Broch

Broch

Broch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

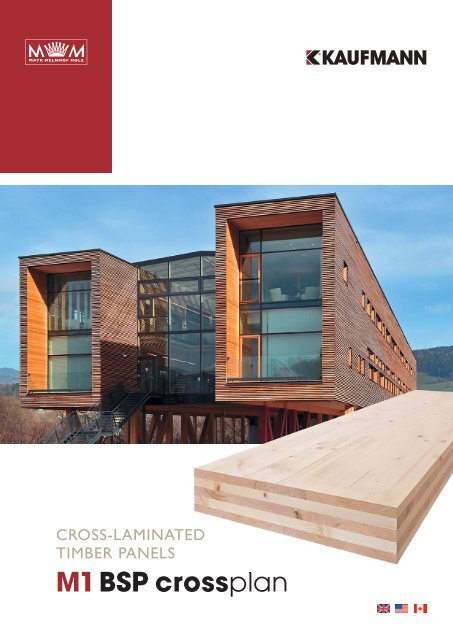

CROSS-LAMINATED TED<br />

TIMBER PANELS<br />

M1 BSP crossplan

M1 BSP crossplan<br />

State of the art, environmental and fl exible –<br />

developed for use in the timber construction<br />

industry.<br />

M1 BSP crossplan is a solid, static load-bearing and spacecreating<br />

timber panel that is ideal for any structural requirement<br />

thanks to its fl exible dimensions and outstanding<br />

physical properties.<br />

Durable bonding of the cross-wise layered construction<br />

made of high-quality raw material guarantees that the<br />

components are absolutely dimensionally stable and<br />

rigid.<br />

The exceptional structural performance and the environmental<br />

properties of M1 BSP crossplan are assured by<br />

national and international certifi cations.<br />

Numerous areas of use<br />

As a wall, ceiling and roof element<br />

• Family houses and apartment buildings<br />

• Multi-storey buildings<br />

• Public buildings<br />

• Nurseries and schools<br />

• Commercial and offi ce buildings<br />

• Industrial and warehouse buildings<br />

• Modular buildings<br />

• Vacation homes, carports, etc.<br />

Contents<br />

Features 2 - 3<br />

Advantages 4 - 5<br />

Technical data 6<br />

Product range 7<br />

Surface qualities 8<br />

2 Mayr-Melnhof Kaufmann<br />

At a glance<br />

FEATURES<br />

• High-quality, value-maintaining construction<br />

• Space gain due to reduced component thickness<br />

• Flexible design without grid pattern<br />

• Excellent shape and dimensional accuracy<br />

• Outstanding structural properties<br />

• Prefabricated, ready-to-assemble elements<br />

• Short building time due to dry construction<br />

• Recommended for environmentally compatible<br />

architecture<br />

• CO 2 reservoir, reduced carbon foot print<br />

Structural design 9 - 21<br />

Order processing 22<br />

Loading / transport 23 - 25<br />

Construction details 26 - 33<br />

Tender texts 34 - 35<br />

Version 1 / 2011

FEATURES<br />

Weighty arguments take shape<br />

The range of M1 BSP crossplan applications extend from individually<br />

designed detached houses to large-volume building<br />

projects. The large-format solid wood panels make it possible<br />

to cope eff ortlessly with special static challenges.<br />

The clearly structured, layered design principle with simple<br />

jointing details guarantees extremely cost-eff ective use in all<br />

areas of building.<br />

Rapid and straightforward assembly of the elements results<br />

in a signifi cant reduction of building time. The creative fl exibility<br />

meets the needs of modern architecture fans and also<br />

of enthusiasts of traditional building styles.<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

Facts M1 BSP crossplan:<br />

Types of wood<br />

• Spruce<br />

Thicknesses<br />

• 57 – 278 mm<br />

Formats<br />

• Max. 3,00 x 16,50 m<br />

Technical approvals<br />

• European technical approval<br />

ETA-09 / 0036<br />

• German technical approval<br />

Z-9.1-638<br />

Surface qualities<br />

• Industrial<br />

• Standard<br />

European technical<br />

approval (ETA) ETA -09 / 0036<br />

CE conformity certifi cation<br />

German technical<br />

approval (GCA) Z-9.1-638<br />

PEFC<br />

Chain of Custody<br />

Environmental seal of approval<br />

(IBR Rosenheim)<br />

Component classifi cation EN<br />

13501-2 (HFA)<br />

Mayr-Melnhof Kaufmann 3

M1 BSP crossplan<br />

4 Mayr-Melnhof Kaufmann<br />

ADVANTAGES<br />

Individual scope for architectural design<br />

M1 BSP crossplan provides architects and planners with new<br />

design freedom as there is no need to adhere to any particular<br />

pattern. This high degree of fl exibility in planning allows<br />

for customised solutions to a variety of building tasks.<br />

The use of cross-laminated timber panels creates new attractive<br />

possibilities and forms of expression in the architecture<br />

of modern timber constructions.<br />

High degree of prefabrication<br />

M1 BSP crossplan is cut to size at the factory by our computer-controlled<br />

CNC machining systems on request.<br />

The extremely high degree of prefabrication results in short<br />

assembly times and, hence, to lower building costs.<br />

The ready-to-assemble elements are of a consistently high<br />

product quality and minimise the risk of assembly errors due<br />

to accurately fi tting components.<br />

Solid construction<br />

Solid construction using M1 BSP crossplan not only fulfi ls the<br />

traditional advantages of solid building structures but optimises<br />

them with lower component thicknesses, lower transport<br />

weight, shorter building times and outstanding structural<br />

properties.<br />

The solid, cross-wise layered construction and the innovative<br />

production process are the reason why M1 BSP crossplan<br />

keeps its excellent shape and dimensional stability.<br />

This signifi cantly simplifi es design and building with M1 BSP<br />

crossplan as there is no need to allow for tolerances and<br />

changes in shape.<br />

Version 1 / 2011

ADVANTAGES<br />

Excellent structural properties<br />

Thanks to its outstanding structural properties M1 BSP crossplan<br />

opens up new opportunities in modern timber construction.<br />

The high load-bearing capacity with lower dead weight<br />

allows tight dimensioning of the components even in large<br />

span applications. This results in wall cross-sections well below<br />

any other building materials. Consequently creating more<br />

living space with the same outer dimensions.<br />

The special cross-wise layered construction of M1 BSP crossplan<br />

results in all-round load transfer that makes it ideal for<br />

use as a panel or diaphragm. Point-supported structures or<br />

projections across corners are unproblematic.<br />

What’s more M1 BSP crossplan enables earthquake-proof<br />

construction.<br />

Outstanding environmental life cycle assessment<br />

The raw material for the manufacture of M1 BSP crossplan<br />

mainly originates from domestic forests. For generations,<br />

these forests have been managed and tended according to<br />

the principle of sustainability which means, therefore, our<br />

raw material is not only always available but is also replanted<br />

on a sustainable basis. This is also confi rmed by our 100 %<br />

PEFC certifi cation.<br />

In addition, timber is the only building material that is distinguished<br />

by its positive contribution to the carbon footprint.<br />

For this reason, building with timber constitutes an active<br />

contribution to climate protection.<br />

Recommended for environmentally compatible<br />

architecture<br />

Timber lends a pleasant ambience to rooms and is distinguished<br />

by its visual appeal. It also conveys a sense of cosy<br />

familiarity and warmth.<br />

The perceived surface temperature of M1 BSP crossplan lies<br />

signifi cantly above any other type of building material. Even<br />

at lower room temperatures this leads to a pleasant perception<br />

of temperature.<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

Mayr-Melnhof Kaufmann 5

M1 BSP crossplan<br />

Product<br />

Lay-up and production<br />

Dimensions<br />

Technical approvals<br />

Types of wood<br />

Lamellas<br />

Strength classes<br />

(lamellas)<br />

Gluing<br />

Density<br />

Moisture content<br />

Dimensional stability<br />

Thermal conductivity<br />

Heat capacity<br />

Water vapour<br />

resistance factor<br />

Airtightness<br />

Sound insulation<br />

Reaction to fi re<br />

Charring rate<br />

Service classes<br />

6 Mayr-Melnhof Kaufmann<br />

TECHNICAL DATA<br />

M1 BSP crossplan is a large-format, solid timber panel (cross-laminated timber panel) with<br />

multi-layered, crosswise laminated lay-up.<br />

Finger-jointed and planed lamellas are loosely laid next to each other and the fl at surfaces of<br />

the layers glued at right angles to one another.<br />

To avoid uncontrolled stress cracks, the narrow sides are not edge-glued.<br />

The layers are pushed laterally to dimension before applying the pressure (1,2 N/mm 2 ) in<br />

order to obtain a gap-free surface.<br />

Lengths to 16,50 m<br />

Widths to 3,00 m<br />

Thicknesses 57 to 278 mm<br />

European technical approval ETA−09 / 0036<br />

German technical approval Z-9.1-638<br />

Spruce (Picea abies) from domestic forests; other wood species on request<br />

19 to 40 mm, kiln-dried, quality graded and fi nger-jointed<br />

C 24 acc. to EN 338 (equivalent to S 10 acc. to DIN 4074)<br />

A proportion of max. 10 % C 16 is permissible (ETA-09 / 0036)<br />

Melamine resin-based adhesive, Adhesive Type I acc. to EN 301 approved for the gluing of<br />

load-bearing timber components, for both interiors and exteriors, weather-resistant with<br />

transparent glued joint<br />

Approx. 480 kg / m 3<br />

12 % (+ / - 2 %) on delivery<br />

II to panel plane 0,01 % per % change in moisture content<br />

⊥ to panel plane 0,20 % per % change in moisture content<br />

λ = 0,13 W / mK<br />

c = 1,60 kJ / kgK<br />

μ = 60 (at 12 % moisture content)<br />

Airtight from a panel thickness of 95 mm<br />

Dependent on wall or ceiling build-up � see tested sample wall constructions<br />

