Colleges with integrated teaching, research and frontline<br />

extension were established starting 1960 providing<br />

trained human resource, location specific technologies<br />

and their frontline demonstrations. Indian Council <strong>of</strong><br />

<strong>Agricultural</strong> Research (ICAR) reorganised itself (1965).<br />

The commodity institutes with the Deptt. <strong>of</strong> Agriculture<br />

and Cooperation and Central Commodity Committees<br />

were transferred to ICAR leaving tea, c<strong>of</strong>fee, silk etc.<br />

Central and State Governments invested in infrastructure<br />

development to provide irrigation water, seed, fertilizer,<br />

pesticides and credits, minimum support price (MSP)<br />

and buffer stocking to prevent wild fluctuation in market<br />

prices besides food security. However, food security<br />

eluded India <strong>for</strong> two decades, food imports at times being<br />

the largest import bill <strong>of</strong> the country. India witnessed<br />

Green Revolution in 1967-68 and subsequently White<br />

Revolution, Blue Revolution and Yellow Revolution,<br />

achieving quantum jumps in production and productivity<br />

in foodgrains, milk, fishery, and oilseeds, respectively.<br />

It is experiencing horticultural revolution, revolution in<br />

poultry production. Peers and policy makers are looking<br />

towards Evergreen Revolution.<br />

1.2.2 A separate note (App-I) is included on the<br />

subject <strong>of</strong> “AGRICULTURAL MECHANIZATION<br />

RESEARCH IN INDEPENDENT INDIA”. The note<br />

provides a broad summary <strong>of</strong> the major initiatives taken<br />

<strong>for</strong> introducing <strong>Agricultural</strong> Mechanization in India.<br />

1.3 Growth in <strong>Agricultural</strong> Mechanization<br />

1.3.1 These amendments in agriculture were<br />

accompanied with due inputs <strong>of</strong> mechanisation in natural<br />

resource development, agricultural field operations and<br />

on-farm primary processing. After intensive testing and<br />

evaluation in late 1950s, manufacturing <strong>of</strong> irrigation<br />

pumping sets commenced. Initially two-thirds were<br />

engine operated and one-third electric operated. As rural<br />

electrification advanced, proportions have changed in<br />

◆ 176 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

favour <strong>of</strong> electrical power. Animal drawn improved<br />

equipment such as seed drills, seed-cum-fertilizer drills,<br />

5 hp power threshers primovers like diesel engines,<br />

electric motors got into manufacture and use. Central<br />

Tractor Organisation (CTO) established soon after<br />

independence to reclaim marshy lands in Tarai <strong>of</strong> UP<br />

and scrub <strong>for</strong>ests elsewhere to settle displaced people<br />

who came from across the border set the pace <strong>of</strong><br />

tractorisation in India. CTO used crawler tractors, their<br />

operation, upkeep and later on indigenous fabrication<br />

<strong>of</strong> certain fast wearing components, after OE stocks<br />

exhausted, were locally developed. For tractorisation<br />

<strong>of</strong> agricultural field operations around mid-1960s small<br />

4-wheel general purpose tractors were brought in CKD<br />

(completely knocked down) condition and assembled,<br />

marketed, operated, and serviced by training Indian<br />

technicians. Confidence thus gained resulted in<br />

progressive indigenous manufacture. Swaraj 35 hp from<br />

M/s Punjab Tractor was the first totally indigenous<br />

tractor. A little later two-wheeled tractors popularly<br />

known as power tillers were introduced and at one stage<br />

more than a dozen firms had manufacturing licenses.<br />

However farming system in vogue, wet cultivation<br />

during kharif and upland farming during rabi, and lack<br />

<strong>of</strong> proper after-sales-services support adversely affected<br />

their growth. All but two Mitsubishi and Kubota by<br />

M/s VST Tillers, Bangalore and M/s Kerala Agro-<br />

Industries Corporation survived. Today India is the<br />

largest producer <strong>of</strong> tractors in world with about 2,75,000<br />

tractors per year and about 15,000 power tillers. China<br />

is able to market its power tillers in India at cheaper<br />

prices, nevertheless there are after sales service problems<br />

in many cases<br />

1.3.2 With the introduction and growth <strong>of</strong> tractors in<br />

India in production <strong>of</strong> matching equipment <strong>for</strong> scraping<br />

and land levelling, seedbed preparation, seeding and<br />

planting, seed-cum-fertilizer drilling, spraying and<br />

dusting, harvesting and power threshing, 2-wheel and<br />

4-wheel tractor trolleys got in to indigenous manufacture<br />

and these got reserved <strong>for</strong> Small Scale Industries (SSI)<br />

sector. It became a very competitive farm equipment<br />

industrial activity in Punjab and in pockets all over the<br />

country. However, to enhance quality <strong>of</strong> farm equipment<br />

many items have been dereserved, now.<br />

1.3.3 By early 1980s vertical conveyor reapers (VCR)<br />

were introduced to mechanise sickle harvesting, initially<br />

walking type, then a larger tractor version and<br />

subsequently riding type self propelled units. During<br />

1982-84 production <strong>of</strong> tractor mounted VCRs increased<br />

ten fold each subsequent year reaching to 3000 in third<br />

year but got reduced to 2000 annual production in the<br />

fourth year, the year insurgency in Punjab touched its<br />

peak. At this point <strong>of</strong> time Punjab farmers found

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

combining <strong>of</strong> rice and wheat cheaper and less risky.<br />

Several manufacturers (29) in Small Scale Sector took<br />

to general purpose standard grain harvesting combines<br />

by manufacturing tractor mounted, self propelled and<br />

tractor driven versions. Combining, however, created<br />

problem <strong>of</strong> rice and wheat straw gathering, trans<strong>for</strong>ming<br />

and handling as Bhusa. Straw disposal through<br />

incineration was found creating serious environment<br />

pollution whereas straw incorporation in to the soil was<br />

leading to nitrogen stealing. Invention and introduction<br />

<strong>of</strong> straw combines did provide a solution to reclaiming<br />

wheat Bhusa but still about 50-60% <strong>of</strong> the rice and wheat<br />

straw is being disposed by burning. It may not be entirely<br />

due to combines, demand <strong>for</strong> wheat bhusa has also<br />

declined. Its transport to feed deficit areas in loose farm<br />

is expensive and uneconomical. Complete feedblock<br />

bufferstocking to fight feed famines is a possibility.<br />

1.4 Current Imperatives<br />

1.4.1 Mechanisation is now demand driven. With<br />

increasing labour wages and agricultural produce market<br />

prices as they are, engineered to be low <strong>for</strong> food and<br />

nutritional security and food accessibility to the masses,<br />

the farmers, specially medium and large ones, are<br />

looking <strong>for</strong> labour saving devices to remain competitive<br />

more so with the globalization <strong>of</strong> the world markets.<br />

And the farm working groups, policy makers and social<br />

scientists are looking <strong>for</strong> mechanisation to remove<br />

drudgery from farm operations so that rural educated<br />

youth do not run to urban areas in pursuit <strong>of</strong> jobs which<br />

are already in short supply. With prepondence <strong>of</strong><br />

marginal and small farms, below 2 ha above 76% <strong>of</strong> the<br />

total land holdings, custom servicing in farm operations<br />

is in vogue and rightly so because individual ownership<br />

is not af<strong>for</strong>dable.<br />

1.4.2 For the reasons explained, agricultural<br />

mechanisation in India has come a long way in the last<br />

50 years. India produces wide range <strong>of</strong> agricultural<br />

equipment needed to practice modern intensive farming.<br />

However, there are unit operations in certain commercial<br />

crops and commodities where mechanisation is needed,<br />

and <strong>for</strong> which presently there is no viable solution. With<br />

quantitative restrictions removed from 1st April, 2001<br />

it is faced with new challenges, some have reservations<br />

whether it will be able withstand pressures <strong>of</strong><br />

multinational companies and countries that are<br />

aggressively marketing their goods in export markets.<br />

Indian farm equipment industry has demonstrated its<br />

resilience and responsiveness to changing market<br />

situations in the past and should come out victorious at<br />

the end adopting modernization measures. Nevertheless,<br />

the challenge is <strong>for</strong>midable.<br />

1.4.3 To meet food, feed, fibre, fuel, and industrial<br />

◆ 177 ◆<br />

raw material needs Indian agriculture is required to<br />

double food production in a decade i.e. by 2010. With<br />

the available land mass remaining at about 142 million<br />

hectares (Mha) it has to come through essentially a<br />

vertical expansion, gains through productivity in<br />

commodities and the regions there is scope like E-India<br />

and returns on investment favourable. Globalization and<br />

its basic demand <strong>of</strong> competitiveness asks <strong>for</strong> greater<br />

