Fanuc Wiring Diagrams - 1.8MB - Flint Machine Tools, Inc.

Fanuc Wiring Diagrams - 1.8MB - Flint Machine Tools, Inc.

Fanuc Wiring Diagrams - 1.8MB - Flint Machine Tools, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

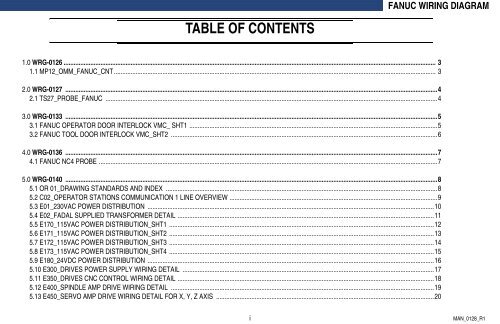

TABLE OF CONTENTS<br />

FANUC WIRING DIAGRAM<br />

1.0 WRG-0126 .............................................................................................................................................................................................................................. 3<br />

1.1 MP12_OMM_FANUC_CNT................................................................................................................................................................................................ 3<br />

2.0 WRG-0127 ..............................................................................................................................................................................................................................4<br />

2.1 TS27_PROBE_FANUC ......................................................................................................................................................................................................4<br />

3.0 WRG-0133 ..............................................................................................................................................................................................................................5<br />

3.1 FANUC OPERATOR DOOR INTERLOCK VMC_ SHT1 ....................................................................................................................................................5<br />

3.2 FANUC TOOL DOOR INTERLOCK VMC_SHT2 ...............................................................................................................................................................6<br />

4.0 WRG-0136 ..............................................................................................................................................................................................................................7<br />

4.1 FANUC NC4 PROBE ..........................................................................................................................................................................................................7<br />

5.0 WRG-0140 ..............................................................................................................................................................................................................................8<br />

5.1 OR 01_DRAWING STANDARDS AND INDEX ..................................................................................................................................................................8<br />

5.2 C02_OPERATOR STATIONS COMMUNICATION 1 LINE OVERVIEW ............................................................................................................................9<br />

5.3 E01_230VAC POWER DISTRIBUTION ...........................................................................................................................................................................10<br />

5.4 E02_FADAL SUPPLIED TRANSFORMER DETAIL .........................................................................................................................................................11<br />

5.5 E170_115VAC POWER DISTRIBUTION_SHT1 ..............................................................................................................................................................12<br />

5.6 E171_115VAC POWER DISTRIBUTION_SHT2 ..............................................................................................................................................................13<br />

5.7 E172_115VAC POWER DISTRIBUTION_SHT3 ..............................................................................................................................................................14<br />

5.8 E173_115VAC POWER DISTRIBUTION_SHT4 ..............................................................................................................................................................15<br />

5.9 E180_24VDC POWER DISTRIBUTION ...........................................................................................................................................................................16<br />

5.10 E300_DRIVES POWER SUPPLY WIRING DETAIL ......................................................................................................................................................17<br />

5.11 E350_DRIVES CNC CONTROL WIRING DETAIL .........................................................................................................................................................18<br />

5.12 E400_SPINDLE AMP DRIVE WIRING DETAIL .............................................................................................................................................................19<br />

5.13 E450_SERVO AMP DRIVE WIRING DETAIL FOR X, Y, Z AXIS ..................................................................................................................................20<br />

i MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.14 E600_OPTIONAL SERVO AMP DRIVE WIRING DETAIL FOR A & B AXIS MOTORS ..............................................................................................21<br />

5.15 E801_INPUT CARD FOR C001 BOARD_SHT1 ..........................................................................................................................................................22<br />

5.16 E802_INPUT CARD FOR C001 BOARD_SHT2 ..........................................................................................................................................................23<br />

5.17 E803_INPUT CARD FOR C001 BOARD_SHT3 ..........................................................................................................................................................24<br />

