2005-2006 steep-slope roofing materials guide - National Roofing ...

2005-2006 steep-slope roofing materials guide - National Roofing ...

2005-2006 steep-slope roofing materials guide - National Roofing ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

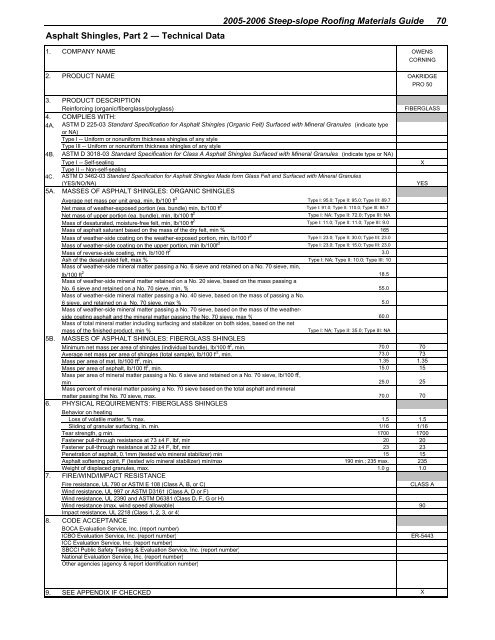

Asphalt Shingles, Part 2 ― Technical Data<br />

<strong>2005</strong>-<strong>2006</strong> Steep-<strong>slope</strong> <strong>Roofing</strong> Materials Guide 70<br />

1. COMPANY NAME OWENS<br />

CORNING<br />

2. PRODUCT NAME OAKRIDGE<br />

PRO 50<br />

3. PRODUCT DESCRIPTION<br />

Reinforcing (organic/fiberglass/polyglass) FIBERGLASS<br />

4. COMPLIES WITH:<br />

4A.<br />

Type I -- Uniform or nonuniform thickness shingles of any style<br />

Type III -- Uniform or nonuniform thickness shingles of any style<br />

4B.<br />

Type I -- Self-sealing<br />

Type II -- Non-self-sealing<br />

X<br />

4C.<br />

YES<br />

5A. MASSES OF ASPHALT SHINGLES: ORGANIC SHINGLES<br />

Average net mass per unit area, min, lb/100 ft 2<br />

Type I: 95.0; Type II: 95.0; Type III: 89.7<br />

Net mass of weather-exposed portion (ea. bundle) min, lb/100 ft 2<br />

Type I: 91.0; Type II: 110.0; Type III: 85.7<br />

Net mass of upper portion (ea. bundle), min, lb/100 ft 2<br />

Type I: NA; Type II: 72.0; Type III: NA<br />

Mass of desaturated, moisture-free felt, min, lb/100 ft 2<br />

Type I: 11.0; Type II: 11.0; Type III: 9.0<br />

Mass of asphalt saturant based on the mass of the dry felt, min % 165<br />

Mass of weather-side coating on the weather-exposed portion, min, lb/100 f 2<br />

Type I: 23.0; Type II: 30.0; Type III: 23.0<br />

Mass of weather-side coating on the upper portion, min lb/100ft 2<br />

Type I: 23.0; Type II: 15.0; Type III: 23.0<br />

Mass of reverse-side coating, min, lb/100 ft 2<br />

ASTM D 225-03 Standard Specification for Asphalt Shingles (Organic Felt) Surfaced with Mineral Granules (indicate type<br />

or NA)<br />

ASTM D 3018-03 Standard Specification for Class A Asphalt Shingles Surfaced with Mineral Granules (indicate type or NA)<br />

ASTM D 3462-03 Standard Specification for Asphalt Shingles Made form Glass Felt and Surfaced with Mineral Granules<br />

(YES/NO/NA)<br />

3.0<br />

Ash of the desaturated felt, max % Type I: NA; Type II: 10.0; Type III: 10<br />

Mass of weather-side mineral matter passing a No. 6 sieve and retained on a No. 70 sieve, min,<br />

lb/100 ft 2 18.5<br />

Mass of weather-side mineral matter retained on a No. 20 sieve, based on the mass passing a<br />

No. 6 sieve and retained on a No. 70 sieve, min, % 55.0<br />

Mass of weather-side mineral matter passing a No. 40 sieve, based on the mass of passing a No.<br />

6 sieve, and retained on a No. 70 sieve, max %<br />

Mass of weather-side mineral matter passing a No. 70 sieve, based on the mass of the weather-<br />

5.0<br />

side coating asphalt and the mineral matter passing the No. 70 sieve, max %<br />

Mass of total mineral matter including surfacing and stabilizer on both sides, based on the net<br />

60.0<br />

mass of the finished product, min % Type I: NA; Type II: 35.0; Type III: NA<br />

5B. MASSES OF ASPHALT SHINGLES: FIBERGLASS SHINGLES<br />

Minimum net mass per area of shingles (individual bundle), lb/100 ft 2 , min. 70.0 70<br />

Average net mass per area of shingles (total sample), lb/100 ft 2 , min. 73.0 73<br />

Mass per area of mat, lb/100 ft 2 , min. 1.35 1.35<br />

Mass per area of asphalt, lb/100 ft 2 , min.<br />

Mass per area of mineral matter passing a No. 6 sieve and retained on a No. 70 sieve, lb/100 ft<br />

15.0 15<br />

2 ,<br />

min<br />

Mass percent of mineral matter passing a No. 70 sieve based on the total asphalt and mineral<br />

25.0 25<br />

matter passing the No. 70 sieve, max. 70.0 70<br />

6. PHYSICAL REQUIREMENTS: FIBERGLASS SHINGLES<br />

Behavior on heating<br />

Loss of volatile matter, % max. 1.5 1.5<br />

Sliding of granular surfacing, in. min. 1/16 1/16<br />

Tear strength, g min. 1700 1700<br />

Fastener pull-through resistance at 73 ±4 F, lbf, min 20 20<br />

Fastener pull-through resistance at 32 ±4 F, lbf, min 23 23<br />

Penetration of asphalt, 0.1mm (tested w/o mineral stabilizer) min. 15 15<br />

Asphalt softening point, F (tested w/o mineral stabilizer) min/max 190 min.; 235 max. 235<br />

Weight of displaced granules, max. 1.0 g 1.0<br />

7. FIRE/WIND/IMPACT RESISTANCE<br />

Fire resistance, UL 790 or ASTM E 108 (Class A, B, or C)<br />

Wind resistance, UL 997 or ASTM D3161 (Class A, D or F)<br />

Wind resistance, UL 2390 and ASTM D6381 (Class D, F, G or H)<br />

CLASS A<br />

Wind resistance (max. wind speed allowable)<br />

Impact resistance, UL 2218 (Class 1, 2, 3, or 4)<br />

90<br />

8. CODE ACCEPTANCE<br />

BOCA Evaluation Service, Inc. (report number)<br />

ICBO Evaluation Service, Inc. (report number)<br />

ICC Evaluation Service, Inc. (report number)<br />

SBCCI Public Safety Testing & Evaluation Service, Inc. (report number)<br />

<strong>National</strong> Evaluation Service, Inc. (report number)<br />

Other agencies (agency & report identification number)<br />

ER-5443<br />

9. SEE APPENDIX IF CHECKED X