timeliness, precision in metering and placement <strong>of</strong> inputs<br />

that are going to be increasingly costlier, minimisation<br />

<strong>of</strong> pre and post harvest losses, on-farm value addition<br />

<strong>for</strong> additional income and employment that provide<br />

greater sustainability to farm families and make farming<br />

and associated post-harvest activities less arduous and<br />

economically rewarding and satisfying. Environment<br />

control in plant and animal production will have to be<br />

employed to realise the productivity levels targeted and<br />

prevent morbidity and mortality in livestock husbandry.<br />

As we can see, increasingly, there is going to be demand<br />

<strong>for</strong> precision farming, farming equipment that are<br />

ergonomically sound, economically af<strong>for</strong>dable, system<br />

that reduce unit cost <strong>of</strong> production through economy in<br />

inputs use and quantum jumps in productivity. This paper<br />

aims to bring out evolution <strong>of</strong> agricultural mechanization<br />

status, current ef<strong>for</strong>ts, and ventures in postulating likely<br />

future requirements and trends in agricultural<br />

mechanisation.<br />

2. STATUS OF FARM POWER<br />

Unlike industry where men machines and materials<br />

are brought under one ro<strong>of</strong>, the agriculture requires men,<br />

machinery and material being moved to field and various<br />

unit operations per<strong>for</strong>med timely, with required<br />

precision, that gives desired productivity in a manner it<br />

does not cause drudgery and health hazards to the<br />

workers. In this context availability <strong>of</strong> appropriate farm<br />

power sources are required. Traditionally humans and<br />

draft animals met this need. Draftability <strong>of</strong> draft animals<br />

has been studied. Bullocks and he buffaloes pull about<br />

10% <strong>of</strong> their body weight, camels about 18% <strong>of</strong> the body<br />

weight and donkeys about 34%. With improved yokes<br />

and harnesses and appropriate work rest cycle<br />

draftability and work output can be increased by 15-<br />

30%. However, <strong>for</strong> the current level <strong>of</strong> intensity <strong>of</strong><br />

farming, required levels <strong>of</strong> productivity, with a work<br />

environment required can not be met by animate sources<br />

alone. As a result electro-mechanical sources<br />

supplement and substitute animate sources. For<br />

stationery operations like operation <strong>of</strong> irrigation pump,<br />

power thresher, a chaff cutter and grinder engines and<br />

motors are in use. Where as <strong>for</strong> tractive field operations<br />

there are tractors and power tillers (Table 1) run by diesel<br />

engines mounted on them. These can per<strong>for</strong>m varied

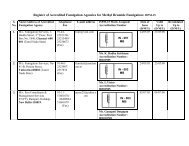

Table 1. Population Growth Trends in Mechanical Farm Power Sources in India<br />

additional functions with the help <strong>of</strong> proper attachments.<br />

Large farm machines are <strong>of</strong>ten self propelled with built<br />

in power source. These farm power sources are<br />

commercially available but their distribution and<br />

availability and use in certain regions like E and NE<br />

and hilly areas can not be considered satisfactory<br />

(Table 3). There is close nexus between farm power<br />

availability and agric productivity (Fig. 1). The level <strong>of</strong><br />

farm power availability during 2001 was about 1.35 kW/<br />

ha (Table 2). At the present level <strong>of</strong> sophistication in<br />

◆ 178 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

(number in million)<br />

1950 1960 1970 1980 1990 1997 2000* Growth rate<br />

(%) Base<br />

year 1970<br />

Tractive power<br />

Tractor 0.008 0.031 0.148 0.518 1.222 2.037 2.471 9.84<br />

Power Tiller - - 0.003 0.021 0.040 0.085 0.110 12.7<br />

Stationary power<br />

Electric pump 0.020 0.100 1.629 4.330 6.019 8.254 9.525 6.06<br />

Diesel pump 0.083 0.230 1.546 3.101 4.659 5.899 6.465 4.88<br />

Others<br />

Power sprayer/duster - - 0.045 0.124 0.200 0.245 0.311 6.66<br />

Note: *Estimated<br />

Source: Singh, et al., 1999<br />

Table 2. Availability <strong>of</strong> Farm Power in India<br />

Year Total Power, Source-wise%<br />

KW/ha<br />

Animal Mechanical Electrical<br />

1951 0.25 97.4 2.1 0.5<br />

1961 0.31 94.9 3.7 1.4<br />

1971 0.36 79.2 16.3 4.5<br />

1981 0.63 48.2 32.3 19.5<br />

1991 0.92 34.5 34.7 30.8<br />

2001 1.35 18.0 55.0 27.0<br />

(36.68)<br />

Note: *Figure in parenthesis is mobile farm power<br />

Power, kW/ha<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

1950 1954 1958 1962 1966 1970 1974 1978 1982 1986 1990 1994 1998<br />

Animate power, kW/ha Mechanical power, kW/ha<br />

Total power,kW/ha Productivity, kg/ha<br />

Fig. 1. Trend <strong>of</strong> farmpower availability and land productivity in India<br />

1.8<br />

1.6<br />

1.4<br />

1.2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

Land productivity, kg/ha<br />

Table 3. Farm Power availability in NEH Region<br />

State Availability farm power,<br />

hp/ha <strong>of</strong> cropped area<br />

Arunachal Pradesh 0.23<br />

Manipur 1.40<br />

Meghalaya 1.44<br />

Mizoram 0.77<br />

Nagaland 0.45<br />

Tripura 0.99<br />

agriculture <strong>for</strong> taking two crops per year an average farm<br />

power available <strong>of</strong> 2.0 KW/ha is considered essential.<br />

<strong>Agricultural</strong>ly advanced states and regions in the country<br />

have farm power availability <strong>of</strong> 2-4 kW/ha. Law <strong>of</strong><br />

diminishing return is also applicable in farm power<br />

availability and mechanization. Excessive<br />

mechanization does not bring rewards instead block the<br />

capital, add to overhead costs and at times cause<br />

indebtness and its negative impacts.<br />

2.1 Status <strong>of</strong> Farm Implements and <strong>Machines</strong><br />

2.1.1 Land and Water Resource Development<br />

Equipment: It involves clearing <strong>of</strong> land <strong>of</strong> the unwanted<br />

vegetation, levelling and grading so as to per<strong>for</strong>m field<br />

operations properly and apply seed, fertilizer/manure,<br />

and irrigation water uni<strong>for</strong>mly. It also involves creating<br />

access to field and mobility <strong>of</strong> machines through farm<br />

roads with irrigation and drainage ditches, creating<br />

irrigation water resources both surface and ground water.<br />

Most ancient practice <strong>of</strong> land development was use <strong>of</strong><br />

fire and later on slash and burn a practice still vogue in<br />

a few remote areas. However, axe, hoe, pickaxe, spade,<br />

crowbar, and heavy duty ploughs have come in use and<br />

still in vogue where mechanization has not advanced.<br />

Subsequently not long ago animal drawn buck scraper,<br />

floats, V-ditchers, bund <strong>for</strong>mers were developed and<br />

got in use <strong>for</strong> levelling, smoothing, land shaping. With<br />

industrial revolution and development <strong>of</strong> IC-engines and

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

advancements in mechanization the tractor drawn<br />

scrapers, levellors, terracers, floats, smoothers have<br />

come in use and are available in the market. However,<br />

<strong>for</strong> the large scale mechanized land clearing, land<br />

development, construction <strong>of</strong> farm ponds, laying <strong>of</strong><br />

irrigation and drainage systems there are bulldozers,<br />

motor graders, excavators, dumpers, trenchers, trenchercum-subsurface<br />

drainage pipe systems available in the<br />

Indian market. Heavy earthmoving machinery are costly.<br />

Laser guided land levellors are in the process <strong>of</strong><br />

introduction in India and may be indigenised soon. For<br />

laying tubewells to tap ground water (GW) there are<br />

percussion and rotary rigs along with casing and strainers<br />

<strong>of</strong> steel and plastics and submersible pumps available.<br />

Where GW tables are low and rich aquifers available at<br />

lower depths centrifugal pumps installed in dugwells<br />

are in use. Shallow tubewells in many states rich in GW<br />

have paid rich dividends like Assam, West Bengal,<br />

Punjab, Haryana, Western UP, and pockets elsewhere.<br />

2.1.2 Irrigation and Drainage Equipment:<br />

Mechanization in lifting <strong>of</strong> the irrigation water was the<br />

first important land mark in modernization <strong>of</strong> Indian<br />

agriculture when in late 1950s and early 1960s the ef<strong>for</strong>ts<br />

