Newsletter - PFI Germany Start

Newsletter - PFI Germany Start

Newsletter - PFI Germany Start

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Pirmasens-Winzeln<br />

Energy Park<br />

Forging Ahead<br />

<strong>Newsletter</strong><br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

Customised Training<br />

ISC <strong>Germany</strong>: Competence in Footwear and Leather<br />

Audible “Beep“ Warns<br />

of Impending Injury?<br />

Injury Prevention<br />

Optimum Dosage<br />

Antimicrobial Agents

2<br />

<strong>Newsletter</strong><br />

Contents<br />

01.2013 01. 01.2013 2013<br />

Contents ................................................................... 02<br />

Editorial ................................................................... 04<br />

<strong>PFI</strong> Internal<br />

“Plot a strategic course“ ........................................... 05<br />

“<strong>PFI</strong> can score with excellent service“ ..................... 06<br />

“Continue along the path already chosen“ ............. 08<br />

News<br />

CADS Concern Well Received in Asia ............... 10<br />

<strong>PFI</strong> Fareast Reaccredited by DAkkS ........................... 11<br />

<strong>PFI</strong> Inspection and Advisory Service in Asia .............. 12<br />

Biotechnology Department Reorganised ................. 13<br />

UITIC Congress 2013 in Guangzhou ......................... 62<br />

ISC <strong>Germany</strong><br />

Customised Training .................................................. 14<br />

Certifi cation<br />

01.2013<br />

<strong>PFI</strong> Grants CE Mark and GS Mark Approval .............. 16

Research<br />

Audible “Beep“ Warns of Impending Injury? .......... 20<br />

Dynamics in Design ................................................... 24<br />

Improved Access to Material Properties .................. 26<br />

Toe Cap Optimisation ................................................ 28<br />

Electric Benchtop Lastometer ................................... 29<br />

Improved Penetration Resistance of Safety Shoes ... 30<br />

Self-lacing Shoe ......................................................... 31<br />

Biotechnology<br />

Pirmasens-Winzeln Energy Park Forges Ahead ....... 32<br />

Harnessing Waste Heat.............................................. 34<br />

<strong>PFI</strong> Develops Power-to-Gas Technology ................... 38<br />

<strong>PFI</strong> at BIOGAS 2013 .................................................... 41<br />

<strong>PFI</strong> Biotechnology Intensifi es European<br />

Level Activities .......................................................... 42<br />

Masthead<br />

Publisher: <strong>PFI</strong> Test and Research Institute Pirmasens<br />

Prüf- und Forschungsinstitut Pirmasens e. V.<br />

Member of <strong>PFI</strong> Group<br />

Directors of Institute:<br />

Dr. Gerhard Nickolaus | Dr. Kerstin Schulte<br />

Address: Marie-Curie-Straße 19<br />

66953 Pirmasens / <strong>Germany</strong><br />

Phone: +49 (0)6331 2490 0<br />

Telefax: +49 (0)6331 2490 60<br />

E-Mail: info@pfi -germany.de<br />

Internet: www.pfi -germany.de<br />

Editor: Elisabeth Rouiller<br />

Translation: Tony Rackstraw<br />

Design Concept and Layout:<br />

Konzept fünf - Agentur für Werbung und Design<br />

Internet: www.konzept-fuenf.de<br />

Chemistry<br />

01.2013 01. 01.2013 2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

Hunt for Allergens .................................................... 46<br />

Chromium VI in Leather Articles .............................. 49<br />

The Formamide Problem ............................................ 50<br />

Revised Catalogue of SG Test Criteria ..................... 52<br />

SVHC Candidate List Grows Longer ......................... 53<br />

Microbiology<br />

New International Standard – DIN EN ISO 16187 .... 54<br />

Wash Me! .................................................................. 56<br />

Optimum Dosage: Controlled Release<br />

of Antimicrobial Agents ........................................... 58<br />

Images:<br />

<strong>PFI</strong>, ISC, HDS/L, Fotolia (pp. 20, 28,<br />

30, 31, 46, 47, 50), Uni Stuttgart (pp. 2, 22 and 23),<br />

Wikipedia (p. 42), Plastics Europe (p. 43)<br />

No part of this newsletter may be reproduced<br />

without authorisation of the <strong>PFI</strong>.<br />

The online version of the <strong>PFI</strong>-<strong>Newsletter</strong> is available<br />

under www.pfi -group.org/newsletter.html<br />

3

4<br />

Editorial<br />

<strong>Newsletter</strong><br />

Dear Readers,<br />

This is my fi rst opportunity to greet you as the new Director<br />

of <strong>PFI</strong>. Many of you will know me as Head of the<br />

Analytical Chemistry Department and have hopefully<br />

read my contributions on current topics concerning<br />

hazardous substances with some degree of interest. In<br />

future these articles will be penned by my colleagues<br />

in the chemistry department and I am sure that they<br />

will continue to provide you with a wealth of highly<br />

relevant information in this area.<br />

It is my heartfelt wish to express my sincere thanks for<br />

all the messages of congratulation you have sent me<br />

on the occasion of my appointment as Director. The<br />

development of <strong>PFI</strong> in recent years has been a success<br />

story for which Dr. Nickolaus must take much of the<br />

credit. Our task is now to successfully pursue the path<br />

we have embarked upon with all its challenges. We<br />

are called to constantly develop new ideas and put<br />

them into practice. I can approach the tasks ahead<br />

of me with great energy and enthusiasm in the sure<br />

knowledge of the unique expertise and capabilities<br />

of <strong>PFI</strong>. And, with your support, dear members, clients,<br />

and co-workers, we are bound to succeed.<br />

Sincerely, Dr. Kerstin Schulte<br />

<strong>PFI</strong> Group<br />

EDITORIAL<br />

Dear Readers,<br />

Today is the last time I shall address you in this publication<br />

as Director of <strong>PFI</strong>. Most reader will already<br />

know that Dr. Kerstin Schulte has been appointed as<br />

my successor and will assume full responsibility for running<br />

the Institute after a brief handover phase. Imposing<br />

and demanding tasks await her. Thus, in 2012, <strong>PFI</strong><br />

began expansion of its biotechnology activities in the<br />

Winzeln district of Pirmasens. In the shape of this largescale<br />

project, <strong>PFI</strong> has established a unique competence<br />

centre in the Western Palatinate and secured the future<br />

of <strong>PFI</strong> and the location Pirmasens as a centre of<br />

excellence. I am supremely confi dent that Dr. Schulte<br />

will master these challenges. She was for good reason<br />

my candidate of choice as successor and I am delighted<br />

that she has indeed been selected for the position from<br />

among a large number of other applicants.<br />

Although I shall continue to work for <strong>PFI</strong>, in particular<br />

for the <strong>PFI</strong> subsidiaries in Asia, for some time to come, I<br />

