Medium Duty Diesel Common Rail (DCR) System - Delphi

Medium Duty Diesel Common Rail (DCR) System - Delphi

Medium Duty Diesel Common Rail (DCR) System - Delphi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Description<br />

To meet future stringent emissions requirements and to offer<br />

further improvements in fuel economy, <strong>Delphi</strong> <strong>Diesel</strong> <strong>System</strong>s, one<br />

of the world’s largest producers of fuel injection equipment, has<br />

developed a high-pressure fuel injection system—the <strong>Delphi</strong> <strong>Diesel</strong><br />

<strong>Common</strong> <strong>Rail</strong> (<strong>DCR</strong>) system.<br />

Fuel injection equipment with the capacity of operating at very high<br />

pressure is required to meet ultra-low emissions challenges and<br />

low noise demands. The latest developments made to the <strong>DCR</strong><br />

system extend capabilities to medium-duty and commercial vehicle<br />

applications.<br />

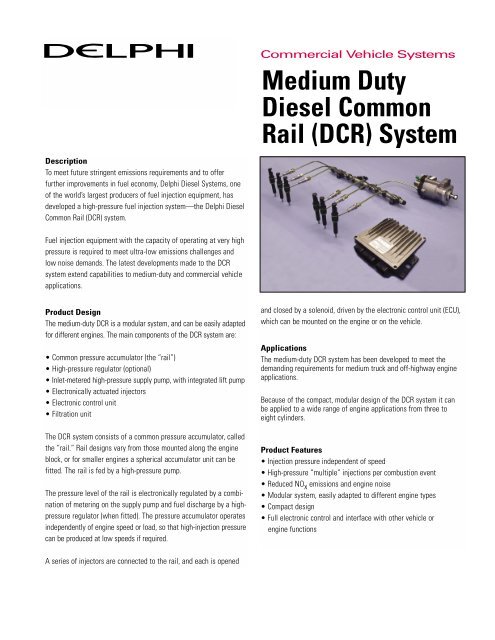

Product Design<br />

The medium-duty <strong>DCR</strong> is a modular system, and can be easily adapted<br />

for different engines. The main components of the <strong>DCR</strong> system are:<br />

• <strong>Common</strong> pressure accumulator (the “rail”)<br />

• High-pressure regulator (optional)<br />

• Inlet-metered high-pressure supply pump, with integrated lift pump<br />

• Electronically actuated injectors<br />

• Electronic control unit<br />

• Filtration unit<br />

The <strong>DCR</strong> system consists of a common pressure accumulator, called<br />

the “rail.” <strong>Rail</strong> designs vary from those mounted along the engine<br />

block, or for smaller engines a spherical accumulator unit can be<br />

fitted. The rail is fed by a high-pressure pump.<br />

The pressure level of the rail is electronically regulated by a combination<br />

of metering on the supply pump and fuel discharge by a highpressure<br />

regulator (when fitted). The pressure accumulator operates<br />

independently of engine speed or load, so that high-injection pressure<br />

can be produced at low speeds if required.<br />

A series of injectors are connected to the rail, and each is opened<br />

Commercial Vehicle <strong>System</strong>s<br />

<strong>Medium</strong> <strong>Duty</strong><br />

<strong>Diesel</strong> <strong>Common</strong><br />

<strong>Rail</strong> (<strong>DCR</strong>) <strong>System</strong><br />

and closed by a solenoid, driven by the electronic control unit (ECU),<br />

which can be mounted on the engine or on the vehicle.<br />

Applications<br />

The medium-duty <strong>DCR</strong> system has been developed to meet the<br />

demanding requirements for medium truck and off-highway engine<br />

applications.<br />

Because of the compact, modular design of the <strong>DCR</strong> system it can<br />

be applied to a wide range of engine applications from three to<br />

eight cylinders.<br />

Product Features<br />

• Injection pressure independent of speed<br />

• High-pressure “multiple” injections per combustion event<br />

• Reduced NO x emissions and engine noise<br />

• Modular system, easily adapted to different engine types<br />

• Compact design<br />

• Full electronic control and interface with other vehicle or<br />

engine functions

<strong>Medium</strong> <strong>Duty</strong><br />

<strong>Diesel</strong> <strong>Common</strong> <strong>Rail</strong> (<strong>DCR</strong>) <strong>System</strong><br />

<strong>DCR</strong> Advantages<br />

• Compact design—The compact design of the injector outline<br />

enables the <strong>DCR</strong> system to be used on two or four valves-percylinder<br />

engines.<br />

• Modular system—With one electronically driven injector per<br />

engine cylinder, the system is modular and can be used on<br />

three to eight cylinder engines.<br />

• Low drive torque—As the pumping pressure to the rail is not<br />

phased with the injection, the <strong>DCR</strong> system requires a low drive<br />

torque from the engine.<br />

www.delphi.com<br />

Printed on Recycled Paper<br />

©2002 <strong>Delphi</strong> Automotive <strong>System</strong>s. All rights reserved.<br />

W-CV-025-Nov02<br />

• Independent injection pressure—The injection pressure is independent<br />

of the engine speed and load, enabling high pressures at low speed<br />

if required.<br />

• Multi injections per firing cycle—Injection sequences which include<br />

periods both pre- and post-main injection can be utilized to reduce<br />

emissions, particularly NO x , enabling the system to meet the stringent<br />

emission levels required by Euro-3 and US-98 legislation and<br />

beyond. The inclusion of pilot injection also results in significant reduction<br />

in engine noise.<br />

• Full Electronic Control—<strong>DCR</strong> offers all the benefits of full electronic<br />

control fuel metering and timing, as well as the option to interface<br />

with other vehicle functions.<br />

<strong>Delphi</strong> Energy & Chassis <strong>System</strong>s<br />

5820 <strong>Delphi</strong> Drive<br />

Troy, MI 48098