IN WESTERN AUSTRALIA - Department of Mines and Petroleum

IN WESTERN AUSTRALIA - Department of Mines and Petroleum

IN WESTERN AUSTRALIA - Department of Mines and Petroleum

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

36<br />

PWA April Edition - Coal Seam Methane<br />

Other considerations<br />

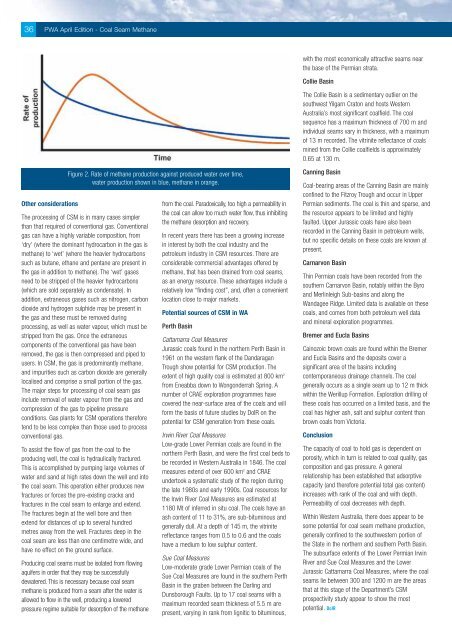

Figure 2. Rate <strong>of</strong> methane production against produced water over time,<br />

water production shown in blue, methane in orange.<br />

The processing <strong>of</strong> CSM is in many cases simpler<br />

than that required <strong>of</strong> conventional gas. Conventional<br />

gas can have a highly variable composition, from<br />

‘dry’ (where the dominant hydrocarbon in the gas is<br />

methane) to ‘wet’ (where the heavier hydrocarbons<br />

such as butane, ethane <strong>and</strong> pentane are present in<br />

the gas in addition to methane). The ‘wet’ gases<br />

need to be stripped <strong>of</strong> the heavier hydrocarbons<br />

(which are sold separately as condensate). In<br />

addition, extraneous gases such as nitrogen, carbon<br />

dioxide <strong>and</strong> hydrogen sulphide may be present in<br />

the gas <strong>and</strong> these must be removed during<br />

processing, as well as water vapour, which must be<br />

stripped from the gas. Once the extraneous<br />

components <strong>of</strong> the conventional gas have been<br />

removed, the gas is then compressed <strong>and</strong> piped to<br />

users. In CSM, the gas is predominantly methane,<br />

<strong>and</strong> impurities such as carbon dioxide are generally<br />

localised <strong>and</strong> comprise a small portion <strong>of</strong> the gas.<br />

The major steps for processing <strong>of</strong> coal seam gas<br />

include removal <strong>of</strong> water vapour from the gas <strong>and</strong><br />

compression <strong>of</strong> the gas to pipeline pressure<br />

conditions. Gas plants for CSM operations therefore<br />

tend to be less complex than those used to process<br />

conventional gas.<br />

To assist the flow <strong>of</strong> gas from the coal to the<br />

producing well, the coal is hydraulically fractured.<br />

This is accomplished by pumping large volumes <strong>of</strong><br />

water <strong>and</strong> s<strong>and</strong> at high rates down the well <strong>and</strong> into<br />

the coal seam. This operation either produces new<br />

fractures or forces the pre-existing cracks <strong>and</strong><br />

fractures in the coal seam to enlarge <strong>and</strong> extend.<br />

The fractures begin at the well bore <strong>and</strong> then<br />

extend for distances <strong>of</strong> up to several hundred<br />

metres away from the well. Fractures deep in the<br />

coal seam are less than one centimetre wide, <strong>and</strong><br />

have no effect on the ground surface.<br />

Producing coal seams must be isolated from flowing<br />

aquifers in order that they may be successfully<br />

dewatered. This is necessary because coal seam<br />

methane is produced from a seam after the water is<br />

allowed to flow in the well, producing a lowered<br />

pressure regime suitable for desorption <strong>of</strong> the methane<br />

from the coal. Paradoxically, too high a permeability in<br />

the coal can allow too much water flow, thus inhibiting<br />

the methane desorption <strong>and</strong> recovery.<br />

In recent years there has been a growing increase<br />

in interest by both the coal industry <strong>and</strong> the<br />

petroleum industry in CSM resources. There are<br />

considerable commercial advantages <strong>of</strong>fered by<br />

methane, that has been drained from coal seams,<br />

as an energy resource. These advantages include a<br />

relatively low “finding cost”, <strong>and</strong>, <strong>of</strong>ten a convenient<br />

location close to major markets.<br />

Potential sources <strong>of</strong> CSM in WA<br />

Perth Basin<br />

Cattamarra Coal Measures<br />

Jurassic coals found in the northern Perth Basin in<br />

1961 on the western flank <strong>of</strong> the D<strong>and</strong>aragan<br />