would like to take this opportunity to bid you farewell,<br />

to thank you for your valuable collaboration during the<br />

past in 30 odd years, and to wish you all the very best<br />

for the future.<br />

Sincerely, Dr. Gerhard Nickolaus<br />

<strong>PFI</strong> Group

<strong>PFI</strong> INTERNAL<br />

Interview with Manfred Junkert,<br />

Managing Director of the Federal Association of the<br />

German Footwear and Leather Goods Industry<br />

(Bundesverband der Schuh- und Lederwarenindustrie e.V. - HDS/L)<br />

“ Plot a strategic<br />

course”<br />

What were the decisive criteria persuading you and<br />

the other members of the <strong>PFI</strong> board to award the directorship<br />

to Dr. Schulte?<br />

It was particularly important that Dr. Kerstin Schulte<br />

has already amply demonstrated her skills. She has<br />

adeptly managed the Analytical Chemistry Department<br />

and, as Deputy Head, she has a very thorough<br />

knowledge of the Institute. Moreover, she has also<br />

gained an excellent scientifi c reputation through her<br />

publications. We are confi dent that Dr. Schulte has the<br />

ambition and the ability to steer the Institute into a<br />

highly promising future and to introduce many new<br />

and valuable ideas.<br />

What does HDS/L expect of Dr. Schulte and of <strong>PFI</strong>?<br />

In recent years the Institute has pursued a path of<br />

highly dynamic and successful development and has<br />

also diversifi ed its activities. Clients have come to value<br />

<strong>PFI</strong> as a very reliable service provider. The present challenge<br />

is to plot a strategic course for the future, for<br />

example by exploring those areas of activity in which<br />

<strong>PFI</strong> can grow profi tably. The basis is, and will continue<br />

to be, the footwear and leather industry. Over and<br />

above this sector the Institute can make a name for<br />

itself in related industries and also gain a fi rm foothold<br />

in completely new areas, as it has recently done<br />

in biogas production.<br />

Manfred Junkert<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

The second important factor is internationalisation.<br />

<strong>PFI</strong> certainly enjoys top ranking in <strong>Germany</strong>. However,<br />

we now face the question: How can <strong>PFI</strong> strengthen<br />

its international profi le, where must it be physically<br />

present with its service offerings, where can it attract<br />

new clients? <strong>PFI</strong> has already established a presence in<br />

Hong Kong and in Istanbul. Further internationalisation<br />

steps now have to be considered.<br />

Partnerships and cooperative ventures will surely also<br />

be important for the future. On its own, a mediumsized<br />

institute will clearly be unable to set up all the<br />

structures necessary to be present for all industries in<br />

all world markets. It is therefore important to enter<br />

into strategic partnerships in order to offer an optimum<br />

service to immediately relevant industries and to<br />

remain competitive.<br />

5

6<br />

<strong>Newsletter</strong><br />

Interview with Dr. Kerstin Schulte,<br />

Director Designate of the Test and<br />

Research Institute Pirmasens<br />

In May Dr. Kerstin Schulte paid her fi rst offi cial visit as<br />

Director to Eveline Lemke, Minister of Economic Affairs,<br />

Climate Protection, Energy, and Regional Planning of<br />

Rhineland-Palatinate<br />

“<br />

<strong>PFI</strong> can score<br />

with excellent<br />

service“<br />

<strong>PFI</strong> INTERNAL<br />

What induced you to apply for the position of Director?<br />

What are your motivations for the new post?<br />

More than two years ago Dr. Nickolaus asked me<br />

whether I could imagine taking on the directorship of<br />

<strong>PFI</strong> and how I envisaged the future of the Institute.<br />

That was the fi rst time that I had thought about taking<br />

on such a challenge, and I put forward a number<br />

of proposals. I am very familiar with the Institute and<br />

my wish is that it should continue to develop in the<br />

same positive way as in the past. Any handover of<br />

leadership inevitably means changes, but these changes<br />

should be in accord with the spirit of the Institute.<br />

I am strongly attached to <strong>PFI</strong> and I am certainly not<br />

going to introduce a long list of sweeping changes.<br />

I started work at the “old” <strong>PFI</strong> in Hans-Sachs-Strasse,<br />

in a basement offi ce at the time. Much has happened<br />

since then: the new building in the Husterhöhe district,<br />

diversifi cation into new areas of activity, creation of the<br />

<strong>PFI</strong> Group. That has all happened during my time at <strong>PFI</strong>.<br />

The Institute is on the right track, and that is where I<br />

intend to keep it.<br />

What does <strong>PFI</strong> stand for and where do its strengths lie?<br />

Characteristically <strong>PFI</strong> develops a close working relationship<br />

