Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

12<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> <strong>Express</strong><br />

A recipe for success:<br />

quality and process automation<br />

Melike İplik San. Ve Tic A.Ş. (Turkey)<br />

winds with first linked Autoconer X5 system<br />

Melike İplik<br />

San. Ve Tic<br />

A.Ş., based in<br />

Gaziantep, is a<br />

very new company that was only established<br />

in 2007. Thanks to its consistent quality<br />

orientation, however, the company has<br />

already built up an outstanding reputation<br />

for the production of chenille yarns. 12,000<br />

tonnes of acrylic yarn are produced each<br />

year, dyed in the company’s own dye shop<br />

and 70% of this is processed directly in the<br />

weaving mill belonging to Melike. 30% of<br />

production is sold in Turkey and exported<br />

e.g. to the USA, Spain, Egypt, Germany and<br />

Greece. Each of the workforce numbering<br />

around 150 is geared consistently to the<br />

successful “Net-Quality” principle, and the<br />

entire process sequence is oriented to this<br />

too. No matter whether in regard to raw<br />

material selection, continuous quality monitoring<br />

of the entire process sequence or<br />

bringing together the machinery required for<br />

production, Melike demands the highest<br />

standards in all areas. Also included in the<br />

“Net-Quality” principle is the ongoing education<br />

and training of its staff as a basic element.<br />

Research and development as a whole is<br />

targeted to consistent, rising product quality.<br />

From the outset, <strong>Oerlikon</strong> <strong>Schlafhorst</strong> has<br />

been the supplier of winding technology,<br />

because the package quality of the Autoconer<br />

is convincing. Up to this summer, 10<br />

Autoconer 338, type D machines were<br />

producing the packages for inhouse<br />

downstream processing and for sale. Based<br />

on the favourable experience acquired with<br />

the Autoconer, the management of Melike<br />

decided to opt for <strong>Oerlikon</strong> <strong>Schlafhorst</strong><br />

again in the capacity expansion planned for<br />

mid-2010, this time choosing a linked<br />

system. In June, nine brand-new Autoconer<br />

X5, type V machines were delivered to<br />

Melike. It was the first installation of this<br />

new machine type worldwide. Mill director<br />

Ergün Yilmaz justifies the decision in favour<br />

of the Autoconer X5 linked system thus:<br />

“With this highly automated system we have<br />

the opportunity to meet the demands for<br />

quality at a constantly high level even more<br />

reliably while reducing labour costs.” After<br />

the first few months in which the machines<br />

are now working in full production, the feedback<br />

on the new performance features is<br />

entirely positive: “Of particular benefit to our<br />

“Net-Quality” principle is SPID spindle identification.<br />

Quality defects at the ring spinning<br />

machine are detected at an early stage and<br />

Customers & markets<br />

can be eliminated in a targeted manner. The<br />

quality monitoring is integrated directly into<br />

the process sequence.” The reconfigured<br />

material flow, the new doffer X-Change and<br />

the process details and piecing cycles,<br />

which have been optimised compared with<br />

the Autoconer 338, also increase productivity.<br />

The significantly reduced consumption of<br />

energy and resources is a convincing factor<br />

above all in the overall bill.<br />

The employees are extremely satisfied with<br />

the performance of the new linked system.<br />

They like working with the Autoconer X5,<br />

because it makes handling considerably<br />

simpler, and operation can be limited almost<br />

exclusively to monitoring functions. Investment<br />

in future-ready machine concepts<br />

such as those of <strong>Oerlikon</strong> <strong>Schlafhorst</strong> have<br />

always been the top priority for the management<br />

of Melike, because its plans for the<br />

future envisage further expansion with<br />

regard both to the production quantity and<br />

the yarn spectrum. But the strict orientation<br />

to the “Net-Quality” principle continues to<br />

apply to this, because Melike’s claim and<br />

recipe for success is to establish itself<br />

successfully with top product quality and<br />

consolidate its market position further.<br />

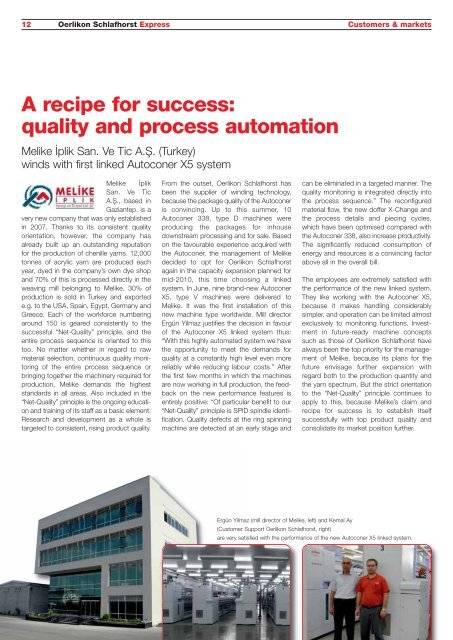

Ergün Yilmaz (mill director of Melike, left) and Kemal Ay<br />

(Customer Support <strong>Oerlikon</strong> <strong>Schlafhorst</strong>, right)<br />

are very satisfied with the performance of the new Autoconer X5 linked system.