5.18 E804_C001 BOARD JUMPER SETUP DETAIL ...........................................................................................................................................................25<br />

5.19 E805_IMPUT CARD FOR C003 BOARD_SHT1 ..........................................................................................................................................................26<br />

5.20 E806_INPUT CARD FOR C003 BOARD_SHT2 ..........................................................................................................................................................27<br />

5.21 E807_INPUT CARD FOR C003 BOARD_SHT3 ..........................................................................................................................................................28<br />

5.22 E808_C003 BOARD JUMPER SETUP DETAIL ...........................................................................................................................................................29<br />

5.23 E809_C004 BOARD JUMPER SETUP DETAIL_SHT1 ...............................................................................................................................................30<br />

5.24 E810_C004 BOARD JUMPER SETUP DETAIL_SHT2 ...............................................................................................................................................31<br />

5.25 E850_OUTPUT CARD FOR C001 BOARD_SHT1 ......................................................................................................................................................32<br />

5.26 E851_OUTPUT CARD FOR C001 BOARD_SHT2 ......................................................................................................................................................33<br />

5.27 E852_OUTPUT CARD FOR C003 BOARD_SHT1 ......................................................................................................................................................34<br />

5.28 E853_OUTPUT CARD FOR C003 BOARD_SHT2 ......................................................................................................................................................35<br />

5.29 E854_OUTPUT CARD FOR C004-1 BOARD_SHT1 ...................................................................................................................................................36<br />

5.30 E855_OUTPUT CARD FOR C004-1 BOARD ..............................................................................................................................................................37<br />

5.31 E856_OUTPUT CARD FOR C004-2 BOARD_SHT1 ...................................................................................................................................................38<br />

5.32 E857_OUTPUT CARD FOR C004-2 BOARD_SHT2 ...................................................................................................................................................39<br />

