Final Report - Claymore - Grand Valley State University

Final Report - Claymore - Grand Valley State University

Final Report - Claymore - Grand Valley State University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ROBOTIC WORLD CUP<br />

<strong>Final</strong> <strong>Report</strong><br />

Team 6:<br />

Ben Davison, Cody Holstege, Travis Knoper,<br />

Greg Loveland, Michael Olson, David Santellan<br />

EGR345 Dynamic Systems Modeling & Controls<br />

Dr. Nael Barakat and Dr. Hugh Jack<br />

December 4, 2006

Table of Contents<br />

Section page<br />

Executive Summary 2<br />

1. Design Description 3<br />

1.1 Drawing Summary 3<br />

Figure 1.1 3<br />

Figure1.2 3<br />

1.2 System Block Diagrams 4<br />

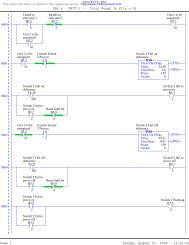

Figure 1.3: Block diagram of control system for offensive robot. 4<br />

Figure 1.4: Block diagram of control system for defensive robot. 5<br />

1.3 Description of Control Scheme 5<br />

Figure 1.5: Block diagram of the general system architecture. 5<br />

1.4 Flow Charts 6<br />

1.5 Schematics 7<br />

1.6 Calculations 7<br />

1.7 Projected Budget, Weight Inventory, and BOM 8<br />

2. Test Results 8<br />

2.1 Simulation Results 8<br />

2.2 Performance Testing 9<br />

2.3 Results of Formal Tests 9<br />

2.4 Comparison of Overall Score Estimates 10<br />

3. Conclusions 11<br />

4. Recommendations 12<br />

Appendix A – Drawings 13<br />

Appendix B – Electrical Schematics 28<br />

Appendix C – Calculations 31<br />

Appendix D – Receipts and Cost Validation 35<br />

Appendix E – C Programs 44<br />

1

Executive Summary<br />

Two robots were designed to compete in a robotic foosball tournament. One<br />

robot was designed to defend three goals spaced evenly on one side. The other robot was<br />

designed to launch practice golf balls past the opponents’ two robots and into one of their<br />

goals. The robots had to measure less than 12 inches in their longest dimension, and<br />

could not extend past the overhead guide rails. Robots were graded based on weight,<br />

cost, build quality, theory quality and points scored by both teams. Both robots<br />

functioned as designed and competed in the EGR101 versus EGR345 competition.<br />

The robots were constructed using aluminum. The group decided on a thin plate<br />

chassis with angled supports to secure the robots to the trains. The defensive robot was<br />

designed to guard our three goals. This was accomplished by tracking the position of the<br />

opponents’ offensive robot and mirroring its movement. The offensive robot used an air-<br />

cannon to fire the practice golf balls. The robot takes as input the position and velocity of<br />

the two opponent robots and calculates the precise time to fire.<br />

2

1. Design Description<br />

1.1 Drawing Summary<br />

Figure 1.1: Isometric view of offensive robot<br />

Figure 1.2: isometric view of defensive robot<br />

3

From Figure 1 and 2 it can be seen that the design approach was to minimize the<br />

material used in the construction to reduce the cost and weights of the robots. Wherever<br />

possible, material was cut out to save weight. The uprights were designed as the<br />

strongest part of the robot because they are expected to take the largest load. The design<br />

of each robot is the same, with the exception of a barrel on the offensive robot and a net<br />

on the defensive robot, this is to make the manufacturing of the robots easier and cheaper.<br />

More detailed Pro-E drawings can be viewed in appendix A.<br />

1.2 System Block Diagrams<br />

Figure 2.1 shows a block diagram for the offensive robot. A setpoint generator<br />

will be combined with a proportional gain controller using the opponent’s position as<br />

feedback for proper target acquisition.<br />

Figure 2.2 is the block diagram for the defensive robot. This control system will<br />

track the opponent’s offensive robot in order to defend against incoming projectiles.<br />

Figure 1.3: Block diagram of system architecture for offensive robot.<br />

4

Figure 1.4: Block diagram of system architecture for defensive robot.<br />

1.3 Description of Control Scheme<br />

Figure 2.3 shows a block diagram for the general system architecture for both<br />

robots. Electrical components include the ATMega32 board, an L293D push-pull 4<br />

channel driver (H-Bridge), and the driving motor. A DB-25 connector will supply<br />

positional feedback for the opponent’s robots.<br />

Figure 1.5: Control Block Diagram.<br />

5

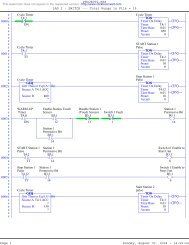

1.4 Flow Charts<br />

Flow charts were created to map the desired function of the C programs which<br />

can be seen in Appendix E. Flow charts for the defensive and offensive controller<br />

programs can be seen in Figures 1.6 and 1.7 respectively.<br />

Figure 1.6: Flow chart of defensive controller program.<br />

6

1.5 Schematics<br />

Figure 1.7: Flow chart of defensive controller program.<br />

For ease of manufacturability, both robots used very similar wiring layouts. The<br />

schematics for both of these layouts can be seen in Appendix B.<br />

1.6 Calculations<br />

Using Kinematics equations, the required velocity of the ball was determined to<br />

be 29.4 ft/s. This would allow the ball to cross the playing field in 0.225 seconds with a<br />

