AMMJ - Library

AMMJ - Library

AMMJ - Library

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>AMMJ</strong><br />

Asset Criticality Analysis<br />

Everyone says they have identified their critical equipment. But, in many cases, equipment criticality could<br />

change based on how upset people are about an equipment problem or because people are confused about what<br />

consequences associate to failure and the probability it will occur if we manage equipment reliability effectively. The<br />

purpose of the Asset Criticality Analysis is to identify which equipment has the most serious potential consequences<br />

on business performance, if it fails. Consequences on the business can include:<br />

• Production Throughput or Equipment / Facility Utilization • Cost due to lost or reduced output<br />

• Environmental Issues • Safety Issues • Other<br />

The resulting Equipment Criticality Number is used to prioritize resources performing maintenance work.<br />

The Intercept Ranking Model illustrates this process (Figure 4). On the “Y” axis you see the asset criticality is listed<br />

from none to high. I like using a scale of 0-1000 because all assets are not necessarily equal.<br />

TEST & CONDITION<br />

MONITORING SERVICES<br />

High Voltage<br />

Equipment<br />

Power Transformers & HV Cables deteriorate<br />

with age and excessive stress, and can fail<br />

without warning at enormous cost.<br />

Our services will provide fingerprinting,<br />

trending, grading of the worst offenders and<br />

accurately pinpoint likely failure.<br />

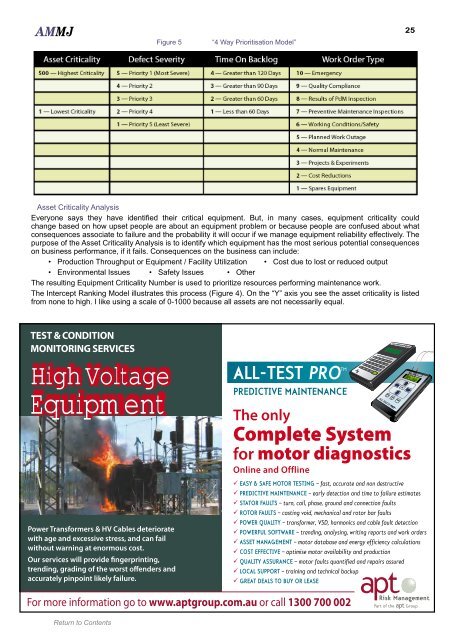

Figure 5 “4 Way Prioritisation Model”<br />

ALL-TEST PRO TM<br />

PREDICTIVE MAINTENANCE<br />

The only<br />

Complete System<br />

for motor diagnostics<br />

Online and Offline<br />

For more information go to www.aptgroup.com.au or call 1300 700 002<br />

25<br />

EASY & SAFE MOTOR TESTING – fast, accurate and non destructive<br />

PREDICTIVE MAINTENANCE – early detection and time to failure estimates<br />

STATOR FAULTS – turn, coil, phase, ground and connection faults<br />

ROTOR FAULTS – casting void, mechanical and rotor bar faults<br />

POWER QUALITY – transformer, VSD, harmonics and cable fault detection<br />

POWERFUL SOFTWARE – trending, analysing, writing reports and work orders<br />

ASSET MANAGEMENT – motor database and energy efficiency calculations<br />

COST EFFECTIVE – optimise motor availability and production<br />

QUALITY ASSURANCE – motor faults quantified and repairs assured<br />

LOCAL SUPPORT – training and technical backup<br />

GREAT DEALS TO BUY OR LEASE<br />

Risk Management<br />

Part of the apt Group