Final Report - Claymore - Grand Valley State University

Final Report - Claymore - Grand Valley State University

Final Report - Claymore - Grand Valley State University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Grand</strong> <strong>Valley</strong> <strong>State</strong> <strong>University</strong><br />

Padnos School of Engineering<br />

Target Acquisition and Firing System Design Project<br />

EGR 345 Dynamic Systems Modeling and Control<br />

Instructor: Dr. Jack<br />

Team 9 – “Young Gunners”<br />

Brian Coleman<br />

Steve Johnson<br />

Coty Lindell<br />

Bryan Masselink<br />

Haley Nghiem<br />

December 7, 2005

Executive Summary<br />

The objective of this design project was to develop a device to read a signal,<br />

locate a target, and fire a practice golf ball through the target autonomously in the least<br />

amount of time possible. An ATMega32 microcontroller and L298P H-bridge driver<br />

were used to control the device. Cost, weight, and size constraints were put under<br />

consideration.<br />

A stationary device with a rotating turret and launch mechanism was the optimal<br />

design choice upon consideration of the design parameters. The launch mechanism was a<br />

directed air nozzle contained within a 9 inch by 1.5 I.D. low-pressure PVC pipe. The<br />

positioning of the launch mechanism was controlled by a high-torque stepper motor. The<br />

stepper motor was fastened to an aluminum coupler, which was fastened to the launching<br />

mechanism. The balls were fed to the launching mechanism using a gravity fed, helical<br />

track wire hopper. The ATMega32 microcontroller was utilized to receive 5V inputs<br />

from an external source. When a signal was received, the stepper motor aligned the<br />

barrel with one of four targets and launched a practice golf to disable the target.<br />

Testing was executed to determine how the device would perform in the final<br />

competition. The test results revealed that air provided an adequate force to shoot the<br />

balls at the targets. Furthermore, the stepper motor provided accurate positioning of the<br />

barrel at an acceptable rate.<br />

1

Table of Contents<br />

1. Design Description......................................................................................................... 3<br />

1.1 Design Specifications................................................................................................ 3<br />

1.2 Mechanical Design.................................................................................................... 3<br />

1.2.1 Design Summary ................................................................................................ 3<br />

1.2.2. Mass and Budget of Materials .......................................................................... 4<br />

1.3 Software Design........................................................................................................ 5<br />

1.3.1 System Architecture ........................................................................................... 5<br />

1.3.2 Control System Block Diagram ......................................................................... 6<br />

1.4 Electrical Design....................................................................................................... 7<br />

2. Free Body diagram and Differential Equations .............................................................. 8<br />

2.1 Panning Angle Calculation ....................................................................................... 8<br />

2.1.1 Differential Equations for Stepper Motor.......................................................... 8<br />

2.1.2 Scilab Calculation for Panning Motor Selection.............................................. 9<br />

2.2 Ball Characteristic Calculations.............................................................................. 11<br />

2.2.1 Ball Velocity Before Launch ............................................................................ 11<br />

2.2.2 Projectile Motion Derivation........................................................................... 13<br />

2.2.3 Derivation for Individual Target Distance and Angle..................................... 15<br />

3. Test Results.................................................................................................................. 16<br />

3.1 Scilab Simulation Results ....................................................................................... 16<br />

3.2 Estimated Design Score .......................................................................................... 17<br />

4. Conclusions.................................................................................................................. 17<br />

5. Recommendations......................................................................................................... 18<br />

6. Digital Picture ............................................................................................................... 18<br />

7. Appendices................................................................................................................... 19<br />

7.1 Pro-E Drawings....................................................................................................... 19<br />

7.1.1 Exploded Assembly View with BOM............................................................... 19<br />

7.1.2 Orthographic Prints......................................................................................... 21<br />

7.1.3 Pro-E drawings................................................................................................ 22<br />

7.2 Gantt Chart.............................................................................................................. 30<br />

7.3 C Code .................................................................................................................... 31<br />

7.4 Scilab Code ............................................................................................................. 38<br />

2

1. Design Description<br />

1.1 Design Specifications<br />

The target acquisition and firing system device must contain all electrical<br />

and mechanical components except for the supplied power sources. The largest<br />

dimension of the design must be less than 12 inches, but smaller designs will<br />

receive more points. The device must have a mass less than 3 kg excluding any<br />

external power sources. The device may be powered by an external AC/DC<br />

voltage device or a pneumatic line or both. The equipment costs should be<br />

minimized, with a goal of $200 or less. The device must shoot practice golf balls<br />

approximately 1.5 inches in diameter at randomly activated targets 6 feet away.<br />

