Prakties 2 - Electrical, Electronic and Computer Engineering

Prakties 2 - Electrical, Electronic and Computer Engineering

Prakties 2 - Electrical, Electronic and Computer Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Departement Elektriese,<br />

Elektroniese en Rekenaar-<br />

Ingenieurswese<br />

<strong>Prakties</strong> 2:<br />

Ontwerp en realisering<br />

van PID beheerders<br />

Kopiereg voorbehou<br />

Beheerstelsels<br />

EBB320<br />

Department of <strong>Electrical</strong>,<br />

<strong>Electronic</strong> <strong>and</strong> <strong>Computer</strong><br />

<strong>Engineering</strong><br />

Practical 2:<br />

Design <strong>and</strong> realisation of<br />

PID controllers<br />

Copyright reserved<br />

Control Systems<br />

EBB320<br />

Compiled by Hein Swart <strong>and</strong> Prof F. R. Camisani-Calzolari. Updated by Björn Matthews<br />

1. Introduction<br />

The aim of this practical is to design <strong>and</strong> build PID controllers to control the system built in Practical 1.<br />

2. Background<br />

A basic knowledge of the following is needed:<br />

1. Cohen-Coon tuning by using the process reaction curve (p.169 in Goodwin et al., (2001))<br />

2. Ziegler-Nichols oscillation method (p.162 in Goodwin et al., (2001) or p.317 in Seborg et al.,<br />

(2004))<br />

3. Bode stability criterion (p.365 in Seborg et al., (2004))<br />

A short description of each of these topics is given next. Please refer to references for more complete<br />

descriptions.<br />

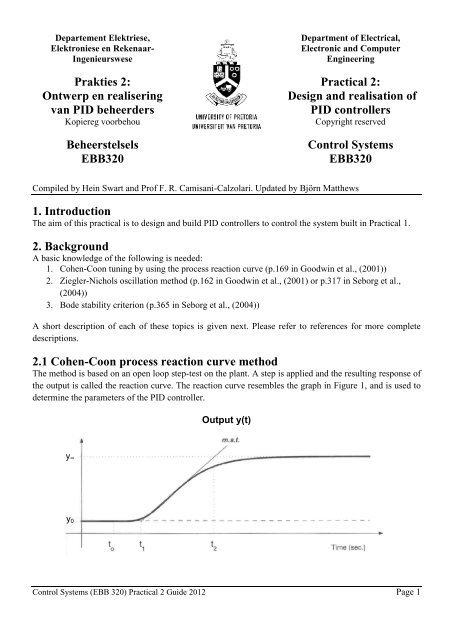

2.1 Cohen-Coon process reaction curve method<br />

The method is based on an open loop step-test on the plant. A step is applied <strong>and</strong> the resulting response of<br />

the output is called the reaction curve. The reaction curve resembles the graph in Figure 1, <strong>and</strong> is used to<br />

determine the parameters of the PID controller.<br />

y∞<br />

y0<br />

Output y(t)<br />

Control Systems (EBB 320) Practical 2 Guide 2012 Page 1

Figure 1. Reaction curve (m.s.t = maximum slope tangent. Reproduced from Goodwin et al., (2001))<br />

The values for , <strong>and</strong> are read off from the reaction curve where is the time at which the step was<br />

applied, is the time at which the system starts to react <strong>and</strong> is the time where the maximum slope<br />

tangent (drawn from ) intercepts the steady state output value. Once , <strong>and</strong> have been<br />

determined from the graph, the dead time, approximate time constant <strong>and</strong> gain are calculated. The dead<br />

time of the system is calculated as . The approximate time constant is <strong>and</strong> the<br />

gain is calculated as:<br />

where is the output <strong>and</strong> is the input. These values are then substituted into the equations from the<br />

following table to determine the PID parameters.<br />

[<br />

]<br />

( )<br />

Table 1: Controller settings for the Cohen-Coon process reaction curve method<br />

The st<strong>and</strong>ard form for the PID controller is given by:<br />

( ) (<br />

Note that the values in Table 1 (<strong>and</strong> Table 2) are given for the st<strong>and</strong>ard PID controller form.<br />

2.2 Ziegler-Nichols oscillation method<br />

This method is described in Seborg et al., (2004) as follows:<br />

1. After the process has reached steady state, eliminate the integral <strong>and</strong> derivative action (i.e.<br />

implement proportional only control).<br />

2. Set the controller gain to a small non-zero value.<br />

3. Introduce a small momentary set-point change <strong>and</strong> observe the output. Gradually increase the<br />

controller gain <strong>and</strong> repeat the introduction of the momentary set-point change until sustained<br />

oscillation is seen at the output. The oscillation at the output should have a constant amplitude (i.e.<br />

it should not die out over time). The numerical value of the proportional controller gain that<br />

produces the continuous oscillation is called the ultimate gain . The period of the oscillation is<br />

called the ultimate period .<br />

4. Calculate the PID controller settings from the Ziegler-Nichols tuning settings table.<br />

Ziegler-Nichols Method<br />

PID<br />

Table 2: Controller settings based on the Ziegler-Nichols oscillation method<br />

Control Systems (EBB 320) Practical 2 Guide 2012 Page 2<br />

)

The numeric value for the ultimate controller gain may be calculated from the method of Goodwin et al.,<br />

(2001) (p.162) or from the Bode stability criterion (in Seborg p.317, (2004)).<br />