According EN 13501: D, s2, d0<br />

(standard infl ammability, average smoke emission, no combustible drips)<br />

Fire resistance according to classifi cation report of HFA, EN 13501-2 REI 30 to REI 120<br />

Wall: 0,64 mm/min<br />

Ceiling: 0,71 mm/min<br />

1 or 2 acc. to ETA-03 / 0036<br />

Standard widths 2,40 m / 2,65 m / 2,75 m /<br />

2,90 m / 3,00 m<br />

Version 1 / 2011

PRODUCT RANGE<br />

Product range<br />

Description Layers Panel build-up<br />

Bold = parallel to outer layers<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

Thickness Standard widths Length Dead weight<br />

M1 BSP crossplan mm mm m m kN / m 2<br />

57* 3s 3 19 19 19 57 0,26<br />

78 3s 3 25 28 25 78<br />

0,38<br />

94 3s 3 33 28 33 94 0,45<br />

95 5s 5 19 19 19 19 19 95 0,46<br />

98 3s 3 32 34 32 98 0,47<br />

106 3s 3 39 28 39 106 0,51<br />

118 3s 3 39 40 39 118 0,57<br />

134 5s 5 27 20 40 20 27 134 0,65<br />

140 5s 5 33 20 34 20 33 140 2,40<br />

0,67<br />

146 5s 5 32 27 28 27 32 146 2,65<br />

0,70<br />

160 5s 5 40 20 40 20 40 160<br />

2,75<br />

2,90<br />

max. 16,50<br />

0,77<br />

173 5s 5 40 27 39 27 40 173 3,00<br />

0,83<br />

184 5s 5 39 33 40 33 39 184 0,89<br />

198 5s 5 39 40 40 40 39 198 0,95<br />

214 7s 7 39 19 39 20 39 19 39 214 1,03<br />

214 7ss 7 39 39 19 20 19 39 39 214 1,03<br />

240 7s 7 39 27 40 28 40 27 39 240 1,16<br />

240 7ss 7 39 40 40 28 40 40 39 240 1,16<br />

258 7ss 7 39 40 33 28 27 27 39 258 1,24<br />

278 7ss 7 39 40 40 40 40 40 39 278 1,34<br />

ss: outer layers consist of 2 parallel top layers.<br />

Further dimensions (e.g. optimised for 2-axis load transfer) possible on request.<br />

The orientation of the top layer, lengthwise (DL) or transverse (DQ), can be selected according to the application.<br />

* available in pairs only, on request<br />

Mayr-Melnhof Kaufmann 7

M1 BSP crossplan<br />

Industrial quality Standard quality<br />

Surface qualities<br />

Industrial quality<br />

Standard quality<br />

Note<br />

8 Mayr-Melnhof Kaufmann<br />

M1 BSP crossplan is supplied in two surface qualities.<br />

SURFACE QUALITIES<br />

For non-visual applications in compliance with all structural requirements, for subsequent<br />

installation (e.g. plasterboard).<br />

• The top lamellas are exclusively sorted according to the sorting criteria of the loadbearing<br />

strength C24 in line with EN 338. A proportion of max. 10 % C 16 is permissible<br />

(ETA-09 / 0036).<br />

• Colour variations of individual lamella (e.g. blue stain) as well as loose knots, bark<br />

ingrowths and resin pockets are permitted.<br />

• Isolated gaps in the outer layers, glue stains as well as isolated pressure points and<br />

markings can appear<br />

• Planed surface only<br />

With additional requirements for a visual application.<br />

• Stringent visual criteria for outer layers are applied in addition to the sorting criteria for<br />

load-bearing strength.<br />

• Selected outer lamellas with healthy intergrown knots. A few isolated loose knots are possible,<br />

defects and small resin pockets are permissible.<br />

• Planed and sanded surface.<br />

Timber is a natural product. Variations in the surface quality can occur with even the most<br />

careful selection of the raw material.<br />

The appearance of the M1 BSP crossplan surface is determined by the board structure of<br />

the top layer. Gaps may occur between the individual boards over time due to shrinkage, etc.<br />

Drying checks are also possible.<br />

Version 1 / 2011

STRUCTURAL DESIGN<br />

General<br />

Building practice approximation<br />

method<br />

for calculation of<br />

cutting forces and<br />

deformations.<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

Components made of M1 BSP crossplan are designed and executed according to the following<br />

standards:<br />

• Design according to DIN 1052:2008 allowing for German technical approval<br />

(Z-9.1-638)<br />

or<br />

• Design according to EN 1995 (Eurocode 5) allowing for Appendices 2 to 4 of European<br />

technical approval ETA-09 / 0036<br />

The structural analysis for M1 BSP crossplan must be conducted in each individual case and<br />

the standards and regulations applicable at the site of use must be complied with.<br />

Analysis of the stress distribution and internal forces and moments must be conducted according<br />

to the composite theory allowing for shear deformations.<br />

An approximation method is required in practical use. Here, the calculation is carried out as<br />

for a beam under bending moment with fl exible joining means (Austrian standard B 4100 / 2;<br />

DIN 1052; EN 1995-1-1, Appendix B), but the shear deformation of the transverse layers is<br />

taken into consideration instead of the fl exibility of the joining means.<br />

Using this approach, it is possible to achieve a good approximation for the stress and deformation<br />

calculations.<br />

At the same time, for the actual design the moments of inertia are multiplied by a reduction<br />

factor - which takes into account the net moments of inertia and the rolling shear deformation<br />

of the transverse layers.<br />

Using the eff ective moments of inertia (Ieff ) obtained as a result, it is possible to calculate<br />

the cutting forces and deformations as for beams under bending moment with a rigid bond.<br />

M Q<br />

Lamellas stressed in the direction of the fibres<br />

� High stiffness<br />

Cross-section<br />

Q<br />

Tension<br />

Lamellas stressed transverse to the direction of the fibres<br />

� No stiffness E = 0<br />

M<br />

σ = 0<br />

Normal stress due to bending<br />

Pressure<br />

σ = 0<br />

Shear stress<br />

Rolling shear transversally<br />

Rolling shear transversally<br />

Note:<br />

The solution only applies exactly for single span beams with sinusoidal uniform load. It should<br />

also be noted that the eff ective moments of inertia Ieff depend on the width between supports<br />

of the panels. The shorter the width between supports, the greater the proportion of<br />

shear deformation and thus also the percentage reduction of the moments of inertia (compare<br />

table of cross-sectional values). Beyond this, a more accurate calculation method is<br />

necessary particularly in the case of point loads and very short beam lengths.<br />

In the case of continuous beams, the width between supports of the fi eld concerned should<br />

be used for the width between supports for selection of the eff ective moment of inertia 4 / 5<br />

Ieff , in the case of cantilever beams double the protruding length should be used (cf. EN<br />

1995-1-1, Appendix B). However, calculation of the cutting force and deformation must be<br />

performed using the actual widths between supports or protruding lengths.<br />

This approximation method is also the basis of the design charts.<br />

Mayr-Melnhof Kaufmann 9

M1 BSP crossplan<br />

Design as panel acc.<br />

to DIN 1052:2008<br />

(Z-9.1-638)<br />

Design as a slab acc.<br />

to DIN 1052:2008<br />

(Z-9.1-638)<br />

Wall slab<br />

Lintel design<br />

Wall slab as column<br />

Vibration design<br />

Fire resistant design<br />

10 Mayr-Melnhof Kaufmann<br />

STRUCTURAL DESIGN<br />

The stress perpendicular to the panel plane is applicable for the design. Analysis of the stress<br />

distribution and internal forces and moments must be conducted according to the German<br />

technical approval (Z-9.1-638) in line with the composite theory referred to above allowing<br />

for shear deformations (DIN 1052:2008, Appendix D).<br />

The various bending stiff nesses of the relevant clamping directions must be allowed for in the<br />

panel stress. That is to say, that in the longitudinal direction of the panel (main load-bearing<br />

direction) the lamella layers may be taken into consideration in the panel’s longitudinal direction<br />

and in the transverse direction of the panel the lamella layers may be taken into consideration<br />

in the panel’s transverse direction.<br />

If the panel lay-up transverse to the direction of span corresponds to the lay-up of a 3-layer<br />

panel, then the cross-sectional values must thus be taken from the table (page 11).<br />

Note:<br />

In the case of 3-layer panels, when designing transverse to the main load-bearing direction,<br />

the middle layer must be calculated as a solid timber cross-section.<br />

In the case of stress in the panel plane, only those layers where the fi bre direction runs<br />

parallel to the force components considered may be taken into account (German technical<br />

approval Z-9.1-638).<br />

The following models must be diff erentiated when designing in the panel plane.<br />

In the case of stress as a wall slab (bracing ceilings and walls), it is necessary to conduct<br />

the corresponding shear stress analyses in accordance with the German technical approval.<br />