SEPTEMBER 2005 ii

FANUC WIRING DIAGRAM<br />

1.0 WRG-0126<br />

2.0 WRG-0127<br />

3.0 WRG-0133<br />

4.0 WRG-0136<br />

5.0 WRG-0140<br />

FANUC WIRING DIAGRAM<br />

1 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

1.0 WRG-0126_A<br />

NOTE:<br />

1. SET SWITCH SW2 (#3) IN MI12 INTERFACE UNIT<br />

TO THE AUTO START POSITION<br />

1.1 MP12_OMM_FANUC_CNT<br />

SEPTEMBER 2005 2 of 38

2.0 WRG-0127_A<br />

2.1 TS27_PROBE_FANUC<br />

FANUC WIRING DIAGRAM<br />

3 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

3.0 WRG-0133_D<br />

1 2<br />

RED<br />

BLACK<br />

BELDEN 8451 OR EQUIV. 2-CONDUCTOR<br />

Contacts shown in door closed<br />

state.<br />

Euchner<br />

TP3-4121A024PG<br />

OUTPUT C004-2<br />

BOARD<br />

Y10.1 35<br />

856SOL2<br />

<strong>Fanuc</strong> side:<br />

4-Pin Plug, Amp 350779-1 (WIR-1298)<br />

Sockets, Amp 350689-1 (WIR-1296) qty=4<br />

Interlock side:<br />

4-Pin Female Connector, Amp 350780-1 (WIR-1297)<br />

Pins, Amp 350690-1 (WIR-1299) qty=4<br />

180F52<br />

180J54<br />

180F52<br />

+24V<br />

RED<br />

BLK<br />

1<br />

2<br />

YELLOW<br />

YELLOW<br />

BRN<br />

802DV2<br />

GREEN<br />

INTERFACE<br />

BOARD<br />

35<br />

BROWN<br />

FRONT DOOR N.C.<br />

WHITE<br />

<strong>Fanuc</strong> side:<br />

6 Pos Male Connector, Molex 03-09-1064 (WIR-0052)<br />

Sockets, Molex 02-09-1204 18-22 awg (WIR-0056) qty=6<br />

Interlock side:<br />

6 Pos Female Connector, Molex 03-09-2062 (WIR-0051)<br />

Pins, Molex 02-09-2118 18-22 awg (WIR-0544) qty=6<br />

802DV1<br />

WHITE<br />

GREEN<br />

FRONT DOOR N.O.<br />

RED<br />

BLACK<br />

GRN<br />

WHT<br />

3<br />

4<br />

DOOR UNLOCK OUTPUT E856<br />

2A<br />

4<br />

5<br />

6<br />

3<br />

WHITE/BLK 20 AWG<br />

RED/BLK 20 AWG<br />

RED<br />

BLACK<br />

WHITE<br />

GREEN<br />

3.1 FANUC OPERATOR DOOR INTERLOCK VMC_ SHT1<br />

Reduced Feeds and Speeds Limit:<br />

Spindle rpm and axis feed rates are limited<br />

when this input is open.<br />

<strong>Fanuc</strong> DATC Arm - E855<br />

OUTPUT C004-1<br />

BOARD<br />

INTERFACE<br />

BOARD<br />

C004-1<br />

Y9.2 4<br />

855E19<br />

4<br />

855FU3<br />

Y9.3<br />

DOOR UNLOCK<br />

SEPTEMBER 2005 4 of 38<br />

5<br />

GRN 802E11<br />

WHT 802E15<br />

BELDEN 8451 OR EQUIV. 2-CONDUCTOR<br />

RED/BLK 20 AWG<br />

PINK 20 AWG<br />

855E23<br />

5<br />

856SOL2<br />

180K54<br />

855FU4<br />

FRONT DOOR INPUTS E802<br />

INTERFACE<br />

BOARD<br />

25<br />

26<br />

855J19<br />

855J23<br />

INPUT C001 BD<br />

SOURCING INPUTS<br />

25<br />

X5.0<br />

26<br />

X5.1<br />

