Miniature Sensors for Biological Warfare Agents using Fatty Acid ...

Miniature Sensors for Biological Warfare Agents using Fatty Acid ...

Miniature Sensors for Biological Warfare Agents using Fatty Acid ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4. Results and Discussion<br />

During the three years of this LDRD much has been learned about the devices<br />

(micropyrolyzer, micro gas chromatographic (microGC) column, and the surface<br />

acoustic wave (SAW) detector in the context of rapid biological agent detection.<br />

The results have demonstrated that the micropyrolyzer is capable of per<strong>for</strong>ming<br />

the desired pyrolysis reaction, that the microGC is capable of separating FAMEs,<br />

and the SAW detector is capable of reversible response to low molecular weight<br />

FAMEs. Each component is discussed separately.<br />

4.1. Micropyrolysis<br />

4.1.1. Device characteristics<br />

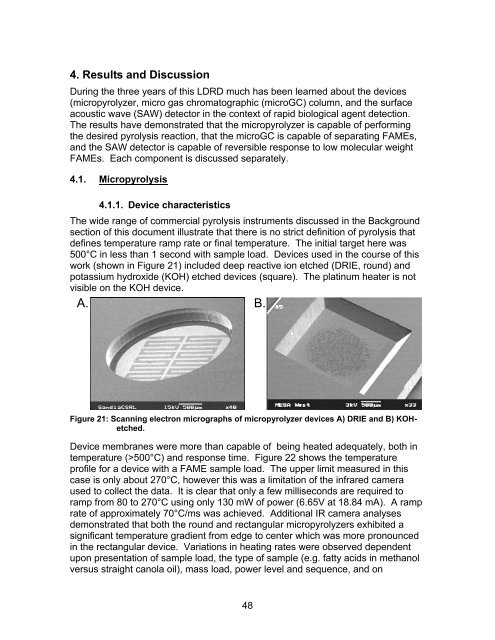

The wide range of commercial pyrolysis instruments discussed in the Background<br />

section of this document illustrate that there is no strict definition of pyrolysis that<br />

defines temperature ramp rate or final temperature. The initial target here was<br />

500°C in less than 1 second with sample load. Devices used in the course of this<br />

work (shown in Figure 21) included deep reactive ion etched (DRIE, round) and<br />

potassium hydroxide (KOH) etched devices (square). The platinum heater is not<br />

visible on the KOH device.<br />

A. B.<br />

Figure 21: Scanning electron micrographs of micropyrolyzer devices A) DRIE and B) KOHetched.<br />

Device membranes were more than capable of being heated adequately, both in<br />

temperature (>500°C) and response time. Figure 22 shows the temperature<br />

profile <strong>for</strong> a device with a FAME sample load. The upper limit measured in this<br />

case is only about 270°C, however this was a limitation of the infrared camera<br />

used to collect the data. It is clear that only a few milliseconds are required to<br />

ramp from 80 to 270°C <strong>using</strong> only 130 mW of power (6.65V at 18.84 mA). A ramp<br />

rate of approximately 70°C/ms was achieved. Additional IR camera analyses<br />

demonstrated that both the round and rectangular micropyrolyzers exhibited a<br />

significant temperature gradient from edge to center which was more pronounced<br />

in the rectangular device. Variations in heating rates were observed dependent<br />

upon presentation of sample load, the type of sample (e.g. fatty acids in methanol<br />

versus straight canola oil), mass load, power level and sequence, and on<br />

48