Near Net Shape Manufacturing of CuCr Vacuum Switching Contacts ...

Near Net Shape Manufacturing of CuCr Vacuum Switching Contacts ...

Near Net Shape Manufacturing of CuCr Vacuum Switching Contacts ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WS 15/6 17th Plansee Seminar 2009, Vol. 3 Feist, Oberbreyer et al.<br />

sinter density £s [g/cm³]<br />

8.5<br />

8.0<br />

7.5<br />

7.0<br />

6.5<br />

6.0<br />

5.5<br />

¢th <strong>CuCr</strong> alloy 1<br />

¢th <strong>CuCr</strong> alloy 2<br />

<strong>CuCr</strong> alloy 1<br />

<strong>CuCr</strong> alloy 2<br />

lin. regr. <strong>CuCr</strong> alloy 1<br />

lin. regr. <strong>CuCr</strong> alloy 2<br />

5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5<br />

¢g green density [g/cm³]<br />

axial shrinkage ¤z [%]<br />

5.0<br />

4.0<br />

3.0<br />

2.0<br />

1.0<br />

0.0<br />

5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5<br />

¢g green density [g/cm³]<br />

5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5<br />

¢g green density [g/cm³]<br />

(a) (b) (c)<br />

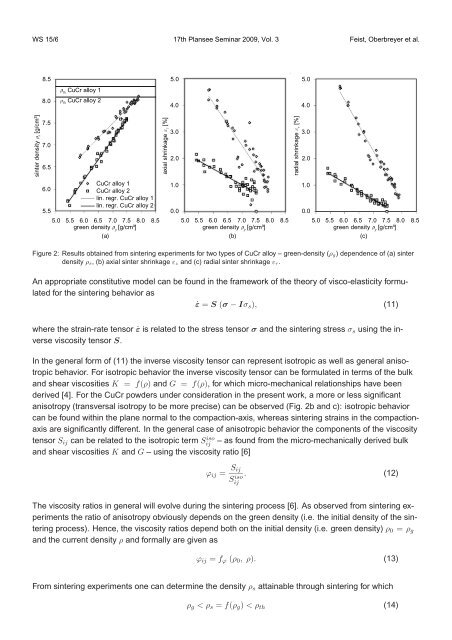

Figure 2: Results obtained from sintering experiments for two types <strong>of</strong> <strong>CuCr</strong> alloy – green-density (ρg) dependence <strong>of</strong> (a) sinter<br />

density ρs, (b) axial sinter shrinkage εz and (c) radial sinter shrinkage εr.<br />

An appropriate constitutive model can be found in the framework <strong>of</strong> the theory <strong>of</strong> visco-elasticity formulated<br />

for the sintering behavior as<br />

˙ε = S (σ − Iσs), (11)<br />

where the strain-rate tensor ˙ε is related to the stress tensor σ and the sintering stress σs using the inverse<br />

viscosity tensor S.<br />

In the general form <strong>of</strong> (11) the inverse viscosity tensor can represent isotropic as well as general anisotropic<br />

behavior. For isotropic behavior the inverse viscosity tensor can be formulated in terms <strong>of</strong> the bulk<br />

and shear viscosities K = f(ρ) and G = f(ρ), for which micro-mechanical relationships have been<br />

derived [4]. For the <strong>CuCr</strong> powders under consideration in the present work, a more or less significant<br />

anisotropy (transversal isotropy to be more precise) can be observed (Fig. 2b and c): isotropic behavior<br />

can be found within the plane normal to the compaction-axis, whereas sintering strains in the compactionaxis<br />

are significantly different. In the general case <strong>of</strong> anisotropic behavior the components <strong>of</strong> the viscosity<br />

– as found from the micro-mechanically derived bulk<br />

and shear viscosities K and G – using the viscosity ratio [6]<br />

tensor Sij can be related to the isotropic term S iso<br />

ij<br />

ϕij = Sij<br />

radial shrinkage ¤r [%]<br />

5.0<br />

4.0<br />

3.0<br />

2.0<br />

1.0<br />

0.0<br />

Siso. (12)<br />

The viscosity ratios in general will evolve during the sintering process [6]. As observed from sintering experiments<br />

the ratio <strong>of</strong> anisotropy obviously depends on the green density (i.e. the initial density <strong>of</strong> the sintering<br />

process). Hence, the viscosity ratios depend both on the initial density (i.e. green density) ρ0 = ρg<br />

and the current density ρ and formally are given as<br />

ij<br />

ϕij = fϕ (ρ0, ρ). (13)<br />

From sintering experiments one can determine the density ρs attainable through sintering for which<br />

ρg < ρs = f(ρg) < ρth<br />

(14)