A1<br />

RED/BLK 20 AWG<br />

RED/BLK 20 AWG<br />

RED/BLK 20 AWG<br />

A2<br />

+24V<br />

A1<br />

Sentrol GE<br />

INT-22.5R1-24<br />

A2<br />

S23<br />

S13<br />

13<br />

14<br />

WHITE/BLK 20 AWG<br />

S24<br />

S14<br />

855M3<br />

855M19A<br />

A1 A2<br />

JUMPER<br />

855M4<br />

FRONT DOOR N.C.<br />

FRONT DOOR N.O.<br />

+24V<br />

23<br />

24<br />

S33<br />

S35<br />

33<br />

34<br />

S22 S34<br />

850CR2<br />

1 2<br />

SAFETY RESET<br />

J1<br />

SPINDLE ROTATING<br />

+24V<br />

DATC/ATC FWD<br />

COM<br />

Standstill monitor:<br />

1. Prevent opening of door while spindle is moving.<br />

2. Second monitor could be set to stop machine if<br />

maximum rpm-while-doors-open is exceeded.<br />

S13 + output<br />

S23 - output<br />

S34 Falling edge Reset<br />

S35 Rising edge Reset<br />

Manual Start - S34 to S35 with a NO switch.<br />

Auto Start - connect S35 to S33.<br />

S14 & S33 Channel 1 input, active hi (closed)<br />

S22 Channel 2 input, active lo (open)<br />

S24 Channel 2 input, active hi (closed)<br />

Safety Relay Door Interlocks:<br />

Controlled by door interlock contacts.<br />

Outputs:<br />

Disables spindle and axis movement.<br />

(Can be bypassed by Door Override circuit.)<br />

Activates reduced feeds and speeds when door is open.<br />

Disables tool changer arm (or slide) when door is open.<br />

(Cannot be overridden.)<br />

Contacts shown in door open state.<br />

180K54<br />

180C8<br />

OL DATC TOOL ARM<br />

96 95 FORWARD<br />

DATC TOOL ARM<br />

REVERSE<br />

Fadal PCB-0321<br />

FRONT DOOR LOCK<br />

DATC/ATC REV<br />

SPARE<br />

SPINDLE<br />

SENSOR<br />

STATUS<br />

UNLOCK DELAY<br />

R22<br />

DOOR<br />

UNLOCK<br />

ENABLE<br />

UNLOCK DOOR<br />

5V POWER<br />

K5<br />

24V POWER<br />

J2<br />

FWD REV SPARE<br />

5 6<br />

180CR2<br />

850CR2 is added for CE.<br />

MULTI #10<br />

MULTI #11<br />

MULTI #8<br />

MULTI #9<br />

This circuit has the following functions:<br />

1. Estop shuts down:<br />

all drives (180CR2 3&4),<br />

all outputs to: motors, pumps, and air solenoids.<br />

2. Do not allow door to unlock if:<br />

spindle is on or moving (standstill monitor and PLC),<br />

axes in motion (PLC),<br />

tool changer in motion (PLC),<br />

pallet changer in motion (PLC).<br />

3. When door is open: drives and tool changer arm (or slide) are disabled.<br />

(drives: 180CR2 3&4 and PLC; tool changer: safety relay and PLC)<br />

Do Not Use<br />

Do Not Use<br />

Requires manual override to allow axis or spindle movement, then only at reduced feeds and speeds.<br />