7

maximum height of 4 inches above where it is fired. Robot velocities were calculated for<br />

several different gear ratios. This information was used to choose the proper gear ratio.<br />

The selected gear ratio was 41.7:1 which was capable moving the robot between 1.06 ft/s<br />

to 1.32 ft/s. All of the calculations used to obtain these values can be seen in Appendix<br />

C.<br />

1.7 Projected Budget, Weight Inventory, and BOM<br />

All of the supplies which were not directly purchased from a supplier were<br />

researched and priced. The final price for both robots was $121.68. The mass of each<br />

part on the robot was measured, the total mass came to 0.593 kg for the offensive robot<br />

and 0.498 kg for the defensive robots. All of the researched prices, receipts for purchased<br />

products, and the weight inventory can be seen in appendix D.<br />

2. Test Results<br />

2.1 Simulation Results<br />

Simulations were conducted to determine motion of the robots prior to placing<br />

them on the playing field. Using proximity sensors, the actual competition playing field<br />

is to supply the robots with 4 analog signals ranging from 0 to 5 volts, depending on the<br />

robot’s distance from the sensor. The greater the distance between the robot and the<br />

proximity sensor, the greater the voltage supplied, and the greater the analog signal.<br />

In order to simulate position data, variable power supplies were used to generate<br />

analog position feedback. The output voltage on two power supplies was varied between<br />

0 and 5 volts and fed into port A of the ATMega32. The robot controllers took advantage<br />

of the ATMega32 onboard analog-to-digital converter, and the simulated position voltage<br />

was correctly converted on 2 analog input channels. As expected, the controller program<br />

output motor voltage in an attempt to track the enemy and mirror its simulated position.<br />

With the exception of frequently overshooting the enemy’s simulated position, the<br />

controller program correctly tracked and mirrored its attacker. Analysis of the controller<br />

program showed a tendency for the robot to decelerate at the same rate as it would<br />

accelerate, causing the robot to overshoot its desired position. Code was added which<br />

8

allowed the robot controller to monitor its position more accurately, decreasing the<br />

amount of overshoot.<br />

2.2 Performance Testing<br />

Several tests were performed before conducting the individual in-class tests. One<br />

of the first tests was to compare the performance of two gearboxes—the Tamiya High-<br />

Speed Gearbox and the Tamiya High-Power Gearbox. The gearboxes were tested<br />

by supplying each with a range of voltages and weight loads, then measuring the<br />

resulting velocities. It was observed that the high-speed gearbox indeed had higher<br />

velocity, but could not handle the required weight loads. However, the high-power<br />

gearbox met our velocity requirements throughout the voltage range, and was also<br />

capable of handling the expected weight loads.<br />

Once a gearbox had been chosen, the robot was tested on the track. It was<br />

observed that the robot bound with the truck and could not move. This was fixed by<br />

enlarging the slot that the pins go through.<br />

The barrel was tested by supplying 85 psi through a ¼” air hose. Initially, the ball<br />

did not have enough velocity to cross the playing field. The barrel was modified by<br />

covering the holes with electrical tape and retested. This modification gave the ball<br />

enough velocity to cross the field and score a goal.<br />

Several tests were performed on the program. Once the program was functioning<br />

properly, there were still several calibration problems. The defensive program was<br />

modified to stop the motor upon reaching the desired destination so that it did not<br />

overshoot. The offensive program was calibrated to find desired shooting positions that<br />

were not blocked by the opposing team’s defensive robot.<br />

2.3 Results of Formal Tests<br />

There were three main in-class tests of the robot’s function. For the first test, the<br />

base of the robot was completed and the robot’s ability to move on the track was<br />

demonstrated. For the second test, the mechanical aspects of both the offensive and<br />

defensive robots were completed. Both robots traversed the path without binding on the<br />

truck and the offensive robot fired a ball with sufficient velocity to score a goal. The goal<br />

9

of the final in-class test was a test of the defensive robot’s control system. The defensive<br />

robot was able to track the truck on the opposite side of the playing field using signals<br />

sent through the DB-25 connector.<br />

Several problems with the robots were noted from these tests. One of the first<br />

significant observations was that when 5 volts was supplied instantaneously to the motor,<br />

the motor produced so much torque that the front wheels lifted off the track causing the<br />

truck to bind. The problem was fixed by ramping up the voltage to the motor.<br />