An electrical line will provide a 5 volt signal to the ATMega32 microcontroller.<br />

A different signal is provided for each of the four targets. The overall score of the<br />

design will depend on the number of targets hit in 2 minutes, total cost, largest<br />

dimension, build quality, theory quality, and mass of the device.<br />

1.2 Mechanical Design<br />

1.2.1 Design Summary<br />

The assembled drawing, shown in Figure 1, displays the major<br />

components of the target acquisition and firing device. The base of the machine<br />

was made of black polycarbonate, which was lightweight with high machinability.<br />

Four threaded rod supports were placed in the four corners of the base plate. The<br />

pan angle was controlled by a stepper motor. The PVC pipe firing mechanism was<br />

attached to the top of the stepper motor via a coupler and mounting bracket, and<br />

was approximately nine inches long by 1.5 inches I.D.. Since the stepper motor<br />

was mounted on the bottom of the base, the ATMega32 and the controller board<br />

were attached to the back of the base with two bolts for easy connections. A steel,<br />

sheet metal bracket, attached to the back of the barrel, was used to mount the air<br />

nozzle used to fire the balls. The steel bracket was designed to the increase<br />

airflow into the barrel. Thus, providing a larger force to the ball. When air<br />

3

pressure was applied, the flap rotated approximately 90º, preventing multiple balls<br />

from entering the barrel.<br />

Figure 1: Assembled view of the fire mechanism<br />

Appendix 7.1.1 shows the assembly exploded view of the mechanism,<br />

appendix 7.1.2 includes the orthographic prints of the machined part and appendix<br />

7.1.3 shows the pro-E drawings for all components used in the production of the<br />

device.<br />

1.2.2. Mass and Budget of Materials<br />

The total budget of the device was not exceed $200. A budget inventory<br />

was used to monitor the overall budget of the device. The mass of the device was<br />

a factor in the overall design score. The total mass of the device excluding<br />

external power sources must not exceed 3kg. The mass and budget of materials,<br />

shown in Table 1, were updated on a regular basis. Table 1 includes the unit price<br />

and mass for each item and where each item was purchased. The total money<br />

4

spent was $97.96 and the total mass of the machine was 995 grams. All receipts<br />

for purchased components are shown in Appendix 7.6.<br />

Table 1: Mass and Budget Inventory<br />

Quantity Unit<br />

Part Total<br />

Description<br />

used Price Source of Unit Price Mass(g) Mass(g)<br />

17Y series High Torque step<br />

Anaheim automation<br />

motor 1 $22.00 receipt 364 364<br />

Machined Polycarbonate plate 1 $1.97 Mcmaster/carr pg.3314 55 55<br />

(1) bottle Super Glue 1 $3.65 GVSU Book Store 0.01 0.01<br />

(2) packs of wiffle balls 2 $4.95 Target 0 0<br />

assorted hardware 1 $10.62 Godwin's hardware 20 46.49<br />

(1) ATMega circuit board 1 $30.00 GVSU 35 35<br />

2 feet, 1.5' diameter PVC pipe 1 $1.58 Menards 50 50<br />

Surface savers 1 $1.49 Godwin's hardware 5 20<br />

(8) U Joint 8 $0.29 Godwin's hardware 5 40<br />

(4) 1' Threaded rod 4 $1.29 Godwin's hardware 30 120<br />

1 ", 3/4" diameter aluminum rod 1 $0.59 Mcmaster/carr pp.3368 30 30<br />

1" Aluminum C channel 1 $0.52 Mcmaster/carr pp.3367 15 15<br />

1/2, 1 cubic foot sheet metal 1 $1.30 Mcmaster/carr pp.3379 10 10<br />

Motor controlled board with wires 1 $15.00 GVSU 85 85<br />

Air fitting 1 $1.47 Mcmaster/carr pp.238 20 20<br />

Hopper wire (11') 1 $1.89 Godwin's hardware 9.5 104.5<br />

Total Machine mass(g): 985<br />

Total Machine cost ($): $98.60<br />

1.3 Software Design<br />

1.3.1 System Architecture<br />

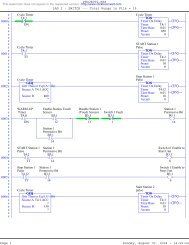

The system architecture of the device is shown in Figure 2. An<br />

ATMega32 microcontroller combined with an L298P H-bridge driver was used to<br />

control the air pulse and panning motor. The C program was written to control<br />

the ATMega32, and L298P is located in Appendix 7.3. The stepper motor was<br />

used to rotate the launching mechanism.<br />

5

ATMega32<br />

1 2 3 4<br />

Target Lines<br />

PWM<br />

A0 A1 A2 A3<br />

Figure 2: System Architecture<br />

1.3.2 Control System Block Diagram<br />

The control system block diagram was developed to control the target<br />

acquisition and firing device as shown in Figure 3. When a target was activated,<br />

the controller input port received a digital-high signal. When a target (1, 2, 3 or<br />