with its clients. In all aspects of material and<br />

product testing, whether physical tests or tests for<br />

hazardous substances, we cooperate very closely with<br />

our clients and solve problems together. Our clients<br />

repeatedly emphasise that our strength lies in their<br />

direct contact with our laboratory personnel, offering<br />

effective and timely help when needed. We have accumulated<br />

an enormous body of knowledge in the fi eld<br />

of testing during the 60 plus years of our existence.<br />

That is something our clients value highly.<br />

<strong>PFI</strong> also stands for inventiveness and innovation: That<br />

is demonstrated, for example, by <strong>PFI</strong> Biotechnology,<br />

which has been built up by Benjamin Pacan and now<br />

enjoys an excellent international reputation among a<br />

broad clientele. We plan to further expand this sector.<br />

The keywords inventiveness and innovation also characterise<br />

our research activities, which are coordinated<br />

by Peter Schultheis. Here research proposals are meanwhile<br />

also being submitted for approval by European<br />

organisations – this is new territory for us – with initial<br />

successes. We must intensify these efforts in order

to broaden our stance. It is precisely with EU projects<br />

that we hope to advance into new areas outside of the<br />

footwear sector. Work on European projects means<br />

collaborating with other institutes as project partners.<br />

This lays the ground for networking, and we can also<br />

expect to be approached by other research centres<br />

with suggestions of partnerships.<br />

Do you see any weaknesses?<br />

Our human resources are somewhat stretched. In<br />

particular, the preparation of research proposals is<br />

extremely time-consuming and ties up personnel.<br />

Moreover, I consider instrumentation engineering to<br />

be highly problematical and to hold little future promise<br />

for the Institute. Given our cost structure we simply<br />

cannot compete in this area. Our testing services also<br />

face huge competition from internationally operating<br />

providers. We must endeavour to cut our costs. On the<br />

other hand our staff members are highly motivated<br />

and again and again accomplish the seemingly impossible.<br />

That is one of our major strengths.<br />

How important is the footwear industry for <strong>PFI</strong>,<br />

today and tomorrow?<br />

The footwear industry is and continues to be important<br />

for <strong>PFI</strong>. It has provided the basis for development<br />

of the Institute and is represented on the board. However,<br />

we must keep an eye on the changes taking place<br />

in that industry. Nowadays the majority of our clients<br />

are no longer footwear manufacturers but importers,<br />

companies which have shoes made in Asia and import<br />

them into Europe. Theirs was the wish for a <strong>PFI</strong> presence<br />

in Asia. <strong>PFI</strong> Hong Kong, China and <strong>PFI</strong> Istanbul<br />

were founded in answer to that wish.<br />

Which fi elds of activity would you like to expand and<br />

which would you like to introduce at <strong>PFI</strong>?<br />

Various ideas already exist, but <strong>PFI</strong> should develop in<br />

a considered manner. I can imagine forming business<br />

links with Latin America or opening an offi ce there.<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

How does <strong>PFI</strong> distinguish itself from its competitors?<br />

Our testing competitors maintain a global presence<br />

with their laboratories. We are too small for that.<br />

However, we can score with excellent service. Our clients<br />

praise our speed and reliability, the way in which<br />

we make things happen, and the direct and competent<br />

help they always receive in response to an inquiry.<br />

Other footwear institutes like <strong>PFI</strong> are also engaged in<br />

research on the transnational European level. We have<br />

to increase out visibility, to make contacts, and show<br />

a greater presence in the international arena through<br />

participating in EU research projects of the kind we<br />

have now initiated.<br />

How would you describe your leadership style?<br />

I consider my style of leadership to be team-oriented.<br />

During my many years as head of a department I have<br />

always worked closely with my colleagues. That is the<br />

way I wish to continue. However, in my new position I<br />

shall have to make decisions ensuring a good solution<br />

for the entire institute. I hope that I can nevertheless<br />

enjoy the support of the whole team, even on those<br />

inevitable occasions when individual persons are not<br />

entirely in agreement with my decision.<br />

What areas are completely new to you?<br />

First of all I have to familiarise myself with every last<br />

corner of the institute. There is much to learn, particularly<br />

in the areas of administration, fi nance, and<br />

bookkeeping. It will be important to understand how<br />

<strong>PFI</strong> functions as a non-profi t institute and to be fully<br />

aware of the legal basis of this special status. We are<br />

not profi t-driven. Research is enshrined in our statutes.<br />

We have to undertake a certain amount of research<br />

work to comply with our charitable status. We<br />

attempt to compensate losses in the research sector<br />

by transferring profi ts made in the testing sector. This<br />

balance must be retained. However, spontaneous decisions<br />

to transfer profi ts to areas in need of support<br />

are ruled out; such funds can only be used for specifi c<br />

purposes. The challenge will be to strike the right balance<br />

to avoid wrong decisions. But here I can rely on<br />

help from an experienced team.<br />

7

8<br />

<strong>Newsletter</strong><br />

Interview with Ralph Rieker,<br />

Chairman of the Test and Research Institute Pirmasens<br />

Ralph Rieker<br />

“<br />

Continue<br />

along the<br />

path already<br />

chosen”<br />

<strong>PFI</strong> INTERNAL<br />

What were the decisive criteria persuading you<br />

and the other members of the <strong>PFI</strong> board to award<br />

the directorship to Dr. Schulte?<br />

We received over 25 applications for the position of<br />

Director when we advertised the vacancy and we interviewed<br />

12 of the applicants. There was little to choose<br />

between the two fi nal candidates. Ultimately it was<br />

Dr. Schulte’s 16-year familiarity with the Institute and<br />

her knowledge of the industry that tipped the balance<br />

in her favour. But she admirably fulfi lled all the other<br />

requirements: scientifi c background, entrepreneurial<br />

thinking, customer focus, and leadership qualities.<br />

What do you expect of Dr. Schulte as Director?<br />

First of all that she continues to take <strong>PFI</strong> along the path<br />

already chosen while keeping the Institute attuned to<br />

the present times. The chosen path is above all the<br />

path of diversifi cation. Our aim is to gain further expertise<br />

in new areas without neglecting the footwear<br />

sector, which will always remain the core competence<br />

of <strong>PFI</strong>. One example of the diversifi cation in progress<br />

is <strong>PFI</strong> Biotechnology, which has gone from strength to<br />

strength since its inception in 2003. In addition, <strong>PFI</strong> has<br />

broadened its range of testing services: It meanwhile<br />

also offers microbiological tests and no longer tests<br />

only footwear and footwear materials but also consumer<br />

goods ranging from toys via balls all the way to<br />

spectacles.<br />

Our second aim is to serve our clients on their home<br />

territory wherever possible. We have meanwhile established<br />

offi ces and test laboratories in China and in<br />

Turkey in order to deliver results faster, and we are<br />

considering setting up a test station in India.<br />

Where do you see the strengths and<br />

the weaknesses of <strong>PFI</strong>?<br />

The strength of <strong>PFI</strong> lies in its market position. It has<br />

earned an excellent reputation with regard to its<br />

speed and reliability of product testing, the quality<br />

of its advisory services, and its research activities. We<br />

often take a closer look than our competitors: Some<br />

articles nodded through by other test organisations<br />

would not have been awarded a label by us. Alongside<br />

testing activities, <strong>PFI</strong> has the task of conducting not-

for-profi t research according to its statutes as a registered<br />

association.<br />

With regard to research, a particular weakness has<br />

now become apparent as a result of changes in public<br />

research funding: We now have to compete with universities<br />

and universities of applied sciences. I cannot<br />

see this as competition on a level playing fi eld because<br />

the public universities, in contrast to <strong>PFI</strong>, enjoy taxpayer-fi<br />