A second observation was that the defensive robot tended to overshoot its desired<br />

location when tracking the opposite truck. It was determined that this was due to large<br />

acceleration caused by a function in the code. The function not only caused the robot to<br />

accelerate when beginning to move but also caused the robot to decelerate when<br />

stopping, in turn causing the robot to overshoot its desired location. This was fixed by<br />

eliminating the robot’s ability to decelerate and changing the code so that, slightly before<br />

reaching its desired location, the voltage was completely shut off.<br />

2.4 Comparison of Overall Score Estimates<br />

Where<br />

The scoring from the competition will be calculated with the following equation:<br />

S = Shots blocked by opponent<br />

H = Shots scored<br />

C = Cost of both robots<br />

B = Build Quality<br />

T = Theory rating<br />

M = Mass of both robots<br />

S<br />

2<br />

H<br />

C<br />

4<br />

−2<br />

80 −B<br />

−T<br />

⎛ M ⎞<br />

( 4)<br />

( 10)<br />

( 10)<br />

⎜ ⎟<br />

⎝ 0.<br />

5 ⎠<br />

10<br />

(2.1)<br />

It is desired to have to lowest score possible. The effect of the final score by each<br />

variable was determined by only changing one variable at a time and keeping every other<br />

variable constant, S = 5, H = 5, C = 175, B = 0.9, T = 0.7, M =0.9 From this it was<br />

determined that the best way to have a low score is to miss as few shots as possible.

The robot is expected to have accuracy of at least 70% if it fires all of the possible<br />

balls in the two minute interval the expected score will be:<br />

3.0 Conclusions<br />

3<br />

2<br />

7<br />

−2<br />

(<br />

4)<br />

175<br />

80<br />

( 10)<br />

−<br />

0.<br />

9<br />

( 10)<br />

11<br />

−<br />

0.<br />

7<br />

⎛ 0.<br />

9 ⎞<br />

⎜ ⎟<br />

⎝ 0.<br />

5 ⎠<br />

4<br />

= 1.<br />

005<br />

(1) Premature exclusion of any ideas submitted during brainstorming was detrimental<br />

to the development of the team and teamwork. As the project progressed, the<br />

team learned that regardless of frivolity all ideas submitted were to be given their<br />

due attention in order to cultivate the best design from all team members.<br />

(2) Crude hand sketches were used to communicate initial designs. As the project<br />

approached the decision-making phase, 3D computer models were necessary to<br />

determine the physical dimensions and to perform mass analysis, both critical in<br />

meeting project requirements.<br />

(3) After many calculations, three items were chosen as the most influential in<br />

determination of the estimated final score: (a) total mass, (b) total cost, and (c)<br />

total projectiles blocked. The benefit of mass reduction was worth far more than<br />

the extra strength provided by thicker plates and supports. The thickness of the<br />

chassis was reduced to 1/16 in. and most unneeded material was removed. Total<br />

cost was reduced by relying on in-house fabrication of several components. The<br />

reduction in mass allowed an increase in speed and acceleration, thereby allowing<br />

the defensive robot to block a greater number of projectiles.<br />

(4) The team learned that “Attention to Detail” was the best approach to component<br />

fabrication and mechanical and electrical assembly. Too often the most minute of<br />

details was overlooked and resulted in prolonged and unnecessary<br />

troubleshooting. “Do the job right the first time” eventually became the team<br />

mantra.<br />

(5) Due to limited time and playing field availability, simulations were absolutely<br />

necessary. During the controller design and programming phase especially, a<br />

simulated position generator was used to save time that would translate to money<br />

in the real world.

(6) During initial competitions versus EGR101 students it was seen that EGR345<br />

robots had a significant advantage with respect to speed and reaction time.<br />

However, as the competitions progressed, the autonomous robots bore an<br />

increasingly obvious disadvantage against their human-controlled counterparts.<br />

The human element allowed for learning and adaptation, while the autonomous<br />

robots were “hard-coded” to perform in a limited, eventually predictable manner.<br />

4.0 Recommendations<br />

(1) While mass reduction was a benefit to the overall calculated project score, it<br />

eventually proved to be detrimental in the long run, causing slipping and loss of<br />

responsiveness. Further analysis should be performed in order to determine the<br />

most effective total mass and mass distribution for both robots.<br />

(2) During the course of fabrication, assembly, and testing, electrical components<br />

were found to be extremely sensitive to their thermal and conductive<br />

environment. An investigation should be undergone in order to determine the<br />

optimal placement of the electrical components to prevent exposure to heat, static<br />

electricity, and inadvertent short-circuits.<br />

(3) The storage capacity of the current circuit boards would certainly be challenged<br />

by more proliferative programs (i.e. artificial intelligence). Since these advanced<br />

programming techniques would increase the efficiency and effectiveness of an<br />

autonomous robot, further programming should commence. Additionally,<br />

research should be conducted that may indicate whether a more powerful<br />

microprocessor would benefit this project after such programming is completed.<br />