4) was activated, a signal was sent to an input pin A0, A1, A2, or A3,<br />

respectively. The C program, shown in Appendix 7.3, commanded the stepper<br />

motor to turn to the desired target and deliver an air pulse to fire the ball. The<br />

software utilized an interrupt sequence to monitor the status of each target. The<br />

device launched balls until the target was deactivated. The sequence continues<br />

upon activation of the next target.<br />

Ci<br />

Air Valve<br />

H-bridge Vs Stepper<br />

Motor<br />

Pan<br />

Angle<br />

Air Valve<br />

θp<br />

Launch<br />

Mechanism<br />

Figure 3: System block diagram<br />

6<br />

w<br />

Launch<br />

Mechanism

Where,<br />

Ci = Target input signal<br />

θ = Panning Angle<br />

p<br />

1.4 Electrical Design<br />

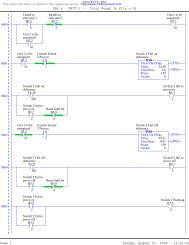

The electrical schematic of the device is shown in Figure 4. The electrical<br />

schematic includes the ATMega32 microcontroller, a L298P H-bridge push-pull<br />

four channel<br />

driver chip, and a 4 volt power supply. Four 1 KΩ resistors were<br />

used to reduce noise from the stepper motor.<br />

Figure 4: Electrical Schematic<br />

7

2. Free Body diagram and Differential Equations<br />

The calculations shown in subsequent sections was used to determine the required<br />

launch angle torque and launch speed needed to fire the ball the required distance. This<br />

calculation was helpful in the selection process of motors.<br />

2.1 Panning Angle Calculation<br />

2.1.1 Differential Equations for Stepper Motor<br />

τ Motor<br />

N<br />

FNR θ<br />

Figure 5: FBD for the Turn Table<br />

where, N= normal force (The hopper weight)<br />

W(hopper) = weight of the hopper and its configurations<br />

* *<br />

J θ = mass moment of inertia<br />

The differential equation for the launching angle from Figure 2.1 is<br />

* *<br />

∑ M : τ Motor − FNR = J θ .<br />

*<br />

Put (2.1) into state equation, let θ = ω<br />

ω *<br />

= τ<br />

Motor −<br />

J<br />

W(hopper)<br />

FNR<br />

8<br />

* *<br />

J θ<br />

(2.1)<br />

, (2.2)

where, ω = angular velocity of the launcher motor, τ = torque motor give, J =<br />

mass moment. The state equations above allow us to find the angular velocity the<br />

motor gives. Once angular velocity is found, time is found by<br />

dθ<br />

ω = . (2.3)<br />

dt<br />

Integrate (2.3), and solve for t = time<br />

t = θ / ω<br />

(2.4)<br />

2.1.2<br />

Scilab Calculation for Panning Motor Selection<br />

Figure 2.2: The torque and inertia in a basic motor model<br />

The first-order differential equation can developed from motor properties using<br />

some basic measurements.<br />

Tm = KI<br />

(2.6)<br />

Tm<br />

I = ( 2 .7)<br />

K<br />

where, T = motor torque, K= constant, and I = current. Then consider the<br />

m<br />

power in motor,<br />

P m +<br />

= V I = Tω<br />

KIω<br />

(2.8)<br />

V m = Kω<br />

(2.9)<br />

V m<br />

where, = voltage supply to motor, and P = power. The dynamics of the<br />

rotating masses can be found by summing moments,<br />

9

∑ ⎟ ⎞ ⎛ d<br />

M = Tm<br />

− TF<br />

= J⎜<br />

ω<br />

(2.10)<br />

⎝ dt ⎠<br />

⎛ d ⎞<br />

T m = J⎜<br />

⎟ω<br />

+ TF<br />

(2.11)<br />

⎝ dt ⎠<br />

where, J= motor rotor, T = frictional torque, and w= motor speed. The current-<br />

