Broch

Broch

Broch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

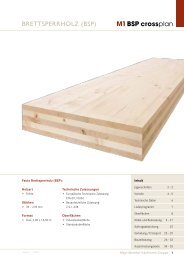

M1 BSP crossplan<br />

Transport procedure<br />

Flatwise transport<br />

Upright transport<br />

Storage<br />

Lifting devises<br />

24 Mayr-Melnhof Kaufmann<br />

TRANSPORT<br />

The transport will be scheduled once the loading plans and delivery dates have been defi ned.<br />

Special transports are almost always necessary because most of the loads contain components<br />

with lengths exceeding 13,60 m and / or widths or heights exceeding 2,50 m.<br />

These special tranports require national and international road use permits and should,<br />

therefore, only be carried out by carriers familiar with them and equipped for the task.<br />

The transport costs referred to include 2,5 hours for unloading of the lorry at the building site.<br />

Each additional hour of the lorry’s waiting time will be invoiced additionally if delays occur<br />

during unloading.<br />

The elements may be transported either upright or fl at.<br />

Component deliveries lying fl at are particularly appropriate for panels with less machining<br />

(e.g. ceiling elements) or raw panels. This is also the more cost-eff ective variation for widths<br />

up to 3,00 m as platform semi-trailers may be used without additional structures. Appropriate<br />

ex works protection against dirt is guaranteed by packaging in plastic foil.<br />

Upright element transport is used primarily for material with a high level of machining such<br />

as walls with window and door cut-outs, visible components, and similar. The use of fl atbed<br />

semi-trailers with appropriate loading area structures is, however, more expensive than transport<br />

elements lying fl at using platform semi-trailers.<br />

The basic principles of timber storage must be observed where it is necessary to store<br />

M1 BSP crossplan.<br />

M1 BSP crossplan elements may be provided with assembly aids. These are used to manipulate<br />

the elements at the plant and on the building site. Loops or special screw systems will be<br />

used depending on the type of component and size. The number of assembly aids attached<br />

depends on the safety requirements and the measurements of the relevant components.<br />

Version 1 / 2011