12

Appendix A: Drawings<br />

13

Appendix B: Electrical Schematics<br />

28

Defensive Robot<br />

29

Offensive Robot<br />

30

Appendix C: Calculations<br />

31

Calculated Ball velocity<br />

Kinematics equations can be written in the x and y directions using the equation<br />

1<br />

s = s0<br />

+ v0<br />

+ at<br />

2<br />

Where s is the final position of the ball, s0 is the initial position of the ball, v0 is the initial<br />

velocity of the ball, a is the acceleration of the ball, and t is the time that the ball travels.<br />

Assuming that the angle is 10°, the resultant equation in the y direction is:<br />

In the x direction, the resultant equation is:<br />

1 ft<br />

0. 333 ft = 0 ft + v0<br />

sin( 10)<br />

+ ( −32.<br />

2 ) t 2<br />

2 s<br />

1 ft<br />

6. 5 ft = 0 ft + v0<br />

cos( 10)<br />

t + ( 0 ) t 2<br />

2 s<br />

Since there are 2 equations with two unknowns, t and v0 can be solved for.<br />

t = 0.<br />

225<br />

v<br />

0 =<br />

29.<br />

4<br />

s<br />

ft<br />

s<br />

Gear Ratio Calculations<br />

To purchase the appropriate motor, calculations were performed to determine the<br />

required voltage and RPM ratings based on the use of a 2 in. diameter wheel/tire:<br />

32<br />

2<br />

2<br />

2

Based on the gearbox and motor manufacturers’ specifications, final drive-shaft angular<br />

velocities were calculated for varying gear ratios as follows:<br />

Rated motor velocity range @ gear ratio = drive-shaft velocity range<br />

5040 RPM – 6300 RPM @ 64.8:1 = 78 RPM – 97 RPM<br />

33

Appendix D: Receipts and Cost Validation<br />

35

BOM<br />

Item #<br />

Item Description<br />

Qty.<br />

Offense<br />

Table 1.1: Project budget and weight inventory.<br />

Qty.<br />

Defense<br />

Total<br />

Qty.<br />

Cost per<br />

Unit<br />

14 Base plate 1 1 2 $2.87<br />

3 Barrel 1 0 1 $3.89<br />

9 Top Hinge 1 0 1 $0.35<br />

10 Bottom Hinge 1 0 1 $0.35<br />

6 Cage 1 1 2 $1.33<br />

18 Rear Pillow Plock 2 2 4 $0.04<br />

7 Fron Pillow Plock 2 2 4 $0.05<br />

16 Wheel 4 4 8 $0.60<br />

16 Tire 4 4 8 $0.30<br />

19 Axles<br />

2 2<br />

15 Spacer 4 4 8 $0.23<br />

2 Barrel cap 1 0 1 $0.34<br />

1 Top Plate 1 1 2 $0.43<br />

12 Coupler 4 4 8 $0.06<br />

11 Bushings 4 4 8 $0.05<br />

16 Nylon Fastener 4 4 8 $0.21<br />

17 FHCS, 6-32 x 1/4 14 12 26 $0.07<br />

8 Gearbox/motor<br />

4 Misc. Electrical Components<br />

5 Mega32 microcontroller<br />

*Supplier abbreviations<br />

McMC McMaster-Carr<br />

GVSU <strong>Grand</strong> <strong>Valley</strong> <strong>State</strong> <strong>University</strong><br />

