You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ATLAS <strong>3D</strong>Si Sensors<br />

Project Status Report<br />

Ole Myren Røhne, University of Oslo<br />

For the ATLAS <strong>3D</strong>Si R&D Project

Outline<br />

• Progress at the fabrication facilities<br />

• Lab characterization<br />

• Measurements w/ATLAS FE-I3<br />

• Test beam program<br />

• Outlook

The <strong>3D</strong>Si ATLAS Upgrade R&D Project<br />

Development, Testing and Industrialization of Full-<strong>3D</strong> Active-Edge<br />

and Modified-<strong>3D</strong> Silicon Radiation Pixel Sensors with<br />

Extreme Radiation Hardness Results, Plans.<br />

Proponents: C. Da Viá, S. Parker, G. Darbo<br />

Status: APPROVED<br />

Topics and goals of the R&D proposal:<br />

The primary goal is the development, fabrication, characterization, and testing, with and without the front-end readout chip, of Full-<strong>3D</strong>– activeedge<br />

and Mod-<strong>3D</strong> silicon <strong>pixel</strong> sensors of extreme radiation hardness and high speed for the the Super-LHC ATLAS upgrade and, possibly, the<br />

ATLAS B-layer replacement. A secondary goal is to start design work for a reduced material B-layer <strong>detector</strong> module using these sensors.<br />

FP420 is used as a test bench for the technology<br />

Participating ATLAS Institutions: 10<br />

Bonn University, Freiburg University, University of Genova, Glasgow University, the University of Hawaii, Lawrence Berkeley National<br />

Laboratory, Manchester University, the University of New Mexico, Oslo University and the Czech Technical University.<br />

Fabrication Facilities: 4<br />

CNM/Valencia, IceMOS/Belfast, IRST/Trento and SINTEF/Oslo.<br />

At present C. Kenney (Molecular Biology Consortium) and Jasmine Hasi (Manchester University), working at the Stanford Nanofabrication<br />

Facility, made all of the Full-<strong>3D</strong> sensors. For this project industrial companies will join the above mentioned institutions to study the feasibility<br />

of a large volume production in time for the upgrade.

<strong>3D</strong>Si basics<br />

• MEMS technology + VLSI to sensor fab: Deep Reactive Ion Etching (DRIE)<br />

• Electrode implants: etched, doped, filled columns (S. Parker 1995)<br />

• Dicing: etched, doped edge trench (C. Kenney 1997)<br />

• Key benefits: Radiation hardness and active edges<br />

wafer diced by<br />

etching edges doped<br />

Silicon chip<br />

n - and p – electrode holes<br />

etched through wafer. Doped<br />

and filled with poly-silicon

Fabrication facilities: Overview<br />

Full <strong>3D</strong><br />

Active edge<br />

iceMOS- Being presently fabricated<br />

Work performed in the RD50 framework<br />

(No data available yet)<br />

The <strong>3D</strong> sensors family:<br />

<strong>3D</strong>C Fabricated at Stanford<br />

and tested with Atlas <strong>pixel</strong><br />

Readout – and SLHC fluences<br />

Design at its 5 th<br />

Generation<br />

Being also fabricated at SINTEF in<br />

the ATLAS Upgrade framework as<br />

part of the <strong>3D</strong>C Consortium.<br />

(No data available yet)<br />

Full <strong>3D</strong><br />

No active edge<br />

Single column<br />

No active edge<br />

IRST and separately CNM.<br />

Being presently fabricated<br />

(No data available yet)<br />

IRST/CNM fabricated in the RD50<br />

Framework in 2005 Tested with SCTA<br />

readout Electronics. Data and Simulations<br />

show that the design is NOT radiation hard<br />

For B-layer replacement.<br />

Double column<br />

No active edge

CNM (Barcelona/Valencia)<br />

FIRST BATCH COMPLETED<br />

•First run on n-type substrate, p-type column read-out<br />

(not usable w/FE-I3)<br />

•Strip sensor w/Beetle chip<br />

•Basic characterization started in CNM, Glasgow<br />

•Next run starting before end 2007: p-type substrate, ntype<br />

column<br />

p-on-n<br />

300-250µm<br />

Full depletion occurs at 2-3 V since<br />

the electrode pitch is 55µm<br />

Strips

FBK-IRST (Trento, Italy)<br />

FIRST BATCH COMPLETED<br />

<strong>3D</strong> Double-side Double-Type Column (<strong>3D</strong>-DDTC) <strong>detector</strong>s<br />