No tool change allowed with door open (PLC and safety relay).<br />

Chip conveyor is off unless unless Enable is pressed and held.<br />

4. When tool cage door is open, disables tool magazine (PLC).<br />

Requires manual override (PLC) to allow movement with door open.<br />

Reference numbers are to Quad drawing 4365-CAD (21 Oct 04).<br />

OVERRIDE PRESSED<br />

OVERRIDE PRESSED<br />

ENABLE<br />

ENABLE

180F52<br />

180J54<br />

180F52<br />

+24V<br />

1<br />

If Tool Inserter is in place, the tool magazine<br />

cannot be moved.<br />

If the Tool Door is open, the Override must be<br />

pressed to move the tool magazine.<br />

OUTPUT C004-1<br />

BOARD<br />

INTERFACE<br />

BOARD<br />

C004-1<br />

Y9.0 2<br />

855E11<br />

2<br />

855FU1<br />

Y9.1<br />

4<br />

3<br />

<strong>Fanuc</strong> DATC Tool Magazine - E855<br />

855E15<br />

<strong>Fanuc</strong> side:<br />

6 Pos Male Connector, Molex 03-09-1064 (WIR-0052)<br />

Sockets, Molex 02-09-1204 18-22 awg (WIR-0056) qty=6<br />

Interlock side:<br />

6 Pos Female Connector, Molex 03-09-2062 (WIR-0051)<br />

Pins, Molex 02-09-2118 18-22 awg (WIR-0544) qty=6<br />

Switch closed when door<br />

is closed.<br />

802SS1<br />

Tool Door Override Switch<br />

Normally Closed Contact, Idec HW-F01 (ELE-0094) (qty=1)<br />

Normally Open Contacts, Idec HW-F10 (ELE-0093) (qty=3)<br />

Momentary Switch Operator, Idec ABFW-200 (ELE-0670)<br />

White Switch Cap, Idec ABW-2B-W (ELE-1068)<br />

Tool Inserter Interlock<br />

Open when tool inserter is<br />

present.<br />

3<br />

855FU2<br />

Switch open when door is<br />

closed.<br />

Tool Magazine Door Interlock<br />

ELE-1504<br />

Omron D4DS-35FS or equivalent<br />

802SS2<br />

1<br />

5<br />

2<br />

6<br />

3<br />

7<br />

9<br />

10<br />

11<br />

3.2 FANUC TOOL DOOR INTERLOCK VMC_SHT2<br />

4<br />

12<br />

8<br />

4 Pole 24 VDC relay and socket<br />

Omron MY4N-DC24 and PY14-02<br />

ELE-1110 and ELE-0406<br />

14 13 or equivalent<br />

2<br />

5<br />

855J11<br />

855J15<br />

A1<br />

802SS3<br />

3<br />

802E35<br />

Turret CW and CCW Remote Switches<br />

Normally open contact, Idec HW-F10 (ELE-0093)<br />

Momentary Switch Operator, Idec ABFW-200 (ELE-0670)<br />

Green Switch Cap, Idec ABW-2B-G (ELE-0669)<br />

802SS4<br />

6<br />

802E39<br />

855M1<br />

855M11A<br />

A1 A2<br />

JUMPER<br />

855M2<br />

802E27<br />

802E31<br />

Note changes in types<br />

of switches.<br />

A2<br />

180K54<br />

180C8<br />

OL DATC TOOL MAGAZINE<br />

96 95 FORWARD<br />

DATC TOOL MAGAZINE<br />

REVERSE<br />

TOOL DOOR and REMOTE TURRET INPUTS E802<br />

INTERFACE<br />

BOARD<br />

INPUT C001 BD<br />

SOURCING INPUTS<br />

29 29<br />

X5.4<br />

30<br />

30<br />

X5.5<br />

31 31<br />

X5.6<br />

32<br />

32<br />

X5.7<br />

180F52<br />

180J54<br />

180F52<br />

+24V<br />

ATC<br />

ATC<br />

CANNON PLUG<br />

CANNON PLUG<br />

H 805DV3<br />

G<br />

1<br />

ATC FAULT<br />

SWITCH<br />

4<br />

C003 BREAKOUT<br />

BOARD<br />

FANUC WIRING DIAGRAM<br />

<strong>Fanuc</strong> ATC Fault Input - E805<br />

INPUT C003 BD<br />

SOURCING INPUTS<br />

5 of 38 MAN_0128_R1<br />

44<br />

805E19<br />

44<br />

X7.2<br />

When there is a DATC the ATC Fault input is not used<br />

and so may be used to signal the PLC that tool magzine<br />

is disabled.<br />

Reference numbers are to Quad drawing 4365-CAD (21 Oct 04).<br />

ATC Fault

FADAL MACHINING CENTERS<br />

4.0 WRG-0136_A<br />

4.1 FANUC NC4 PROBE<br />

SEPTEMBER 2005 6 of 38<br />

SET SWITCH 3 OF SW1 TO POSITION ON<br />

SET SWITCH 1 OF SW2 TO POSITION ON

5.0 WRG-0140<br />

5.1 OR 01_DRAWING STANDARDS AND INDEX<br />

FANUC WIRING DIAGRAM<br />

7 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.2 C02_OPERATOR STATIONS COMMUNICATION 1 LINE OVERVIEW<br />

SEPTEMBER 2005 8 of 38

5.3 E01_230VAC POWER DISTRIBUTION<br />

FANUC WIRING DIAGRAM<br />

9 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.4 E02_FADAL SUPPLIED TRANSFORMER DETAIL<br />

INPUT JUMPER AC INPUT<br />

VOLTAGE<br />

190 NONE 2<br />

200 2-7 8<br />

210 2-5 6<br />

230 2-6 7<br />

240 2-6 8<br />

250 2-5 7<br />

260 2-5 8<br />

340 NONE 3<br />

350 3-7 8<br />

360 3-5 6<br />

380 3-6 7<br />

390 3-6 8<br />

400 3-5 7<br />

410 3-5 8<br />

440 NONE 4<br />

450 4-7 8<br />

460 4-5 6<br />

480 4-6 7<br />

490 4-6 8<br />

500 4-5 7<br />

501 4-5 8<br />

NOTE: - TRANSFORMER JUMPERS HAVE TO BE SET<br />

ACCORDING TO THE VOLTAGE SHOWED<br />

IN THE TABLE 1.<br />

SEPTEMBER 2005 10 of 38

5.5 E170_115VAC POWER DISTRIBUTION_SHT1<br />

FANUC WIRING DIAGRAM<br />

11 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.6 E171_115VAC POWER DISTRIBUTION_SHT2<br />