ZR Zagros Robotics<br />

TBB Toy Brick Brigade<br />

RC Radio Shack<br />

1 1<br />

1 1<br />

1 1<br />

4<br />

2<br />

2<br />

2<br />

Total Cost<br />

per Item<br />

36<br />

Supplier*<br />

Supplier<br />

Part #<br />

$5.74 McMC 8199K33<br />

$3.89<br />

$0.35<br />

$0.35<br />

$2.66<br />

$0.16<br />

$0.20<br />

$4.80<br />

$2.40<br />

Material<br />

Mass per Unit<br />

(kg)<br />

Aluminum 0.039<br />

McMC 89965K128 Aluminum 0.141<br />

McMC 8975K64 Aluminum 0.011<br />

McMC 8975K65 0.007<br />

Kutsches Aluminum 0.053<br />

McMC 9536K19 0.005<br />

McMC 9536K19 Aluminum 0.012<br />

TBB 6595 Plastic 0.016<br />

TBB 6594 Rubber 0.010<br />

Tot. Mass Off.<br />

Robot (kg)<br />

Tot. Mass Def.<br />

Robot (kg)<br />

0.039 0.039<br />

0.141 0.000<br />

0.011 0.000<br />

0.007 0.000<br />

0.053 0.053<br />

0.010 0.010<br />

0.024 0.024<br />

0.064 0.064<br />

0.040 0.040<br />

$0.34 $1.36 FAB 88625K63 Steel 0.014 0.028 0.028<br />

$1.84 Lowes<br />

$0.34<br />

Nylon 0.001<br />

McMC 86985K56 Aluminum 0.014<br />

$0.86 McMC 8199K33<br />

$0.48<br />

$0.40<br />

$1.68<br />

$1.81<br />

Aluminum 0.005<br />

Kutsches Aluminum 0.003<br />

McMC 8538K16 Nylon 0.001<br />

Lowes 0.001<br />

McMC 92210A196 Steel 0.001<br />

0.004 0.004<br />

0.014 0.000<br />

0.005 0.005<br />

0.012 0.012<br />

0.004 0.004<br />

0.004 0.004<br />

0.014 0.012<br />

$9.95 $19.90 ZR 72003 N/A 0.055 0.055 0.055<br />

$6.23 $12.46 RC 0.029 0.029 0.029<br />

$30.00 $60.00 GVSU N/A 0.035 0.035 0.035<br />

Total Cost $121.68 Total Mass per Robot 0.593 0.418

--------------------------------------<br />

Order Date: 10/4/2006 6:33:57 PM<br />

Payment By: Paypal.com<br />

Buyer Requests Insurance: No<br />

--------------------------------------<br />

Comments from Buyer:<br />

--------------------------------------<br />

Order Batch Summary:<br />

--------------------------------------<br />

Total Items: 16<br />

Unique Items (lots): 2<br />

Total: $7.20<br />

--------------------------------------<br />

Items in Order:<br />

--------------------------------------<br />

[Used] Black Tire 49.6 x 28 VR (x8) ..... $0.30 each = $2.40<br />

[Used] Dark Gray Wheel 49.6 x 28 VR with Axle Hole (x8) ..... $0.60<br />

each =<br />

$4.80<br />

--------------------------------------<br />

Buyer Information:<br />

--------------------------------------<br />

BrickLink Username: cody_116 (0)<br />

E-Mail: kodice_116@hotmail.com<br />

IP Address: 148.61.176.128<br />

Address:<br />

cody Holstege<br />

10599 taylor street<br />

Zeeland, MI 49464<br />

USA<br />

--------------------------------------<br />

Seller Information:<br />

--------------------------------------<br />

BrickLink Username: ToyBrickBrigade (8032)<br />

E-Mail: bricklink@toybrickbrigade.com<br />

BrickLink Store Name: Toy Brick Brigade<br />

http://www.BrickLink.com/store.asp?p=ToyBrickBrigade<br />

41

Top and bottom Hinge Plates:<br />

Alloy 6061 Aluminum Square Bar 1/2" Square, 6' Length<br />

In stock at $16.41 Each<br />

Cost: $0.035 / foot<br />

Barrel:<br />

McMaster Prices<br />

9008K23<br />

89965K128<br />

(Same as 89965K781)<br />

Aluminum Tubing 1-3/4" Od, , 1.62" Id, .065" Wall Thickness, 3'L<br />

In stock at $20.02 Each<br />

Cost: $0.56 / foot<br />

Base and Top Plates<br />

8199K33<br />

Alloy 5052 Aluminum Sheet W/#4 Satin Finish .062" Thick, 12" X 24"<br />

In stock at $20.63 Each<br />

Cost: $0.072 / square inch<br />

Pillow Blocks<br />

Colored Aluminum Shim Stock .025" Thick, 6" X 24", White<br />

In stock at $6.94 Each<br />

Cost: $0.048 / square inch<br />

Axles<br />

9536K19<br />

88625K63<br />

O1 Tool Steel Tight-Tolerance Rod 4 Millimeter Diameter, 3' Length<br />

In stock at $2.22 Each<br />

Cost: $0.062 / inch<br />

Barrel Cap<br />

42

Alloy 2024 Aluminum Rod 7/8" Diameter, 1' Length<br />

In stock at $9.12 Each<br />

Cost $0.913 / in<br />

Bushings<br />

White Nylon 6/6 Rod 3/8" Diameter<br />

In stock at $0.55 per Ft.<br />

This product is sold in Lengths of 5 Ft.<br />

Cost: $0.05 / foot<br />

Fasteners:<br />

86985K411<br />

(Same as 86985K56)<br />

8538K16<br />

92949A144<br />

18-8 Ss Button Head Socket Cap Screw 6-32 Thread, 1/4" Length<br />

In stock at $5.29 per Pack<br />

This product is sold in Packs of 100<br />

Cost: $0.053 / fastener<br />

43

Appendix E: C Programs<br />

44

Defensive Robot Controller Program<br />

// Include header files, .c file<br />

#include <br />

#include <br />

#include <br />

#include <br />

#include "sio.c"<br />

//======================================================================================<br />

// Global Definitions<br />

#define c_kinetic_pos 0xC0 // Define kinetic friction coefficient for + direction<br />

#define c_kinetic_neg 0xC0 // Define kinetic friction coefficient for - direction<br />