2.3 Bode stability criterion<br />

The Bode stability criterion is a method to evaluate the stability of a system containing time delays. There<br />

is a host of applications for this method but all we are interested in is the calculation of the ultimate<br />

controller gain that leads to sustained oscillation. This gain is achieved at the point where the system is<br />

marginally stable. From the Bode stability criterion this is the point where or equivalently<br />

| | <strong>and</strong> . Here is the open loop transfer function. In our case it is simply the<br />

product of the proportional controller <strong>and</strong> the plant transfer function (first order plus time delay).<br />

Rewrite the open loop transfer function into magnitude <strong>and</strong> phase form. Determine the frequency at<br />

which the phase becomes . At this frequency the magnitude must equal 1 for marginal stability.<br />

Substitute the calculated frequency back into the magnitude equation <strong>and</strong> solve for the ultimate controller<br />

gain.<br />

3. Additional circuits<br />

The controller ( ) can be written in the following form:<br />

( ) ( )<br />

( ) [(<br />

Note that you will need to rewrite the st<strong>and</strong>ard PID controller form, given in section 2.1, into this form to<br />

calculate the component values.<br />

Figure 1: Realization of controller ( ( )).<br />

Control Systems (EBB 320) Practical 2 Guide 2012 Page 3<br />

)<br />

⁄<br />

]

Figure 2: Realisation of controller with <strong>and</strong> represented by resistors <strong>and</strong> capacitors.<br />

The implementation of the controller is shown in Figure 1 <strong>and</strong> Figure 2.<br />

4. Closed Loop System<br />

The closed loop system is shown in Figure 3 <strong>and</strong> can be implemented as in Figure 4.<br />

Figure 3: The closed loop system.<br />

Figure 4: The closed loop system for practical implementation.<br />

The summation function can be implemented as in Figure 5. Set . is the feedback signal,<br />

is the set point input <strong>and</strong> is the input of the controller.<br />

Control Systems (EBB 320) Practical 2 Guide 2012 Page 4

Figure 5: The implementation of the summation function.<br />

5. Preparation<br />

All pre-assignments must be done in the lab book (of each student) <strong>and</strong> will be marked during the<br />

practical session. Each member of the group must participate in the preparation.<br />

1. Design (i.e. calculate the tuning parameters) a PID controller by simulating the step response of<br />

the plant of practical 1, <strong>and</strong> making use of the Cohen-Coon reaction curve method. Use the system<br />

with the Padé approximation applied.<br />

2. Design a PID controller from the Ziegler-Nichols oscillation method by theoretically calculating<br />

the ultimate controller gain <strong>and</strong> ultimate oscillation period from the transfer function of the<br />

system. Use the system with the Padé approximation applied.<br />

3. Compute the capacitor <strong>and</strong> resistor values for each of the designed PID controllers.<br />

4. Simulate the closed loop system using both controllers (see Figure 4). Measure the peak time ( ),<br />

percentage overshoot ( ) <strong>and</strong> steady-state-error from each simulation.<br />

(Note that the simulations may be done in PSpice or Simulink. The setup <strong>and</strong> the results of each<br />

simulation should be explicitly indicated.)<br />

6. Lab assignments<br />

1. Build the Cohen-Coon controller you designed in 5.1 (use own components!).<br />

2. Measure (look on oscilloscope) the system the peak time ( ), percentage overshoot ( ) <strong>and</strong><br />

steady-state-error <strong>and</strong> compare this with the controller from your simulated response. The<br />

definitions of these quantities may be found from Nise, (2008).<br />

(Note: Please build the Cohen-Coon <strong>and</strong> Ziegler-Nichols controllers separately such that they can be<br />

interchanged easily in the demo. They should however be implemented on the same plant).<br />

3. Build the Ziegler-Nichols controller (as designed in 5.2).<br />

4. Measure , <strong>and</strong> the steady-state-error for the system with the Ziegler-Nichols controller<br />

implemented, <strong>and</strong> compare this with the simulation results found in 5.4.<br />

Control Systems (EBB 320) Practical 2 Guide 2012 Page 5

7. Report<br />

The report must be written in English <strong>and</strong> include the following:<br />

1. Design of the PID controller with the Cohen-Coon method.<br />

2. Design of the controller with the Ziegler-Nichols oscillation method.<br />

3. Component values calculated for realisation of the controllers.<br />

4. The measured , <strong>and</strong> steady-state-error values from the simulations as well as from the<br />

practical results.<br />

5. Comparison of these values for the simulation <strong>and</strong> practically implemented controllers.<br />

6. PSpice or Simulink simulation of the closed loop systems.<br />

7. Discussion of results.<br />

8. A conclusion.<br />

8. Demo<br />

The demo will be based on the following:<br />

1. Lab books with completed preparation assignments.<br />

2. Closed loop response of the implemented Cohen-Coon based PID controller.<br />

3. Closed loop response of the implemented Ziegler-Nichols based PID controller.<br />

4. Performance measures achieved ( , <strong>and</strong> steady-state-error) for the practical controllers.<br />

5. Answering of questions.<br />

(Note: Please build the Cohen-Coon <strong>and</strong> Ziegler-Nichols controllers separately such that they can be<br />

interchanged easily in the demo. They should however be implemented on the same plant).<br />

9. References<br />

[1] Goodwin, G.C., Graebe, S.F., Salgado, M.E., Control System Design, 2001, Prentice Hall.<br />

[2] Seborg, D.E., Edgar, T.F., Mellichamp, D.A, Process Dynamics <strong>and</strong> Control, 2004, Wiley.<br />

[3] Norman S. Nise, Control Systems <strong>Engineering</strong>, 5th Ed., 2008, John Wiley & Sons.<br />

Control Systems (EBB 320) Practical 2 Guide 2012 Page 6