Atlas Copco Air Motors

Atlas Copco Air Motors

Atlas Copco Air Motors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

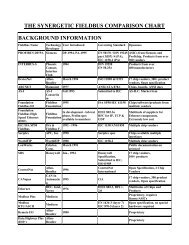

Methods of modifying motor<br />

output<br />

Throttling<br />

A throttle is usually fitted into the motor´s inlet hose, although<br />

it can also be fitted into the exhaust hose. When it is<br />

desirable to maintain a high starting torque but reduce running<br />

speed – throttling is the best method of modifying the<br />

motor´s output, Figure 5.<br />

Torque<br />

[Nm]<br />

Pressure regulation<br />

When using a pressure regulator it is mostly fitted into the<br />

motor´s inlet hose. The use of pressure regulation is ideal<br />

when control of the stall torque is required and a high starting<br />

torque is not so important, Figure 6.<br />

Torque<br />

[%]<br />

100<br />

Par<br />

[Nm]<br />

Speed [r/min]<br />

Operating pressure<br />

7 bar<br />

6 bar<br />

5 bar<br />

4 bar<br />

3 bar<br />

100<br />

Speed [%]<br />

Using the catalogue<br />

Motor data, specification and performance<br />

curves<br />

Velocidad [r/min]<br />

Figure 5<br />

Figure 6<br />

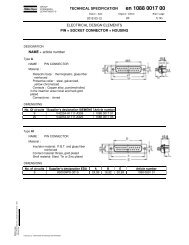

For each <strong>Atlas</strong> <strong>Copco</strong> motor/gear unit combination the following<br />

information is presented in this catalogue.<br />

1. Tabular Data – Summary of main performance<br />

parameters.<br />

2.Dimensional drawings.<br />

3.Performance curves.<br />

Notes on performance data<br />

The performance data stated in this catalogue is valid for an<br />

air supply pressure of 6.3 bar (91 psi), gauge. <strong>Air</strong> consumption<br />

values are for free air delivery – (ie, the volume the consumed<br />

air would occupy if allowed to expand to atmospheric<br />

pressure).<br />

The direction of rotation for a motor is always stated looking<br />

from the back of the motor. Figure 7 illustrate clockwise rotation.<br />

Figure 7<br />

Understanding the performance curves<br />

The output of an air motor is most clearly seen from its<br />

performance curves Figure 8. For each motor/gear unit the<br />

power, torque and air consumption are shown as a function<br />

of speed.<br />

The diagrams shown apply to an inlet pressure of 6.3 bar, to<br />

calculate performance at other pressures refer to page 70 in<br />

this catalogue.<br />

Torque<br />

[Nm]<br />

Power<br />

[kW]<br />

Max<br />

output<br />

Torque<br />

at max<br />

output<br />

Motor selection<br />

Guidelines on motor selection are given on page 70 in this<br />

catalogue – Choosing Your Motor.<br />

Installation<br />

Power<br />

Torque<br />

<strong>Air</strong> cons.<br />

[l/s]<br />

<strong>Air</strong>. cons.<br />

Speed [r/min]<br />

Note. The starting torque<br />

produced by an air motor is<br />

variable and depends on vane<br />

position. These diagrams<br />

do not indicate the starting<br />

torque – this can be obtained<br />

from data tables, where the<br />

minimum value is shown.<br />

Figure 8<br />

General installation recommendations are given on page 72.<br />

Details specific to a motor are shown in the section relevant<br />

to that motor type.<br />

AT L A S C O P C O A I R M O T O R S 7