Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Innovations<br />

Zinser Modernisation Kit<br />

Tube feeding system CoWeFeed<br />

Clearly more efficiency at the CoWeMat<br />

Know-how<br />

CoWeFeed significantly reduces machine<br />

operating outlay and eliminates manual tube<br />

sorting into boxes. The efficiency of the<br />

machine is increased by the reliability of the<br />

system.<br />

CoWeMat plus CoWeFeed:<br />

maximum productivity<br />

With CoWeFeed, the empty tubes can<br />

be supplied unsorted into the feed<br />

container of the ring spinning machine.<br />

They are aligned fully automatically,<br />

taken and placed on bobbin trays,<br />

which safely transport your tubes and<br />

bobbins. Digitally controlled by means of<br />

a user-friendly graphical touch screen.<br />

With CoWeFeed, your Zinser ring spinning<br />

machine and the production factors time,<br />

space, and personnel are utilised much<br />

more efficiently. CoWeFeed is particularly<br />

attractive for long machines: here too bobbin<br />

removal and the feeding of empty tubes are<br />

easily implemented between two doffing<br />

operations, as the cycle times are very fast.<br />

We offer:<br />

• Equipping of older CoWeMat generations<br />

with bobbin tray belt and CoWeFeed<br />

for Zinser ring spinning machines 319,<br />

319L, 320/420, 321/421 and 350/450<br />

Your benefit:<br />

Less handling effort<br />

• Easy and quick handling:<br />

time-consuming sorting is dropped<br />

• Less expenditure: filling and transporting<br />

tube boxes is no longer required<br />

More safety and efficiency<br />

• The bobbin tray conveyor belt ensures<br />

a reliable and rapid transport of tubes<br />

and bobbins<br />

• The optimum CoWeMat control with<br />

graphical interface allows quick and safe<br />

operation with short training times<br />

• Excellent machine availability with higher<br />

output<br />

Cost reduction<br />

• Lower personnel, time, space, and<br />

material expenditure<br />

• Replacement of many wear parts<br />

included, thus reduced spare part<br />

requirements in subsequent years<br />

• Reduction of down times<br />

• Abolition of tube boxes<br />

For quick production cycles and higher output.<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> <strong>Express</strong> 7<br />

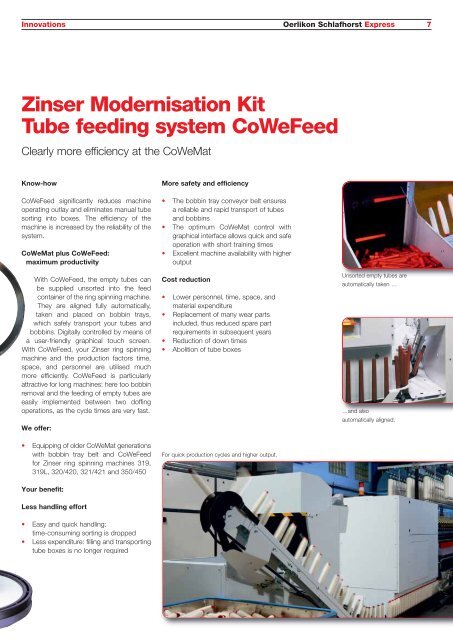

Unsorted empty tubes are<br />

automatically taken …<br />

…and also<br />

automatically aligned.