#define c_static_pos 0xC0 // Define static friction coefficient for + direction<br />

#define c_static_neg 0xC0 // Define static friction coefficient for - direction<br />

#define c_max 255 // Define maximum position<br />

#define c_min 255 // Define magnitude of minimum position<br />

#define CLK_ms 10 // Set the updates for every 10ms<br />

#define T 10 // Define as 10 ms, must divide by 1000 later<br />

#define Kp 10 // Define to 1,3,1<br />

#define Ki 0 // Define to 1,1,3<br />

#define Kd 0<br />

#define US_DEF 1<br />

#define THEM_OFF 3<br />

#define THRESHOLD 15<br />

#define mult 3.0<br />

int moving = 0; // Set variable to show it starts without moving<br />

int e_sum = 0; // Used in integrate function<br />

int prev_err = 0; // used in derivitive function<br />

unsigned int CNT_timer1; // Time variable<br />

volatile unsigned int CLK_ticks = 0; // Current number of ms<br />

volatile unsigned int CLK_seconds = 0; // Current number of seconds<br />

int rpos[5];<br />

int pos_last = 0;<br />

//======================================================================================<br />

// Function definitions<br />

//<br />

//......................................................................................<br />

int integrate(int e)<br />

{<br />

e_sum += e*T;<br />

}<br />

if(e_sum > 10000) e_sum = 10000; // Set an upper limit<br />

if(e_sum < -10000) e_sum = -10000; // Set a lower limit<br />

return e_sum;<br />

//......................................................................................<br />

int derivitive(int e)<br />

{<br />

int diff;<br />

diff = (e - prev_err)/10;<br />

45

eturn diff;<br />

}<br />

//......................................................................................<br />

int controller(int Cd, int Cf)<br />

{<br />

int Ce; // Error variable<br />

int Cw; // Corrected count<br />

}<br />

Ce = Cd - Cf;<br />

Cw = (Kp * Ce) + (Ki * integrate(Ce) / 1000) + (Kd * derivitive(Ce));<br />

if(US_DEF == 1) {<br />

if((rpos[THEM_OFF] < THRESHOLD) && (rpos[US_DEF] < THRESHOLD)) Cw = 0;<br />

else Cw *= -1;<br />

}<br />

return Cw;<br />

//......................................................................................<br />

void AD_setup()<br />

{<br />

ADCSRA = 0x80;// turn on ADC<br />

DDRA = (unsigned char)0; // set port A to input<br />

}<br />

//......................................................................................<br />

void AD_read(void) { // interrupt driven encoder update<br />

int count;<br />

for (count = 0; count < 4; count++) {<br />

ADMUX = (0x40 + count); // REFS1=0,REFS0=1,ADLAR=0,MUX4=0 |<br />

MUX3=0,MUX2=0,MUX1=0,MUX0=1<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

rpos[count + 1] = ADCW >> 2;<br />

}<br />

}<br />

if(pos_last != rpos[US_DEF])<br />

{<br />

moving = 1;<br />

}<br />

else<br />

{<br />

moving = 0;<br />

}<br />

//......................................................................................<br />

int deadband(int c_wanted)<br />

{// Call this routine when updating<br />

int c_pos;<br />

int c_neg;<br />

int c_adjusted;<br />

if(moving == 1) // If moving -> kinetic<br />

{<br />

c_pos = c_kinetic_pos;<br />

c_neg = c_kinetic_neg;<br />

}<br />

else // Not moving -> static<br />

{<br />

c_pos = c_static_pos;<br />

c_neg = c_static_neg;<br />

}<br />

46

}<br />

if(c_wanted == 0)<br />

{ // Turn off the output<br />

c_adjusted = 0;<br />

}<br />

else if(c_wanted > 0)<br />

{ // Positive motion<br />

c_adjusted = c_pos + (unsigned)(c_max - c_pos) * c_wanted / c_max;<br />

if(c_adjusted > c_max)<br />

c_adjusted = c_max;<br />

}<br />

else { //Negative motion<br />

c_adjusted = -c_neg - (unsigned)(c_min - c_neg) * -c_wanted / c_min;<br />

if(c_adjusted < -c_min) c_adjusted = -c_min;<br />

}<br />

return c_adjusted;<br />

//......................................................................................<br />

void PWM_init()<br />

{ // Initialize the PWM outputs, configure<br />

}<br />

DDRD |= (1 = 0)<br />

{ // Set the direction bits to CW on, CCW off<br />

PORTC = (PINC & 0xFC) | 0x02; /* bit 1 on, 0 off */<br />

if(v_adjusted > 255){ // Clip output over maximum<br />

RefSignal = 255;<br />

} else{<br />

RefSignal = v_adjusted;<br />

}<br />

} else{ // Reverse output sign<br />

// Set the direction bits to CW off, CCW on<br />

47

}<br />

}<br />

PORTC = (PINC & 0xFC) | 0x01; // bit 0 on, 1 off<br />

if(v_adjusted < -255){ // Clip output below minimum<br />

RefSignal = 255;<br />

} else{<br />

RefSignal = -v_adjusted; /* flip sign */<br />

}<br />

return RefSignal;<br />

//......................................................................................<br />

void IO_update()<br />

{ // This routine will run once per interrupt to update PWM<br />

}<br />

AD_read();<br />

PWM_update(v_output(deadband(controller(rpos[US_DEF],rpos[THEM_OFF]))));<br />

//......................................................................................<br />