Only the lamella layers running parallel to the direction of force or direction of internal forces<br />

and moments are taken into account for the design. The height of the individual beam crosssections<br />

must be specifi ed in a particular case. Thus wall slabs may also be calculated allowing<br />

for door and window openings.<br />

Only the lamella layers running parallel to the direction of force are taken into account for<br />

the design of the load carrying capacity in the panel plane. The buckling analysis required<br />

for this must be conducted according to the equivalent member method in accordance with<br />

DIN 1052 or EN 1995. The corresponding slendernesses (λ) and the associated reduction<br />

factors (κ) must be determined in the process.<br />

It must be ensured that impacts on components or supporting structures that are to be<br />

anticipated frequently do not give rise to any vibrations which could impair the structure’s<br />

function or lead to unease. The required analysis must be conducted in accordance with<br />

EN 1995-1-1 whereby a special investigation must be carried out for apartment ceilings with<br />

a resonant frequency not exceeding 8 Hz.<br />

Note:<br />

When conducting an analysis in accordance with DIN 1052, the defl ection on the ideal single<br />

span beam must be determined from the continuous and quasi-continuous load. With a<br />

defl ection of more than 6 mm, a separate analysis must also be performed.<br />

The fi re resistant design of M1 BSP crossplan is carried out in accordance with EN 1995 or<br />

DIN 1052 / 4102 (referred to as thermal design with inclusion of the residual load-bearing<br />

capacity). Charring rate: See technical data on page 6<br />

Version 1 / 2011

STRUCTURAL DESIGN<br />

Material characteristics<br />

(acc. to Z-9.1-638)<br />

Calculation value I eff<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

Description Lay-up A voll A netto I voll I eff (dependent on span between supports of single span beam)<br />

M1 BSP crossplan<br />

Thicknesses<br />

Layers<br />

Bold = parallel to<br />

fi bre direction of<br />

outer layers<br />

Property Numerical value<br />

Strength classes of lamellas C24<br />

Modulus of elasticity parallel<br />

• For the lamella layers parallel in load-bearing direction<br />

E II 1 1000,00 [N / mm2 ]<br />

Modulus of elasticity perpendicular E L 370,00 [N / mm2 ]<br />

Modulus of shear<br />

• As a result of rolling shear stress<br />

G R 50,00 [N / mm2 ]<br />

Rolling shear<br />

• Rolling shear stress of the crosswise layers<br />

(bxd 3 ) /<br />

12<br />

1,00 m 2,00 m 2,50 m 3,00 m 4,00 m 6,00 m 8,00 m<br />

I eff I eff /I Voll I eff I eff /I Voll I eff I eff /I Voll I eff I eff /I Voll I eff I eff /I Voll I eff I eff /I Voll I eff I eff /I Voll<br />

[mm] [ ] [mm] [cm²] [cm²] [cm 4 ] [cm 4 ] [%] [cm 4 ] [%] [cm 4 ] [%] [cm 4 ] [%] [cm 4 ] [%] [cm 4 ] [%] [cm 4 ] [%]<br />

57 3s 19 19 19 570 380 1468 1085 70 1358 88 1401 91 1426 92 1452 94 1471 95 1477 96<br />

78 3s 25 28 25 780 500 3955 2255 57 3211 81 3391 86 3498 88 3612 91 3699 94 3730 94<br />

94 3s 33 28 33 940 660 6922 3664 53 5508 80 5889 85 6123 88 6376 92 6572 95 6644 96<br />

95 5s 19 19 19 19 19 950 570 7145 3248 45 4760 67 5047 71 5219 73 5402 76 5542 78 5592 78<br />

98 3s 32 34 32 980 640 7843 3741 48 5927 76 6408 82 6707 86 7037 90 7294 93 7389 94<br />

106 3s 39 28 39 1060 780 9925 4994 50 7741 78 8347 84 8723 88 9138 92 9463 95 9583 97<br />

118 3s 39 40 39 1180 780 13692 5507 40 9539 70 10564 77 11231 82 11994 88 12612 92 12845 94<br />

134 5s 27 20 40 20 27 1340 940 20051 7772 39 12668 63 13765 69 14451 72 15209 76 15804 79 16025 80<br />

140 5s 33 20 34 20 33 1400 1000 22867 8449 37 14637 64 16139 71 17101 75 18187 80 19056 83 19382 85<br />

146 5s 32 27 28 27 32 1460 920 25934 7959 31 14884 57 16722 64 17936 69 19340 75 20493 79 20931 81<br />

160 5s 40 20 40 20 40 1600 1200 34133 11770 34 21354 63 23872 70 25530 75 27441 80 29006 85 29599 87<br />

173 5s 39 28 39 28 39 1730 1170 43148 11870 28 23466 54 26867 62 29196 68 31978 74 34334 80 35246 82<br />

184 5s 39 33 40 33 39 1840 1180 51913 25658 49 29853 58 32807 63 36425 70 39567 76 40805 79<br />

198 5s 39 40 40 40 39 1980 1180 64687 28216 44 33493 52 37340 58 42207 65 46580 72 48342 75<br />

214 7s 39 19 39 20 39 19 39 2140 1560 81670 54885 67 58399 72 62400 76 65632 80 66848 82<br />

214 7ss 39 39 19 20 19 39 39 2140 1760 81670 54727 67 60359 74 67488 83 73897 90 76478 94<br />

240 7s 39 27 40 28 40 27 39 2400 1580 115200 73025 63 79582 69 85078 74 87195 76<br />

240 7ss 39 40 40 28 40 40 39 2400 1860 115200 76001 66 87804 76 99117 86 103879 90<br />

258 7ss 39 40 33 28 27 27 39 2580 1920 143113 102032 71 117910 82 124844 87<br />

278 7ss 39 40 40 40 40 40 39 2780 1980 179041 118227 66 140134 78 150028 84<br />

All details relate to a 1 m wide panel strip<br />

Avoll total of cross-section<br />

Anetto cross-sectional value for the verifi cation of the compressive strength in the direction of<br />

orientation of the top layer<br />

Ivoll moment of inertia of the full section – as a reference value<br />

Ieff eff ective moment of inertia of the full section – as reference value only<br />

Ieff / Ivoll ratio that specifi es to what extent the cross-wise layers alter the cross-section’s<br />

eff ective moment of inertia<br />

zul τ R<br />

0,45 [N / mm 2 ]<br />

Bending strength zul σ B 10,00 [N / mm2 ]<br />

Tension parallel<br />

• For the lamella layers parallel in load-bearing direction<br />

zul σ Z, II 7,00 [N / mm2 ]<br />

Tension perpendicular zul σ Z, ⊥ 0,05 [N / mm2 ]<br />

Compressive strength parallel<br />

• For the lamella layers in the direction of the grain<br />

zul σ D, II 8,50 [N / mm2 ]<br />

Compressive strength perpendicular<br />

• An increase by 20% is permitted in the case of unobjectionable indentations<br />

zul σ D, ⊥<br />

2,00 [N / mm 2 ]<br />

Mayr-Melnhof Kaufmann 11

M1 BSP crossplan<br />

Design according to<br />

ETA-09 / 0036<br />

General<br />

The following applies for<br />

a 5-layer symmetrical<br />

lay-up:<br />

Flexibility factors γ<br />

12 Mayr-Melnhof Kaufmann<br />

STRUCTURAL DESIGN<br />

Design of the cross-laminated timber may be carried out according to EN 1995-1-1 and EN<br />

1995-1-2 allowing for Appendices 2 to 4 of the European technical approval. Only lamellas<br />

which are arranged in the direction of the mechanical stress may be taken into consideration<br />

for calculation of the characteristic cross-sectional values. Reference must be made to the<br />

characteristic strength and stiff ness of the solid timber according to to Appendix 3 (of European<br />

Technical Approval 09-0036) for designing the components made of cross-laminated timber<br />

in accordance with E 1995-1-1. Diff erent stiff nesses must be taken into consideration in both<br />

main directions for cross-laminated timber with multi-axial spaning in both main directions.<br />

Panel stress of the cross-laminated timber<br />

The eff ective bending stiff ness depends on the eff ective moment of inertia Ieff . Calculation of<br />

the eff ective moment of inertia and therefore of the eff ective bending stiff ness time is carried<br />

out acc. to E 1995-1-1 (Section 9.1.3 and Appendix B):<br />

� Distances between centres of gravity:<br />

with<br />

and<br />

for symmetrical lay-up<br />

The fl exibility factors γ allow for the shear deformation (rolling shear) of the cross-wise layers,<br />

the expression of EN 1995-1-1 should be replaced by<br />

� The fl exibilities thus arise from:<br />

� where:<br />

E 1,3 = 11600 N / mm² modulus of elasticity for C24<br />

G 9090 = 50 N / mm² modulus of shear for C24<br />

l = decisive width between supports<br />

where<br />

where<br />

t tot<br />

individual moment of inertia of longitudinal layers i = 1 to 3<br />

areas of the longitudinal layers<br />

t 1<br />

t 2<br />

t 3<br />

b<br />

t 1<br />

t 2<br />

Version 1 / 2011

STRUCTURAL DESIGN<br />

Slab stress of the<br />

cross-laminated timber<br />

Panel load<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

The following equations may be used for stress in the panel plane (slab stress) under the<br />

requirements of the technical column theory:<br />

Thickness of the lamella layers in the direction of stress<br />

Thickness of the lamella layers normal to the direction of stress<br />

� Distances between centres of gravity:<br />

Maximum<br />

where<br />

Design value of the shear force<br />

Calculation of the bending stresses and bending stiff ness may be carried out using the full<br />

section of the lamella layers in the direction of stress. When calculating the shear stresses,<br />

the net area with the smaller cross-section of the two stress directions is decisive.<br />

