Airetool Tube Cleaner and Expanders Catalog - Tecno Italia s.r.l

Airetool Tube Cleaner and Expanders Catalog - Tecno Italia s.r.l

Airetool Tube Cleaner and Expanders Catalog - Tecno Italia s.r.l

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

58<br />

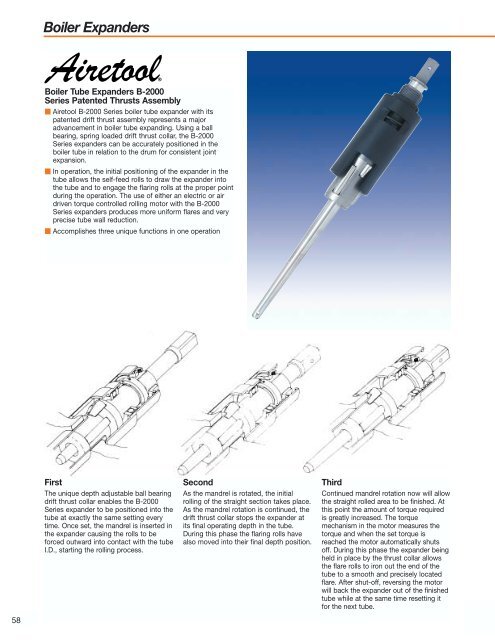

Boiler Exp<strong>and</strong>ers<br />

Boiler <strong>Tube</strong> Exp<strong>and</strong>ers B-2000<br />

Series Patented Thrusts Assembly<br />

<strong>Airetool</strong> B-2000 Series boiler tube exp<strong>and</strong>er with its<br />

patented drift thrust assembly represents a major<br />

advancement in boiler tube exp<strong>and</strong>ing. Using a ball<br />

bearing, spring loaded drift thrust collar, the B-2000<br />

Series exp<strong>and</strong>ers can be accurately positioned in the<br />

boiler tube in relation to the drum for consistent joint<br />

expansion.<br />

In operation, the initial positioning of the exp<strong>and</strong>er in the<br />

tube allows the self-feed rolls to draw the exp<strong>and</strong>er into<br />

the tube <strong>and</strong> to engage the flaring rolls at the proper point<br />

during the operation. The use of either an electric or air<br />

driven torque controlled rolling motor with the B-2000<br />

Series exp<strong>and</strong>ers produces more uniform flares <strong>and</strong> very<br />

precise tube wall reduction.<br />

Accomplishes three unique functions in one operation<br />

First<br />

The unique depth adjustable ball bearing<br />

drift thrust collar enables the B-2000<br />

Series exp<strong>and</strong>er to be positioned into the<br />

tube at exactly the same setting every<br />

time. Once set, the m<strong>and</strong>rel is inserted in<br />

the exp<strong>and</strong>er causing the rolls to be<br />

forced outward into contact with the tube<br />

I.D., starting the rolling process.<br />

Second<br />

As the m<strong>and</strong>rel is rotated, the initial<br />

rolling of the straight section takes place.<br />

As the m<strong>and</strong>rel rotation is continued, the<br />

drift thrust collar stops the exp<strong>and</strong>er at<br />

its final operating depth in the tube.<br />

During this phase the flaring rolls have<br />

also moved into their final depth position.<br />

Third<br />

Continued m<strong>and</strong>rel rotation now will allow<br />

the straight rolled area to be finished. At<br />

this point the amount of torque required<br />

is greatly increased. The torque<br />

mechanism in the motor measures the<br />

torque <strong>and</strong> when the set torque is<br />

reached the motor automatically shuts<br />

off. During this phase the exp<strong>and</strong>er being<br />

held in place by the thrust collar allows<br />

the flare rolls to iron out the end of the<br />

tube to a smooth <strong>and</strong> precisely located<br />

flare. After shut-off, reversing the motor<br />

will back the exp<strong>and</strong>er out of the finished<br />

tube while at the same time resetting it<br />

for the next tube.