Atlas Copco Air Motors

Atlas Copco Air Motors

Atlas Copco Air Motors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Lubrication free air motors<br />

<strong>Atlas</strong> <strong>Copco</strong>’s lubrication free air motors are<br />

equipped with low-friction vanes, sealed bearings<br />

and vented cylinder plates. Since they<br />

release no lubricants into the air, they offer a<br />

viable drive solution for sensitive processes<br />

and hygienic environments where oil contamination<br />

would be at best a problem and, at<br />

worst, a catastrophe.<br />

LZB 33 high torque –<br />

low speed air motors<br />

Accomplishing high torques generally calls for<br />

very large motors with correspondingly high air<br />

consumption. The LZB 33 high torque/low speed<br />

air motors are based on the combination of LZB<br />

33, the work horse in <strong>Atlas</strong> <strong>Copco</strong>´s air<br />

motor program, and the gears<br />

used in the large LZB 42-54<br />

motors. This gives a compact<br />

motor/gear package. The gears<br />

are dimensioned to stand being loaded at full stall torque<br />

indefinitely. Competing low speed air motors often have to<br />

limit their output torques to prevent gear breakage.<br />

LZB 22LR and 33LR –<br />

low speed air motors<br />

When there is a need for low speed only, the LR<br />

motors offer a complete and low price solution<br />

compared to the high torque LZB 33 airmotors.<br />

<strong>Motors</strong> with brake<br />

The most popular vane motors, LZB 33, are<br />

available with parking brake. This brake is located<br />

between the motor and the gear. It is a disc brake<br />

that is spring activated when the motor is not<br />

running. When the motor is started the brake is<br />

released by a built in pneumatic piston. The<br />

brake is used when it is important<br />

that the output shaft must not<br />

turn when the motor isn’t<br />

running and a torque is applied<br />

on the shaft.<br />

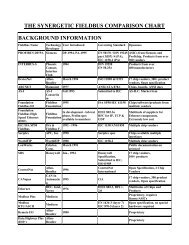

A: Clockwise rotation<br />

AR: Reversible<br />

AV: Anti-clockwise rotation<br />

L: Lubrication free<br />

LB: With brake module<br />

LR: Low speed<br />

R: Stainless steel<br />

RL: Stainless steel, lubrication free<br />

RLB: Stainless steel, with brake module<br />

RLR: Stainless steel, low speed<br />

Table 1 illustrates what features the letters in the motor<br />

designation stands for. Table 1<br />

LZL Vane motors – 1.3 kW to 6.5 kW<br />

Type LZL <strong>Atlas</strong> <strong>Copco</strong> vane motors have been designed to<br />

offer outstanding starting and low speed performance. These<br />

general purpose motors are powerful, rugged and hard wearing,<br />

Figure 10.<br />

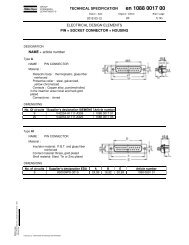

Helical gear units<br />

<strong>Atlas</strong> <strong>Copco</strong> helical gear units are normally fitted to Type LZL<br />

vane motors. Standard units are highly efficient, providing<br />

speeds of 500 r/min down to 15 r/min at torques of up to<br />

4500 Nm. The gear unit is flange-coupled to the motor and<br />

the shafts are joined by a flexible coupling, Figure 11.<br />

5000 r/min<br />

500 r/min<br />

Figure 10<br />

Figure 11<br />

AT L A S C O P C O A I R M O T O R S 9