Cameron Subsea Wellheads Brochure - cedip

Cameron Subsea Wellheads Brochure - cedip

Cameron Subsea Wellheads Brochure - cedip

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRESSURE<br />

TM<br />

Certified System Components<br />

<strong>Subsea</strong> <strong>Wellheads</strong><br />

For deep and shallow water applications

2<br />

Pre-engineered subsea wellheads from <strong>Cameron</strong>: fewer trips, lower costs<br />

and better sealing in shallow or deep water drilling operations.<br />

For more than seventy-five<br />

years, the leader<br />

<strong>Cameron</strong>’s experience in pressure control<br />

can be traced back to 1922. The introduc-<br />

tion of the first BOP that became an indus-<br />

try standard began an unequaled history<br />

of innovation. Type “A” casing hanger,<br />

All-Welded Body Ball Valve, first subsea<br />

wellhead completion, the legendary U BOP,<br />

first hydraulic production controls system,<br />

first guidelineless drilling system, first free-<br />

standing riser system — these are just a<br />

few familiar milestones along <strong>Cameron</strong>’s<br />

path of leadership.<br />

This leadership continues today<br />

with such innovations as the SpoolTree <br />

Christmas tree and the MOSAIC (Modular<br />

<strong>Subsea</strong> and Integrated Completions)<br />

Production System.<br />

More advances are on the horizon.<br />

As the industry pushes into new frontiers,<br />

we’ll be there, as always, with the<br />

technology to do it right.<br />

1962: The industry’s first subsea<br />

wellhead completion is a <strong>Cameron</strong><br />

Christmas tree in the Gulf of Mexico.<br />

The <strong>Cameron</strong> family of STM and STC <br />

subsea wellheads delivers the economic<br />

benefits of modularity and the performance<br />

benefits of advanced design.<br />

These benefits mean faster delivery,<br />

easier installation and reduced costs in<br />

nearly every subsea drilling application.<br />

And that is especially important for<br />

today’s deepwater challenges.<br />

With modularity at the component<br />

level, there are no performance tradeoffs.<br />

<strong>Cameron</strong> subsea wellheads contain<br />

technology found nowhere else and<br />

reflect the depth of our pressure control<br />

experience. The STM wellhead, for<br />

example, demonstrates our no-compro-<br />

mise design approach with parallel bore<br />

metal seals, better connection options<br />

with BOPs and Christmas trees and<br />

interchangeable components.<br />

A selection of running tools (including<br />

the unique CHSART tool - see page 7)<br />

and ancillary equipment is also part of<br />

the highest performing subsea wellhead<br />

systems in the world’s offshore oilfields.<br />

Single Trip Metal Seal <strong>Subsea</strong><br />

Wellhead System<br />

The STM wellhead reduces drilling costs<br />

by eliminating unnecessary trips while<br />

providing the most advanced pressure<br />

control technology, at any depth, in any<br />

<strong>Cameron</strong>’s most advanced, field proven pressure-control technology is<br />

pre-engineered into the STM wellhead.<br />

Three connection<br />

options (mandrel,<br />

hub and DWHC)<br />

Angled shoulder<br />

prevents debris<br />

accumulation<br />

Interchangeable<br />

parallel bore metal<br />

seal assemblies on<br />

13-3/8”, 10-3/4"<br />

(or 9-5/8”) and<br />

7-5/8” (or 7")<br />

casing hangers<br />

SD016697<br />

High pressure<br />

18-3/4” housing<br />

Optional passively<br />

activated, preloaded<br />

lockdown<br />

High strength<br />

landing shoulder<br />

on 18-3/4” housing<br />

Optional 16” casing<br />

hanger available for<br />

six-string programs<br />

(see page 5)