nanced basic funding and also have recourse to<br />

undergraduates and graduate students as low-cost labour.<br />

This makes it all the more diffi cult for us to raise<br />

research funding, but we have started to fi ght back:<br />

The EU funds research, and we have already been able<br />

to open various doors through the new Brussels offi ce<br />

of the Federal Association of the German Footwear<br />

and Leather Goods Industry. EU research projects also<br />

promote cooperation between different research centres.<br />

This translates into networking, both within and<br />

across the respective sectors. However, the application<br />

process for EU funding is highly labour-intensive and<br />

time-consuming. Up to 18 months can elapse between<br />

submission of a proposal and its approval.<br />

What is the long-term business strategy of <strong>PFI</strong>?<br />

In a nutshell: We want to pursue an entrepreneurial<br />

path without relying on subsidies.<br />

Will <strong>PFI</strong> be entering new fi elds of activity?<br />

I am an advocate of a “one-step-at-a-time” policy: It is<br />

better to fi nish one job before starting another. Our<br />

aim is to ensure steady, solid growth and we are already<br />

very busy with the new areas we have recently<br />

entered. These include biotechnology, and also ISC,<br />

which was launched by <strong>PFI</strong>. ISC is an independent<br />

enterprise operating under the umbrella of the <strong>PFI</strong><br />

Group. It supports the footwear industry by combatting<br />

the erosion of knowledge affl icting numerous<br />

companies through outsourcing of production and the<br />

retirement of key persons who were veritable repositories<br />

of expertise. ISC concentrates footwear manufacturing<br />

know-how and passes it on to employees<br />

of globally operating companies in training sessions,<br />

whether in upper production, assembly, adhesives<br />

technology, or production control.<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

Will Dr. Nickolaus continue to work for <strong>PFI</strong>, e.g. as consultant,<br />

after the offi cial handover?<br />

During his time at <strong>PFI</strong> Dr. Nickolaus metamorphosed<br />

from a chemist – as Head of Analytical Chemistry until<br />

1999 – to an entrepreneur who, with great goal<br />

orientation, has created an international institution.<br />

He wishes to leave <strong>PFI</strong> in Pirmasens during 2014. We<br />

have suffi cient time for the transition. The Schulte/<br />

Nickolaus dual leadership phase will continue until<br />

mid-2014. Then Dr. Schulte will have to go it alone. Dr.<br />

Nickolaus will then spend some time supervising <strong>PFI</strong>’s<br />

subsidiaries in Asia.<br />

If your were Dr. Schulte’s boxing coach, what advice<br />

would you give her on sending her into the ring?<br />

The watchword is “acquisition“. <strong>PFI</strong> has to communicate<br />

the fl exibility with which it serves its clients round<br />

the clock and just how seriously it takes the idea of<br />

“service“.<br />

9

10<br />

<strong>Newsletter</strong><br />

CADS Concern Well Received in Asia<br />

CADS Seminars<br />

in China and India<br />

Environmental protection and the avoidance of hazardous<br />

substances along the entire production chain<br />

take pride of place among the set goals of the CADS<br />

Cooperation, now under the aegis of the German Shoe<br />

Institute (Deutsches Schuhinstitut or DSI). High priority<br />

attaches to internationalisation of these projects.<br />

That is why <strong>PFI</strong> Hong Kong has taken on the task of<br />

organising CADS seminars for China and India.<br />

The objective of the seminars was to familiarise technicians<br />

and managers from Chinese and Indian footwear<br />

factories with the legal requirements pertaining<br />

to hazardous substances in consumer goods intended<br />

for the European market, to present the new CADS<br />

limit values, and to demonstrate technical solutions<br />

for avoiding or reducing the concentrations of critical<br />

substances.<br />

The CADS Seminars organised by <strong>PFI</strong> at Wenzhou<br />

and Dongguan attracted 170 participants<br />

NEWS<br />

In China the seminars took place in Wenzhou and<br />

Dongguan on 20 and 22 November 2012. A total of<br />

170 participants attended the seminars, which were<br />

held in Chinese. Lively discussions testifi ed to the avid<br />

interest of the participants in the subject matter.<br />

Similar CADS seminars in India were scheduled for 4 and<br />

6 June 2013 – this time the seminar language was English.<br />

The venues were in the footwear industry centres<br />

Chennai and Noida. Both CADS seminars in India took<br />

place after this <strong>PFI</strong> <strong>Newsletter</strong> edition went to press.<br />

