Airetool Tube Cleaner and Expanders Catalog - Tecno Italia s.r.l

Airetool Tube Cleaner and Expanders Catalog - Tecno Italia s.r.l

Airetool Tube Cleaner and Expanders Catalog - Tecno Italia s.r.l

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Five roll exp<strong>and</strong>er vs. Three roll exp<strong>and</strong>er<br />

Setting the tube exp<strong>and</strong>er’s collar<br />

Double <strong>Tube</strong> Sheet Application<br />

<strong>Airetool</strong> Heat Exchanger – Condenser Exp<strong>and</strong>ers<br />

Many manufacturers prefer the five-roll exp<strong>and</strong>er for applications that use tube materials that work harden quickly such<br />

as stainless steel <strong>and</strong> titanium. Also used in applications with closely spaced tubes having triangular pitch. The five-roll<br />

exp<strong>and</strong>er inherently has more contact area with the tube than the three-roll. This extra contact with the tube reduces<br />

the amount of work hardening <strong>and</strong> spring back effect, which is common with these tube materials. The thinner the<br />

tube walls, 18 BWG (.049"/1.25mm) <strong>and</strong> thinner, the more apt this is to occur.<br />

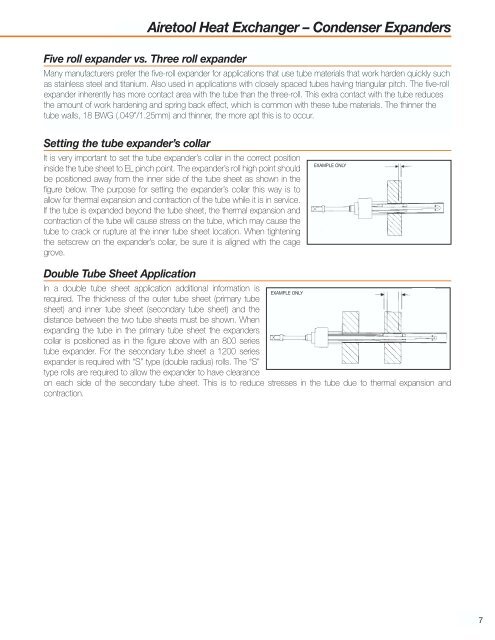

It is very important to set the tube exp<strong>and</strong>er’s collar in the correct position<br />

inside the tube sheet to EL pinch point. The exp<strong>and</strong>er’s roll high point should<br />

be positioned away from the inner side of the tube sheet as shown in the<br />

figure below. The purpose for setting the exp<strong>and</strong>er’s collar this way is to<br />

allow for thermal expansion <strong>and</strong> contraction of the tube while it is in service.<br />

If the tube is exp<strong>and</strong>ed beyond the tube sheet, the thermal expansion <strong>and</strong><br />

contraction of the tube will cause stress on the tube, which may cause the<br />

tube to crack or rupture at the inner tube sheet location. When tightening<br />

the setscrew on the exp<strong>and</strong>er’s collar, be sure it is aligned with the cage<br />

grove.<br />

EXAMPLE ONLY<br />

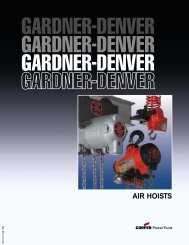

In a double tube sheet application additional information is EXAMPLE ONLY<br />

required. The thickness of the outer tube sheet (primary tube<br />

sheet) <strong>and</strong> inner tube sheet (secondary tube sheet) <strong>and</strong> the<br />

distance between the two tube sheets must be shown. When<br />

exp<strong>and</strong>ing the tube in the primary tube sheet the exp<strong>and</strong>ers<br />

collar is positioned as in the figure above with an 800 series<br />

tube exp<strong>and</strong>er. For the secondary tube sheet a 1200 series<br />

exp<strong>and</strong>er is required with “S” type (double radius) rolls. The “S”<br />

type rolls are required to allow the exp<strong>and</strong>er to have clearance<br />

on each side of the secondary tube sheet. This is to reduce stresses in the tube due to thermal expansion <strong>and</strong><br />

contraction.<br />

7