to adopt engine and electric motor operated centrifugal<br />

pumps led to indigenous manufacture <strong>of</strong> small diesel<br />

engines (5 hp) and 3-5 hp agricultural motors, and<br />

matching centrifugal pumps by mid 1960s. It expanded<br />

rapidly and today about 0.90 million irrigation pumps<br />

are manufactured annually, one-third engine operated<br />

and two-third electric motor operated. With over<br />

exploitation <strong>of</strong> GW and water table going down, the<br />

use <strong>of</strong> submersible pumps is on rise. Solar- photovolteric<br />

water pumping sets are also available which at this point<br />

<strong>of</strong> time involve high capital cost but operating cost is<br />

very low.<br />

With irrigation waters getting scarce and costly their<br />

efficient application has become essential. As a result<br />

the pressurised irrigation systems - sprinklers, microsprinklers,<br />

and drip systems have come in use that save<br />

about 35-50% <strong>of</strong> irrigation water with 25-35% increase<br />

in the yield. Through fertigation drips improve the<br />

fertilizer use efficiency also. Ef<strong>for</strong>ts are on to improve<br />

the water use efficiency in Indian agriculture. In ricewheat<br />

cropping zero-till drill and raised bed planting<br />

are found to reduce water require about 35-50% with<br />

about 5-10% yield advantage.<br />

2.1.3 Surface and subsurface drainage systems, and<br />

vertical drainages have been designed, installed and<br />

studied in actual farming conditions which have<br />

facilitated crop cultivation in otherwise water logged<br />

areas and increased yields substantially where water<br />

tables were close to the root zone or soils are saline or<br />

acidic due to adverse geo-hydrological situations<br />

◆ 179 ◆<br />

preventing yield potentials being realised. Lowlift high<br />

discharge pumps have been developed <strong>for</strong> vertical<br />

drainage. Command areas <strong>of</strong> several medium and large<br />

irrigation or multipurpose projects have been studied<br />

and remedial areas evolved to improve water distribution<br />

and productivity through better water management.<br />

2.1.4 Energy audits, however, in many <strong>of</strong> the<br />

irrigation and drainage installations can not be<br />

considered favourable. There is considerable room <strong>of</strong><br />

improvement <strong>of</strong> system efficiency through improved<br />

design, manufacturing, installation and upkeep <strong>of</strong> these<br />

systems tackling corrosion and encrustation problems.<br />

2.1.5 Seedbed Preparation: Leaving deltaic areas <strong>of</strong><br />

the perennial rivers where rice-rice may be dominant<br />

crop rotation, most <strong>of</strong> India has crop cultivation in both<br />

upland and low land situations. For marginal farms,<br />

traditional animal drawn wedge plough (Desi Hal) which<br />

can be used as primary and secondary tillage implement,<br />

with a seeding tube as a seed drill and as an interculture<br />

device continues to be still in use. With over 76%<br />

holdings marginal (below 1 ha) and small size (1-2 ha)<br />

dominating the scene, it is not surprising that the Desi<br />

Hal and other traditional equipment continue to be in<br />

use. Wooden plank as an accessory does pulverization,<br />

land smoothening and seedbed compaction. In vertisols<br />

Bakhar (blade harrow) are used. In wet land seedbed<br />

preparation, wooden pegtooth harrows are also used.<br />

2.1.6 For primary tillage, better weed management<br />

and incorporation <strong>of</strong> organic and green manuring,<br />

bullockdrawn mould board ploughs <strong>of</strong> 10-20 cm size,<br />

long and short beam types, reversible MB ploughs were<br />

introduced and are still in use. For secondary tillage<br />

animal drawn disc and pegtooth harrows were<br />

introduced and got in to indigenous manufacture.<br />

However, these could never gain a popularity as<br />

compared to Desi Hal which is a versatile multipurpose<br />

implement, made and repaired by local craftsmen. For<br />

wet land seedbed preparations there are various animal<br />

drawn puddlers which increase field capacity.<br />

<strong>Agricultural</strong> mechanization process is gradually<br />

changing the scenario. In Punjab, Haryana traditional<br />

farm equipments have practically disappeared.<br />

With tractorisation getting in vogue, 9/11 tyne tillers<br />

with reversible shovels in alluvium and alfisols and<br />

duckfoot type in vertisols, tractordrawn mouldboard and<br />

disc ploughs became popular. For secondary tillage<br />

trailing and mounted type tandem and <strong>of</strong>fset disc<br />

harrows are in use and manufactured in large numbers<br />

through SSIs. However, versatility <strong>of</strong> 9/11 type tillers<br />

have made them most popular tillage implement with<br />

the tractor owners like that <strong>of</strong> Desi Hal in the past. In<br />

some places tandem disc harrows are widely used <strong>for</strong><br />

seedbed preparation with occasional or no ploughing.

Table 4. Selected Equipment <strong>for</strong> Seedbed Preparation<br />

◆ 180 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

S. No. Name <strong>of</strong> the Implement Size, mm Price, Rs Work Capacity Suitability<br />

ha/h h/ha<br />

A. Animal operated<br />

1. M.B. Plough 150 400 0.024 40-42 For all Regions<br />

2. Disc Harrow (4-8 disc) 600-1200 1000-1500 0.18-0.22 5-6 For light soils<br />

3. Cultivator (3 tynes) 300-400 700-1000 0.08 12-14 For light soils<br />

4. Bakhar 500 400 0.06 16-18 For heavy soils<br />

5. Helical Puddler 500 800-1200 0.06 16-18 For puddling in all types <strong>of</strong> soils<br />

6. Harrow Patela 1500-2000 1200-1500 0.2-0.25 4-5 For collection <strong>of</strong> trash and<br />

planking, all regions.<br />

B. Power Tiller operated<br />

1. Rotavator 500-600 15000 0.07-0.09 11-13 All regions<br />

C. Tractor operated<br />

1. M.B. Plough 2x350 10000-15000 0.20-0.25 4-5 All regions<br />

3x350 20000-22000 0.30-0.35 3-4<br />

2. Disc Plough 2x350 14000-16000 0.20-0.25 4-5 All regions<br />

3x350 24000-26000 0.30-0.35 3-4<br />

3. Disc Harrow (16 disc) 2000 15000-18000 0.40-0.50 2-2.5 All regions<br />

4. Cultivator (9-11) 2500 12000-15000 0.40-0.50 2-2.5 Lighter soils<br />

5. Rotavator 1500 40000-50000 0.2 5 All regions<br />

6. Sweep cultivator 5 x 500 12000-15000 0.35 3-3.5 Heavy soils<br />

Table 5. Selected Equipment <strong>for</strong> Sowing and Planting<br />

S. No. Name <strong>of</strong> the Implement Size, mm Price, Rs Work Capacity Suitability<br />

ha/h h/ha<br />

A. Manually operated<br />

1. Mustard seed drill 1 x 600 1000 0.1 10-12 Lighter soils<br />

B. Animal operated<br />

1. CIAE 2-3 row seed-cum- 3 x 225 2500-3000 0.1 10-12<br />

fertilizer drill 3 x 300 0.125 8-8.5<br />

3 x 450 0.155 6-7 All types <strong>of</strong> seeds<br />

2. CRIDA drill plough 1 x 225 500 0.04 20-25 All types <strong>of</strong> seeds<br />

3. CIAE mustard drill 2 x 450 2500-3000 0.125 8-8.5 All types <strong>of</strong> soils<br />

4. CIAE 2-3 row planter 3 x 450 3000-4000 0.155 6-7 Maize, cotton, groundnut and<br />

other types <strong>of</strong> seeds<br />

5. IISR sugarcane planter 1 x 900 3000-4000 0.125 8 Lighter soils<br />

6. Potato planter 2 x 450 3000-4000 0.125 8 Lighter soils<br />

C. Power tiller operated<br />

1. Seed-cum-fertilizer drill 5 x 225 6000-8000 0.164 6-6.5 All types <strong>of</strong> soils<br />

5 x 300 0.21 5-5.5<br />

D. Tractor operated<br />

1. Seed-cum-fertilizer drill 11 x 225 12000-15000 0.75 1.25-1.5 All types <strong>of</strong> soils with suitable<br />

furrow openers<br />

2. No-till-drill 11 x 225 15000 0.75 1.25-1.5 For direct sowing <strong>of</strong> wheat after<br />

paddy in rice-wheat cropping<br />

system<br />

3 Strip-till-drill 1500 25000-30000 0.25 4-5 For direct sowing <strong>of</strong> wheat after<br />

paddy in rice-wheat cropping<br />

system<br />

4. Sugarcane cutter planter 2 x 900 40000-45000 0.25 4 Suitable <strong>for</strong> all regions with<br />

suitable ridger bodies<br />

5 Potato planter 2 x 600 20000-25000 0.25 4 Suitable <strong>for</strong> all regions

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

Research studies under ICAR All India Coordinated<br />

Research Projects on Energy Requirement and Farm<br />

Implements and <strong>Machines</strong> have established roto tilling<br />

as an efficient seedbed preparation equipment both under<br />

upland and wet land situations. As a result it is currently<br />

under promotion with incentives in several states<br />

specially where vegetable crops are taken after rice. For<br />

wetland seedbed preparation power tillers with rototillers<br />

are very useful specially <strong>for</strong> small and marginal farms.<br />

However, many farmers who do not maintain bullocks,<br />

find custom serviced seedbed preparations fast and<br />

af<strong>for</strong>dable. Many tractor owning farmers do custom<br />

servicing in seedbed preparation and seeding and in<br />

transport operations to improve economics <strong>of</strong> tractor<br />

owning. Table 4 presents selected improved seedbed<br />

preparation equipment available.<br />

2.1.7 Sowing, Planting, Transplanting and<br />

Checkrowplanting: Sowing crops in lines so distanced<br />

apart that farm power units can move in inter-row spaces<br />

without damaging the plants is one <strong>of</strong> the perquisites <strong>of</strong><br />