Detector concept able to ease the fabrication process, and<br />

expected to have performance comparable to standard <strong>3D</strong><br />

<strong>detector</strong>s (if d is much smaller than t )<br />

First batch (p-on-n version) completed at FBK-irst in October<br />

2007 Second batch (n-on-p) available by the end of 2007<br />

<strong>3D</strong> diodes2.56mm 2 area<br />

Single-Type-Column<br />

80 μm pitch,<br />

400 columns<br />

100 μm pitch,<br />

256 columns<br />

G.F. Dalla Betta, IEEE-NSS 2007, N18-3<br />

• Very low lateral depletion voltage(

IceMOS (Glasgow)<br />

FIRST BATCH will be COMPLETED by end of 2007<br />

• Full-<strong>3D</strong> sensors<br />

• No support wafer<br />

• Etch from top, back-grind<br />

• First run: p-on-n<br />

SAMPLES EXPECTED BEFORE END 2007

SINTEF/Stanford<br />

(<strong>3D</strong>C Hawaii, Manchester, Oslo, Prague, SINTEF)<br />

FIRST BATCH will be COMPLETED by end 2007<br />

• Implement Stanford design “technology transfer”<br />

• 2nd source full-<strong>3D</strong> active-edge sensors<br />

• In-house DRIE etching<br />

• Out-of-house polysilicon filling<br />

WAFER AFTER 2nd ELECTRODE FILLING AT<br />

STANFORD<br />

Ready for contact hole opening and metal<br />

PROCESSING WILL BE COMPLETED BY<br />

THE END OF 2007<br />

Detail of hole<br />

Detail from wafer showing holes and trench<br />

2

Stanford (Manchester)<br />

<strong>3D</strong> electrode configurations<br />

Design and fabrication by:<br />

J. Hasi, Manchester<br />

C. Kenney, MBC at CIS-Stanford<br />

50 µm<br />

50 µm<br />

50 µm<br />

2E<br />

400 µm<br />

p 103µm<br />

Vfd ~20V<br />

3E<br />

400 µm<br />

4E<br />

n<br />

n<br />

p<br />

71 µm<br />

Vfd ~8V<br />

400 µm<br />

p<br />

Vfd ~5V<br />

n<br />

56 µm<br />

Thickness <br />

p-type substrate 12kΩcm<br />

Baby-2E Baby-3E<br />

Financial support:<br />

STFC-UK for the FP420 project<br />

DOE, USA for ATLAS Upgrade<br />

10 wafers competed. Yield~80% (1 wafer)<br />

Atlas chip<br />

picture from<br />

Bekerle<br />

Vertex03<br />

ATLAS <strong>pixel</strong> chip<br />

7.2 x 8 mm 2<br />

2880 <strong>pixel</strong>s

<strong>3D</strong>Si basics - Radiation hardness<br />

• Decoupled directions: track traversal versus drift field<br />

• Low depletion voltage<br />

• Short charge collection path, fast signal<br />

• Retain full charge from MIP in 250μm Si<br />

• Signal loss dominated by trapping

Radiation hardness<br />

Irradiation and measurements performed in Prague<br />