Material characteristics according to ETA-09 / 0036<br />

Property Numerical value<br />

Strength classes of lamellas<br />

Modulus of elasticity:<br />

C24<br />

• Parallel to fi bre direction of lamellas E0, mean<br />

11600,00 N / mm<br />

• Perpendicular to fi bre direction E90, mean<br />

2<br />

370,00 N / mm2 Modulus of shear:<br />

• Parallel to fi bre direction of lamellas G 090, mean<br />

• Perpendicular to the fi bre direction of the lamellas, modulus of rolling<br />

shear G 9090, mean<br />

Bending strength:<br />

• Parallel to fi bre direction of lamellas f m, k<br />

• f m, k may be increased to to 28,8 N/mm 2 for C 24 (f m, CLT, k) in accordance with the<br />

approval referred to above<br />

Tensile strength:<br />

• Perpendicular to the fi bre direction of the lamellas f t, 90, k<br />

Compressive strength:<br />

• Perpendicular to the fi bre direction of the lamellas f c, 90, k<br />

Shear strength:<br />

• Parallel to fi bre direction of lamellas f v, 090, k<br />

• Perpendicular to the fi bre direction of the lamellas (rolling shear strength) f v, 9090, k<br />

t1 t2 t1 t2 t3 650,00 N / mm 2<br />

50,00 N / mm 2<br />

24,00 N / mm 2<br />

0,12 N / mm 2<br />

2,50 N / mm 2<br />

2,50 N / mm 2<br />

1,10 N / mm 2<br />

Mayr-Melnhof Kaufmann 13<br />

H

M1 BSP crossplan<br />

Slab load<br />

Connecting means<br />

according to<br />

ETA-09 / 0036<br />

14 Mayr-Melnhof Kaufmann<br />

STRUCTURAL DESIGN<br />

Property Numerical value<br />

Strength classes of lamellas<br />

Modulus of elasticity:<br />

C24<br />

• Parallel to fi bre direction of lamellas E0, mean<br />

11600,00 N / mm2 Modulus of shear:<br />

• Parallel to fi bre direction of lamellas G 090, mean<br />

Bending strength:<br />

• Parallel to fi bre direction of lamellas f m, k<br />

Tensile strength:<br />

• Parallel to fi bre direction of lamellas f t, 90, k<br />

Compressive strength:<br />

• Parallel to fi bre direction of lamellas f c, 90, k<br />

Shear strength:<br />

• Parallel to fi bre direction of lamellas f v, 090, k<br />

250,00 N / mm 2<br />

24,00 N / mm 2<br />

14,00 N / mm 2<br />

21,00 N / mm 2<br />

5,00 N / mm 2<br />

The load-carrying connection of M1BSP crossplan elements must be carried out separately<br />

and using suitable joining means for each building task. The design of the connecting means<br />

(diameter, number und distances) should be within the responsibility of a specialist familiar<br />

with cross-laminated timber.<br />

As a recommendation for determining the design values, reference is made to «Bemessungsvorschläge<br />

für Verbindungsmittel in Brettsperrholz» [Design Suggestions for Joining Means<br />

in Cross-laminated Timber] [from Bauen mit Holz [Building with Timber] 111 (2009), BLASS<br />

Hans Joachim, UIBEL Thomas] and to Expert Opinion no. GU07-4-2-1-01 and GU11-402-1 of<br />

the Technical University of Graz. Specifi ed here are the embedment strengths for screwed<br />

and nailed joints, dowel pins, fi t bolts and bolts, in addition to a design suggestion for axial<br />

stress (tension).<br />

A distinction should be made between joints in the narrow surfaces and those in the lateral<br />

surface when referring to joints. The static analyses of the joints must be conducted in<br />

accordance with EN 13501 -1-1.<br />

Version 1 / 2011

STRUCTURAL DESIGN<br />

Minimum distances<br />

between connecting<br />

means in the lateral<br />

surfaces<br />

Minimum distances<br />

between connecting<br />

means in the narrow<br />

surfaces<br />

F<br />

a1, c<br />

a2, c<br />

t i<br />

t M1 BSP<br />

a1<br />

a2, c<br />

a1, t<br />

Sample calculations<br />

Version 1 / 2011<br />

F<br />

F<br />

M1 BSP crossplan<br />

a1,t a1,c a1 a2,t a2,c a2 Screws1) 6 × d 6 × d 4 × d 6 × d 2,5 × d 2,5 × d<br />

Nails (7+3 × cosα) × d 6 × d (3+3 × cosα) × d (3+4 × sinα) × d 3 × d 3 × d<br />

Dowel pins<br />

5 × d 4 × d × sinα (3+3 × cosα) × d 3 × d 3 × d 3 × d<br />

Fit bolts<br />

(min. 3 × d)<br />

Bolts<br />

Screws 1)<br />

α<br />

a1, t<br />

a2<br />

a2<br />

5 × d 6 × d (3+3 × cosα) × d<br />

(min. 4 × d)<br />

Minimum thickness<br />

of decisive lamella layer<br />

t 1 in mm<br />

d > 8 mm : 3 × d<br />

d ≤ 8 mm : 2 × d<br />

Minimum thickness<br />

of cross-laminated timber<br />

t BSP in mm<br />

3 × d 3 × d 4 × d<br />

a 1,t a 1,c a 1 a 2,t a 2<br />

Screws1) 12 × d 7 × d 10 × d 5 × d 3 × d<br />

Dowel pins<br />

Fit bolts<br />

5 × d 3 × d 4 × d 3 × d 3 × d<br />

Bolts 5 × d 4 × d 4 × d 3 × d 4 × d<br />

Minimum anchoring depth<br />

of joining means in narrow<br />

surfaces t 1 or t 2 in mm<br />

10 × d 10 × d<br />

Dowel pins<br />

Fit bolts<br />

d 6 × d 5 × d<br />

Bolts d 6 × d 5 × d<br />

α Angle between force and fi bre direction of top layers<br />

1) Self-tapping wood screws<br />

t 1 Minimum anchoring depth of the joining means in the narrow surfaces of the lateral timber<br />

or lateral timber thickness<br />

t 2 Minimum anchoring depth of the joining means in the narrow surfaces of the central timber<br />

a1, c<br />

α<br />

To make the calculation method of ETA 09-0036 clear, calculation examples with explanatory<br />

demonstration of proof according to EN 1995-1-1 may be found in the download area at<br />

www.mm-kaufmann.com.<br />

F<br />

a1<br />

F<br />

a2<br />

a2, c<br />

a2, t<br />

α<br />

F<br />

Mayr-Melnhof Kaufmann 15<br />

F

M1 BSP crossplan<br />

General<br />

Structural system<br />

Single span beam<br />

Determination of the<br />

permissible load q<br />

for the required width<br />

between supports<br />

Maximum defl ection:<br />

L / 400<br />

Direction of span parallel to<br />

fi bre direction of top layer<br />

perm. load q k [kN / m²]<br />

perm. load q k [kN / m²]<br />

16 Mayr-Melnhof Kaufmann<br />

q = g 2 + p [kN / m 2 ]<br />

g 1 = dead weight of the panel; allowed for in the diagram<br />

g 2 = ceiling build-up<br />

p = live load<br />

Single span beam under uniform load q k ; max f = L / 400<br />

Width between supports L [m]<br />

Width between supports L [m]<br />

DESIGN CHARTS<br />

The tables referred to serve for the preliminary design and do not replace a structural calculation.<br />

p<br />

g = g 1 + g 2<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

0,0<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

0,0<br />

2,0<br />

4,0<br />

2,5<br />

L<br />

3,0<br />

3,5<br />

4,0<br />

4,5<br />

max 3,00 m<br />

5,0<br />

5,5<br />

6,0<br />

max 16,50 m<br />

78 3S DL 98 3S DL 118 3S DL 134 5S DL 140 5S DL 146 5S DL 160 5S DL 173 5S DL<br />

184 5S DL 198 5S DL 214 7S DL 214 7SS DL 240 7S DL 240 7SS DL 258 7SS DL 278 7SS DL<br />

4,5<br />

5,0<br />

5,5<br />

6,0<br />

6,5<br />

7,0<br />

7,5<br />

8,0<br />

6,5<br />

8,5<br />

7,0<br />

9,0<br />

7,5<br />

9,5<br />

Version 1 / 2011<br />

8,0<br />

10,0

DESIGN CHARTS<br />

General<br />

Structural system<br />

Single span beam<br />

Determination of the<br />

permissible load q<br />

for the required width<br />

between supports<br />

Maximum defl ection:<br />

L / 300<br />

Direction of span parallel to<br />

fi bre direction of top layer<br />

Version 1 / 2011<br />

perm. load q k [kN / m²]<br />

perm. load q k [kN / m²]<br />

q = g 2 + p [kN / m 2 ]<br />

g 1 = dead weight of the panel; allowed for in the diagram<br />

g 2 = ceiling buid-up<br />

p = live load<br />

Single span beam under uniform load q k ; max f = L / 300<br />

M1 BSP crossplan<br />

The tables referred to serve for the preliminary design and do not replace a structural calculation.<br />