mechanization <strong>of</strong> post-seeding operations. As a result<br />

drills and planters have become popular. Placement <strong>of</strong><br />

band <strong>of</strong> fertilizer by the side <strong>of</strong> seed slightly deeper is<br />

found to have better plant response and more yields. To<br />

realise this advantage, seed-cum-fertilizer drills<br />

succeeded the seed drills. For best results it is not only<br />

desirable to have seeds in row but also certain distance<br />

between the seeds (plants); to achieve it, there are<br />

planters plate type, cupfeed, and pneumatic seed metered<br />

but not as popular as drills. There is talk about<br />

Madagaskar rice cultivation technology whose main<br />

features are checkrow transplanting <strong>of</strong> young rice<br />

seedling (15-20 days old) and interculture in standing<br />

crop along and across the rows. However, we do not<br />

Table 6. Weeding and Interculture Equipment<br />

S. No. Name <strong>of</strong> the Implement Size, mm Price, Rs Work Capacity Suitability<br />

◆ 181 ◆<br />

ha/h h/ha<br />

A. Manually operated<br />

1. Grubber 150-200 30-50 0.012 80 Lighter soils<br />

2. Dryland peg weeder 150-200 250-300 0.025 40 All soils<br />

3. CIAE twin wheel hoe 150-200 250-300 0.025 40 All soils<br />

4. PAU wheel hoe 150-200 400-500 0.035 30 Lighter soils<br />

B. Animal operated<br />

1. Dora 300 500 0.1 10 Heavy soils<br />

2. Three tyned Sweep/ cultivator 600 700-1000 0.2 5 Lighter soils<br />

C. Power tiller operated<br />

1. 3 tyned cultivator/ sweep 1000 5000-7000 0.2 5 All soils, wider row crops<br />

D. Tractor operated<br />

1. 9-11 tyned tiller 2500 12000-15000 0.45 2-2.5 All soils, wider row crops<br />

2. 5 tyned sweep 2500 12000-15000 0.45 2-2.5 All soils, wider row crop<br />

E. Self propelled weeder<br />

1. CIAE/TNAU power weeder 500 30000 0.125 8 All soils, wider row crops<br />

have yet a mechanical check-row transplanter. Table 5<br />

gives broad specifications <strong>of</strong> sowing and planting<br />

equipment available. Transplanting <strong>of</strong> seedlings/saplings<br />

is also widely practiced in fruit and vegetable and<br />

cultivation, agro-<strong>for</strong>estry where mechanization is needed<br />

<strong>for</strong> which ef<strong>for</strong>t are on <strong>for</strong> some <strong>of</strong> the operations<br />

mechanized options have been created like pit making.<br />

2.1.8 Interculture and Weeding Equipment:<br />

Removal <strong>of</strong> weeds, aeration <strong>of</strong> the root zone, creating<br />

soil mulch, and earthing are major objectives in<br />

interculture. In some cases thinning and gap filling or<br />

band placement <strong>of</strong> fertilizer are also done during<br />

interculture. Traditional interculture tools are Khurpi or<br />

Kudali which are very slow and unaf<strong>for</strong>dable at current<br />

wages. As an improvement wheel hoes have been<br />

developed, some with several attachments to per<strong>for</strong>m<br />

various interculture jobs. These are becoming popular.<br />

There are tractor mounted cultivators, however, due to<br />

absence <strong>of</strong> headlands, failure to create straight rows and<br />

other reasons these are not widely used. For widerow<br />

sown crops like maize, pigeonpea, groundnuts, power<br />

weeders have been developed and commercialized. Self<br />

propelled rice power weeders have been developed but<br />

not popular yet. There are urea supergranule and prilled<br />

urea applicators developed <strong>for</strong> rice that improve fertilizer<br />

use efficiency. Some <strong>of</strong> the interculture and weeding<br />

equipment available are presented in Table 6.<br />

2.1.9 Plant Protection Equipment: For applying<br />

weedicides, insecticides, fungicides as well as certain<br />

growth regulators spraying and dusting is followed. India<br />

has manual, knapsack auxiliary engine operated,<br />

manually pushed auxiliary engine operated, power tiller<br />

& tractor mounted and stationary engine operated<br />

sprayers and dusters in use, indigenously manufactured

Table 7. Equipment <strong>for</strong> Spraying and Dusting Operations<br />

◆ 182 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

S. No. Name <strong>of</strong> the Implement Size Price, Rs Work Capacity Suitability<br />

ha/h h/ha<br />

A. Manually operated<br />

1. Hand compression sprayer 14 litres 1500-2000 0.095 10.5 All regions<br />

2. Lever Operated Knapsack sprayer 13-16 litres 1500 0.095 10.5 All regions<br />

3. Foot sprayer 2500-3000 0.165 6 All regions<br />

4. Duster 4-5 kg 1000 0.25 4 All regions<br />

5. Controlled Droplet sprayer 1 litre 1500 0.25 4 All regions<br />

B. Power operated<br />

1. Knapsack sprayer cum-duster 5 litres 5000-7000 0.22 5 All regions<br />

2. Stationery power operated sprayer 5-10 hp 20000 0.35 3 All regions<br />

C. Tractor operated<br />

1. Tractor operated sprayer 5000 mm 30000-40000 0.5 2 All regions, wider<br />

row crops<br />

D. Self propelled<br />

1. High clearance sprayer 10000 mm 200,000 0.5-1.0 1-2 Cotton, potato and other<br />

tall crops<br />

Table 8. Equipment <strong>for</strong> Harvesting Operation<br />

S. No. Name <strong>of</strong> the Implement Size Price, Rs Work Capacity Suitability<br />

ha/h h/ha<br />

A. Manually operated<br />

1. CIAE Serrated sickle 25-30 0.008 125 All regions<br />

B. Animal operated<br />

1. CIAE groundnut-cum-potato digger 500 mm 2000 0.1 10-12 All regions<br />

C. Power tiller operated<br />

1. Vertical Conveyor Reaper 1200 mm 15000 0.25 4 All regions, suitable <strong>for</strong><br />

paddy and wheat crops<br />

D. Tractor operated<br />

1. Vertical Conveyor Reaper 2000 mm 35000 0.4 2.5 All regions, rice, wheat,<br />

soybean etc.<br />

2. CIAE Soybean Reaper 2000 mm 35000-40000 0.4 2.5 All regions<br />

E. Self propelled machines<br />

1. Vertical Conveyor Reaper 1000 mm 40000-50000 0.25 4 All regions, suitable <strong>for</strong><br />

paddy, wheat, soybean<br />

etc.<br />

2. Combine harvester 4200 mm 6-12 lakhs 1.5-2.00 0.75-0.5 All regions, <strong>for</strong> paddy,<br />

wheat, gram, soybean<br />

etc.<br />

Table 9. Equipment <strong>for</strong> Threshing Operation<br />

S. No. Name <strong>of</strong> the Implement Size Price, Rs Work Capacity Suitability<br />

A. Power operated<br />

1. Power operated thresher 5-10 hp 12000-20000 200-500 All regions, <strong>for</strong> single crop, paddy,<br />

wheat<br />

2. CIAE Multi-crop thresher 5-10 hp 15000-25000 200-500 All regions, wheat, paddy, soyabean,<br />

maize, gram, pigeon pea etc.<br />

3. High capacity multi-crop thresher 15-20 hp 40000-50000 1500-2000 All regions, wheat, paddy, soyabean,<br />

maize, gram, pigeon pea etc.<br />

4. Tractor PTO operated multicrops thresher 25-35 hp 60000-70000 1500-2500 Wheat, soyabean, maize, gram etc.<br />

5. Paddy thresher 5-15 hp 12000-25000 200-1000 All regions, paddy<br />

6. Maize thresher 5-15 hp 12000-25000 500-2000 All regions, maize<br />

7. Groundnut thresher 10-15 hp 25000 500-1000 All regions, groundnut<br />

Kg./h

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

mostly in private sector. Annual production <strong>of</strong> sprayers<br />

and dusters is about 0.4 M. Recently Aeroblast sprayers,<br />

an introduction from Brazil has found good acceptance<br />

<strong>for</strong> cotton and tall tree applications. Manual and power<br />

operated sprayers could be single lance or long boom<br />

swath type, the latter are better <strong>for</strong> field crops and the<br />

<strong>for</strong>mer <strong>for</strong> spot treatment, kitchen gardens and trees.<br />