Trough show potential for CSM production. The<br />

extent <strong>of</strong> high quality coal is estimated at 800 km 2<br />

from Eneabba down to Wongonderrah Spring. A<br />

number <strong>of</strong> CRAE exploration programmes have<br />

covered the near-surface area <strong>of</strong> the coals <strong>and</strong> will<br />

form the basis <strong>of</strong> future studies by DoIR on the<br />

potential for CSM generation from these coals.<br />

Irwin River Coal Measures<br />

Low-grade Lower Permian coals are found in the<br />

northern Perth Basin, <strong>and</strong> were the first coal beds to<br />

be recorded in Western Australia in 1846. The coal<br />

measures extend <strong>of</strong> over 600 km 2 <strong>and</strong> CRAE<br />

undertook a systematic study <strong>of</strong> the region during<br />

the late 1980s <strong>and</strong> early 1990s. Coal resources for<br />

the Irwin River Coal Measures are estimated at<br />

1180 Mt <strong>of</strong> inferred in situ coal. The coals have an<br />

ash content <strong>of</strong> 11 to 31%, are sub-bituminous <strong>and</strong><br />

generally dull. At a depth <strong>of</strong> 145 m, the vitrinite<br />

reflectance ranges from 0.5 to 0.6 <strong>and</strong> the coals<br />

have a medium to low sulphur content.<br />

Sue Coal Measures<br />

Low-moderate grade Lower Permian coals <strong>of</strong> the<br />

Sue Coal Measures are found in the southern Perth<br />

Basin in the graben between the Darling <strong>and</strong><br />

Dunsborough Faults. Up to 17 coal seams with a<br />

maximum recorded seam thickness <strong>of</strong> 5.5 m are<br />

present, varying in rank from lignitic to bituminous,<br />

with the most economically attractive seams near<br />

the base <strong>of</strong> the Permian strata.<br />

Collie Basin<br />

The Collie Basin is a sedimentary outlier on the<br />

southwest Yilgarn Craton <strong>and</strong> hosts Western<br />

Australia’s most significant coalfield. The coal<br />

sequence has a maximum thickness <strong>of</strong> 700 m <strong>and</strong><br />

individual seams vary in thickness, with a maximum<br />

<strong>of</strong> 13 m recorded. The vitrinite reflectance <strong>of</strong> coals<br />

mined from the Collie coalfields is approximately<br />

0.65 at 130 m.<br />

Canning Basin<br />

Coal-bearing areas <strong>of</strong> the Canning Basin are mainly<br />

confined to the Fitzroy Trough <strong>and</strong> occur in Upper<br />

Permian sediments. The coal is thin <strong>and</strong> sparse, <strong>and</strong><br />

the resource appears to be limited <strong>and</strong> highly<br />

faulted. Upper Jurassic coals have also been<br />

recorded in the Canning Basin in petroleum wells,<br />

but no specific details on these coals are known at<br />

present.<br />

Carnarvon Basin<br />

Thin Permian coals have been recorded from the<br />

southern Carnarvon Basin, notably within the Byro<br />

<strong>and</strong> Merlinleigh Sub-basins <strong>and</strong> along the<br />

W<strong>and</strong>agee Ridge. Limited data is available on these<br />

coals, <strong>and</strong> comes from both petroleum well data<br />

<strong>and</strong> mineral exploration programmes.<br />

Bremer <strong>and</strong> Eucla Basins<br />

Cainozoic brown coals are found within the Bremer<br />

<strong>and</strong> Eucla Basins <strong>and</strong> the deposits cover a<br />

significant area <strong>of</strong> the basins including<br />

contemporaneous drainage channels. The coal<br />

generally occurs as a single seam up to 12 m thick<br />

within the Werillup Formation. Exploration drilling <strong>of</strong><br />

these coals has occurred on a limited basis, <strong>and</strong> the<br />

coal has higher ash, salt <strong>and</strong> sulphur content than<br />

brown coals from Victoria.<br />

Conclusion<br />

The capacity <strong>of</strong> coal to hold gas is dependent on<br />

porosity, which in turn is related to coal quality, gas<br />

composition <strong>and</strong> gas pressure. A general<br />

relationship has been established that adsorptive<br />

capacity (<strong>and</strong> therefore potential total gas content)<br />

increases with rank <strong>of</strong> the coal <strong>and</strong> with depth.<br />

Permeability <strong>of</strong> coal decreases with depth.<br />

Within Western Australia, there does appear to be<br />

some potential for coal seam methane production,<br />

generally confined to the southwestern portion <strong>of</strong><br />

the State in the northern <strong>and</strong> southern Perth Basin.<br />

The subsurface extents <strong>of</strong> the Lower Permian Irwin<br />

River <strong>and</strong> Sue Coal Measures <strong>and</strong> the Lower<br />

Jurassic Cattamarra Coal Measures, where the coal<br />

seams lie between 300 <strong>and</strong> 1200 m are the areas<br />

that at this stage <strong>of</strong> the <strong>Department</strong>’s CSM<br />

prospectivity study appear to show the most<br />

potential. DoIR