F<br />

voltage relationship for the left hand side of the equation can be written and<br />

manipulated<br />

to relate voltage and angular velocity.<br />

V Vm<br />

I = (2.12)<br />

R<br />

s −<br />

Tm Vs<br />

− Kω<br />

=<br />

K R<br />

⎛<br />

d<br />

dt<br />

⎞<br />

⎟ω<br />

+ T<br />

⎠<br />

K<br />

J⎜ F<br />

⎝<br />

(2.13)<br />

Vs<br />

− Kω<br />

= (2.14)<br />

R<br />

2<br />

⎛ d ⎞ ⎛ K ⎞ ⎛ K ⎞ TF<br />

⎜ ⎟ω<br />

+ ω = Vs<br />

⎜ ⎟ +<br />

dt ⎜<br />

JR ⎟<br />

⎝ ⎠ ⎝ ⎠ ⎝ JR ⎠ J<br />

From section 2.1,<br />

T F = F*N*R. The coefficients for the differential equation<br />

(2.15) can be found for the motor in a dynamic case using steady state<br />

velocities. At steady state (2.15) becomes<br />

2 ⎛ K ⎞ ⎛ K<br />

ω ⎜<br />

⎟ = Vs<br />

⎜<br />

⎝ JR ⎠ ⎝ JR<br />

K<br />

V<br />

ω<br />

= .<br />

s<br />

⎞<br />

⎟<br />

⎠<br />

Then J can be found because<br />

K 2<br />

(2.15)<br />

(2.16)<br />

(2.17)<br />

τ =<br />

(2.18)<br />

JR<br />

10

2<br />

K<br />

J =<br />

τR<br />

(2.19)<br />

where, τ =time constant.<br />

Time constant can be found by using 63% of steady<br />

value from voltage vs time curve. The static torque value can be found using the<br />

deadband limits,<br />

ω = 0;<br />

T < T<br />

F<br />

T ≠ ; T < 0 ω<br />

2.2 Ball Characteristic Calculations<br />

F<br />

S<br />

K<br />

2.2.1 Ball<br />

Velocity Before Launch<br />

Figure 6 shows the pathway of the ball in hopper<br />

feeder (slider), the arrow<br />

indicates the direction of the ball.<br />

Figure 6: Feeder pathway<br />

To calculate the velocity from the top ( V t ) of feeder to the bottom ( Vb<br />

), principle<br />

of work and energy<br />

is used,<br />

w<br />

here, ( t b)<br />

Start<br />

W +<br />

( t→b ) = W(<br />

t→b<br />

) conservative<br />

W(<br />

t→b<br />

) non−conservative<br />

, (2.20)<br />

W → = work from top to bottom of feeder . Conservative work includes<br />

all work and energy that are path independent,<br />

Finish<br />

W = V + T,<br />

(2.21)<br />

11

where, V= potential energy, and T= kinetic energy. Work due to gravity (potential<br />

energy) occurs when the ball is dropped through a feeder. Work due to gravity is<br />

defined as<br />

Vg = mgh , (2.22)<br />

where V = work due to gravity, m = mass of an object, g = gravity, h= distance<br />

from which the object is dropped, Figure 2.3. The ball is moving with kinetic<br />

energy,<br />

g<br />

1 2<br />

mv<br />

T = , ( 2.23)<br />

2<br />

where, m = mass of an object, and v = object velocity. Non-conservative work is<br />

work due to friction,<br />

W = Fds , (2.24)<br />

friction<br />

sb<br />

where W friction = non conservative work due to friction,<br />

F= friction force as a<br />

function of time, ds = change in distance the ball is dropped, S t = initial position<br />

(2.24), then substitute them in (2.20),<br />

∫<br />

st<br />

of the ball, and Sb<br />

=final position of the ball. Combine (2.21), (2.22), (2.23) and<br />

1<br />

2<br />

mv<br />

2<br />

t<br />

s<br />

b<br />

1 2<br />

+ mght<br />

+ ∫ Fds = mvb<br />

+ mghb<br />

, (2.25)<br />

2<br />

st<br />

where, vt<br />

= initial velocity at top of feeder, v b = velocity of ball at the bottom of<br />

feeder, h = the height at the top of feeder, and h = the height at the bottom of<br />

t b<br />

feeder. Figure<br />

2.4 shows the free body diagram of the ball from feeder. The ball<br />

starts at rest, with the height of h, as shown in Figure 2.3.<br />

12

Figure 7: Free body diagram of the ball<br />

Equation (2.25) is used to calculate the speed of the ball at the bottom of feeder<br />