Impingement, distribution, coverage and drift are major<br />

issues is spraying and dusting which can be addressed<br />

by electrostatic spraying and dusting. However, India<br />

lack oil based pesticides required <strong>for</strong> electrostatic<br />

spraying. Air assisted sprayers and dusters improve the<br />

coverage which is essential when using contact type<br />

pesticide. There are already a few in the market.<br />

Selection <strong>of</strong> right kind <strong>of</strong> nozzles is vital in achieving<br />

efficacy. R&D ef<strong>for</strong>ts continue to be made in this<br />

direction. Table 7 presents some <strong>of</strong> the sprayers and<br />

dusters available and in use.<br />

2.1.10 Harvesting, Threshing and Combining:<br />

Timely harvesting, separation <strong>of</strong> the produce and residue<br />

i.e. threshing and cleaning are very basic unit operations<br />

to save the crop from the qualitative and quantitative<br />

losses. Delayed harvesting means over maturity, and loss<br />

<strong>of</strong> quality, shedding in field, weather damages, damage<br />

due to fire and theft etc. Sickle, sythe, axe, Kudali,<br />

Gandasa, Dau are traditional harvesting equipment.<br />

Improved serrated sickles are available in the market at<br />

af<strong>for</strong>dable price which save time and ef<strong>for</strong>ts. Sickle and<br />

sythe action are now mechanized with the introduction<br />

<strong>of</strong> walking, riding and tractor mounted vertical conveyer<br />

reapers. Table 8 gives broad specifications <strong>of</strong> improved<br />

harvesting equipment available.<br />

Power threshing, replacing the tiring and slow bullock<br />

treading or threshing with flail or sheaves striked on<br />

hard surface, got introduced in 1960’s. Wheat power<br />

thresher developed at Allahabad <strong>Agricultural</strong> Institute<br />

(now a deemed university), Allahabad revolutionized<br />

not only the wheat threshing but set a process in motion<br />

that today we have power threshers specialized and<br />

multi-crop handling all cereals, pulses and oilseed crops.<br />

Traditional threshing <strong>of</strong> wheat and several other crops<br />

is totally replaced by power threshing where current<br />

trend is <strong>for</strong> high capacity bulk-fed power threshers.<br />

Though the power threshers have feeding chutes<br />

designed to avoid hazards to operators but some people<br />

remove them and under fatigue or toxicants get injured.<br />

It brought a legislation on farm machinery safety.<br />

Nevertheless injury due to farm equipment continue to<br />

exist. Reaping with VCR and power threshing optimizes<br />

harvesting, threshing, residue management, and feed<br />

recovery system.<br />

However, combining is found to be the cheapest<br />

method <strong>of</strong> harvesting and threshing rice and wheat. As<br />

◆ 183 ◆<br />

a result combining has become popular and there are<br />

about 30 manufacturers manufacturing combines -<br />

tractormounted, tractor driven, and self-propelled with<br />

8'-14' headers. Standard combines, however, do not<br />

handle crop residue which have feed value and create<br />

residue management problem. Straw combines do<br />

provide a solution however, in about 60-70% combined<br />

fields straw is insitu incinerated to clear the field <strong>for</strong> the<br />

next crop. Researchers are trying to develop straw/crop<br />

residue management strategies.<br />

Many crops specially fruits and vegetables, tuber<br />

crops continue to be cultivated and harvested in the<br />

traditional way but <strong>for</strong> groundnut and potato diggers<br />

that have been developed and commercialised. There<br />

are improved fruit pluckers, coconut tree climbers,<br />

manual and power operated coconut and arecanut<br />

dehuskers developed and commercialised. With<br />

increasing labour wages, conventional harvesting and<br />

threshing have become unaf<strong>for</strong>dable as a result rising<br />

demand <strong>for</strong> mechanized harvestors specially <strong>of</strong> F&V<br />

and commercial crops <strong>for</strong> which solutions may not be<br />

easy to come. Ef<strong>for</strong>ts have been started to adopt<br />

appropriate harvesting machinery in use in developed<br />

world, however, most <strong>of</strong> these are high capital cost<br />

machinery which can be used on custom hire basis or as<br />

part <strong>of</strong> contract farming. There is demand <strong>for</strong> cotton<br />

pickers and sugarcane combines <strong>for</strong> harvesting<br />

commercial crops - cotton and sugarcane.<br />

2.1.11 Transport Machinery: Traditional transport<br />

<strong>of</strong> carrying on head, shoulder or shouldersling or even<br />

as animal pack have lost relevance except where material<br />

to be transported are in very small quantities and <strong>for</strong> a<br />

short distance. Tradition bullock, camel or and horse<br />

carts are good <strong>for</strong> about 1-1.5 t <strong>of</strong> pay load. Pneumatic<br />

wheeled bullock carts can pull up to 2-3t <strong>of</strong> payload at<br />

2.5-3.5 kmph and are still found economical <strong>for</strong> 5-10<br />

km lead distance. Tractorised farms are seen keeping a<br />

pneumatic wheeled bullock cart <strong>for</strong> on-farm fodder, farm<br />

produce and input movements. Tractor owning farms<br />

have two wheeled 2-3t, trolley or 3-5t four wheeled<br />

trollies <strong>for</strong> on-farm and <strong>of</strong>f-farm transport. In many cases<br />

30-50% times agricultural tractors are used <strong>for</strong> transport<br />

<strong>of</strong> building construction materials improving annual use<br />

<strong>of</strong> tractors <strong>for</strong> economic sustainability. There are<br />

hydraulically tilting trollies available <strong>for</strong> automatic<br />

unloading <strong>of</strong> bulk loaded materials. Majority <strong>of</strong> the<br />

trollies are back dropped and some back and side<br />

dropped type too. Carts and trollies are multipurpose<br />

transport vehicles used <strong>for</strong> movement <strong>of</strong> men and<br />

materials like seed, fertilizer, soil, manure, agricultural<br />

produce and residues. There is need <strong>for</strong> animal and<br />

power operated manure transporter-cum-spreaders.<br />

However these are not available yet in the market. There

Table 10. Dehuskers, Shellers and Decorticators Developed under NARS<br />

are specialized carts and trollies developed <strong>for</strong><br />

movement <strong>of</strong> men in rural areas but not popular yet.<br />

2.1.12 Dehusking, Shelling and Decortication:<br />

Dehusking, shelling and decortication are important on<br />

-farm value adding primary processing to make the<br />

produce more presentable to the buyer, and help in<br />

reducing transport, handling and storage costs be<strong>for</strong>e<br />

further processing and utilization. Maize cobs need to<br />

be dehusked and shelled to get grain <strong>for</strong> marketing,<br />

processing and use. Coconut, arecanut are dehusked<br />

dried be<strong>for</strong>e bringing in the market. Groundnut, castor,<br />

almonds etc need to be decorticated to get the kennels.<br />

Low cost manual and power operated dehuskers, shellers<br />

and decorticators have been developed (Table 10). For<br />

minor oilseeds like cucumber seeds, neem, mango,<br />

kusum etc. decorticators have been developed or adapted<br />

but yet to be fully commercialized.<br />

2.1.13 Cleaning and Grading: Separation under<br />

natural air stream, cleaning with cleaning basket (‘Supa’)<br />

and sieving with manual sieve and manual grading have<br />

been in vogue to remove chaff and <strong>for</strong>eign matter and<br />

quality improvement through grading using sieve in case<br />

<strong>of</strong> foodgrains and oilseeds. In case <strong>of</strong> F&V manual<br />

washing and grading are generally practiced. Improved<br />

◆ 184 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

Particulars Manual Coconut Tubular Maize Manual TNAU Arecanut TNAU Groundnut<br />

