Thermal Systems Testing Services - Delphi

Thermal Systems Testing Services - Delphi

Thermal Systems Testing Services - Delphi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A comprehensive variety of technical testing services for climate<br />

control and powertrain cooling systems, components and modules<br />

are offered at several <strong>Delphi</strong> facilities. <strong>Testing</strong> services are available<br />

for automotive and non-automotive applications and include climatic<br />

wind tunnels, airflow, heat transfer, noise and vibration, corrosion<br />

and compression laboratories; and support services including<br />

engineers and technicians. Each facility has security precautions<br />

in place to assure customer confidentiality. <strong>Delphi</strong> <strong>Thermal</strong> <strong>Testing</strong><br />

<strong>Services</strong> are managed by Sverdrup Technologies Automotive<br />

Operations*. Sverdrup has over fifty years experience in the design,<br />

build and operations of test facilities worldwide. <strong>Delphi</strong> <strong>Thermal</strong><br />

<strong>Systems</strong> and Sverdrup have teamed together to offer state-of-the-art<br />

facilities and expertise. <strong>Delphi</strong>’s thermal testing services are available<br />

at our Lockport, New York and Juarez, Mexico facilities and at the<br />

Sverdrup facility in Amherst, New York.<br />

Lockport, New York<br />

■ Six Climatic Wind Tunnels<br />

Fully equipped engineering garage for vehicle preparation<br />

and instrumentation<br />

• Four (4) tunnels: ambient to +130°F (+54°C)<br />

• Two (2) tunnels: -35°F (-37°C) to +130°F (+54°C)<br />

• Solar simulation<br />

• Chassis dynamometers: full road simulation—idle to<br />

120 MPH (193 KPH)<br />

• Wind Speed: idle to 100 MPH (160 KPH)<br />

■ Component Test Laboratory<br />

• Seventy-five (75) performance, durability, vibration test stands<br />

• Heat transfer dissipation—radiators, condensers,<br />

evaporators, heaters<br />

• Corrosion chambers—temperature, humidity, salt fog (SWAAT),<br />

sulfur dioxide<br />

• Vibration machines: mechanical, hydraulic, electro-dynamic<br />

• M.A.S.T. (multi-axis simulation table) with environmental<br />

chamber: -40°F (-40°C) to +185°F (+85°C)<br />

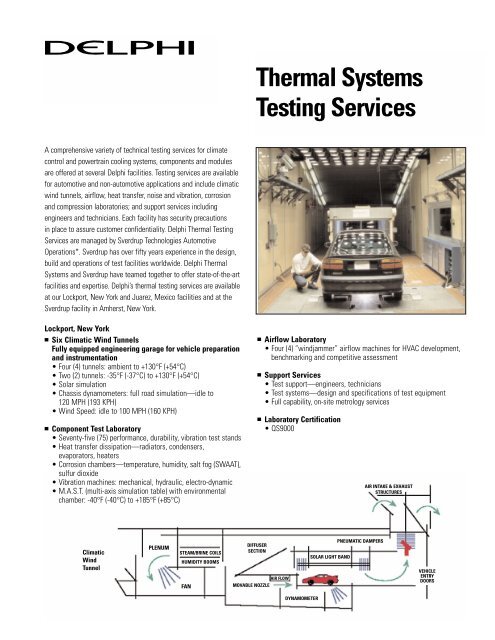

Climatic<br />

Wind<br />

Tunnel<br />

PLENUM<br />

STEAM/BRINE COILS<br />

HUMIDITY BOOMS<br />

FAN<br />

<strong>Thermal</strong> <strong>Systems</strong><br />

<strong>Testing</strong> <strong>Services</strong><br />

DIFFUSER<br />

SECTION<br />

■ Airflow Laboratory<br />

• Four (4) “windjammer” airflow machines for HVAC development,<br />

benchmarking and competitive assessment<br />

■ Support <strong>Services</strong><br />

• Test support—engineers, technicians<br />

• Test systems—design and specifications of test equipment<br />

• Full capability, on-site metrology services<br />

■ Laboratory Certification<br />

• QS9000<br />

AIR FLOW<br />

MOVABLE NOZZLE<br />

DYNAMOMETER<br />

SOLAR LIGHT BAND<br />

PNEUMATIC DAMPERS<br />

AIR INTAKE & EXHAUST<br />

STRUCTURES<br />

VEHICLE<br />

ENTRY<br />

DOORS

<strong>Thermal</strong> <strong>Systems</strong><br />

<strong>Testing</strong> <strong>Services</strong><br />

Amherst, New York<br />

■ Compressor Laboratories<br />

• Forty (40) computerized water cooled typical system durability<br />

test strands<br />

• Seven (7) air cooled/environmentally controlled durability stands<br />

• Two (2) air cooled typical system performance test stands<br />

• Six (6) water cooled secondary refrigerant calorimeter stands for<br />

compressor performance<br />

• Environmental chamber capable of -20°F (-29°C) to +18°5F (+85°C)<br />

and humidity from 30% to 100%<br />

• One (1) products development laboratory for precision assembly,<br />

mid- and post-test analysis<br />