SIGNAL(SIG_OVERFLOW0){<br />

}<br />

CLK_ticks += CLK_ms;<br />

if(CLK_ticks >= 1000)<br />

{ // The number of interrupts between output changes<br />

CLK_ticks = CLK_ticks - 1000;<br />

CLK_seconds++;<br />

}<br />

IO_update();<br />

TCNT0 = CNT_timer1;<br />

sei();<br />

//......................................................................................<br />

void CLK_setup()<br />

{ // Start the interrupt service routine<br />

TCCR0 = (0

{<br />

}<br />

PWM_init();<br />

sio_init();<br />

AD_setup();<br />

CLK_setup();<br />

DDRB = 0x00;<br />

//======================================================================================<br />

// Main Program Loop<br />

int main(){<br />

}<br />

while((PINB & 0x01) != 1);<br />

IO_setup();<br />

while((PINB & 0x01) == 1)<br />

{<br />

}<br />

outln("outloop");<br />

OCR1A = 0x00;<br />

sio_cleanup();<br />

return 1;<br />

49

Offensive Robot Controller Program<br />

// AUTHOR: TEAM 6<br />

// COURSE: EGR345 PROJECT<br />

// DATE: 11-12-06<br />

// FILENAME: OFFENSE_V1.C<br />

// DESCRIPTION: THIS PROGRAM IMPLEMENTS A MOSTLY-AUTONOMOUS MOTION CONTROLLER FOR<br />

// THE DEFENSIVE ROBOT.<br />

#include <br />

#include <br />

#include <br />

#include <br />

#define C_MAX 255 // Maximum PWM output<br />

#define C_MIN 255 // Minimum PWM output<br />

#define CLK_ms 10 // update every 10 ms<br />

#define US_OFF 1<br />

#define THEM_OFF 3<br />

#define THEM_DEF 4<br />

#define OPEN 1<br />

#define CLOSED 0<br />

#define BALL 1<br />

#define NO_BALL 0<br />

#define PLAY_GAME 1<br />

#define END_GAME 0<br />

int accel = 16,<br />

direction = 0,<br />

moving = 0, // Motor starts from rest<br />

pwm_out = 0, // PWM output<br />

SNEG = 0x80, // PWM output that overcomes static friction, negative direction<br />

SPOS = 0x80, // PWM output that overcomes static friction, positive direction<br />

KNEG = 0x80, // Lowest PWM output that keeps motor moving, negative direction<br />

KPOS = 0x80, // Lowest PWM output that keeps motor moving, positive direction<br />

rpos[5],<br />

START = 0,<br />

Goal[] = {0, 0, 0, 0},<br />

gmin[] = {0, 21, 106, 191},<br />

gmax[] = {0, 63, 149, 234};<br />

unsigned int CNT_timer0; // The delay time<br />

// FUNCTION PROTOTYPES<br />

void AD_setup(void);<br />

int db(int c_target);<br />

void PWM_init();<br />

void PWM_update(int value);<br />

int v_out(int v_adj);<br />

void IO_setup();<br />

void IO_update();<br />

void CLK_setup(void);<br />

int Reload(void);<br />

int AttackGoal(int goal);<br />

void FireCannon(void);<br />

void Delay(int ticks);<br />

// FUNCTION DECLARATIONS<br />

void Delay(int ticks)<br />

{<br />

// ticks are approximately 1ms<br />

volatile int i, j;<br />

for(i = 0; i < ticks; i++)<br />

{<br />

for(j = 0; j < 1000; j++){}<br />

}<br />

}<br />

50

************************************************************************************<br />

void FireCannon(void) {<br />

PORTC |= PC5; // Activate air supply to launch ball...<br />

Delay(500); // ...wait 0.500 sec for ball to leave barrel...<br />

PORTC &= PC5; // ...deactivate air supply.<br />

}<br />

//************************************************************************************<br />

int AttackGoal(int goal) {<br />

// If our offense is closer to prox than min location of goal...<br />

if (rpos[US_OFF] < gmin[goal]) {<br />

// ...accelerate toward min location of goal...<br />

while (rpos[US_OFF] < gmin[goal]) {<br />

if ((pwm_out += accel) > 255) pwm_out = 255;<br />

}<br />

// ...and fire on the move.<br />

FireCannon();<br />

return NO_BALL;<br />

}<br />

// If our offense is further from the prox than max location of goal...<br />

else if (rpos[US_OFF] > gmax[goal]) {<br />

// ...accelerate toward max location of goal...<br />

while (rpos[US_OFF] > gmax[goal]) {<br />

if ((pwm_out -= accel) > -255) pwm_out = -255;<br />

}<br />

// ...and fire on the move.<br />

FireCannon();<br />

return NO_BALL;<br />

}<br />

// Our offense must already be located at the open goal, fire where we stand.<br />