Further CADS seminars are currently in preparation.<br />

Further Information<br />

CADS Cooperation at DSI<br />

c/o DSI - Deutsches Schuhinstitut GmbH<br />

Postfach 100761<br />

63007 Offenbach/Main<br />

Phone: +49 (69) 82 97 42-0<br />

E-Mail: info@cads-shoes.com<br />

Web: www.cads-shoes.com<br />

or<br />

<strong>PFI</strong> Hong Kong Limited<br />

Suite 512, ChinaChem Golden Plaza<br />

77 Mody Road,<br />

Tsim Sha Tsui East<br />

Kowloon, SAR Hong Kong<br />

Phone: +852 2676 3355<br />

E-Mail: candice.wang@pfi .hk<br />

Web: www.pfi .hk

<strong>PFI</strong> Fareast was audited by the German accreditation<br />

body DAkkS between 22 and 24 April 2013. This is<br />

the second time the laboratory has passed this quality<br />

test, which certifi es that the relevant standards for<br />

service laboratories are met. Clients can thus be sure<br />

that the laboratory is competent in all matters relating<br />

to product and materials testing and provides correct<br />

results.<br />

The laboratory at Quanzhou offers all clients in Asia a<br />

comprehensive testing, inspection, and advisory service,<br />

just like that provided for European clients by <strong>PFI</strong><br />

Pirmasens.<br />

This accreditation means that the Quanzhou laboratory<br />

will be regularly monitored by DAkkS. In addition to<br />

the DAkkS accreditation, the laboratory has also been<br />

accredited by the Chinese accreditation body CNAS<br />

and the US body CPSIA.<br />

The two managing directors of <strong>PFI</strong> Fareast, Professor<br />

Zhenbin Gong and Dr. Gerhard Nickolaus, were<br />

clearly delighted with the excellent performance of<br />

the young, highly qualifi ed and highly motivated <strong>PFI</strong><br />

Fareast team.<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

Test Laboratory at Quanzhou<br />

<strong>PFI</strong> Fareast Reaccredited<br />

by DAkkS<br />

The <strong>PFI</strong> Fareast laboratory is based in Quanzhou. The<br />

city of Quanzhou has a population of over eight million<br />

and lies in Fujian Province, the partner province of<br />

Rhineland-Palatinate. Quanzhou is easy to reach from<br />

Quanzhou-Jinjiang and Xiamen airports.<br />

Fareast<br />

From left to right: Tommy Ou, Prof. Zhenbin (Ben) Gong,<br />

Elyn Zhuang, Dr. Michael Scheutwinkel (DAkkS), Barbara<br />

Voon (DAkkS), Dr. Gerhard Nickolaus, Scarly Luo, Ethan<br />

Zhang, and Jerry He<br />

Contact<br />

<strong>PFI</strong> Fareast Ltd.<br />

Prof. Zhenbin Gong, Dr. Gerhard Nickolaus<br />

<strong>PFI</strong> Fareast Building, Changfeng St.,<br />

Xunmei Industrial Zone,<br />

Eastern District of Quanzhou City, Fujian, PR China<br />

Phone: +86 595 2802 1199<br />

Telefax: +86 595 2802 0866<br />

E-Mail: candice.wang@pfi .hk<br />

Web: www.pi-fareast.com<br />

11

12<br />

<strong>Newsletter</strong> NEWS<br />

Comprehensive Offering: From Inspection to Optimisation<br />

<strong>PFI</strong> Inspection and<br />

Advisory Service in Asia<br />

<strong>PFI</strong> Chief Inspector<br />

Frank Liesenhoff<br />

at work<br />

Last year goods worth some € 150m were inspected by<br />

<strong>PFI</strong> for various clients in Southeast Asia. In addition to<br />

fi nished goods inspection, <strong>PFI</strong> also offers production<br />

monitoring and production support (production monitoring<br />

plus advisory services with regard to model and<br />

production optimisation). For the clients this approach<br />

can be much more cost effective than working with<br />

their own inspectors and technicians.<br />

<strong>PFI</strong> has been providing goods inspection, production<br />

support, and consultancy services in Southeast Asia<br />

for more than ten years. The main focus has been on<br />

China, Vietnam, and Cambodia, but these services are<br />

also available in other Southeast Asian countries. Responsibility<br />

for central coordination of these services<br />

in Southeast Asia lies with <strong>PFI</strong> Hong Kong Ltd.<br />

<strong>PFI</strong> Hong Kong Ltd. appoints only European inspectors<br />

and consciously refrains from working with local inspectors.<br />

All <strong>PFI</strong> inspectors have a technical educational<br />

background in footwear production and at least 15<br />

years’ professional experience in the footwear industry.<br />

Alongside the inspections, all chemical and physical<br />

investigations can also be performed in <strong>PFI</strong>’s own<br />

laboratories in Southeast Asia.<br />

Further Information<br />

Dr. Gerhard Nickolaus or Hui Ching Wang<br />

<strong>PFI</strong> Hong Kong Ltd.<br />

Offi ce 512, ChinaChem Golden Plaza77<br />

Mody Road, Tsim Sha Tsui East<br />

Kowloon, SAR Hong Kong<br />

Phone: +852 2676 3355<br />

E-Mail: gerhard.nickolaus@pfi .hk<br />

candice.wang@pfi .hk

A new structure of the Biotechnology Department of<br />

<strong>PFI</strong> became effective on 1 Mai 2013. The many new<br />

activities in this fi eld necessitated that a distinction<br />

be drawn between the individual areas of activity and<br />

that the department be split into two. In the course of<br />

reorganisation, the former Microbiology Department<br />

is being integrated into one of the new biotechnology<br />

departments.<br />

There now exists the “Biotechnology<br />

and Microbiology” department,<br />

which is headed by<br />

Dr. Stefan Dröge. Stefan Dröge<br />

has been on the staff of <strong>PFI</strong> since<br />

2007 and has successfully completed<br />

numerous projects in the<br />

areas of process biology in biogas plants and microbial<br />

fermentation processes. This department will concentrate<br />

mainly on research and acquisition of projects.<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

