Generic HACCP Model for Thermally Processed Commercial

Generic HACCP Model for Thermally Processed Commercial

Generic HACCP Model for Thermally Processed Commercial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

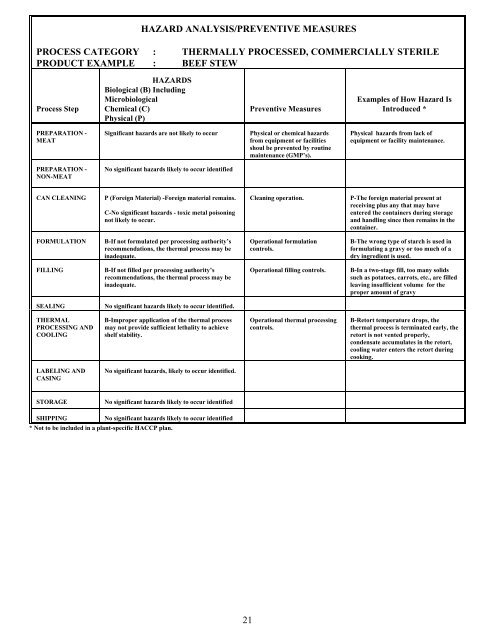

HAZARD ANALYSIS/PREVENTIVE MEASURES<br />

PROCESS CATEGORY : THERMALLY PROCESSED, COMMERCIALLY STERILE<br />

PRODUCT EXAMPLE : BEEF STEW<br />

Process Step<br />

PREPARATION -<br />

MEAT<br />

PREPARATION -<br />

NON-MEAT<br />

HAZARDS<br />

Biological (B) Including<br />

Microbiological<br />

Chemical (C)<br />

Physical (P)<br />

21<br />

Preventive Measures<br />

Significant hazards are not likely to occur Physical or chemical hazards<br />

from equipment or facilities<br />

shoul be prevented by routine<br />

maintenance (GMP’s).<br />

No significant hazards likely to occur identified<br />

CAN CLEANING P (Foreign Material) -Foreign material remains.<br />

C-No significant hazards - toxic metal poisoning<br />

not likely to occur.<br />

FORMULATION B-If not <strong>for</strong>mulated per processing authority’s<br />

recommendations, the thermal process may be<br />

inadequate.<br />

FILLING B-If not filled per processing authority’s<br />

recommendations, the thermal process may be<br />

inadequate.<br />

SEALING No significant hazards likely to occur identified.<br />

THERMAL<br />

PROCESSING AND<br />

COOLING<br />

LABELING AND<br />

CASING<br />

B-Improper application of the thermal process<br />

may not provide sufficient lethality to achieve<br />

shelf stability.<br />

No significant hazards, likely to occur identified.<br />

STORAGE No significant hazards likely to occur identified<br />

SHIPPING No significant hazards likely to occur identified<br />

* Not to be included in a plant-specific <strong>HACCP</strong> plan.<br />

Examples of How Hazard Is<br />

Introduced *<br />

Physical hazards from lack of<br />

equipment or facility maintenance.<br />

Cleaning operation. P-The <strong>for</strong>eign material present at<br />

receiving plus any that may have<br />

entered the containers during storage<br />

and handling since then remains in the<br />

container.<br />

Operational <strong>for</strong>mulation<br />

controls.<br />

B-The wrong type of starch is used in<br />

<strong>for</strong>mulating a gravy or too much of a<br />

dry ingredient is used.<br />

Operational filling controls. B-In a two-stage fill, too many solids<br />

such as potatoes, carrots, etc., are filled<br />

leaving insufficient volume <strong>for</strong> the<br />

proper amount of gravy<br />

Operational thermal processing<br />

controls.<br />

B-Retort temperature drops, the<br />

thermal process is terminated early, the<br />

retort is not vented properly,<br />

condensate accumulates in the retort,<br />

cooling water enters the retort during<br />

cooking.