environment. Central to STM wellhead<br />

performance is <strong>Cameron</strong>’s parallel bore<br />

metal (PBM) seal technology, completely<br />

different from competing tapered bore<br />

designs and far superior.<br />

The STM wellhead is perfect for most<br />

subsea drilling and production applications<br />

with working pressures up to<br />

15,000 psi WP, on single wells, multiwell<br />

templates or TLP operations.<br />

Versions of the STM are available for<br />

shallow or deep water, and it is adaptable<br />

to casing programs with five or six<br />

strings. Only four tools are required to<br />

run a five-string STM system.<br />

Three BOP and Christmas tree<br />

connection profiles. Depending on<br />

your requirements, choose from a hub,<br />

mandrel or <strong>Cameron</strong>’s new deepwater,<br />

high-capacity (DWHC) profile on the<br />

high-pressure 18-3/4" housing. <strong>Cameron</strong><br />

is offering the DWHC profile to the petroleum<br />

industry without charge, to pro-<br />

Hub Mandrel DWHC<br />

mote standardization among deepwater<br />

producers and equipment suppliers.<br />

High-pressure 18-3/4” housing. Rated<br />

up to 15,000 psi WP, <strong>Cameron</strong>’s highpressure<br />

housing provides a parallel<br />

bore sealing surface design for the PBM<br />

casing hanger seals. The high-pressure<br />

housing will accommodate an optional<br />

16" casing hanger and seal assembly.<br />

Because the receptacle for the hanger<br />

and seal is welded to the bottom of the<br />

housing or anywhere in the 20" string,<br />

SD016797<br />

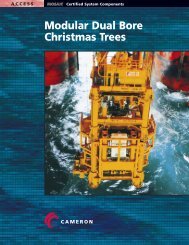

Modular <strong>Subsea</strong> And Integrated Completion systems:<br />

The MOSAIC concept<br />

MOSAIC is the result of a design philoso-<br />

phy that eliminates the usual tradeoffs you<br />

expect with a pre-engineered, modular<br />

system. With MOSAIC systems, you gain<br />

simplified installation procedures, reduced<br />

personnel training<br />

and faster delivery.<br />

Unlike ordinary systems, you don’t have<br />

to give up flexibility, expandability and<br />

desirable product features and benefits.<br />

The ordinary approach to modularity<br />

is fixed assemblies run progressively to<br />

large structures, which are not appropriate<br />

for many applications. MOSAIC systems<br />

it does not add to wellhead height. The<br />

receptacle does not restrict a 17-1/2" bit<br />

or full-bore running equipment.<br />

This housing has a high-strength<br />

landing shoulder rated to 7 million lbs.<br />

The simple, passive design allows the<br />

13-3/8" casing hanger to be reciprocated<br />

inside the 18-3/4" housing without the<br />

possibility of inadvertent setting. It is<br />

fully rated for H 2S service.<br />

The STM design allows all BOP<br />

tests to be performed with the wear<br />

bushings in place, saving a round trip<br />

for each test.<br />

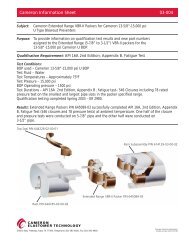

STM wellhead undergoes seal development<br />

testing at <strong>Cameron</strong>’s new, state-of-the-art<br />

Research Center in Houston. This 55,000 sq ft<br />

resource allows us to develop and test product<br />

improvements more quickly. In the photo at<br />

right, the STM is shown in one of our two<br />

25 ft deep, underwater simulation tanks.<br />

are modular at the component level,<br />

standardized to work together in many<br />

combinations. The result is a cost-effective<br />

system that can be adapted to virtually any<br />

subsea job. The MOSAIC system is more<br />

easily expanded as<br />

field development<br />

needs evolve, and its components contain<br />

the technology that provides the perfor-<br />

mance you need.<br />

<strong>Cameron</strong>’s subsea wellheads are<br />

an integral part of the MOSAIC system.<br />

They’re the perfect fit for today’s subsea<br />

economics.<br />

3

4<br />

Advanced lockdown and sealing technology<br />

A closer look at <strong>Cameron</strong> engineering<br />

reveals advanced but practical technology<br />

that works in the real world. A<br />

remarkable history of pressure-control<br />

experience has been pre-engineered into<br />

our subsea wellheads. You can see our<br />

no-compromise design in these features:<br />

