High Resistance Polymermodified Binders to Secure ... - Nynas

High Resistance Polymermodified Binders to Secure ... - Nynas

High Resistance Polymermodified Binders to Secure ... - Nynas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

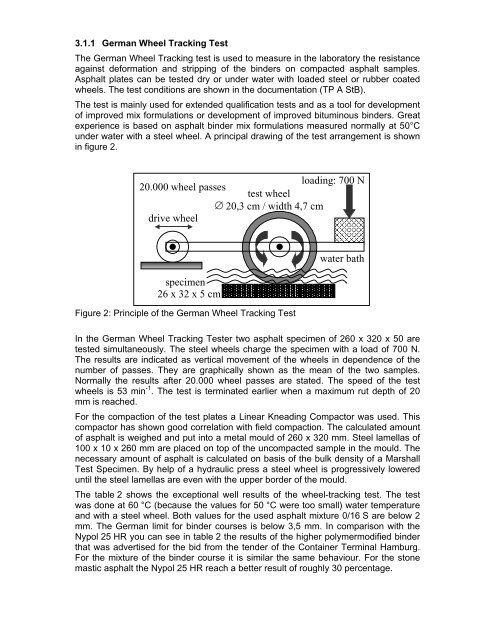

3.1.1 German Wheel Tracking Test<br />

The German Wheel Tracking test is used <strong>to</strong> measure in the labora<strong>to</strong>ry the resistance<br />

against deformation and stripping of the binders on compacted asphalt samples.<br />

Asphalt plates can be tested dry or under water with loaded steel or rubber coated<br />

wheels. The test conditions are shown in the documentation (TP A StB).<br />

The test is mainly used for extended qualification tests and as a <strong>to</strong>ol for development<br />

of improved mix formulations or development of improved bituminous binders. Great<br />

experience is based on asphalt binder mix formulations measured normally at 50°C<br />

under water with a steel wheel. A principal drawing of the test arrangement is shown<br />

in figure 2.<br />

loading: 700 N<br />

20.000 wheel passes<br />

test wheel<br />

∅ 20,3 cm / width 4,7 cm<br />

drive wheel<br />

specimen<br />

26 x 32 x 5 cm<br />

Figure 2: Principle of the German Wheel Tracking Test<br />

water bath<br />

In the German Wheel Tracking Tester two asphalt specimen of 260 x 320 x 50 are<br />

tested simultaneously. The steel wheels charge the specimen with a load of 700 N.<br />

The results are indicated as vertical movement of the wheels in dependence of the<br />

number of passes. They are graphically shown as the mean of the two samples.<br />

Normally the results after 20.000 wheel passes are stated. The speed of the test<br />

wheels is 53 min -1 . The test is terminated earlier when a maximum rut depth of 20<br />

mm is reached.<br />

For the compaction of the test plates a Linear Kneading Compac<strong>to</strong>r was used. This<br />

compac<strong>to</strong>r has shown good correlation with field compaction. The calculated amount<br />

of asphalt is weighed and put in<strong>to</strong> a metal mould of 260 x 320 mm. Steel lamellas of<br />

100 x 10 x 260 mm are placed on <strong>to</strong>p of the uncompacted sample in the mould. The<br />

necessary amount of asphalt is calculated on basis of the bulk density of a Marshall<br />

Test Specimen. By help of a hydraulic press a steel wheel is progressively lowered<br />

until the steel lamellas are even with the upper border of the mould.<br />

The table 2 shows the exceptional well results of the wheel-tracking test. The test<br />

was done at 60 °C (because the values for 50 °C were <strong>to</strong>o small) water temperature<br />

and with a steel wheel. Both values for the used asphalt mixture 0/16 S are below 2<br />

mm. The German limit for binder courses is below 3,5 mm. In comparison with the<br />

Nypol 25 HR you can see in table 2 the results of the higher polymermodified binder<br />

that was advertised for the bid from the tender of the Container Terminal Hamburg.<br />

For the mixture of the binder course it is similar the same behaviour. For the s<strong>to</strong>ne<br />

mastic asphalt the Nypol 25 HR reach a better result of roughly 30 percentage.

![Säkerhetsbestämmelser Gbg rev 5.ppt [Compatibility Mode] - Nynas](https://img.yumpu.com/18742268/1/190x146/sakerhetsbestammelser-gbg-rev-5ppt-compatibility-mode-nynas.jpg?quality=85)