Based on the free body diagram, Figure 7,<br />

mgy<br />

t<br />

sb<br />

1<br />

+ ∫ FNds =<br />

2<br />

st<br />

mv<br />

where, F = force of friction, and N = normal force of ball.<br />

2.2.2 Projectile Motion Derivation<br />

2<br />

b<br />

+ mgy , (2.26)<br />

Figure 8: Projectile motion from launch position to targets.<br />

Start out with the definition of a vector r in space,<br />

r ( t)<br />

= x(<br />

t)<br />

i + y(<br />

t)<br />

j , (2.27)<br />

whe re r (t)<br />

= vector in space, x ( t)<br />

i = position of time in x direction, and y ( t)<br />

j =<br />

position of time in y direction. The acceleration in x direction is 0 ( a = 0 ),<br />

therefore, the function of x direction with respect<br />

to time is defined,<br />

13<br />

b<br />

x

x i 0x<br />

( t)<br />

= x + V t , ( 2.28)<br />

where, x(t)= position in x direction with respect to time, x = initial position,<br />

V0x = initial velocity of the ball in x direction, and t = time. Whereas, acceleration<br />

for the y direction is the gravity (<br />

with respect to time is defined as,<br />

1<br />

2<br />

a y<br />

i<br />

= −g<br />

), therefore, the function of y direction<br />

2<br />

y( t)<br />

= yi<br />

+ V0<br />

yt<br />

− gt , (2.29)<br />

where, y(t) = position in y direction with respect to time, = initial position in y<br />

V 0 = initial velocity in the y direction, g = gravity, and t =<br />

direction, y<br />

time. From<br />

Figure 8, assumed initial position is 0, ( x = y = 0 ), and<br />

0<br />

0<br />

V x = V cosθ<br />

, (2.30)<br />

0<br />

0<br />

V = V sinθ<br />

, (2.31)<br />

0 y<br />

where, V 0 = initial velocity, and<br />

0<br />

(2.30), (2.31) into (2.28) and (2.29) respectively to get<br />

and<br />

Solve (2.32) for t,<br />

θ = the angle of launcher. Substitute value<br />

into<br />

x( t)<br />

= V0<br />

cosθ<br />

( t)<br />

, (2.32)<br />

1<br />

y( t)<br />

− gt<br />

2<br />

2<br />

= V0<br />

sinθ<br />

( t)<br />

(2.33)<br />

x<br />

t = (2.34)<br />

V cosθ<br />

0<br />

then substitute (2.34) back to (2.33),<br />

14<br />

y i

ut<br />

2<br />

x 1 ⎛ x ⎞<br />

y ( x)<br />

= V sinθ<br />

− ⎜ ⎟<br />

0<br />

g<br />

⎜ ⎟<br />

(2.35)<br />

2 2<br />

V0<br />

cosθ 2 ⎝V0<br />

cos θ ⎠<br />

cos<br />

1 2<br />

2<br />

θ<br />

Combine (2.35) and (2.36)<br />

to get<br />

(<br />

= 1 + tan ( θ )<br />

(2.36)<br />

)<br />

2 ( 1 tan θ )<br />

2<br />

gx<br />

y ( x)<br />

= x tanθ<br />

− +<br />

(2.37)<br />

2<br />

2V<br />

If y(x) is z, then solve for V0<br />

from (2.37);<br />

V<br />

0<br />

=<br />

0<br />

2 ( 1+<br />

tan ( ) )<br />

2<br />

gx θ<br />

(2.38)<br />

2(<br />

x tan( θ ) − z<br />

Equation (2.38) is used to find the desired initi al velocity base d on position<br />

of<br />

each target.<br />

2.2.3 Derivation for Individual Target Distance and Angle<br />

Figure 9: Launcher Position.<br />

The triangle above has an angle ofγ . The<br />

distance from the launcher to the<br />

midpoint of the target is the adjacent<br />

side of the triangle, “a”. The distance<br />

between the midpoint to a specific target is the opposite side of the triangle, “o”.<br />