C. Da Viá, T. Slaviceck, V. Linhart, P. Bem, S. Parker,<br />

S. Pospisil, S. Watts (process J. Hasi, C. Kenney)<br />

Samples/fluence As measured<br />

n/cm 2<br />

1MeV n<br />

(1.784)<br />

n/cm 2<br />

Protons<br />

(1/0.51)<br />

p/cm 2<br />

2E, 3E, 4E 4.23 10 14 7.55 10 14 1.48 10 15<br />

2E, 3E, 4E 1.12 10 15 2.00 10 15 3.92 10 15<br />

2E, 3E, 4E 4.94 10 15 8.81 10 15 1.73 10 16<br />

bias<br />

T=-20C<br />

IR Laser<br />

1060nm<br />

Gain = ~10000<br />

Oscilloscope

Radiation Hardness tests with neutrons<br />

using an IR laser source<br />

Irradiation and measurements performed in Prague<br />

C. Da Viá, T. Slaviceck, V. Linhart, P. Bem, S. Parker,<br />

S. Pospisil, S. Watts (process J. Hasi, C. Kenney)<br />

50 µm<br />

50 µm<br />

50 µm<br />

p<br />

2E<br />

V fd ~20V<br />

p<br />

V fd ~8V<br />

V fd ~5V<br />

400 µm<br />

3E<br />

400 µm<br />

4E<br />

n<br />

103µm<br />

400 µm<br />

p<br />

n<br />

71 µm<br />

n<br />

56µm<br />

2E<br />

9000e -<br />

V b ~130V<br />

3E<br />

10200e -<br />

V b ~112V<br />

4E<br />

13200e -<br />

V b ~94V<br />

C. DA VIA presented at the IEEE-NSS 2007<br />

threshold<br />

threshold<br />

threshold<br />

45%<br />

51%<br />

66%<br />

8.81x10 15 n/cm 2<br />

1.73x10 16 p/cm 2

Tests with the FE-I3 chip<br />

Bump bonded at IZM in 2006<br />

Mounted in Bonn<br />

Leakage currents<br />

before irradiation<br />

~325 pA/<strong>pixel</strong><br />

Noise vs<br />

Bias voltage<br />

Tests by E. Bolle, O. Rohne (Oslo) help from M. Garcia-Sciveres and K. Einweiler (LBL)

Estimated S/N at<br />

3.5x10 15 n/cm 2 and 8.81x10 15 n/cm 2<br />

Initial measurements, error bars<br />

would require more statistics<br />

Noise measured on non-irradiated bump-bonded<br />

FE-I3-ATLAS chip<br />

Noise measurements performed at CERN by E. Bolle and O. Rohne (Oslo)<br />

Help from K. Einweiler, M. Garcia-Sciveres (LBL), data analysis and plots from<br />

C. Da Via (Manchester)

Time walk with the FE-I3 chip<br />

•Threshold triggered system<br />

•Difference between t and t gives the time walk<br />

•New bunch crossing every 25ns<br />

•Need to cross threshold within 20ns to be accepted<br />

•How much overdrive is needed to cross threshold within 20ns?<br />

ASIC<br />

settings<br />

sensors<br />

IP = 64<br />

IL = 64<br />

IP = 128 1<br />

IL = 96<br />

Measurements by E. Bolle, K. Einweiler, O.Rohne. Plots by C. Da Viá<br />

IL68 IP68 – STANDARD PLANAR SETTINGS: Analogue current=91mA., VDDA = 1.6V and VDD = 2.0V<br />