Dehusker Sheller Groundnut Dehusker Decorticator<br />

Developed at CPCRI, Kasargod CIAE, Bhopal CIAE, Bhopal TNAU, Coimbatore TNAU, Coimbatore<br />

Specifications<br />

*Type Manual, piercing Manual Oscillating shoe- Power operated Power operated<br />

type concave, manual rotor-concave Osci-drumbatch<br />

continuous concave,<br />

continuous<br />

*Dimension, mm 680x275x1980 72x65 250x500x1100 1560x660x1600 1320x450x1380<br />

*Weight, kg — — — — 195<br />

Test Results<br />

*Suitability Coconut Maize Groundnut, castor Dried arecanut Groundnut<br />

*Capacity 150 nuts/h 15-20 kg/h 40-45 kg/h pods 100 kg/h 260 kg/h<br />

*Labour 1 1 2 1 2<br />

*Power Manual Manual Manual 1 hp motor 1 hp motor<br />

*Shefling (eff %) 100 100 100 — 95-8<br />

Economics<br />

*Capital cost, Rs 3,000 25 800 15,000 15,000<br />

*Unit cost, Rs/q 15 30 50 20 10<br />

*Working capital, Rs 500-1000 Negligible 2000-3000 5000-8000 5000-7000<br />

*RI% 40-45 100 or more 50-60 40-50 30-40<br />

*Pay back period, y 2-3, @ 150 d/y 10-12 days 1.5-2.0 y 2-2.5 y 2.5-3.0 @ 150 d/y<br />

<strong>of</strong> operation @30-40 d/y @150 d/y<br />

Stage <strong>of</strong> exploitation Commercial Commercial Commercial Yet to be Commercial<br />

commercialized<br />

Source <strong>of</strong> availability CPCRI, Kasargod 1. CIAE, Bhopal 1. CIAE, Bhopal TNAU, TNAU,<br />

2. MP Agro-Ind., 2. MP Agro-Ind., Coimbatore Coimbatore<br />

Bhopal Bhopal<br />

3. M/s Bindu 3. M/s Bindu Agro-<br />

Agro-Ind., Bhopal Ind., Bhopal<br />

winnowing fans, winnowers, pre-cleaners, cleaners and<br />

graders both manual and power operated have been<br />

developed and adopted, commercialized and used <strong>for</strong><br />

foodgrain and oilseeds, seed. Power operated washers,<br />

graders and packaging lines have been developed <strong>for</strong><br />

F&V and many <strong>of</strong> them commercialized but not popular<br />

yet. Seed cleaners and graders achieving very high<br />

degree <strong>of</strong> efficiencies (over 98%) are commercially<br />

manufactured and in use. Table 11 and 12 present some<br />

<strong>of</strong> the cleaners and graders developed under Indian<br />

NARS.<br />

2.1.14 Drying and Dryers: Drying under sun or<br />

shade where hot dry air conditions prevail is a common<br />

traditional method <strong>of</strong> drying <strong>of</strong> foodgrains, fruit and<br />

vegetables and many other commodities to extend their<br />

shelf life <strong>for</strong> their safe storage <strong>for</strong> <strong>of</strong>f season use and<br />

have value added products <strong>for</strong> additional income.<br />

However under unfavourable condition <strong>of</strong> hot, humid<br />

and overcast or rainy weather drying gets too slow so<br />

much so that be<strong>for</strong>e drying is accomplished molds and<br />

fungi develop contaminating and spoiling the material.<br />

To overcome this handicap different kind <strong>of</strong> drying<br />

methods and dryers have been developed but not in use<br />

except <strong>for</strong> the milling units or home level solar dryers.

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

In North India, rice and wheat quality is being adversely<br />

affected due to untimely rains and overcast weather, and<br />

inability <strong>of</strong> the farmers to handle safely the moist stalks.<br />

There is a case <strong>for</strong> mechanized combining and drying<br />

to save the foodgrains and oilseeds from weather<br />

damages, discolouration, attack <strong>of</strong> microorganisms etc.<br />

Table 13&14 give brief description <strong>of</strong> dryers developed<br />

<strong>for</strong> various crops and commodities.<br />

2.1.15 Storage: Consumers <strong>of</strong> about 65% <strong>of</strong> the<br />

agricultural commodities produced are rural people who<br />

retain cereals, pulses, oilseeds etc <strong>for</strong> family<br />

consumption and dispose only surpluses (on average<br />

about 35%). Traditional storage practices and storage<br />

structures work satisfactorily under favourable<br />

condition. However, under scientific storages/<br />

warehousing losses to foodgrains are below 3-4%, but<br />

under on-farm storages losses are about 10% or even<br />

more as in the case <strong>of</strong> legumes. As a result farmers tend<br />

to dispose <strong>of</strong>f vulnerable surplus even under depressed<br />

market situation thereby suffering economic losses.<br />

Improved storage structures and practices have been<br />

developed and some <strong>of</strong> them have become popular also<br />

like metallic bins, use <strong>of</strong> tunnage to store foodgrains in<br />

Table 11. Grain Cleaners and Graders Developed under NARS<br />

Particulars Manual Double Pedal Operate Paddy Seed Cleaner- Single Drum<br />

Screen Cleaner Air Screen Winnower cum-Grader Rotary Screen<br />

Grain Cleaner Pre-Cleaner<br />

Developed by CIAE, Bhopal CIAE, Bhopal TNAU, Coimbatore, TNAU, Coimbatore PAU Ludhiana<br />

Specifications<br />

*Type Manual, cradle Pedal operated Power operated Power operated Power operated<br />

type, 2-screen blower, 2- screen reciprocating rotary screen<br />

*Dimensions 900x600x140 1600x500x1000 1210x960x1430 1800x1200x1800 1525x115x1730<br />

*Weight, kg 14 100 -<br />

Test Results<br />

*Suitability Foodgrains and Foodgrain, and Paddy and Paddy and other Wheat, paddy<br />

oilseeds except oilseeds except other grains foodgrain<br />

groundnut groundnut<br />

*Capacity 150-225 kh/h 350-600 kg/h 750 kg/h 20q/h paddy & 12-15 q/h<br />

pearlmillet 32-34 q/h<br />

maize & sorghum<br />

*Cleaning/ grading <strong>of</strong>f,% 99-99.8 99.5-99.9 97 92 95<br />

*Labour 1 2 2 2<br />

*Power Manual 1 hp motor 2 hp motor 1.5 hp motor<br />

Economics<br />

*Capital cost, Rs 1000 10,000 20,000 50,000 20,000<br />

*Unit Cost <strong>of</strong> operation, Rs/q 2-3 2-3 2-3 3-4 0.5-1.0<br />

*Working Capital, Rs 1000-2000 2000-5000 2000-5000 5000-10000 5000-10000<br />

*Return on investment,% 40-50 40-50 25-30 25-30 30-40<br />

*Pay back period, y 2-3 @45 d/y 2-3, @ 45 d/y 3-4, @ 30 d/y 3-4, @ 30 d/y 3-4, @ 45 d/y<br />

Stage <strong>of</strong> exploitation commercial Commercial commercial commercial commercial<br />

Source <strong>of</strong> availability 1. CIAE Bhopal 1. CIAE Bhopal TNAU TNAU 1. PAU Ludhiana<br />

2. M/s Bindu 2. M/s Bindu Coimbatore Coimbatore 2. M/s Hindsons<br />

Agro-Ind Plot Agro-Ind Plot Pvt Ltd, Lower<br />

73, Sector H, 73, Sector H, MAU Patiala<br />

Govindpura, Bhopal Govindpura,<br />

Bhopal<br />

◆ 185 ◆<br />

bags or bulk <strong>for</strong> short term, drying to safe moisture levels<br />

and other prophylactic measures be<strong>for</strong>e storage, use <strong>of</strong><br />

fumigation (phosphene tablet) in case <strong>of</strong> insect<br />

infestation etc. For storage <strong>of</strong> certain perishables use <strong>of</strong><br />

evaporative cooled storage/zero-energy cool chambers<br />

are found useful. Public and private sector cold storages,<br />

controlled atmosphere storages, onion storages are being<br />

used <strong>for</strong> perishables and the Govt <strong>of</strong> India has launched<br />