p<br />

g = g 1 + g 2<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

0,0<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

0,0<br />

2,0<br />

4,0<br />

2,5<br />

L<br />

3,0<br />

3,5<br />

4,0<br />

4,5<br />

max 3,00 m<br />

5,0<br />

5,5<br />

6,0<br />

max 16,50 m<br />

78 3S DL 98 3S DL 118 3S DL 134 5S DL 140 5S DL 146 5S DL 160 5S DL 173 5S DL<br />

4,5<br />

5,0<br />

5,5<br />

6,0<br />

Width between supports L [m]<br />

184 5S DL 198 5S DL 214 7S DL 214 7SS DL 240 7S DL 240 7SS DL 258 7SS DL 278 7SS DL<br />

6,5<br />

7,0<br />

7,5<br />

Width between supports L [m]<br />

8,0<br />

6,5<br />

8,5<br />

7,0<br />

9,0<br />

7,5<br />

9,5<br />

Mayr-Melnhof Kaufmann 17<br />

8,0<br />

10,0

M1 BSP crossplan<br />

General<br />

Structural system<br />

Double span beam<br />

Determination of the<br />

permissible load q<br />

for the required width<br />

between supports<br />

Maximum defl ection:<br />

L / 400<br />

Direction of span parallel to<br />

fi bre direction of top layer<br />

perm. load q k [kN / m²]<br />

perm. load q k [kN / m²]<br />

18 Mayr-Melnhof Kaufmann<br />

Double span beam under uniform load q k ; max f = L / 400<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

0,0<br />

20,0<br />

19,0<br />

18,0<br />

17,0<br />

16,0<br />

15,0<br />

14,0<br />

13,0<br />

12,0<br />

11,0<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

2,5<br />

3,0<br />

3,5<br />

4,0<br />

4,5<br />

max 3,00 m<br />

5,0<br />

DESIGN CHARTS<br />

The tables referred to serve for the preliminary design and do not replace a structural calculation.<br />

p<br />

g = g 1 + g 2<br />

4,0<br />

L L<br />

q = g 2 + p [kN / m 2 ]<br />

g 1 = dead weight of the panel; allowed for in the diagram<br />

g 2 = live load, under worst case conditions<br />

p < 2q / 3<br />

4,5<br />

5,0<br />

5,5<br />

6,0<br />

5,5<br />

6,5<br />

6,0<br />

max 16,50 m<br />

78 3S DL 98 3S DL 118 3S DL 134 5S DL 140 5S DL 146 5S DL 160 5S DL 173 5S DL<br />

Width between supports L [m]<br />

184 5S DL 198 5S DL 214 7S DL 214 7SS DL 240 7S DL 240 7SS DL 258 7SS DL 278 7SS DL<br />

Width between supports L [m]<br />

6,5<br />

7,0<br />

7,0<br />

7,5<br />

7,5<br />

8,0<br />

8,0<br />

Version 1 / 2011

DESIGN CHARTS<br />

General<br />

Structural system<br />

Double span beam<br />

Determination of the<br />

permissible load q<br />

for the required width<br />

between supports<br />

Maximum defl ection:<br />

L / 300<br />

Direction of span parallel to<br />

fi bre direction of top layer<br />

Version 1 / 2011<br />

perm. load q k [kN / m²]<br />

perm. load q k [kN / m²]<br />

Double span beam under uniform load q k ; max f = L / 300<br />

12,0<br />

11,0<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

0,0<br />

29,0<br />

27,0<br />

25,0<br />

23,0<br />

21,0<br />

19,0<br />

17,0<br />

15,0<br />

13,0<br />

11,0<br />

9,0<br />

7,0<br />

5,0<br />

2,0<br />

2,5<br />

3,0<br />

3,5<br />

4,0<br />

4,5<br />

M1 BSP crossplan<br />

The tables referred to serve for the preliminary design and do not replace a structural calculation.<br />

p<br />

g = g 1 + g 2<br />

4,0<br />

L L<br />

q = g 2 + p [kN / m 2 ]<br />

g 1 = dead weight of the panel; allowed for in the diagram<br />

g 2 = live load, under worst case conditions<br />

p < 2q / 3<br />

4,5<br />

5,0<br />

5,5<br />

max 3,00 m<br />

5,0<br />

6,0<br />

5,5<br />

6,5<br />

6,0<br />

max 16,50 m<br />

78 3S DL 98 3S DL 118 3S DL 134 5S DL 140 5S DL 146 5S DL 160 5S DL 173 5S DL<br />

Width between supports L [m]<br />

184 5S DL 198 5S DL 214 7S DL 214 7SS DL 240 7S DL 240 7SS DL 258 7SS DL 278 7SS DL<br />

Width between supports L [m]<br />

6,5<br />

7,0<br />

7,0<br />

7,5<br />

7,5<br />

8,0<br />

Mayr-Melnhof Kaufmann 19<br />

8,0

M1 BSP crossplan<br />

General<br />

Structural system<br />

Triple span beam<br />

Determination of the<br />

permissible load q<br />

for the required width<br />

between supports<br />

Maximum defl ection:<br />

L / 400<br />

Direction of span parallel to<br />

fi bre direction of top layer<br />

perm. load q k [kN / m²]<br />

p<br />

g = g + g 1 2<br />

20 Mayr-Melnhof Kaufmann<br />

q = g 2 + p [kN / m 2 ]<br />

g 1 = dead weight of the panel; allowed for in the diagram<br />

g 2 = ceiling build-up<br />

p = live load, under worst case conditions<br />

p < 2q / 3<br />

Triple span beam under uniform load q k ; max f = L / 400<br />

15,0<br />

14,0<br />

13,0<br />

12,0<br />

11,0<br />

10,0<br />

9,0<br />

8,0<br />

7,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,0<br />

0,0<br />

35,0<br />

33,0<br />

31,0<br />

29,0<br />

27,0<br />

25,0<br />

23,0<br />

21,0<br />

19,0<br />

17,0<br />

15,0<br />

13,0<br />

11,0<br />

9,0<br />

7,0<br />

5,0<br />

2,0<br />

2,5<br />

3,0<br />

3,5<br />

max 3,00 m<br />

DESIGN CHARTS<br />

The tables referred to serve for the preliminary design and do not replace a structural calculation.<br />

3,5<br />

4,0<br />

max 16,50 m<br />

78 3S DL 98 3S DL 118 3S DL 134 5S DL 140 5S DL 146 5S DL 160 5S DL 173 5S DL<br />

184 5S DL 198 5S DL 214 7S DL 214 7SS DL 240 7S DL 240 7SS DL 258 7SS DL 278 7SS DL<br />

4,0<br />

4,5<br />

Width between supports L [m]<br />

4,5<br />

5,0<br />

5,0<br />

5,5<br />

5,5<br />

Version 1 / 2011

DESIGN CHARTS<br />

General<br />

Vertical load on wall<br />

Structural system:<br />

M1 BSP crossplan wall<br />

under vertical load;<br />

R30 / one-sided<br />

Version 1 / 2011<br />

perm. load N k [kN / m]<br />

900,0<br />

800,0<br />

700,0<br />

600,0<br />

500,0<br />

400,0<br />

300,0<br />

200,0<br />

100,0<br />

0,00<br />

1,00 m<br />

2,00 m<br />

M1 BSP crossplan<br />

The tables referred to serve for the preliminary design and do not replace a structural calculation.<br />

• Determination of the permissible vertical load N in relation to 1,0 m wall width.<br />

• Wall pillars must be considered separately<br />

• Load assumptions - wind load: 1,0 kN / m²<br />

• Classifi cation REI 30 / one-sided<br />

• EI according to classifi cations<br />

h<br />

w k = 1,0 kN/m<br />

zul N k<br />

Top layer in vertical direction<br />

max 3,00 m<br />

max 16,50 m<br />

95 5S DQ 98 3S DQ 118 3S DQ 134 5S DQ 146 5S DQ 160 5S DQ<br />

Wall height<br />

2,50 m<br />

3,00 m<br />

Mayr-Melnhof Kaufmann 21

M1 BSP crossplan<br />

Enquiry<br />

Preparation of quote<br />

Order confi rmation<br />

and production release<br />

22 Mayr-Melnhof Kaufmann<br />

ORDER PROCESSING<br />

We off er our partners quality, reliability and an innovative range of high-quality products. Our<br />

aim, therefore, is to make the processing of enquiries and orders as clear and effi cient as<br />

possible.<br />

The quality and level of detail in our quotes depend on the details in the enquiry and the<br />

validity of the tender texts (e.g. measurement details, span widths, load systems, snow loads,<br />

dimensioning, etc.).<br />

a) Basic tender text<br />

Quotes based on enquiries specifying only overall square metres and without detailed<br />

plans involve inaccuracy of up to 10% (cost estimates). The dimensioning of the panels is<br />

only possible with appropriate detailed information (loads and span widths).<br />

b) Building permission plan<br />

A building permission drawing has a higher validity than the basic tender text. It is possible<br />

to produce an accurate quote at short notice if appropriate measurements, construction<br />

details and regional information for assumption of the snow loads are provided.<br />

c) CAD drawings<br />

On the basis of clearly defi ned dimensions of the panels we are able to prepare a binding<br />

quote immediately.<br />

The exact delivery location and maximum panel sizes are decisive for calculating the freight<br />

costs.<br />

Our order confi rmation is issued once the customer has placed the order. This confi rmation<br />

contains the fi nished project design including element usage and exact representation of<br />

the elements in the form of planning documents. All measurements, surface conditions and<br />

machining measures are thus clearly defi ned.<br />

This data is given to the customer with a request for counter-signature. The counter-signature<br />

is valid as the customer’s approval for planning and production and as the start of the delivery<br />

period specifi ed.<br />

Version 1 / 2011

LOADING SEQUENCE<br />

Loading plans<br />

Loading sequence in accordance<br />

with customer’s request.<br />

Mayr-Melnhof Kaufmann may<br />

deviate from the loading sequence<br />

in the case of technical impracticability.<br />

The lorry will be loaded at our own<br />

discretion without specifying the<br />

loading sequence.<br />

The transport costs include 2,5<br />

hours for unloading of the lorry.<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