■ Noise and Vibration Laboratory<br />

• Two (2) full anechoic test chambers for component/systems<br />

acoustic and vibration measurement<br />

• One (1) semi-anechoic chamber for full-size vehicle noise and<br />

vibration evaluations<br />

• Two (2) dynamic compressor test stands for force transmission<br />

measurement<br />

• One (1) pressure pulsation test stand for heating, ventilating<br />

and air conditioning pressure systems<br />

• One (1) squeak and rattle shaker table and analysis system<br />

■ Miscellaneous Test Laboratory<br />

• Four (4) pulley bearing evaluation test stands<br />

• Six (6) gas cycle test stands for clutch durability and development<br />

• One (1) Refrigerant Emissions Analysis Laboratory (R.E.A.L.) for<br />

leak rate analysis<br />

• A/C Controls test area for performance evaluation, thermal &<br />

pressure cycling, burst and corrosion—salt fog (SWAAT),<br />

humidity testing<br />

• One (1) clutch tribology stand for friction and engagement<br />

• One (1) clutch inertia stand for development and evaluation<br />

• One (1) carbon dioxide stand for evaluating performance of CO 2<br />

as refrigerant<br />

■ Airflow Laboratory<br />

• Constant temperature anemometer used to measure velocity<br />

flow fields quantitatively<br />

• Laser doppler anemometer used to precisely measure flows fields<br />

• Motor dynamometer used to measure torque characteristics of<br />

motor used in conjunction with airflow measurement machine<br />

to demonstrate fan/motor efficiency<br />

• Airflow measurement machine to evaluate components as to<br />

their volume flow rate<br />

■ Support <strong>Services</strong><br />

• Machine shop—fully equipped for laboratory wide support<br />

• Instrumentation department for calibration, repair and support<br />

of all test activities<br />

■ Laboratory Certification<br />

• A2LA—mechanical, acoustic and vibration fields<br />

Acoustic analysis anechoic chamber tests HVAC module for<br />

noise and vibration<br />

Compressor noise and vibration analysis is conducted in <strong>Delphi</strong>’s<br />

anechoic sound chambers<br />

Vehicle in the semi-anechoic noise measurement chamber with<br />

Aachen head measurement system in the driver’s seat of the vehicle

<strong>Thermal</strong> <strong>Systems</strong><br />

<strong>Testing</strong> <strong>Services</strong><br />

Juarez, Mexico<br />

■ Component Test Laboratory<br />

• Ten (10) performance and durability test stands<br />

• Heat transfer dissipation—radiators, condensers<br />

• Corrosion chambers—temperature, humidity, salt fog (SWAAT)<br />

• M.A.S.T. (multi-axis simulation table) with environmental<br />

chamber: -40°F (-40°C) to +185°F (+85°C)<br />

■ Packaging Test Laboratory<br />

• Servo-hydraulic vibration table with environmental chamber:<br />

-20°F (-29°C) to +185°F (+85°C), 20-95% RH<br />

• Transportation simulator—repetitive shock<br />

• Incline impact and drop testing<br />

• Compression (burst pressure) testing<br />

■ Airflow Laboratory<br />

• “Windjammer” airflow machines for HVAC development,<br />

benchmarking and competitive assessment<br />

■ Laboratory Certification<br />

• QS9000<br />

* Actual testing services are performed by employees of Sverdrup and/or <strong>Delphi</strong> under<br />

Sverdrup supervision. Agreements to perform testing are between customer and Sverdrup.<br />

www.delphi.com<br />

Printed on Recycled Paper<br />

©2002 <strong>Delphi</strong> Corporation. All rights reserved.<br />

M.A.S.T. is used to test representative HVAC modules and<br />

other components under various degrees of motion,<br />

temperatures and humidities<br />

<strong>Delphi</strong> Harrison <strong>Thermal</strong> <strong>Systems</strong><br />

200 Upper Mountain Road<br />

Lockport, New York 14094<br />

U.S.A.<br />

Tel: [1] 716.439.2639<br />

Fax: [1] 716.439.2386