Three STM wellhead-to-conductor<br />

housing lockdown options<br />

Passively activated, preloaded<br />

lockdown. This locks the high-pressure,<br />

18-3/4" housing to the 30" conductor<br />

with twelve vertical pre-load segments,<br />

in a collet finger design. This pre-loaded<br />

lockdown offers superior fatigue resistance.<br />

When locked down, bending and<br />

axial loads are transferred from the BOP<br />

stack to the conductor. Fatigue loading<br />

of the 20" casing is eliminated.<br />

Lockdown is achieved without a separate<br />

trip, and the mechanism can be<br />

fully recoverable and reusable. Eight,<br />

two-inch diameter bypass holes provide<br />

for cement returns.<br />

Passively activated,<br />

standard lockdown.<br />

An outwardly biased,<br />

split-metal ring is held<br />

in position with a<br />

keeper ring. The split<br />

ring is compressed by<br />

the inside diameter of<br />

the 30” conductor<br />

housing until it is<br />

landed in a retainer<br />

groove.<br />

SD016698<br />

High-capacity lockdown. <strong>Cameron</strong>’s<br />

new high-strength, pre-loaded lockdown<br />

is engineered for high-temperature<br />

applications where thermal expansion<br />

is a critical factor. This hydraulically set<br />

lockdown offers outstanding bending<br />

resistance. It is also ideal for deepwater<br />

applications.<br />

Unlocked Locked<br />

SD016702 SD016703<br />

Passively activated, preloaded lockdown<br />

<strong>Cameron</strong>’s proprietary sealing<br />

technology<br />

STM Parallel Bore Metal seal.<br />

This seal is for casing hangers in the<br />

18-3/4" high-pressure housing and is<br />

interchangeable on 13-3/8", 10-3/4”<br />

(or 9-5/8") and 7-5/8" (or 7") hangers.<br />

It is radially engaged, bi-directional,<br />

and provides constant contact pressure<br />

on inner and outer sealing surfaces.<br />

Because the PBM seal is designed for<br />

a parallel-bore sealing surface, it<br />

provides equal seal protection from<br />

pressures above or below. The inability<br />

to effectively seal pressures from below<br />

is a weakness of tapered-bowl seal<br />

designs offered by some wellhead<br />

manufacturers.<br />

The <strong>Cameron</strong> parallel bore design<br />

allows for slight vertical movement of<br />

the seal without affecting seal integrity.<br />

During lab testing, the seal assembly was<br />

moved as much as 1/4" while maintaining<br />

full test pressure of 15,000 psi. PBM<br />

seals are rated for continuous operation<br />

in temperatures of up to 350˚F (177˚C),<br />

with excursions to 400˚F (204˚C), and<br />

can be used in H 2S environments.<br />

The PBM seal assembly and highpressure<br />

housing design provides for<br />

two additional contingency seals: an<br />

optional elastomer seal and a metal seal<br />

in a recessed bore. The metal seals on<br />

the OD and ID always retain pressure<br />

before the elastomer seal. The elastomer<br />

seal is a true secondary seal.<br />

PBM seals are set hydraulically with<br />

<strong>Cameron</strong>’s CHSART running tool,<br />

which runs the casing hanger and seal<br />

assembly in one trip.<br />

STC Metal-End Cap seal. Field proven<br />

in hundreds of wells, the MEC seal<br />

assembly is used in the 10,000 psi STC<br />

wellhead. Rated for temperatures up<br />

to 250˚F (121˚C), the proprietary<br />

CAMLAST elastomer seal element is<br />

resistant to H 2S, CO 2, chlorides, diesel<br />

fluid and oil or water-based amine<br />

corrosion inhibitors.<br />

Stainless steel caps on the upper and<br />

lower surfaces of the elastomer prevent<br />

extrusion, limit the elastomer’s exposure<br />

to corrosive wellbore fluids and prevent<br />

seal roll-off during installation. The<br />

Metal-End Cap seal will often work<br />

when ordinary seals won’t because the<br />

seal is highly tolerant of sealing surface<br />

damage. The seal is radially energized<br />

and requires less energy to set than<br />

ordinary seals. Well or test pressure<br />

compresses the elastomer, which adds<br />

to seal quality.<br />

PBM Seal in<br />

running position<br />

PBM Seal in<br />

energized position<br />

Parallel<br />

Bore<br />

Metal<br />

Seals<br />

Optional<br />

CAMLAST<br />

Insert<br />

Seal<br />