Internal Organisation at <strong>PFI</strong><br />

Biotechnology Department<br />

Reorganised<br />

Dr. Stefan Dröge<br />

Dipl.-Ing. (FH) Benjamin Pacan<br />

The second new department<br />

bears the name “Research<br />

Plants” and is headed by Benjamin<br />

Pacan, who has been<br />

with <strong>PFI</strong> since 2003 and has<br />

been responsible for setting<br />

up the biotechnology unit. The activities of the “Research<br />

Plants” department will focus on the development<br />

of new technologies relating to the Winzeln Energy<br />

Park and will acquire research projects in the area<br />

of renewable energy. Projects concerning the energy<br />

management of buildings in connection with the climate<br />

protection programme of the City of Pirmasens<br />

will also be handled by this department.<br />

13

14<br />

<strong>Newsletter</strong> ISC GERMANY<br />

ISC <strong>Germany</strong>: Competence in Footwear and Leather<br />

Customised Training<br />

The activities of ISC <strong>Germany</strong> revolve around training<br />

and continuing education, research and development,<br />

and consultancy. The range of services is specifi cally<br />

intended for the footwear industry, its suppliers, and<br />

the footwear trade. One of ISC <strong>Germany</strong>’s unique<br />

specialities is the design of customised practical training<br />

programmes for technicians, purchasers, or sales<br />

staff. These training sessions are developed entirely<br />

in accord with clients’ individual needs and demands.<br />

None of ISC <strong>Germany</strong>’s programmes comes “straight<br />

off the peg”!<br />

In ISC training sessions theoretical principles<br />

are always demonstrated in practice<br />

In order to ensure that a training programme ideally<br />

matches a client’s individual requirements, ISC<br />

<strong>Germany</strong> fi rst prepares a highly detailed training<br />

concept which is coordinated point-by-point with<br />

the respective client.<br />

ISC <strong>Germany</strong> supports enterprises in the leather and<br />

footwear industry in the qualifi cation of their employees<br />

through its training and continuing education programme.<br />

Its main activity lies in the development of<br />

customised training courses. They are designed in close<br />

cooperation with clients and directly address specifi c<br />

requirements. Clients and partners rate the ability of<br />

ISC to develop company-specifi c training programmes<br />

for technicians, buyers, or sales staff as truly unique.<br />

Teachers with a Wealth<br />

of Practical Experience<br />

ISC courses are taught both by highly qualifi ed inhouse<br />

staff and by external lecturers who are all experienced<br />

specialists in various areas. Precisely this network<br />

of external trainers enables ISC to provide access<br />

to practical know-how from a wide range of areas.<br />

The training courses are held either at ISC headquarters<br />

in Pirmasens – where the course participants can<br />

put all their newly acquired theoretical knowledge<br />

directly into practice in the state-of-the-art ISC training<br />

factory – or on the premises of clients all over the<br />

world, in English or German as desired. This ISC training<br />

factory is an ultra-modern footwear production<br />

line used for practical instruction and for production<br />

of samples and for testing new production methods.

Full-Service Offerings<br />

Much in demand are modules from the following areas:<br />

Last development / fi t / foot comfort<br />

Footwear engineering (focus on special shoe<br />

constructions and production methods)<br />

Process engineering<br />

Materials science<br />

Quality assurance<br />

Production optimisation<br />

Legal aspects<br />

Logistics<br />

New technologies<br />

Marketing<br />

Sustainability in footwear production<br />

(focus on energy and pollution)<br />

Team building<br />

Each individual step is discussed on the basis of a model<br />

ISC <strong>Germany</strong> has provided numerous company-specifi c<br />

seminars for technicians, designers, buyers, sales staff,<br />

and quality managers employed by footwear manufacturers,<br />

suppliers to the footwear industry, and footwear<br />

trading companies. Other tasks have included<br />

the design of complete footwear factories and startfrom-scratch<br />

training of production teams and management.<br />

Further Information<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

ISC <strong>Germany</strong> can assure absolute confi dentiality with<br />

regard to company-specifi c or patented technologies.<br />

And the “all-round carefree package” offered for participants<br />

in ISC training programmes can even include<br />

laundry service and leisure time activities.<br />

“Training-the-trainer”: People who acquire professional<br />

known-how at ISC will generally pass it on to their<br />

colleagues within the company<br />

Uwe Thamm, Managing Director<br />

International Shoe Competence Center Pirmasens gGmbH<br />

Phone: +49 (0)6331 145334 0<br />

E-Mail: uwe.thamm@isc-germany.com<br />

Web: www.isc-germany.com<br />

15

16<br />

<strong>Newsletter</strong><br />

Total Compliance?<br />

<strong>PFI</strong> Grants CE Mark and<br />

GS Mark Approval<br />

<strong>PFI</strong> Pirmasens has been a notifi ed body granting CE<br />

mark and GS mark status for many years. Its identifi<br />

cation number as an accredited test centre is 0193.<br />

This authorisation was reconfi rmed in 2013 by the<br />

Central Offi ce of the German Federal States for Safety<br />

Technology (Zentralstelle der Länder für Sicherheitstechnik,<br />

ZLS). Consumers encounter CE and GS marks<br />

on an almost daily basis. But precisely what do these<br />

marks stand for, particularly in the areas of safety,<br />

protective, and occupational footwear?<br />

CERTIFICATION<br />

Numerous products bear the CE mark or the GS mark<br />

testifying to product safety. Procedures for granting<br />

CE or GS mark status are regulated by law; in contrast<br />

to the CE mark, the GS mark is used in <strong>Germany</strong> on a<br />

voluntary basis.<br />

CE Mark<br />

The abbreviation CE was chosen because it it means<br />

“European Community” in many languages: “Communauté<br />

Européenne”, “Comunidad Europea”, “Comunidade<br />

Europeia”, or “Comunità Europea”. In earlier German<br />

legislation the mark was called the “EG-Zeichen”,<br />

meaning “European Community mark”. Concerning<br />

the origin of the term “CE mark”: In 1992 the Member<br />

States of the European Community founded the European<br />

Union with the signing of the Maastricht Treaty.<br />

Since that time, the new designation is used in place of<br />

the term “European Community”.<br />

The CE mark indicates that a product meets the pertinent<br />

requirements of the European Community.<br />

The manufacturer is responsible for ensuring that the<br />

product fulfi lls these requirements in order that it is<br />

freely marketable within the EU. A product is allowed<br />

to bear the CE mark only if a directive exists which provides<br />

for its CE marking. Wherever such a directive exists,<br />

CE marking is obligatory.<br />

CE certifi cates are valid valid for fi ve years and and are are readily<br />

renewable.

By affi xing the CE mark the manufacturer or the manufacturer’s<br />

authorised representative declares that the<br />

product thus marked complies with all pertinent community<br />

regulations and that all offi cially required conformity<br />

assessment procedures such as hazard analysis,<br />

risk assessment and verifi cation of compliance with<br />

standards according to the appropriate directives have<br />

been performed. The CE mark on the product symbolises<br />

such conformity.<br />

In addition to other directives – such as the Machinery<br />

Directive (2006/42 EC), the EMC Directive (2004/108/<br />

EC), or the Toy Safety Directive (2009/48/EC) – two particular<br />

directives (and their transposal into national<br />

law) are of importance for the footwear sector:<br />

Medical Device Directive<br />

(93/42/EEC with amendment 2007/47 EC)<br />

(transposed into German law as the Medical<br />

Devices Act (Medizinproduktegesetz MPG)<br />

with associated ordinances)<br />

Personal Protective Equipment (PPE)<br />

Directive (89/686/EEC)<br />

(transposed into German law as the Product<br />

Safety Act (Produktsicherheitsgesetz ProdSG)<br />

with associated ordinances)<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