From trigonometry, hypotenuse (“h” or the distance from launcher to a specific<br />

target) of the triangle can be found by using Pythagorean theorems,<br />

15

2 2 2<br />

h = a + o , ( 2.39)<br />

where, h= hypotenuse, a=adjacent, and o=opposite. Solve for h from (2.39),<br />

2 2<br />

h = a + o . (2.40)<br />

The angle can be found be using the tangent equation,<br />

o<br />

tan γ = .<br />

a<br />

Then solve for γ from (2.41),<br />

3. Test Results<br />

(2.41)<br />

−1⎛<br />

o ⎞<br />

γ = tan ⎜ ⎟ . (2.42)<br />

⎝ a ⎠<br />

3.1 Scilab Simulation Results<br />

A Scilab program was used to simulate the motion of the panning motor.<br />

The Scilab results are shown below in Figure 3.1. Figure 3.1 shows the position<br />

and angular speed of the panning motor with respect to time. Scilab program is<br />

shown in Appendix 7.4.<br />

Figure 10: Scilab Simulation Results<br />

16

3.2 Estimated Design Score<br />

The design<br />

score depends on the cost, mass, build quality, technical<br />

quality, and number<br />

of targets hit. The estimated contest score is shown in Table<br />

2. The following equation was<br />

used to asses the overall score for the design.<br />

Score = H<br />

Where,<br />

−2<br />

4)<br />

H = targets hit in 2 minutes<br />

C = total cost of<br />

( 10)<br />

parts<br />

L = largest dimensions<br />

(<br />

c<br />

80<br />

−B<br />

( 10)<br />

(inches)<br />

B = build quality (1 = best, 0 = worst)<br />

T = Technical quality (1 = best, 0 = worst)<br />

M = mass of machine (Kg)<br />

−T<br />

( 2)<br />

L<br />

( )<br />

3<br />

M<br />

Table 2: Estimated contest score<br />

H 143<br />

C 98.6<br />

L 12<br />

B 1<br />

T 1<br />

M 0.985<br />

Estimated Score<br />

4<br />

0.0000409205101<br />

4. Conclusions<br />

The machine that was designed and built for the purpose of target acquisition and<br />

elimination,<br />

performed as expected. When a target became active the stepper quickly<br />

moved the barrel into position and a ball was fired at the target. Through the design,<br />

build,<br />

and implementation of this machine, certain conclusions were arrived upon.<br />

17

1. The flap in front of the nozzle was sufficient at providing the ball with an<br />

initial acceleration and holding the next ball back.<br />

2. Mass was the most important factor in this project. By using light-weight<br />

components for the base and hopper, the mass of the device was under a<br />

kilogram causing a drastic effect on the score.<br />

3. Launch velocity increased as the airflow through the barrel increased.<br />

5. Recommendations<br />

After the performance the device was analyzed through testing and competition.<br />

The following are recommendations to improve the function of the mechanism:<br />