At the same time as approval is given for production, detailed loading plans are drawn up in<br />

consultation with the customer. Agreement must be reached here between the customer’s<br />

wishes and the practical possibilities of unloading.<br />

The legal regulations regarding securing of the cargo have been tightened up considerably<br />

recently and compliance with them is inspected very carefully, the result being that unfortunately<br />

it is often necessary to deviate from the best loading sequences.<br />

max. 4.000<br />

1.200<br />

Delivery address:<br />

Delivery date: Week:<br />

Day:<br />

Time:<br />

Contact:<br />

Tel.:<br />

4100<br />

3000<br />

1100<br />

Delivery address:<br />

Delivery date: Week:<br />

Day:<br />

Time:<br />

Contact:<br />

Tel.:<br />

950 950<br />

13.600<br />

Loading sequence<br />

Deliver off cuts: � Yes / � No<br />

Type of unloading: � Crane / � forklift<br />

Max. package size: kg<br />

Max. lorry load: 50 m 3 / 24 t<br />

Max. element size: 3,0 x 16,5 m<br />

Excess width: from 2,5 m<br />

Lorry no.:<br />

Deliver off cuts: � Yes / � No<br />

Max. package size: kg<br />

Max. lorry load: 50 m 3 / 24 t<br />

Max. element size: 3,0 x 16,5 m<br />

Excess width: from 2,5 m<br />

Lorry no.:<br />

Mayr-Melnhof Kaufmann 23

M1 BSP crossplan<br />

Transport procedure<br />

Flatwise transport<br />

Upright transport<br />

Storage<br />

Lifting devises<br />

24 Mayr-Melnhof Kaufmann<br />

TRANSPORT<br />

The transport will be scheduled once the loading plans and delivery dates have been defi ned.<br />

Special transports are almost always necessary because most of the loads contain components<br />

with lengths exceeding 13,60 m and / or widths or heights exceeding 2,50 m.<br />

These special tranports require national and international road use permits and should,<br />

therefore, only be carried out by carriers familiar with them and equipped for the task.<br />

The transport costs referred to include 2,5 hours for unloading of the lorry at the building site.<br />

Each additional hour of the lorry’s waiting time will be invoiced additionally if delays occur<br />

during unloading.<br />

The elements may be transported either upright or fl at.<br />

Component deliveries lying fl at are particularly appropriate for panels with less machining<br />

(e.g. ceiling elements) or raw panels. This is also the more cost-eff ective variation for widths<br />

up to 3,00 m as platform semi-trailers may be used without additional structures. Appropriate<br />

ex works protection against dirt is guaranteed by packaging in plastic foil.<br />

Upright element transport is used primarily for material with a high level of machining such<br />

as walls with window and door cut-outs, visible components, and similar. The use of fl atbed<br />

semi-trailers with appropriate loading area structures is, however, more expensive than transport<br />

elements lying fl at using platform semi-trailers.<br />

The basic principles of timber storage must be observed where it is necessary to store<br />

M1 BSP crossplan.<br />

M1 BSP crossplan elements may be provided with assembly aids. These are used to manipulate<br />

the elements at the plant and on the building site. Loops or special screw systems will be<br />

used depending on the type of component and size. The number of assembly aids attached<br />

depends on the safety requirements and the measurements of the relevant components.<br />

Version 1 / 2011

INVOICING SYSTEM<br />

Invoicing<br />

Surcharges<br />

Version 1 / 2011<br />

M1 BSP crossplan<br />

The basis of every M1 BSP crossplan invoice is the unit m 2 and the surface condition in industrial<br />

quality.<br />

The smallest circumscribed rectangle based on the fi nished dimension of the nearest grid<br />

width is always applicable as the invoicing area. This gross measuring system also includes<br />

recalculation of all openings typical of residential buildings. Generally speaking, the basic<br />

calculation includes free, right-angled cutting to format of each element.<br />

All additional services are presented in a transparent surcharge system to make the pricing<br />

policy easy and clear for the customer.<br />

1. Surface condition:<br />

Additional price for one-sided surface in standard quality. Price basis per m 2<br />

Additional price for two-sided surface in standard quality. Price basis per m 2<br />

2. Element machining:<br />

Additional price for machining operations such as door and window openings, bevel cuts<br />

in the gable region, cut to length and notches in a number typical for residential buildings.<br />

Price basis per m 2<br />

3. Rebates and profi les:<br />

Milling of all conventional rebate systems such as butt board rebates and stepped rebates<br />

in all element widths. Price basis per linear metre.<br />

4. Assembly aids:<br />

Supply of appropriate aids for safe manipulation and assembly of wall and ceiling elements.<br />

Price basis per unit.<br />

5. Transport:<br />

Documentation of the transportation charges. Price basis per transport<br />

6. Special custom joinery:<br />

Additional price for custom joinery works (e.g. special drilled holes, mortices, etc.) using<br />

5-axis machining robot, invoiced according to actual time and expenses. Price basis<br />

all-in price<br />

7. Special surfaces:<br />

Additional pricing for customized orders, such as diff erent wood species, special<br />

surfaces and other customized requests. Price basis per m²<br />

Mayr-Melnhof Kaufmann 25

M1 BSP crossplan<br />

AW 01<br />

I<br />

outside inside<br />

AW 02<br />

outside inside<br />

AW 03<br />

outside inside<br />

AW 04<br />

outside inside<br />

26 Mayr-Melnhof Kaufmann<br />

Wall cross-section from<br />

outside to inside<br />

CONSTRUCTION DETAILS<br />

WALL CONSTRUCTION<br />

Thickness<br />

mm<br />

Timber larch cladding 20,0<br />

Timber spruce battens (30 / 60) 30,0<br />

Vapour-permeable membrane<br />

Sd ≤ 0,3 m<br />

–<br />

Wood fi bre insulation board 100,0<br />

M1 BSP crossplan 95,0<br />

Gypsum fi breboard (12,5 mm) 12,5<br />

Overall<br />

thickness mm<br />

Fire protection Sound<br />

insulation<br />

258 REI 90*<br />

Airborne noise<br />

R W 42 dB<br />

Exterior wall / with timber façade / not ventilated / with service layer<br />

Exterior wall / with plaster façade / not ventilated / with service layer<br />

Wall cross-section from<br />

outside to inside<br />

Thickness<br />

mm<br />

Plaster 4,0<br />

Rockwool MW-PT<br />

120,0<br />

Plaster-base sheeting<br />

M1 BSP crossplan 98,0<br />

Timber spruce battens (40 / 50)<br />

on bracket<br />

70,0<br />

Glasswool [0,040; R = 16]<br />

d = 50 mm<br />

Gypsum fi breboard (2 × 12,5 mm)<br />

or Gypsum fi breboard (2 × 10 mm)<br />

25,0<br />

Overall<br />

thickness mm<br />

Fire protection Sound<br />

insulation<br />

317 REI 120*<br />

Airborne<br />

noise<br />

R W 53 DB<br />

Thermal<br />

insulation<br />

U value<br />

0,35 [W / m 2 K]<br />

Wall cross-section from<br />

Thickness Overall Fire protection Sound Thermal<br />

outside to inside<br />

mm thickness mm<br />

insulation insulation<br />

Exterior wall cladding 20,0<br />

339 REI 90*<br />

Airborne<br />

noise<br />

RW 51 DB<br />

U value<br />

0,19 [W / m2 Timber spruce battens (30 / 60) 30,0<br />

Vapour-permeable membrane Sd ≤ 0,3 M –<br />

Timber spruce battens (50 / 60)<br />

Rockwool [0,040; R ≥ 70]<br />

50,0<br />

Timber battens spruce (80 / 60)<br />

Rockwool [0,040; R ≥ 70]<br />

M1 BSP crossplan<br />

Timber spruce battens (40 / 50)<br />

80,0<br />

98,0<br />

K]<br />

on bracket<br />

Rockwool [0,040; R ≥ 28] d = 50<br />

50,0<br />

Gypsum fi breboard (12,5 mm) or<br />

Gypsum fi breboard (10 mm)<br />

12,5<br />

Thermal<br />

insulation<br />

U value<br />

0,20 [W / m 2 K]<br />

Exterior wall / with plaster façade / not ventilated / without service layer<br />