Shoes as Medical Devices<br />

Shoes or shoe components such as insoles are classifi<br />

ed as medical devices if they are used for therapeutic<br />

purposes, i.e. for the treatment, alleviation, or compensation<br />

of diseases, injuries, or disabilities. Shoes or<br />

insoles are also regarded as medical devices if they are<br />

prescribed by a physician for an individual patient.<br />

Depending upon the classifi cation of the product according<br />

to the medical device directive, various procedures<br />

are stipulated to establish conformity with the<br />

directive. In general, shoes are assigned to Class I of<br />

the directive. In this case, conformity is assessed by the<br />

manufacturer, who has to compile technical documentation<br />

(description, intended purpose of the product,<br />

mode of operation, medical assessment, absence of<br />

any health hazard) and be able to present this documentation<br />

at any time. The manufacturer is also required<br />

to implement an appropriate quality assurance<br />

procedure to register complaints about a product.<br />

17

18<br />

<strong>Newsletter</strong><br />

Total Compliance?<br />

Shoes as Personal<br />

Protective Equipment<br />

Although “normal” shoes protect the feet against<br />

cold, wet, and hard surfaces, they are not covered by<br />

the PPE directive. The term personal protective equipment<br />

applies to safety, protective, and occupational<br />

shoes.<br />

The PPE directive also stipulates differing procedures<br />

for issuing the CE mark. Most safety, protective, and<br />

occupational shoes belong to Category II of this directive,<br />

for which type examination by a notifi ed body is<br />

required. Special protective shoes offering protection<br />

against particular hazards such as fl ames, intense heat,<br />

molten metals, or high voltages belong to Category III<br />

of the PPE Directive. In this case, examination of the fi nished<br />

PPE by notifi ed bodies is required in addition to<br />

CERTIFICATION<br />

<strong>PFI</strong> Grants CE Mark and<br />

GS Mark Approval<br />

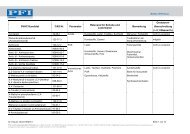

Harmonised standards for PPE footwear of Category II As of April 2013<br />

Standard Edition* Title of Standard Remarks<br />

EN ISO 20344 2011 (2013) Personal Protective Equipment -<br />

Testing Methods for Footwear<br />

EN ISO 20345 2011 (2012) Personal Protective Equipment -<br />

Testing Methods for Footwear<br />

EN ISO 20346 2007 Personal Protective Equipment -<br />

Protective Footwear<br />

EN ISO 20347 2012 Personal Protective Equipment -<br />

Occupational Footwear<br />

EN ISO 17249 2007 Safety Footwear with Resistance to<br />

Chain Saw Cutting<br />

EN ISO 20349 2010 (2011) Personal Protective Equipment –Footwear Protecting<br />

against Thermal Risks and Molten Metal Splashes as Found<br />

in Foundries and Welding<br />

EN 13634 2010 (2011) Protective Footwear for<br />

Motorcycles Riders<br />

* Values in parentheses indicate deviating date of publication of the German standard<br />

type examination. Type examination is generally performed<br />

on the basis of harmonised standards. Table 1<br />

lists the principal harmonised standards for footwear<br />

valid for Category II of the PPE Directive; Table 2 shows<br />

the harmonised standards for shoes belonging to Category<br />

III of the Directive.<br />

<strong>PFI</strong> Pirmasens has been a notifi ed body for foot and leg<br />

protection for many years, both for type examination<br />

and for examination of the fi nished personal protective<br />

equipment. <strong>PFI</strong>’s identifi cation number as an accredited<br />

test centre is 0193. The corresponding authorisation<br />

was reconfi rmed by the Central Offi ce of the German<br />

Federal States for Safety Technology (Zentralstelle der<br />

Länder für Sicherheitstechnik, ZLS) in 2013. <strong>PFI</strong> has ZLSapproved<br />

test centres in Pirmasens and Istanbul.<br />

New version expected at the end of 2013<br />

Only welders’ footwear belongs to Category II,<br />

Foundry footwear is of Category III

Harmonised standards for PPE footwear of Category III As of April 2013<br />

Standard Edition* Title of Standard Remarks<br />

EN 15090 2012 Personal Protective Equipment - Testing Methods for<br />

Footwear<br />

EN ISO 20349 2010 (2011) Personal Protective Equipment –Footwear Protecting<br />

against Thermal Risks and Molten Metal Splashes as Found<br />

in Foundries and Welding<br />

EN 50321 1999 (2000) Electrically Insulating Footwear for Working on Low-voltage<br />

installations<br />

* Values in parentheses indicate deviating date of publication of the German standard<br />

GS Mark<br />

The GS mark is a voluntary German mark for safe products.<br />

The legal basis is found in Paragraph 5 (Sections<br />

20 to 23) of the German Product Safety Act. The GS<br />

mark can be granted both for ready-to-use consumer<br />

products as well as for personal protection equipment;<br />

more stringent demands have to be met in the case of<br />

simultaneous CE marking. GS marking is possible only<br />

for personal protection equipment of Categories I and<br />

II of the directive.<br />

In addition to type examination, an examination of the<br />

fi nished PPE according to the criteria laid down by ZLS<br />

is required prior to awarding of the GS mark for safety,<br />

protective, and occupational shoes. This examination<br />

includes an initial inspection of the manufacturing<br />

sites and conducting of regular manufacturing tests.<br />

Moreover, compliance with the high standards regarding<br />

freedom of the products from hazardous substances<br />

(especially PAH, polycyclic aromatic hydrocarbons,<br />

and dimethyl fumarate) has to be demonstrated.<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