IL96 IP128- Analogue current=126mA (+38%) VDDA = 1.6V VDD= 2.0V<br />

IL64 IP192 Analogue current =158mA (+76%) VDDA = 1.6V VDD= 2.0V<br />

IP = 196 2<br />

IL = 64<br />

2E-A 1807e - 1119e - 813e -<br />

3E-G 2798e - 1828e - 1434e -<br />

4E-C 3338e - 2122e - 1597e -<br />

Planar 1244e -

Data analysis<br />

By M. Mathes/Bonn<br />

Test beam setup 2006 M. Mathes, Presented at the IEEE-NSS 2007<br />

Picture by F. Roncarolo<br />

Manchester<br />

M. Mathes1, C. DaVia2, J. Hasi2, S. Parker3, M. Ruspa4,<br />

L. Reuen1, J. Velthuis1, S. Watts2, M. Cristinziani1, K.<br />

Einsweiler4, M. Gracia-Sciveres4,K. Kenney5, N. Wermes1<br />

1Bonn, Germany<br />

2Manchester University, UK<br />

3University of Hawaii, USA<br />

4LBL, Berkeley, USA<br />

5Molecular Biology Consortium, Stanford, USA<br />

Analysis<br />

By S. Watts/Manchester Beam profile<br />

Using 3x3mm 2<br />

scintillator

Tracking efficiency – 2006 test beam<br />

bump-bonding at IZM (Bonn)- not problematic<br />

M. Mathes1, C. DaVia2, J. Hasi2, S. Parker3, M. Ruspa4,<br />

L. Reuen1, J. Velthuis1, S. Watts2, M. Cristinziani1, K.<br />

Einsweiler4, M. Gracia-Sciveres4,K. Kenney5, N. Wermes1<br />

1Bonn, Germany<br />

2Manchester University, UK<br />

3University of Hawaii, USA<br />

4LBL, Berkeley, USA<br />

5Molecular Biology Consortium, Stanford, USA<br />

beam<br />

0 o<br />

ε = (95.9 ± 0.1) %<br />

beam<br />

15 o<br />

ε = (99.9 ± 0.1) %<br />

3E 3200 e -<br />

threshold<br />

Data analyisis and silulation by M. Mathes, M. Cristinziani (Bonn)<br />

S. Watts (Manchster)<br />

data<br />

simulation<br />

data<br />

simulation

Test beam 2007<br />

• Infrastructure from ATLAS Pixel TB<br />

• Stanford full <strong>3D</strong> FE-I3, irrad’ed<br />

• IRST STC <strong>3D</strong> strips<br />

• FP420 “blades” (Stanford full-<strong>3D</strong> FE-I3)<br />

Participating Institutions:<br />

Bonn, CERN, Freiburg, Glasgow, Hawaii, Manchester, Oslo,<br />

Prague, Trento

Test beam 2007 - preliminary plots<br />

IRST STC strip correlation with telescope<br />

Stanford full-<strong>3D</strong> (Håvard Gjersdal, Oslo)<br />

Stanford full-<strong>3D</strong> time vs charge

Active edge (Kenney 97)<br />

• DRIE trench etch can replace saw<br />

dicing<br />

• Horizontal field, no need for guard<br />

ring structures<br />

• Edge itself is an electrode<br />

• 2-way butt-able, edge sensitive<br />

tiles<br />

~4µm<br />

trench<br />

electrode

Conclusions and 2008 Plans<br />

<strong>3D</strong>Si project formed and approved as ATLAS upgrade project<br />

Tests with <strong>3D</strong>+FE-I3 chip completed and promising:<br />

S/N estimated before and after irradiation<br />

Time walk under control with moderate extra power<br />

Radiation Hardness proven with neutrons and IR laser source:<br />

IRRADIATED <strong>3D</strong>-<strong>pixel</strong> assembly (1x10 15 p/cm 2 ) under bias tested at RT in the beam<br />

WORKED! More tests after bonding mystery solved…<br />

ACTIVE EDGE PROCESSING : standard in Stanford and SINTEF, will be implemented<br />

at CNM, IceMOS, IRST<br />

ALL COMMERCIAL PARTNERS COMPLETED FIRST BATCH<br />

CNM / Barcellona-Valencia<br />

IceMos/Glasgow<br />

IRST/Trento<br />

SINTEF/Stanford<br />

First common test beam completed in October 2007 – data being analysed<br />

PLANS:<br />

Test beam period requested for 1 week in June and 1 in November 2008<br />

Irradiations and tests will be performed at CERN (common lab-space) and Institutes<br />

OVERALL PROGRESS ENCOURAGING!!!

Back-up slides

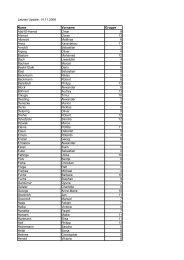

TIMESCHEDULE 3-D PROCESSING AT SINTEF<br />

6-weeks delay waiting for fix of boron deposition tube.<br />

Did go to Stanford instead for poly silicon filling of electrodes<br />

Expected completion January 04, 2008<br />

ICT