else FireCannon();<br />

return NO_BALL;<br />

}<br />

//************************************************************************************<br />

int Reload(void) {<br />

// Wherever we are, stop.<br />

pwm_out = 0;<br />

IO_update();<br />

}<br />

// While our offense is not at home position...<br />

while (US_OFF > 0) {<br />

// ...accelerate toward home.<br />

if ((pwm_out -= accel) < -255) pwm_out = -255;<br />

IO_update();<br />

}<br />

// Offense has reached home postion.<br />

// Wait 2 seconds for manual reload.<br />

Delay(2000);<br />

return BALL;<br />

//************************************************************************************<br />

void AD_setup(void) {<br />

DDRA = 0x00; // Set Port A to inputs<br />

}<br />

//************************************************************************************<br />

int db(int c_target) {<br />

int c_pos,<br />

c_neg,<br />

c_adj;<br />

if (moving) {<br />

c_pos = KPOS;<br />

51

}<br />

}<br />

else {<br />

c_neg = KNEG;<br />

c_pos = SPOS;<br />

c_neg = SNEG;<br />

}<br />

if (c_target == 0) { // Turn off output<br />

c_adj = 0;<br />

}<br />

else if (c_target > 0) { // Positive output<br />

c_adj = c_pos + (unsigned)(C_MAX - c_pos) * c_target / C_MAX;<br />

if (c_adj > C_MAX) c_adj = C_MAX;<br />

}<br />

else { // Negative output<br />

c_adj = -c_neg - (unsigned)(C_MIN - c_neg) * -c_target / C_MIN;<br />

if (c_adj < -C_MIN) c_adj = -C_MIN;<br />

}<br />

return c_adj;<br />

//************************************************************************************<br />

void PWM_init() { // Initialize PWM output<br />

DDRD |= (1 255) {<br />

RefSig = 255;<br />

}<br />

else {<br />

RefSig = v_adj;<br />

}<br />

}<br />

else { // Set CW off, CCW on<br />

PORTC = (PINC & 0xFC) | 0x01; // Bit 1 off, 0 on<br />

if (v_adj < -255) {<br />

RefSig = 255;<br />

}<br />

else {<br />

RefSig = -v_adj;<br />

}<br />

}<br />

return RefSig;<br />

}<br />

//************************************************************************************<br />

void IO_setup() {<br />

CLK_setup();<br />

PWM_init();<br />

AD_setup();<br />

DDRB = 0x00; // Set PB3 to digital input for "Start Game"<br />

}<br />

52

************************************************************************************<br />

void IO_update() {<br />

PWM_update(v_out(db(pwm_out)));<br />

}<br />

//************************************************************************************<br />

SIGNAL(SIG_OVERFLOW0) {<br />

IO_update();<br />

TCNT0 = CNT_timer0;<br />

// Change to and read ADC channel 0 for our offense position<br />

ADMUX = 0x40; // REFS1=0,REFS0=1,ADLAR=0,MUX4=0 | MUX3=0,MUX2=0,MUX1=0,MUX0=1<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

rpos[1] = ADCW >> 2;<br />

// Change to and read ADC channel 2 for enemy defense position<br />

ADMUX = 0x42; // REFS1=0,REFS0=1,ADLAR=0,MUX4=0 | MUX3=0,MUX2=0,MUX1=0,MUX0=1<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

rpos[3] = ADCW >> 2;<br />

// Change to and read ADC channel 3 for enemy offense position<br />

ADMUX = 0x43; // REFS1=0,REFS0=1,ADLAR=0,MUX4=0 | MUX3=0,MUX2=0,MUX1=1,MUX0=0<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

ADCSRA = 0xC0;<br />

while ((ADCSRA & _BV(ADSC)) != 0);<br />

rpos[4] = ADCW >> 2;<br />

}<br />

// Check PB3 for START signal<br />

if((PORTB & PB3)==(PB3)) START = 1;<br />

else START = 0;<br />

//************************************************************************************<br />

void CLK_setup(void) { // Start the interrupt service routine<br />

TCCR0 = (0

There is always at least one goal open.<br />

// Determine which goal is currently open.<br />

for (count = 1; count <br />

gmax[count])) &&<br />

((rpos[THEM_OFF] < gmin[count]) || (rpos[THEM_OFF] ><br />

gmin[count])))<br />

Goal[count] = OPEN;<br />

else Goal[count] = CLOSED;<br />

}<br />

}<br />

// Attempt an attack on an open goal.<br />

for (count = 1; count