Marine Report 236, Independent investigation into the engine room ...

Marine Report 236, Independent investigation into the engine room ...

Marine Report 236, Independent investigation into the engine room ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

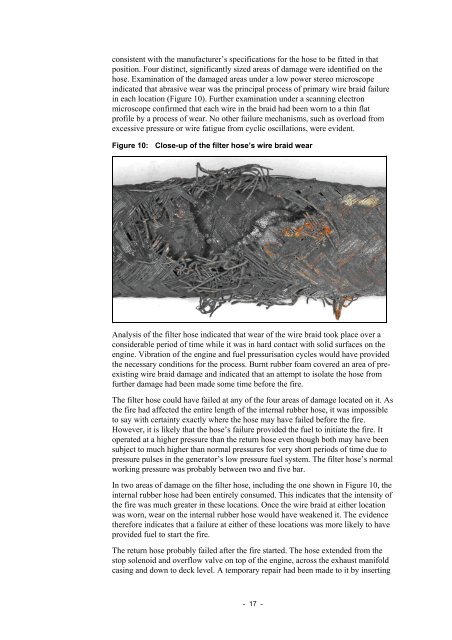

consistent with <strong>the</strong> manufacturer’s specifications for <strong>the</strong> hose to be fitted in that<br />

position. Four distinct, significantly sized areas of damage were identified on <strong>the</strong><br />

hose. Examination of <strong>the</strong> damaged areas under a low power stereo microscope<br />

indicated that abrasive wear was <strong>the</strong> principal process of primary wire braid failure<br />

in each location (Figure 10). Fur<strong>the</strong>r examination under a scanning electron<br />

microscope confirmed that each wire in <strong>the</strong> braid had been worn to a thin flat<br />

profile by a process of wear. No o<strong>the</strong>r failure mechanisms, such as overload from<br />

excessive pressure or wire fatigue from cyclic oscillations, were evident.<br />

Figure 10: Close-up of <strong>the</strong> filter hose’s wire braid wear<br />

Analysis of <strong>the</strong> filter hose indicated that wear of <strong>the</strong> wire braid took place over a<br />

considerable period of time while it was in hard contact with solid surfaces on <strong>the</strong><br />

<strong>engine</strong>. Vibration of <strong>the</strong> <strong>engine</strong> and fuel pressurisation cycles would have provided<br />

<strong>the</strong> necessary conditions for <strong>the</strong> process. Burnt rubber foam covered an area of preexisting<br />

wire braid damage and indicated that an attempt to isolate <strong>the</strong> hose from<br />

fur<strong>the</strong>r damage had been made some time before <strong>the</strong> fire.<br />

The filter hose could have failed at any of <strong>the</strong> four areas of damage located on it. As<br />

<strong>the</strong> fire had affected <strong>the</strong> entire length of <strong>the</strong> internal rubber hose, it was impossible<br />

to say with certainty exactly where <strong>the</strong> hose may have failed before <strong>the</strong> fire.<br />

However, it is likely that <strong>the</strong> hose’s failure provided <strong>the</strong> fuel to initiate <strong>the</strong> fire. It<br />

operated at a higher pressure than <strong>the</strong> return hose even though both may have been<br />

subject to much higher than normal pressures for very short periods of time due to<br />

pressure pulses in <strong>the</strong> generator’s low pressure fuel system. The filter hose’s normal<br />

working pressure was probably between two and five bar.<br />

In two areas of damage on <strong>the</strong> filter hose, including <strong>the</strong> one shown in Figure 10, <strong>the</strong><br />

internal rubber hose had been entirely consumed. This indicates that <strong>the</strong> intensity of<br />

<strong>the</strong> fire was much greater in <strong>the</strong>se locations. Once <strong>the</strong> wire braid at ei<strong>the</strong>r location<br />

was worn, wear on <strong>the</strong> internal rubber hose would have weakened it. The evidence<br />

<strong>the</strong>refore indicates that a failure at ei<strong>the</strong>r of <strong>the</strong>se locations was more likely to have<br />

provided fuel to start <strong>the</strong> fire.<br />

The return hose probably failed after <strong>the</strong> fire started. The hose extended from <strong>the</strong><br />

stop solenoid and overflow valve on top of <strong>the</strong> <strong>engine</strong>, across <strong>the</strong> exhaust manifold<br />

casing and down to deck level. A temporary repair had been made to it by inserting<br />

- 17 -