1. The inside diameter of the barrel should be decreased to improve the<br />

accuracy of the firing mechanism.<br />

2. A method<br />

to ensure that the stepper motor is consistently starting at the<br />

3. Eliminate all loose connections by soldering wires directly onto the L298P<br />

6. Digital<br />

Picture<br />

same position should be implemented.<br />

motor driver.<br />

Figure 11: Digital Photo of final Machine<br />

18

7. Appendices<br />

7.1 Pro-E Drawings<br />

7.1.1 Exploded Assembly View with BOM<br />

19

7.1.2 Orthographic Prints<br />

21

7.1.3 Pro-E drawings<br />

Figure 12: Machined base<br />

Figure 14: Stepper motor<br />

22

Figure 13: Barrel<br />

Figure 15: Air nozzle bracket<br />

23

Figure 16: Air fitting<br />

Figure 17: Barrel bracket<br />

24

Figure 18: Ball stopper flap<br />

Figure 19: Ball stopper flap hinge<br />

25

Figure 20: L_bracket (connect the barrel and ball stopper)<br />

Figure 21: Stepper motor shaft<br />

26

Figure 22: Rubber foot<br />

Figure 23: Helical hopper (one of two wires)<br />

27

Figure 24: Ball stopper<br />

Figure 25: Supporting rod<br />

28

Figure 26: Hopper U-joint<br />

Figure 27: Hopper bar<br />

Figure 28: Hopper slider<br />

29

7.2 Gantt Chart<br />

30

7.3 C Code<br />

//Author: Brian Coleman<br />

//Class: EGR 345<br />

//Date: 11/29/05<br />

//Include files<br />

#include<br />

#include <br />

#include <br />

#include "sio.c"<br />

//Function prototypes<br />

void CLK_setup(void);<br />

void IO_setup(void);<br />

void IO_update(void);<br />

void move_step(int dir, int step_delay);<br />

void write_step(int step);<br />

int check_targets(void);<br />

void delay(int ticks);<br />

void stop(void);<br />

//Global Constants<br />

#define UP 1<br />

#define DOWN 0<br />

#define HIGH 1<br />

#define LOW 0<br />

#define Start 0 //Initial target<br />

#define TARGET_1 -9 //Left-most target<br />

#define TARGET_2 -4 //Inner-left target<br />

#define TARGET_3 1 //Inner-right target<br />

#define TARGET_4 6 //Right-most target<br />

# define NUM_INTERRUPTS 10 //Number of interrupts per sec<br />

# define DELAY_TIME 25 //1 is the maximum speed<br />

#define FIRE_DELAY 200 //Air release time<br />

//Variables<br />

int<br />

steps[] = {1, 2, 4, 8};<br />

int<br />

position = 0;<br />

int last_target = 0;<br />

31

int current_target = 0;<br />

int destination = 0;<br />

int current_step =<br />

int i;<br />

-1;<br />

unsigned int CNT_timer1;<br />

//The delay time<br />

volatile unsigned int CLK_ticks<br />

= 0; //The current number of ms since<br />

last increment of CLK_seconds<br />

volatile unsigned<br />

since<br />

start<br />

int CLK_seconds = 0; //The current number of seconds<br />

/*-------------------------------<br />

Interrupt Stuff ---------------------<br />

----------*/<br />

SIGNAL(SIG_OVERFLOW1) / /The interrupt calls this function<br />

{<br />

CLK_ticks += (NUM_INTERRUPTS*10);<br />

if(CLK_ticks >= 1000)<br />

{<br />

beginning<br />

}<br />

}<br />

CLK_ticks -= 1000;<br />

CLK_seconds++;<br />

//Counts the number of seconds from the<br />

IO_update();<br />

TCNT1 = CNT_timer1;<br />

void CLK_setup(void) //Starts the interrupt service<br />

routine<br />

{<br />

TCCR1A = (0

}<br />

CNT_timer1 = 0xFFFF - 80;<br />

TCNT1 = CNT_timer1;<br />

//Start at the right point<br />

TIFR<br />

&= ~(1

}<br />

destination = current_target - position;<br />

if(destination > 0)<br />

{<br />

}<br />

{<br />

}<br />

{<br />

}<br />

for(i = 0; i < destination; i++)<br />

delay(250);<br />

delay(250);<br />

move_step(UP,<br />

DELAY_TIME);<br />

PORTB |= 0x20; //Set PB5<br />

delay(FIRE_DELAY);<br />

PORTB &= ~0x20; //Clear PB5<br />

delay(1500);<br />

else if (destination < 0)<br />

else<br />

for(i = 0; i > destination; i--)<br />

move_step(DOWN, DELAY_TIME);<br />

PORTB |= 0x20; //Set PB5<br />

delay(FIRE_DELAY);<br />

PORTB &= ~0x20; //Clear PB5<br />

delay(1500);<br />

PORTB |= 0x20;<br />

//Set PB5<br />

delay(FIRE_DELAY);<br />

PORTB &= ~0x20; //Clear PB5<br />

delay(1500);<br />

34

}<br />

}<br />

/*-------------------------------<br />

Stepper Control ---------------------<br />

-- ---* /<br />

void move_step(int dir, int step_delay)<br />

//step_delay determines the<br />

rotational speed<br />

{<br />

}<br />

if(dir == UP)<br />

{<br />