Recessed<br />

Contingency<br />

Seal Bore<br />

SD016230

DETAIL A<br />

18-3/4" Housing<br />

with16" Receptacle<br />

Attached<br />

16" Seal<br />

Assembly<br />

17-13/16" I.D.<br />

16" Hanger<br />

17-7/8" I.D.<br />

Seal Area<br />

18" I.D.<br />

16" Receptacle<br />

17-9/16" I.D.<br />

SD016231<br />

DETAIL A<br />

16" Hanger and<br />

Seal Assembly Installed<br />

in Receptacle<br />

Optional 16-inch casing hanger<br />

The 16" hanger and seal assembly are<br />

available for both the STM and STC<br />

wellheads in six-string casing programs.<br />

The receptacle can be welded to the bottom<br />

of the 18-3/4" high-pressure housing<br />

extension or anywhere in the 20" string<br />

so height is not added to the wellhead.<br />

The receptacle contains a passive load<br />

shoulder with a 17-9/16" minimum ID.<br />

The shoulder is rated to 1.2 million lbs.<br />

Full-bore running tools or a 17-1/2" bit<br />

can be used without restriction.<br />

The 16" boll weevil style hanger and<br />

seal assembly are installed and tested in<br />

a single trip without having to pull the<br />

bore protector in the 18-3/4" housing.<br />

A CAMLAST elastomer seal in the<br />

assembly is energized to seal in the bore<br />

of the receptacle. The seal location is<br />

protected from drill string damage.<br />

The totally weight-set and compact STC<br />

wellhead is a popular choice for lower<br />

pressure wells to 10,000 psi WP. Attractive<br />

pricing and rig-time savings during installa-<br />

tion make it the most cost-effective well-<br />

head in its operating range.<br />

The STC wellhead shares some of the<br />

same benefits as <strong>Cameron</strong>’s STM wellhead.<br />

It has a compact design, casing hangers<br />

and seal assemblies that can be run in a<br />

single trip and interchangeable parallel<br />

bore elastomeric seal assemblies. It is sup-<br />

plied with the “passive” lockdown, which<br />

is standard on the STM wellhead. The 18-<br />

3/4" high-pressure housing is available<br />

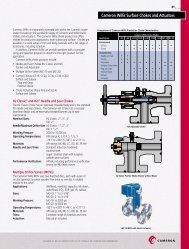

High-pressure<br />

18-3/4” housing<br />

Single-trip<br />

casing hanger<br />

and seal<br />

assemblies<br />

Interchangeable<br />

seal assemblies<br />

on each casing<br />

hanger<br />

Passively activated,<br />

standard lockdown<br />

Single Trip Compact <strong>Subsea</strong> Wellhead System<br />

with hub or mandrel BOP and Christmas<br />

tree connection profiles.<br />

The STC wellhead uses <strong>Cameron</strong>’s<br />

proprietary Metal-End Cap seals with CAM-<br />

LAST elastomer. When setting the seals in<br />

the STC wellhead system, the seal cannot<br />

be completed unless the seal assembly is<br />

locked in place correctly, eliminating the<br />

possibility of a false test. Like the STM,<br />

only four tools are required to run a five-<br />

string STC system.<br />

An optional 16" hanger can be<br />

used in six-string casing programs. The<br />

16" hanger and seal assembly are run<br />

in one trip.<br />

SD016696<br />

Hub or<br />

mandrel<br />

connection<br />

profiles<br />

<strong>Cameron</strong> weightset,<br />

Metal-End Cap<br />

elastomer seals<br />

Optional 16” casing<br />

hanger available for<br />

six-string programs<br />

5

6<br />

Guidebases and running tools<br />

The benefits of modularity are preengineered<br />

into <strong>Cameron</strong>’s remotely<br />

retrievable/reinstallable guidebase<br />

(RRGB). Guideline or guidelineless<br />

versions of the RRGB are available.<br />

Guide posts are permitted to stroke<br />

approximately six inches to allow BOP<br />

orientation prior to loading the post.<br />

This reduces the risk of damage when<br />

landing the BOP stack. Multiple guidebases<br />

can be combined into a single,<br />

pre-tested template. Any number of<br />

wells can be accommodated through<br />

multiples of the guidebases. Multi-well<br />

units allow wellbores to be spaced as<br />

closely as 7-1/2 ft on center.<br />

SD016699<br />

The STM spring-loaded locking mechanism<br />

automatically locks the 30” conductor housing<br />

to the guidebase.<br />

<strong>Cameron</strong> STM/STC Running Tool<br />

Package and ancillary equipment<br />

The <strong>Cameron</strong> STM and STC Running<br />