a scheme to promote cold stores and onion storages.<br />

Scientific on-<strong>for</strong>m storage can bring down losses<br />

dramatically at the same time enable the farmers to sell<br />

their produce <strong>of</strong>f season at better prices.<br />

2.1.16 On-Farm Milling and Processing: Indian<br />

villages have traditionally been producer-cum-primary<br />

processing centres. To enable the rural sector to meet<br />

its needs at least cost and market value added products<br />

<strong>for</strong> additional income and employment, processes and<br />

equipment/pilot plants (Table 15) have been developed<br />

like mini-rice mills, mini-dal mills, mini-grain mills,<br />

mini-soy milk-cum-t<strong>of</strong>u plant which are commercially<br />

available (Table 14). High per<strong>for</strong>mance mini-oil<br />

expellers have been developed and commercialized<br />

enabling growers crushing and filtering oilseed <strong>for</strong> fresh

wholesome vegetable oil <strong>for</strong> own consumption,<br />

marketing in the nearby towns and retaining cake <strong>for</strong><br />

the livestock or sale to solvent extraction units. Models<br />

<strong>of</strong> Agro-Processing Centres have been developed.<br />

Additional income and employment contributes to<br />

capital <strong>for</strong>mation and stimulation to increased<br />

production and productivity, acquisition <strong>of</strong> modern<br />

equipment and machinery. It is a <strong>for</strong>ward linkage that<br />

grows with mechanization in agriculture providing<br />

incentives to investments in increasing production and<br />

productivity.<br />

2.2 Policy and Legislative<br />

2.2.1 Mechanization Policy: <strong>Agricultural</strong><br />

mechanization is a relatively less regulated sector.<br />

Increasingly need <strong>for</strong> agricultural mechanization have<br />

been demanded and discussed in legislative and policy<br />

making bodies. Perceptions vary but the most common<br />

description <strong>of</strong> agricultural mechanization needed in India<br />

is appropriate selective mechanization which brings<br />

Table 12. Grader <strong>for</strong> Horticultural Crops, Groundnut<br />

◆ 186 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

Particulars Groundnut Apple Grader Potato Grader Weight based CIPHET Fruit<br />

Grader Fruit Grader Grader<br />

Developed at TNAU, Coimbatore GBPUAT, Pantnagar PAU Ludhiana GBPUAT, Pantnagar CIPHET,<br />

Ludhiana<br />

Specifications<br />

*Type Power operated, Power operated Power operated Power operated Size based,<br />

slotted oscillating differential speed ex expanding pitch weight based grader expanding pitch<br />

sieve panding pitch v-belts rubber-spool rollers, 6-8 grades<br />

*Dimensions 2250x1050x1350 4900x1500x1340 5200x1640x1690 1500x1500x1200 3000x2000x1500<br />

*Weight, kg 500 550 70 200<br />

Test Results<br />

*Suitability Groundnut Apples, potatoes Potato, apples, Round shaped Kinnow, citrus,<br />

citrus fruits, 25-225 mm other round fruits<br />

50-250 mm<br />

diameter<br />

*Capacity, q/h 6 15 15 3-4 10-15<br />

*Labour 2 2 2 2 3-4<br />

*Power 1hp motor 2 hp motor 1 hp motor 1 hp motor 2 hp motor<br />

Economics<br />

*Capital cost Rs 20,000 30,000 40,000 15,000 35,000<br />

*Unit Cost <strong>of</strong> operation, Rs/q 2-3 1-2 3-4 10-15 10<br />

*Working Capital, Rs 2000-3000 5000-10000 5000-10000 2000-5000 5000-10,000<br />

*RI,% 25-30 35-40 35-40 50-60 50-70<br />

*Pay back period, y 3-4, @ 30-40 d/y 3-4, @ 30 d/y 3-4, @ 30 d/y 1.2 – 2.0, @ 45-50 d/y 1.5-2.0<br />

Stage <strong>of</strong> exploitation Yet to be Yet to be Yet to be Released <strong>for</strong> Commercial<br />

commercialized commercialized commercialised commercial<br />

production<br />

Source <strong>of</strong> availability College <strong>of</strong> Agric GBPUAT, 1. College <strong>of</strong> College <strong>of</strong> M/s Regency<br />

Engg TNAU, Pantnagar Agric Engg Technology, Agro Pvt. Ltd.,<br />

Coimbatore PAU, Ludhiana GBPUAT, Malout (Pb)<br />

2. M/s Universal Pantnagar<br />

Farm Machinery<br />

Corpn, Patiala<br />

Road, Nivwarna<br />

Jind (Haryana)<br />

economic competitiveness and removes avoidable<br />

drudgery. National Commission on Agriculture (NCA)<br />

made stipulations on agricultural mechanization. High<br />

powered committees appointed by GOI have given<br />

direction the subject. National <strong>Agricultural</strong> Policy<br />

(NAP) amplifies agricultural policies. A draft<br />

agricultural mechanization policy has been worked out<br />

jointly by Machinery Division, DAC, GOI, which needs<br />

to be nationally agreed and adopted.<br />

2.2.2 Standardization & Certification: To protect<br />

the farmers’ interests from introduction <strong>of</strong> inappropriate<br />

trouble some equipment in Indian market, GOI has<br />

requirement <strong>of</strong> testing and certification by DAC which<br />

is carried out its Testing and Training Institutes at Budni<br />

and Hissar. As a mark <strong>of</strong> standardization and quality<br />

BIS standards are there on farm equipment, ISI<br />

certification on critical components and machines. There<br />

is a long list <strong>of</strong> such standards. BIS standards are steadily<br />

getting closer to ISO where available.<br />

2.2.3 There are farm implements and attachments to

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

Table 13. Solar Dryers <strong>for</strong> Crops and Commodities<br />

Particulars Solar Cabinet Dryer CPCRI Solar Dryer Low cost Poly Solar Dryer Solar Fish Dryer<br />

Developed by CIAE, Bhopal CPCRI, Kasargod CPCRI, Kasargod CIFT, Cochin<br />

Specifications<br />

*Type Natural convection Cabinet, natural Cabinet, natural Batch, <strong>for</strong>ced solar<br />

trays, portable convection convection convection flat plateair<br />

heater<br />

*Dimensions, mm 2260x1440x2410 1350x950x7000 1150x900x600 8000x5000x2000<br />

Test Results<br />

*Suitability Chilli, potatochips/ Coconut, arecabnut, Coconut, pepper, All kins <strong>of</strong> fish<br />

cubes, cauliflower pepper, cardamom, fish, papad etc.<br />

leafy vegetables<br />

*Capacity 30-50 kg/batch 80-100 coconut, 60 nuts/batch 40 kg/batch<br />

50 kg arecanut,<br />

18 kg pepper/batch<br />

*Labour 2-3 man h/d 1-2 man h/d 1 man h/d 2-3 man h/d<br />

*Power - - - 1 hp motor<br />

*Heat Solar Solar Solar Solar<br />

*Drying time, d/batch 1-5 4 coconut, pepper 6 batch <strong>of</strong> 60 nuts 2<br />

30 arecanut<br />

Economics<br />

*Capital Cost Rs 8000 4000 500 50,000<br />

*Unit cost <strong>of</strong> 200-250 200-300 300-400 300-400<br />

drying, Rs/q<br />

*Working Capital Rs 2000-3000 2000-3000 2000-3000 20000-30000<br />

*RI,% 50-60 40-50 40-50 25-30<br />

*Pay back 1.5-2.0,@150 d/y 2-3,@100 d/y 2-2.5, @100 d/y 3-4@ 150 d/y<br />

period, yr<br />

Stage <strong>of</strong> exploitation Commercial Commercial Commercial Ready <strong>for</strong><br />

commercialisation<br />

Source <strong>of</strong> availability CIAE, Bhopal CPCRI, Kasargod CPCRI, Kasargod CIFT, Cochin<br />

Table 14. Food Grain Dryers<br />

Particulars Community Heated Sand Batch Dryer Continues<br />

GrainDryer grain Dryer Grain Dryer<br />

Developed by CRRI, Cuttack TNAU, Coimbatore TNAU, Coimbatore GBPUAT, Pantnagar<br />

Specifications<br />

*Type Recirculating batch, Continuous flow Batch, <strong>for</strong>ced convention Continuous, cross<br />

Solar-cum-rice husk flow<br />

*Dimensions 1200 diax2500 3320x1230x1710 2290x1700x1100 1260x1220x3300<br />

Test Results<br />

*Suitability Paddy Drying paddy and roasting Paddy, pearlmillet, sorghum, groundnut<br />