}<br />

else<br />

{<br />

}<br />

current_step++;<br />

position++;<br />

current_step--;<br />

position--;<br />

if(current_step > 3) current_step = 0;<br />

else if(current_step<br />

< 0) current_step = 3;<br />

write_step(steps[current_step]);<br />

delay(step_delay);<br />

/*---------------------------------------------------------------------<br />

-*/<br />

void write_step(int step)<br />

{<br />

}<br />

PORTB = step;<br />

/*--------------------------------------------------------------------<br />

-*/<br />

int check_targets(void)<br />

35

{<br />

}<br />

int target;<br />

if((PINA & 0x01) !=0) //PA0<br />

{<br />

}<br />

target = TARGET_1;<br />

else if((PINA & 0x02) !=0) //PA1<br />

{<br />

}<br />

else if<br />

{<br />

}<br />

target = TARGET_2;<br />

((PINA & 0x04) !=0)//PA2<br />

else if ((PINA<br />

& 0x08) !=0) //PA3<br />

else target<br />

= Start;<br />

/* ---------------------------------------------------------------------<br />

-*/<br />

{<br />

}<br />

void<br />

delay(int ticks) //ticks are approximately 1ms<br />

{<br />

}<br />

{<br />

}<br />

target = TARGET_3;<br />

target = TARGET_4;<br />

return target;<br />

volatile int i, j;<br />

for(i = 0; i < ticks;<br />

i++)<br />

for(j = 0;<br />

j < 465; j++);<br />

/*-------------------------------<br />

Main -------------------------------<br />

*/<br />

36

int main(void)<br />

{<br />

}<br />

sio_cleanup();<br />

sio_init();<br />

IO_setup();<br />

CLK_setup();<br />

PORTD = 0x30; //Turn EA and EB to<br />

for(;;);<br />

return 0;<br />

37<br />

high

7.4 S cilab Code<br />

//system component values<br />

K=0.05 // motor constant<br />

R= 20; //motor resistance<br />

J= 1.35*10^10/25.4; //given from<br />

pro-e<br />

F= 407.437; //lbf<br />

.25"diameter hose with 20 psia pressure<br />

N= 100;<br />

//sytem state<br />

theta0= 0; //the initial position<br />

for the motor (rad)<br />

omega0=0;<br />

//<br />

X=[theta0, omega0];<br />

moving=0;//th system is not in motion<br />

//the controller deinition<br />

Cd= 20; //setpoint<br />

Kpot= 1.5; //the angle voltage ratio, slope of angle vs. voltage plot<br />

Vzero= 0; //voltage when the penduleum is vertical<br />

Vadmax= 5; //the A/D voltage range<br />

Vadmin = 0;<br />

Cadmax= 255; //the A/D converter output limits<br />

Cadmin= 0;<br />

Kp= 5;<br />

Vpwmmax= 12; //PWM output limitaitons in V<br />

Cpwmmax= 255; //PWM input range<br />

Cdeadpos_static= 10; //deadband limits for static torque<br />

Cdeadneg_static= 20;<br />

Cdeadpos_dynamic= 10; //deadband limits for kinetic torque<br />

Cdeadneg_dynamic= 20;<br />

function foo=control(state,t)<br />

38

VL= Kpot*state($,1)-Vzero; //estimate input voltage for pot.<br />

Cp=(VL-Vadmin)/(Vadmax-Vadmin)*(Cadmax-Cadmin); //estimat A/D input<br />

if Cp> Cadmax then Cp = Cadmax;<br />

end //c heck for voltages over limits<br />

if Cp< Cadmin then Cp=Cadmin;<br />

end<br />

Ce=Cd-Cp;<br />

Cu=Kp* Ce;<br />

if abs(state($ ,2))>0.01 then<br />

Cdeadpos= Cdeadpos_dynamic;<br />

Cdeadneg= Cdeadneg_dynamic;<br />

else<br />

Cdeadpos=Cdeadpos_static;<br />

Cdeadneg=Cdeadneg_static;<br />

end<br />

Cpwm=0;<br />

if Cu>0.99 then //deadnamd cp,[emsatopm<br />

Cpwm =Cdeadpos + (Cu/Cpwmmax)*(Cpwmmax-Cdeadpos);<br />

end<br />

if Cu Vpwmmax then foo = Vpwmmax;<br />

end //clip voltage if too<br />

large<br />

if foo < -Vpwmmax then foo = -Vpwmmax;<br />

end<br />

endfunction<br />

39

define the state matrix function for a simple motor<br />

function foo =derivative(state,t)<br />

Vs= control(state,t);<br />

foo= [state($,2), state($,2)*(-(K*K)/(J*R))+Vs*K/(J*R)+(F*N*R)/J];<br />

endfunction<br />

//Set<br />

the time length and step size for the integration<br />

steps= 100;<br />

t_start=0;<br />

t_end=2;<br />

h=(t_end-t_start)/<br />

steps;<br />

t=[t_start];<br />

//Loop for integration<br />

for i=1:steps,<br />

t=[t; t($,:)+h] ;<br />

control(X($,:), t($,:));<br />

X=[X; X($,:) + h*derivative(X($,:), t($,:))]; //first order<br />

end<br />

//print out the solution<br />

intervals<br />

=200;<br />

for time_count =1:intervals,<br />

i=int((time_count -1)/intervals *steps +1);<br />

printf("%f\n", X(i,2));<br />

end<br />

// graph the values<br />

plot2d(t,X,style = [-2,-5],leg="speed(rad/s@angle(rad))");<br />

xtitle('Time(s)');<br />

40