Wall cross-section from<br />

outside to inside<br />

Thickness<br />

mm<br />

Plaster 4,0<br />

Rockwool MW-PT<br />

Plaster-base sheeting<br />

120,0<br />

M1 BSP crossplan 95,0<br />

Overall<br />

thickness mm<br />

* according classifi cation reports M1 BSP crossplan of HFA<br />

Fire protection Sound<br />

insulation<br />

219 REI 60*<br />

Airborne noise<br />

R W 38 DB<br />

Source: www.dataholz.com, catalogue «Bauphysikalisch geprüfter Bauteile für den Holzbau»<br />

Thermal<br />

insulation<br />

U value<br />

0,26 [W / m 2 K]<br />

Version 1 / 2011

CONSTRUCTION DETAILS<br />

WALL CONSTRUCTION<br />

Partition wall / without service layer<br />

Wall cross-section from<br />

left to right<br />

Partition wall / without service layer<br />

Partition wall / with service layer<br />

Wall cross-section from<br />

left to right<br />

Partition wall / with service layer<br />

Version 1 / 2011<br />

Thickness<br />

mm<br />

Gypsum fi breboard 12,5 mm 12,5<br />

M1 BSP crossplan 95,0<br />

Impact noise insulation panel MW-T 30,0<br />

M1 BSP crossplan<br />

Timber spruce battens (40 / 50)<br />

95,0<br />

on bracket<br />

Glass wool [0,040; R = 16]<br />

d = 50 mm<br />

50,0<br />

Gypsum fi breboard 12,5 mm 12,5<br />

Wall cross-section from<br />

left to right<br />

Thickness<br />

mm<br />

M1 BSP crossplan 95,0<br />

Impact noise insulation panel<br />

MW-T<br />

30,0<br />

M1 BSP crossplan 95,0<br />

Wall cross-section from<br />

left to right<br />

Thickness<br />

mm<br />

Gypsum fi breboard 12,5 mm 12,5<br />

M1 BSP crossplan 95,0<br />

Impact noise insulation panel MW-T 30,0<br />

M1 BSP crossplan 95,0<br />

Gypsum fi breboard 12,5 mm<br />

Construction without gypsum<br />

fi breboards<br />

12,5<br />

Thickness<br />

mm<br />

Gypsum fi breboard 12,5 mm 12,5<br />

Rockwool [0,04I; R = 27] d = 60 mm<br />

Timber spruce battens (40/50) 70,0<br />

on bracket<br />

M1 BSP crossplan 98,0<br />

Timber spruce battens (40/50)<br />

on bracket<br />

70,0<br />

Rockwool [0,04I; R = 27] d = 60 mm<br />

Gypsum fi breboard 12,5 mm 12,5<br />

Overall<br />

thickness mm<br />

220 REI 60*<br />

Overall<br />

thickness mm<br />

245<br />

Overall<br />

thickness mm<br />

Fire protection Sound<br />

insulation<br />

295 REI 90*<br />

Overall<br />

thickness mm<br />

* according classifi cation reports M1 BSP crossplan of HFA<br />

Fire protection Sound<br />

insulation<br />

Fire protection<br />

263 REI 90*<br />

Airborne noise<br />

R W 48 dB<br />

Fire protection Sound<br />

insulation<br />

REI 90*<br />

Airborne noise<br />

R W 56 dB<br />

Airborne noise<br />

R W 62 DB<br />

Sound<br />

insulation<br />

Airborne noise<br />

R W 58 DB<br />

M1 BSP crossplan<br />

Thermal<br />

insulation<br />

U value<br />

0,39<br />

[W / m 2 K]<br />

Thermal<br />

insulation<br />

U value<br />

0,38 [W / m 2 K]<br />

220 48 dB 0,39 [W / m 2 K]<br />

Source: www.dataholz.com, catalogue «Bauphysikalisch geprüfter Bauteile für den Holzbau»<br />

Thermal<br />

insulation<br />

U value<br />

0,27 [W / m2K] Thermal<br />

insulation<br />

U value<br />

0,25 [W / m 2 K]<br />

WTW 01<br />

inside inside<br />

WTW 02<br />

inside inside<br />

WTW 03<br />

inside inside<br />

WTW 04<br />

inside inside<br />

Mayr-Melnhof Kaufmann 27

M1 BSP crossplan<br />

IW 01<br />

inside inside<br />

IW 02<br />

inside inside<br />

FD 01<br />

outside<br />

inside<br />

FD 02<br />

outside<br />

inside<br />

28 Mayr-Melnhof Kaufmann<br />

Interior wall / without service layer<br />

Wall cross-section from<br />

outside to inside<br />

Interior wall / without service layer<br />

CONSTRUCTION DETAILS<br />

WALL CONSTRUCTION<br />

Thickness<br />

mm<br />

Overall<br />

thickness mm<br />

Flat roof / suspended / without rear ventilation<br />

Flat roof / suspended / without rear ventilation<br />

Fire<br />

protection<br />

M1 BSP crossplan 95,0 95 REI 60*<br />

Wall cross-section from<br />

outside to inside<br />

Wall cross-section from<br />

outside to inside<br />

Thickness<br />

mm<br />

Gravel fi ll<br />

Separating fl eece [Sd ≤ 0,2M]<br />

50,0<br />

Extruded polystyrene 80,0<br />

Bituminous cardboard 9,0<br />

Rockwool [0,040; R = 16]<br />

Vapour barrier Sd ≥ I500M<br />

150,0<br />

M1 BSP crossplan ceiling or<br />

acc. to structural requirement<br />

140<br />

Timber spruce battens suspended<br />

Glasswool [0,040; R = 16] d = 50 mm<br />

70,0<br />

Gypsum fi breboard 12,5<br />

Wall cross-section from<br />

outside to inside<br />

Thickness<br />

mm<br />

Gypsum fi breboard 1 x 12,5 mm 25,0<br />

M1 BSP crossplan 78,0<br />

Gypsum fi breboard 1 x 12,5 mm 25,0<br />

Thickness<br />

mm<br />

Roofi ng membrane<br />

Fibre insulation board 2 x 100 mm 200,0<br />

Vapour barrier bituminous<br />

(= emergency roof)<br />

M1 BSP crossplan<br />

0,2<br />

Ceiling 118 mm or according<br />

to structural requirement<br />

118<br />

Bracket / air space 50,0<br />

Gypsum fi breboard 12,5<br />

Overall<br />

thickness mm<br />

Overall<br />

thickness mm<br />

Fire<br />

protection<br />

512 REI 90*<br />

Overall<br />

thickness mm<br />

* according classifi cation reports M1 BSP crossplan of HFA<br />

Fire<br />

protection<br />

128 REI 60*<br />

Fire<br />

protection<br />

381 REI 60*<br />

Sound<br />

insulation<br />

Airborne noise<br />

R W 33 dB<br />

Sound<br />

insulation<br />

Airborne noise<br />

R W 38 dB<br />

Source: www.dataholz.com, catalogue «Bauphysikalisch geprüfter Bauteile für den Holzbau»<br />