<strong>of</strong> legumes Paddy, wheat, maize,<br />

pigeonpea and other<br />

foodgrain<br />

*Capacity 1 t/batch 0.6-0.8 t/8h 0.5-1.0t/8h 0.8-1.0t/h<br />

*Labour 2 1 1 2<br />

*Power 5 hp motor 3 hp motor 2 hp motor 3 hp blower<br />

* Heat Solar, rice husk Fuelwood LDO, kerosene or 18 kwh electric heaters<br />

@ 10-12 kg/h crop residues<br />

Economics<br />

*Capital Cost, Rs 1,00,000 30,000 40,000 50,000<br />

*Unit Cost <strong>of</strong> operation, 20-25 40-50 50-60 30-40<br />

Rs/q<br />

*Working Capital, Rs 1-2 lakh 50000-75000 20000-30000 0.5-1.0 lakh<br />

*RI, % 25-30 25-30 25-30 30-35<br />

*Pay back period, y 3-4@150 d/y 3-4 @ 200 d/y 3-4 @100 d/y 3-4 y @150 d/y<br />

Stage <strong>of</strong> exploitation Yet to be Yet to be Yet to be Yet to be<br />

commercialised commercialised commercialized commercialized<br />

Source <strong>of</strong> availability CRRI, Cuttack TNAU, Coimbatore TNAU, Coimbatore GBPUAT, Pantnagar<br />

◆ 187 ◆

Table 15. Dal Milling Equipment Developed in NARS<br />

◆ 188 ◆<br />

STATUS OF FARM MECHANIZATION IN INDIA<br />

Particulars Dal Mill-cum- Pantnagar Lowcost CIAE Dal Mill Soybean Dehuller<br />

Wet Grinder Dal Mill Multipurpose<br />

Grain Mill<br />

Developed at TNAU, Coimbatore GBPUAT, CIAE, Bhopal CIAE, Bhopal GBPUAT,<br />

Pantnagar Pantnagar<br />

Specifications<br />

*Type Power operated, Throughput type, Vertical stone burr Emery-carbo Power operated<br />

abrasive type, decuticling, splitting grinder, power rundum, throughput cylinder- concave<br />

portable has two and cleaning operated type type<br />

separate milling and<br />

wet grinding settings<br />

*Dimensions 765x550x790 6000x4000x3000 700x500x700 770x630x1020 1050x500x720<br />

*Weight, kg — — 69 90 —<br />

Test Results<br />

*Suitability Dal making, dry Pigeon pea Ata, besan, dal, All legumes Soybean, pea and<br />

grinding <strong>of</strong> pulses dalia, coriander and Bengalgram<br />

and cereals, wet grinding turmeric powder<br />

*Capacity 6 l <strong>of</strong> wet rice/h 4 q/h 15 kg/h Ata, 50-70 100 kg/h 250 kg/h<br />

kg/h dal,10-11 kg/h<br />

besan and coriander<br />

powder<br />

*Milling efficiency — — — 88-90 —<br />

*Labour 1 2 1 2 1<br />

*Power 0.5 hp motor 5 hp motor 1 hp motor 2.5 hp motor 2 hp motor<br />

Economics<br />

*Capital cost, Rs 10,000 50,000 8,000 12,000 7,000<br />

*Unit cost <strong>of</strong> operation, 100 wet grinding 50-60 10-30 40-50 6<br />

Rs/q<br />

*Working capital, Rs 10,000-20,000 1.5-2.0 lakh 2000-3000 20,000-30,000 5,000-10,000<br />

*RI% 20-25 30-40 30-40 30-40 25-30<br />

*Pay back period, y 4-5, @ 200 d/yr 2.5-3.0, @ 200 d/yr 2.5-3.0, @ 200 d/yr 2.5-3.0, @ 150 d/yr 3-4 @ 250 d/yr<br />

Stage <strong>of</strong> exploitation Yet to be Yet to be Commercialized Commercialized Yet to be<br />

commercialized commercialized commercialized<br />

Source <strong>of</strong> availability College <strong>of</strong> Agril College <strong>of</strong> CIAE, Bhopal CIAE, Bhopal College <strong>of</strong><br />

Engg., TNAU, Technology, Technology,<br />

Coimbatore GBPUAT, Pantnagar GBPUAT,<br />

Pantnagar<br />

tractors reserved <strong>for</strong> SSI which helped in bringing down<br />

the unit cost <strong>of</strong> these equipment. However, the quality<br />

suffered. To get over this crisis following equipment<br />

have been dereserved.<br />

1. Crow bars<br />

2. Levellers<br />

3. Mowers<br />

4. Reapers up to 5 hp<br />

5. Seed Drills up to 5 hp<br />

6. Other agric machinery up to 5 hp<br />

2.2.4 Gender Bias in Mechanization: The National<br />

Commission on Women is exercised putting pressure<br />

on R&D organisations and development departments<br />

to remove drudgery to farm women and to have hand<br />

tools, implements and machines suited to different<br />

sections <strong>of</strong> the farm women. These are receiving<br />

attention. The following items have been identified <strong>for</strong><br />

due attention on priority.<br />

1. Improved sickle<br />

2. Wheel hand hoe<br />

3. Dibbler<br />

4. Maize sheller<br />

5. Groundnut decorticator<br />

6. Horticultural tools<br />

7. Sugarcane stripping knife<br />

8. Cleaners<br />

9. Graders<br />

10. Improved chulhas<br />

11. Solar cookers<br />

12. Husk fired stoves<br />

13. Manually operated seed-drill/planter<br />

14. Manual fruit harvester<br />

15. Cotton stalk puller<br />

16. Dal mill<br />

17. Chilli seed extractor<br />

2.2.5 Demand due to Globalization: Farmers’<br />

interest groups are putting pressure through different<br />

<strong>for</strong>a to mechanize harvesting <strong>of</strong> commercial crops like

FUTURE REQUIREMENTS OF AGRICULTURAL MACHINES FOR MECHANIZING AGRICULTURE<br />

Table 16. Small Scale Pilot Plants<br />

Particulars Soymilk and Model Agro- TNAU Tomato Chillies Seed<br />

T<strong>of</strong>u Plant Processing Centre Seed Extractor Extractor<br />

Developed at CIAE, Bhopal CIAE, Bhopal; PAU, Ludhiana; TNAU, Coimbatore PDKV, Akola<br />

UAS, Bangalore; TNAU,<br />

Coimbatore; GBPUAT, Pantnagar<br />

and CIPHET, Ludhiana<br />

Specifications<br />

*Type Batch; cooker, grinder Multiproduct, agri-produce Power operated, Power operated<br />

<strong>of</strong> soaked beans under ‘ processing and packaging continuous extrusion continuous<br />

oxygenfree’ condition type<br />

*Dimension, mm 5000x3000x2000 10mx5m covered space 1020x615x1050 1090x500x910<br />

Test Results and equal open space<br />

*Suitability Soybean Cereals, pulses, oilseeds, Seed from tomato Seed from dried chillies<br />

spices and condiments fruits<br />

*Capacity 200 l milk or 50 kg t<strong>of</strong>fu 300-500 kg/h cleaning/h 60 kg (fruits)/ h 4q/ 8h (dried chilli)<br />

per 8 hr 100-150 kg/h Ata<br />

200-300 kg/h rice<br />

40-50 kg/h dal<br />

40-50 kg/h oilseed<br />

*Labour 2 4-5 1 1<br />

*Power 1 hp motor 7.5 kW motor or 15 2 hp motor 1 hp motor<br />

hp engine<br />

Economics<br />

*Capital cost, Rs 2.5 lakh 2.0-2.5 lakh (excluding 15,000 35,000<br />

building)<br />

*Unit cost, Rs 5-7 per kg <strong>of</strong> soy 3-5 Rs/q cleaning/h<br />

30-40 Rs/q flour<br />

25-30 Rs/q rice<br />

80-90 Rs/q oil 30 Rs/q 30 Rs/q chillies<br />

*Working capital, Rs 0.50-0.75 lakh 0.5-1.0 lakh 15,000-30,000 50,000-60,000<br />

*RI,% 40-50 40-50 50-60 40-50<br />

*Pay back, y 2-2.5, @ 250 d/yr 2-2.5, @ 250 d/yr 1.5-2.0, @ 30 d/yr 2-2.5, @ 30-35 d/y<br />

Stage <strong>of</strong> exploitation Commercial Release <strong>for</strong> popularization Yet to be commercialized Commercial<br />

Source <strong>of</strong> availability 1. M/s SSP Ltd, 13 1. CIAE, Bhopal College <strong>of</strong> Agric. Engg., College <strong>of</strong> Agric.<br />

Mathura Road, 2. CIPHET, Ludhiana TNAU, Coimbatore Engineering,<br />

Faridabad-121 003 and other mentioned PDKV, Akola<br />

2. M/s Monica Processing organizations<br />

Plants, 10-A, Sneh Nagar,<br />

Indore-452 001<br />

3. M/s Raylans Metal Works,<br />

PO Box 17426, JB Nagar,<br />

Andheri (E), Mumbai-400 059<br />

4. M/s Sanjay K. Gupta, 5,<br />

Gandhi Nagar, Pathakheda,<br />

Betul-460 449<br />

sugarcane, and cotton. Demand is also raised to have<br />

mechanized tea harvesting. Globalization has also put<br />