Tool Package includes the tools required<br />

to run a five-string STM or STC system.<br />

All these tools are simple to make up<br />

and all release with right-hand rotation.<br />

• Retrievable/reinstallable guidebase<br />

running tool;<br />

• 30" housing running tool;<br />

• 18-3/4" housing and BOP test tool;<br />

• Casing Hanger Seal Assembly Running<br />

Tool (CHSART) to install casing hangers<br />

and seals and perform seal tests;<br />

• Wear bushing running/retrieving tool.<br />

CHSART (Casing Hanger Seal<br />

Assembly Running Tool)<br />

<strong>Cameron</strong>’s advanced wellhead technology<br />

includes running tools that contribute<br />

to system cost savings and ease<br />

of use. The CHSART tool is a perfect<br />

example. In the STM system, it allows<br />

installation of casing hangers and PBM<br />

seal assemblies in one trip. The tool is<br />

then used to hydraulically set the casing<br />

hanger seal assembly in a unique way.<br />

Unlike ordinary systems, which set the<br />

seals by pressurizing the BOP stack to<br />

pump the seal down, the CHSART tool<br />

sets the seal assembly by pressurizing<br />

down the drill pipe. This allows the seal<br />

to be set before stack pressure is<br />

applied. After the seal is fully set and in<br />

position, the seal is tested using the<br />

CHSART tool with stack pressure.<br />

SD016798<br />

Ancillary equipment<br />

<strong>Cameron</strong>’s STM/STC Running Tool Packages<br />

are normally all that’s required to run fivestring<br />

systems under most conditions. In addition,<br />

<strong>Cameron</strong> offers a complete line of<br />

special-purpose tools:<br />

• Jetting tool<br />

• Boll weevil test tool with redundant seals<br />

• Weight-set BOP tester<br />

• One-trip Seal Assembly Retrieval Tool (SART)<br />

• Temporary abandonment (TA) caps<br />

• Emergency drill pipe hang-off tool<br />

• Full-bore casing hanger running tools<br />

• Hydraulic 30" running and tieback tool<br />

• Casing hanger cleanout tool<br />

• 30"/36" housing drill-ahead tool<br />

• 18-3/4" housing retrieval tool<br />

• Shallow water flow shutoff systems<br />

• Tieback system<br />

• CAMSMART downhole measurement tool<br />

SD016799<br />

Casing hanger seal assembly is set by pressuring down the drill pipe,<br />

which allows the seal to be set before stack pressure is applied.<br />

SD016800

SD10457-99<br />

30” STM Conductor Housing<br />

Running Tool<br />

The 30” conductor housing running tool<br />

is cam-actuated and has a non-rising<br />

stem. Only 6-1/2 rotations fully make up<br />

and release the tool.<br />

SD10480-99<br />

Wear Bushing Running and<br />

Retrieval Tool<br />

This is the only tool needed to set or<br />

retrieve all wear bushings in a five-string<br />

system including the bore protector.<br />

Running Tool<br />

for 18-3/4" Housing<br />

SD016701<br />

After running the high-pressure<br />

housing, this tool is used to test<br />

the BOP. A position indicator rod<br />

provides visual verification of<br />

tool lock/unlock.<br />

SD016705<br />

CHSART Multipurpose<br />

Running Tool<br />

In a single trip, the Casing Hanger Seal Assembly<br />

Running Tool runs each casing hanger and seal<br />

assembly and hydraulically sets the seal.<br />

7

Western Hemisphere<br />

<strong>Cameron</strong><br />

PO Box 1212<br />

Houston Texas 77251-1212<br />

Tel 713 939 2211<br />

Fax 713 939 2620<br />

www.camerondiv.com<br />

Eastern Hemisphere<br />

Cooper <strong>Cameron</strong> (U.K.) Ltd.<br />

5 Mondial Way<br />

Harlington<br />

Hayes UB3 5AR<br />

Tel 44 181 9901800<br />

Fax 44 181 9901888<br />

www.camerondiv.com<br />

Asia Pacific/Middle East<br />

Cooper <strong>Cameron</strong> (Singapore) Pte. Ltd.<br />

No. 2 Gul Circle, Jurong Industrial Est<br />

Locked Bag Service No. 3<br />

Jurong Town Post Office<br />

Singapore 629560<br />

Republic Of Singapore<br />

Tel 65 8613355<br />

Fax 65 8616197<br />

www.camerondiv.com<br />

MOSAIC, SpoolTree, STM, STC, CAMLAST and CAMSMART are trademarks of the Cooper <strong>Cameron</strong> Corporation, <strong>Cameron</strong> Division.<br />

© Cooper <strong>Cameron</strong> Corporation, <strong>Cameron</strong> Division, Printed in USA, 7/98, HG/5M, WR6568/TC1266