Sound<br />

insulation<br />

Airborne<br />

noise<br />

R W 47 dB<br />

Sound<br />

insulation<br />

Airborne<br />

noise<br />

R W 47 dB<br />

Thermal<br />

insulation<br />

U value<br />

1,1 [W / m 2 K]<br />

Thermal<br />

insulation<br />

U value<br />

0,87 [W / m 2 K]<br />

Thermal<br />

insulation<br />

U value<br />

0,12 [W / m 2 K]<br />

Thermal<br />

insulation<br />

U value<br />

0,15 [W / m 2 K]<br />

Version 1 / 2011

CONSTRUCTION DETAILS<br />

CEILING CONSTRUCTION<br />

Floor / dry / not suspended<br />

Floor cross-section<br />

Thickness<br />

top to bottom<br />

mm<br />

Gypsum fi breboard 10,0<br />

Heraklith-Floor (gypsum fi breboard) 10,0<br />

Heraklith-Floor (Lightweight wood<br />

wool building board)<br />

75,0<br />

Heralan TPS 15 / 13<br />

Impact noise insulation<br />

13,0<br />

Fill (grit) 50,0<br />

Drip protection fi lm –<br />

M1 BSP crossplan (or according<br />

to structural requirement)<br />

160,0<br />

Floor / wet / suspended<br />

Floor cross-section<br />

Thickness<br />

top to bottom<br />

mm<br />

Cement screed / anhydrite screed 50,0<br />

Separating layer plastic sheeting –<br />

Impact noise insulation MW-T 30,0<br />

Polystyrene EPS-W (0,041) 30,0<br />

Fill (grit) 50,0<br />

Drip protection fi lm –<br />

M1 BSP crossplan (or acc. to<br />

structural requirement)<br />

140,0<br />

Timber battens on insulating strips 24,0<br />

Gypsum fi breboard 12,5<br />

Floor cross-section<br />

top to bottom<br />

Cement screed / anhydrite<br />

screed<br />

Separating layer plastic<br />

sheeting<br />

Impact noise insulation<br />

MW-T 35 / 30<br />

M1 BSP crossplan (or acc.<br />

to structural requirement)<br />

Floor / dry / suspended<br />

Version 1 / 2011<br />

Thickness<br />

mm<br />

50,0<br />

–<br />

30,0<br />

118,0<br />

Floor cross-section Thickness<br />

top to bottom<br />

mm<br />

OSB tongue and groove panel 18,0<br />

Heraklith BM<br />

Separating layer<br />

25,0<br />

Heralan-DF 60,0<br />

Grit fi ll<br />

M1 BSP crossplan<br />

60,0<br />

Ceiling 160 mm or according<br />

to static requirement<br />

160,0<br />

Heraklith BM 25,0<br />

Spring rail 50,0<br />

Gypsum fi breboard 12,5 mm 12,5<br />

Overall<br />

thickness mm<br />

Fire<br />

protection<br />

318 REI 90*<br />

Overall<br />

thickness mm<br />

Overall<br />

thickness mm<br />

Fire<br />

protection<br />

337 REI 60*<br />

Fire<br />

protection<br />

198 REI 60*<br />

Overall<br />

thickness mm<br />

Fire<br />

protection<br />

411 REI 90*<br />

Sound<br />

insulation<br />

Airborne noise<br />

R W 65 dB<br />

Impact noise<br />

L'nTw 50 dB<br />

Sound<br />

insulation<br />

Airborne noise<br />

R W 60 dB<br />

Impact noise<br />

L'nTw 48 dB<br />

Sound<br />

insulation<br />

Airborne noise<br />

R W 48 dB<br />

Impact noise<br />

L'nTw 67 dB<br />

Sound<br />

insulation<br />

Airborne noise<br />

R W 58 dB<br />

Impact noise<br />

L'nTw 48 dB<br />

* according classifi cation reports M1 BSP crossplan of HFA<br />

Source: www.dataholz.com, catalogue «Bauphysikalisch geprüfter Bauteile für den Holzbau»<br />

M1 BSP crossplan<br />

Thermal<br />

insulation<br />

U value<br />

0,38 [W / m 2 K]<br />

Thermal<br />

insulation<br />

U value<br />

0,32 [W / m 2 K]<br />

Thermal<br />

insulation<br />

U value<br />

0,53 [W / m 2 K]<br />

Thermal<br />

insulation<br />

U value<br />

0,27 [W / m 2 K]<br />

GD 01<br />

top<br />

bottom<br />

GD 02<br />

top<br />

bottom<br />

GD 03<br />

top<br />

bottom<br />

GD 04<br />

top<br />

bottom<br />

Mayr-Melnhof Kaufmann 29

M1 BSP crossplan<br />

SO 01<br />

Connections:<br />

Outside wall plinth connection<br />

SO 02<br />

30 Mayr-Melnhof Kaufmann<br />

Wall construction<br />

see component AW02<br />

Façade attachment<br />

acc. to structural design<br />

Mortar filler<br />

Insect screen<br />

Wall construction<br />

see component AW02<br />

Facade attachment<br />

acc. to static design<br />

Bird screen<br />

Level of external site<br />

Precast concrete element<br />

Perimeter insulation<br />

5,0 cm<br />

XPS-panel with drainage 5,0 cm<br />

Damp-proofing -- cm<br />

Reinforced concrete wall<br />

acc. to stat. req.<br />

20,0 cm<br />

Insulation<br />

approx. 50 cm<br />

0,5 cm<br />

min 30 cm<br />

min 30 cm<br />

CONSTRUCTION<br />

DETAILS<br />

Glue<br />

butt joints<br />

convection-tight<br />

Separating strip<br />

Plinth plaster 0,5 cm<br />

XPS-panel 5,0 cm<br />

Damp-proofing -- cm<br />

Reinforced concrete<br />

wall acc. to stat. req.<br />

20,0 cm<br />

Internal render 0,5 cm<br />

Glue<br />

butt joints<br />

convection-tight<br />

Separating strip<br />

Floor covering Parquet 2,0 cm<br />

Cement screed 5,0 cm<br />

Separating layer according<br />

to Austrian standard B2232<br />

-- cm<br />

Impact noise insulation 2,0 cm<br />

Bonded fill 5,0 cm<br />

Damp-proofing -- cm<br />

Reinforced concrete ceiling<br />

acc. to stat. req.<br />

20 cm<br />

Internal render 0,5 cm<br />

Precast concrete element<br />

Perimeter insulation<br />

5,0 cm<br />

XPS-panel with drainage 5,0 cm<br />

Damp-proofing -- cm<br />

Reinforced concrete plinth<br />

according to stat. req.<br />

15,0 cm<br />

Cellular glass 5,0 cm<br />

Gypsum fibreboard or drywall 1,25 cm<br />

Floor covering Parquet 2,0 cm<br />

Cement screed 5,0 cm<br />

Separating layer according<br />

to Austrian standard B2232<br />

-- cm<br />

Impact noise insulation 2,0 cm<br />

Bonded fill 5,0 cm<br />

Damp-proofing -- cm<br />

Reinforced concrete ceiling<br />

acc. to stat. req.<br />

20 cm<br />

Thermal insulation 7,5 cm<br />

Version 1 / 2011

CONSTRUCTION<br />

DETAILS<br />

DE 01<br />

Connections:<br />

Exterior wall pitched roof connection<br />

DA 01<br />

Version 1 / 2011<br />

Wall construction<br />

see component AW02<br />

Insect screen<br />

Wall construction<br />

see component AW02<br />

M1 BSP crossplan<br />

95 38 GL<br />

RA<br />

53 60 GM<br />

Glue<br />

butt joints<br />

convection-tight<br />

Separating strip<br />

Glue<br />

butt joints convection-tight<br />

Construction:<br />

see component GD01<br />

Edges and joint finishing acc.<br />

to machining guidelines<br />

Noise reducing separation<br />

Wall construction<br />

see component AW02<br />

Edges and joint finishing acc.<br />

to machining guidelines<br />

Roof covering -- cm<br />

Roof battens 3/5 3,0 cm<br />

Counter battens 4/6 4,0 cm<br />

Vapour-permeable roofing<br />

membrane<br />

20,0 cm<br />

Full formwork 2,5 cm<br />

Spars according to requirement 16 cm<br />

Insulation between -- cm<br />

Battens on bracket 4/5 5 cm<br />

Insulation between<br />

-- cm<br />

Vapour barrier<br />

-- cm<br />

Gypsum fibreboard<br />

1,25 cm<br />

Edges and joint finishing acc.<br />

to machining guidelines<br />

Glue vapour barrier to<br />

cross-laminated timber panel<br />

Mayr-Melnhof Kaufmann 31

M1 BSP crossplan<br />

Connections:<br />

Exterior wall fl at roof connection<br />

DA 02<br />

32 Mayr-Melnhof Kaufmann<br />

Roof parapet attachment<br />

according to structural design<br />

Facade attachment<br />

acc. to structural design<br />

Wall construction<br />

see component AW02<br />

Gradient min. 2%<br />

CONSTRUCTION<br />

DETAILS<br />

min 30 cm<br />

Tapered insulation<br />

roof construction<br />

see component FD02<br />

Gradient min. 2%<br />

Gradient insulation panel EPS<br />

Edges and joint finishing<br />

acc. to machining guidelines<br />

Glue butt joints convection-tight<br />

Version 1 / 2011

CONSTRUCTION<br />

DETAILS<br />

General<br />

Connection technique<br />

Vertical section<br />

In slender buildings tensile<br />

bracing stays must be created!<br />

Shear angle<br />

e.g. BMF 105 with rib<br />

Spacing = approx. 90 cm<br />

or acc. to stat. requirement<br />

Mortar filler<br />

Protection against<br />

rising damp<br />

Connection technique<br />

Horizontal section<br />

Version 1 / 2011<br />

Self-tapping wood screws<br />

M8/e = 33 cm<br />

or acc. to stat. requirement<br />

HSA-M10x120<br />

HSA-M10x120<br />

Shear angle<br />

Spacing = approx. 90 cm<br />

e.g. BMF 105 with rib<br />

or acc. to stat. requirement<br />

Noise reducing separation<br />

(if necessary)<br />

Self-tapping wood screws<br />

M8/e = 33 cm<br />

or acc. to stat. requirement<br />

Self-tapping wood screws<br />

M8/ e = 33 cm<br />

or acc. to stat. requirement<br />

Self-tapping wood screws<br />

M8/ e = 33 cm<br />

or acc. to stat. requirement<br />

Stepped rebate<br />

Butt board rebate<br />

Rebate height = 27 mm<br />

M1 BSP crossplan<br />

All joints (vertical or horizontal) of the M1 BSP crossplan elements shall be sealed by applying<br />

a permanent elastic sealing tape (recommendation).<br />

If required<br />

execute sound-proof and airtight<br />

Full thread screws<br />

arranged in pairs<br />

e.g. WT-T; d = 8,2 mm; e = 33 cm<br />

or acc. to stat. requirement<br />

H<br />

h/2<br />

h/2<br />

50<br />

9090<br />

Exterior corner right-angled<br />

Connection to partition wall<br />

Exterior corner with mitre cut<br />

Self-tapping wood screws<br />

M6/ e = 25 cm<br />

or acc. to stat. requirement<br />

Self-tapping wood screws<br />

M8/ e = 33 cm or according<br />

to stat. requirement<br />

Mayr-Melnhof Kaufmann 33

M1 BSP crossplan<br />

Sample tender text<br />

M1 BSP crossplan –<br />

general material<br />

description<br />

Manufacturer<br />

Qualities<br />

M1 BSP crossplan –<br />

Approvals and<br />

certifi cations<br />

34 Mayr-Melnhof Kaufmann<br />

TENDER TEXT<br />

The following tender text refers to a shell construction made from cross-laminated timber<br />