ThyssenKrupp Magazin

ThyssenKrupp Magazin

ThyssenKrupp Magazin

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

conical tailored tubes – like a fanfare trumpet, their diameter steadily increases<br />

while maintaining consistent wall strength. This form allows the<br />

beams to absorb the energy from a crash much better than a cylindrical<br />

steel beam can.<br />

Working with high-strength steel requires technicians who really<br />

know the material; people who recognize, for example, that when being<br />

pressed into different forms some steels not only take on a new shape<br />

but become stronger. “The structure changes,” explains Markus Weber,<br />

citing the example of a paper clip that is bent back and forth: it eventually<br />

breaks in two, not because the metal gets soft but for the opposite<br />

reason – namely that the stress makes the metal hard, and hence brittle.<br />

Naturally, high-strength steel used in a car should not break in<br />

case of an accident, and the parts are accordingly designed in a way<br />

that their fabrication does not bring them to the limit of their stability<br />

but always leaves a degree of elasticity that in a collision can absorb<br />

energy from a crash. “A lot of auto makers simply don’t have this com-<br />

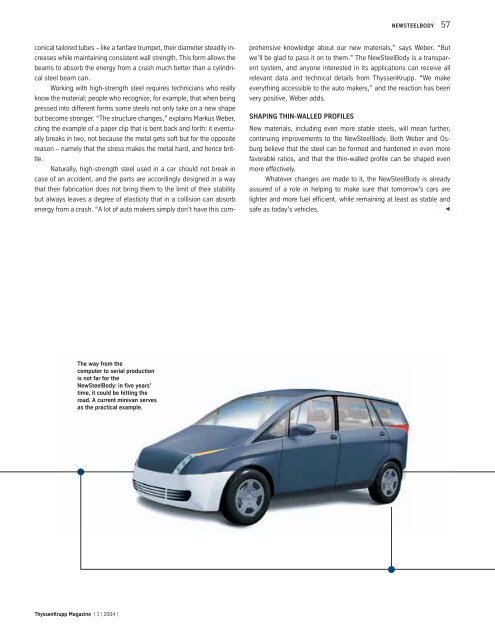

The way from the<br />

computer to serial production<br />

is not far for the<br />

NewSteelBody: in five years’<br />

time, it could be hitting the<br />

road. A current minivan serves<br />

as the practical example.<br />

TK <strong>Magazin</strong>e | 1 | 2004 |<br />

NEWSTEELBODY 57<br />

prehensive knowledge about our new materials,” says Weber. “But<br />

we’ll be glad to pass it on to them.” The NewSteelBody is a transparent<br />

system, and anyone interested in its applications can receive all<br />

relevant data and technical details from <strong>ThyssenKrupp</strong>. “We make<br />

everything accessible to the auto makers,” and the reaction has been<br />

very positive, Weber adds.<br />

SHAPING THIN-WALLED PROFILES<br />

New materials, including even more stable steels, will mean further,<br />

continuing improvements to the NewSteelBody. Both Weber and Osburg<br />

believe that the steel can be formed and hardened in even more<br />

favorable ratios, and that the thin-walled profile can be shaped even<br />

more effectively.<br />

Whatever changes are made to it, the NewSteelBody is already<br />

assured of a role in helping to make sure that tomorrow’s cars are<br />

lighter and more fuel efficient, while remaining at least as stable and<br />

safe as today’s vehicles. 7