SEPTEMBER 2005 12 of 38

5.7 E172_115VAC POWER DISTRIBUTION_SHT3<br />

FANUC WIRING DIAGRAM<br />

13 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.8 E173_115VAC POWER DISTRIBUTION_SHT4<br />

SEPTEMBER 2005 14 of 38

5.9 E180_24VDC POWER DISTRIBUTION<br />

FANUC WIRING DIAGRAM<br />

15 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.10 E300_DRIVES POWER SUPPLY WIRING DETAIL<br />

SEPTEMBER 2005 16 of 38

5.11 E350_DRIVES CNC CONTROL WIRING DETAIL<br />

FANUC WIRING DIAGRAM<br />

17 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

WYE-DELTA<br />

5.12 E400_SPINDLE AMP DRIVE WIRING DETAIL<br />

SEPTEMBER 2005 18 of 38

5.13 E450_SERVO AMP DRIVE WIRING DETAIL FOR X, Y, Z AXIS<br />

FANUC WIRING DIAGRAM<br />

19 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

SEPTEMBER 2005 20 of 38<br />

5.14 E600_OPTIONAL SERVO AMP DRIVE WIRING DETAIL FOR A & B AXIS MOTORS

5.15 E801_INPUT CARD FOR C001 BOARD_SHT1<br />

FANUC WIRING DIAGRAM<br />

21 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.16 E802_INPUT CARD FOR C001 BOARD_SHT2<br />

SEPTEMBER 2005 22 of 38

5.17 E803_INPUT CARD FOR C001 BOARD_SHT3<br />

FANUC WIRING DIAGRAM<br />

23 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.18 E804_C001 BOARD JUMPER SETUP DETAIL<br />

SEPTEMBER 2005 24 of 38

5.19 E805_IMPUT CARD FOR C003 BOARD_SHT1<br />

FANUC WIRING DIAGRAM<br />

25 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.20 E806_INPUT CARD FOR C003 BOARD_SHT2<br />

SEPTEMBER 2005 26 of 38

5.21 E807_INPUT CARD FOR C003 BOARD_SHT3<br />

FANUC WIRING DIAGRAM<br />

27 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.22 E808_C003 BOARD JUMPER SETUP DETAIL<br />

SEPTEMBER 2005 28 of 38

5.23 E809_C004 BOARD JUMPER SETUP DETAIL_SHT1<br />

FANUC WIRING DIAGRAM<br />

29 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.24 E810_C004 BOARD JUMPER SETUP DETAIL_SHT2<br />

SEPTEMBER 2005 30 of 38

5.25 E850_OUTPUT CARD FOR C001 BOARD_SHT1<br />

FANUC WIRING DIAGRAM<br />

31 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.26 E851_OUTPUT CARD FOR C001 BOARD_SHT2<br />

SEPTEMBER 2005 32 of 38

5.27 E852_OUTPUT CARD FOR C003 BOARD_SHT1<br />

FANUC WIRING DIAGRAM<br />

33 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.28 E853_OUTPUT CARD FOR C003 BOARD_SHT2<br />

SEPTEMBER 2005 34 of 38

5.29 E854_OUTPUT CARD FOR C004-1 BOARD_SHT1<br />

FANUC WIRING DIAGRAM<br />

35 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.30 E855_OUTPUT CARD FOR C004-1 BOARD<br />

SEPTEMBER 2005 36 of 38

5.31 E856_OUTPUT CARD FOR C004-2 BOARD_SHT1<br />

FANUC WIRING DIAGRAM<br />

37 of 38 MAN_0128_R1

FADAL MACHINING CENTERS<br />

5.32 E857_OUTPUT CARD FOR C004-2 BOARD_SHT2<br />

SEPTEMBER 2005 38 of 38