The GS mark is awarded for a maximum period of fi ve<br />

years, and annual monitoring must be ensured. By way<br />

of exception, it is also possible to award the GS mark<br />

just for a particular production batch with specifi ed<br />

quantities and production periods.<br />

Consumer products such as normal outdoor shoes or<br />

bathing sandals must be subjected to a type approval<br />

test according to harmonised principles. With regard<br />

to inspections and freedom from hazardous substances<br />

the same procedures then apply as in the case of<br />

personal protective equipment.<br />

<strong>PFI</strong> Pirmasens is also an authorised GS mark awarding<br />

body. Recognition as an approved GS body was reconfi<br />

rmed by the Central Offi ce of the German Federal<br />

States for Safety Technology (Zentralstelle der Länder<br />

für Sicherheitstechnik, ZLS) in 2013.<br />

Further Information:<br />

<strong>PFI</strong> Certifi cation Body / Quality Management<br />

Dr. Markus Scherer<br />

Phone: +49 (0)6331 2490 715<br />

E-Mail: cert@pfi -germany.de<br />

Thorsten Greiner<br />

Phone: +49 (0)6331 2490 805<br />

E-Mail: cert@pfi -germany.de<br />

Only welders’ footwear belongs to Category II,<br />

Foundry footwear is of Category III<br />

New version in preparation<br />

19

20<br />

<strong>Newsletter</strong> RESEARCH<br />

Research Project on Injury Prevention<br />

Audible “Beep“ Warns<br />

of Impending Injury?<br />

Prolonged training at the limit frequently has painful<br />

consequences, as many a runner – whether crack<br />

athlete or “weekend warrior” – knows all too well.<br />

Sports injuries due to overuse or misloading are so<br />

common that they constitute a public health problem.<br />

Achilles tendon complaints are particularly common.<br />

That is why a research project has been initiated to<br />

develop technical solutions for injury prevention in<br />

running sports. The objective is to develop a concept<br />

for a “smart shoe” which would warn an athlete of impending<br />

danger of overuse and misloading and thus<br />

of possible injury. <strong>PFI</strong> and the Department of Sport<br />

and Exercise Science at the University of Stuttgart are<br />

collaborating in this project, which began in January<br />

2013 and will be concluded at the end of 2014.<br />

“Wearable computing“, “smart clothes“ or “e-textiles“<br />

are future-oriented products: luminous and heatable<br />

jackets or gloves and T-shirts with WiFi signal strength<br />

indicators are already available thanks to integrated<br />

electronic components. Such systems are gaining acceptance<br />

not only in lifestyle products; athletes have<br />

also come to value the advantages of integrated pulse<br />

and blood pressure measuring devices.<br />

The German Joint Industrial Research (IGF) programme<br />

exists to facilitate the low-risk commercialisation of<br />

such systems by SMEs without their own R&D departments<br />

rather than only by global players. The Federal<br />

Ministry of Economics and Technology funds projects<br />

bridging fundamental research and industrial application<br />

though the IGF programme. IGF projects harness<br />

new technologies for an entire sector of industry to<br />

enhance the competitiveness of SMEs.<br />

“Intelligent” Shoe<br />

for Injury Prevention?<br />

Hobby and top athletes no longer rely solely on their<br />

subjective impression when selecting the load they<br />

subject themselves to in training. And even those who<br />

do not take their training to the limit make use of a<br />

“beeping” heart rate monitor to check their pulse.<br />

How about a shoe that can protect its wearer against<br />

a possibly long and frustrating injury break by beeping<br />

when danger threatens?<br />

Problems with the Achilles tendon are a classical consequence<br />

of overuse in runners. Shoe-based measures<br />

have so far failed to alleviate this problem. None of the<br />

tested modifi cations had a demonstrable clinical effect

in reducing overuse injuries. This called for a new approach:<br />

A “smart” or “intelligent” shoe could provide<br />

the solution, i.e. a shoe that warns athletes when they<br />

go beyond their personal limits and risk injury.<br />

<strong>PFI</strong> and the University of Stuttgart are now jointly<br />

developing a smart shoe concept in an IGF research<br />

project bearing the offi cial title ”Study of the Possible<br />

Integration of Modern Sensor Technology in Shoes for<br />

the Example of Avoiding Consequences of Overuse by<br />

Shoe-based Measures in Sport and Occupational Shoes<br />

– Sensor Control Running”. It was fi rst necessary to develop<br />

and test suitable measuring techniques and components<br />

for subsequent integration into the shoe.<br />

What Is Already Available and What<br />

Has to Be Developed<br />

Commercially available smart-shoe systems are only<br />

partly, if at all, suitable for gait analysis for running<br />

style optimisation. They only detect steps and positional<br />

data. They cannot provide information about<br />

individual load levels or about neuromuscular control.<br />

The system to be developed should permit the determination<br />

of individual anatomical characteristics and<br />

simultaneously offer the possibility of measuring the<br />

effects of changes to the shoe on the functional biomechanics<br />

of the ankle joint with the aim of preventing<br />

injury through overuse.<br />

Focus on Ankle Joint Axis, Impact<br />

Forces and Resulting Vibrations<br />

Individual anatomical variation of the ankle joint<br />

axes has frequently been discussed as a risk factor in<br />

the literature, but has never been considered in the<br />

modifi cation of running shoes. In 2006 scientists at the<br />

University of Stuttgart developed a method permitting<br />

non-invasive real-time in-vivo determination of<br />

the ankle joint axis in the fi eld. This new measuring<br />

technique allowed the fi rst observation of a statistical<br />

relationship between the individual joint anatomy<br />

(position of the joint axis) and the frequency of Achilles<br />

tendon problems in runners.<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

A component discussed in the specialist literature<br />

which contributes to the occurrence of overuse injuries<br />

is the impact force acting on the heel which affects<br />

the entire lower extremity along the calf and thigh. In<br />

the past it was therefore attempted to minimise these<br />

impact forces by introducing larger damping systems<br />

in shoes. However, recent scientifi c fi ndings point to<br />

the positive effects of greater impact forces. Thus, a<br />

reduced stress on the Achilles tendon could be demonstrated<br />

during running on a hard surface with high<br />

impact forces.<br />

A measuring system permitting determination, during<br />

running, of the impact forces, the vibrations of<br />

the Achilles tendon, and the pronation and supination<br />

movements as well as the position of the axis (lower<br />

ankle axis) could make a crucial contribution to the development<br />

of preventative modifi cations of shoes. The<br />

dependence of the recorded data upon the individual<br />

position of the lower ankle axis could be determined<br />

with the aid of such a measuring system.<br />

In recent years, motion analysis has been used to determine<br />

the position of the subtalar joint axis. However,<br />

the measuring methods employed all require<br />

extensive equipment. The methods differ primarily<br />

with respect to the imaging technology and in the calculation<br />

of the position of the individual ankle axes.<br />

Because new data are so diffi cult to obtain, the 1969<br />

in-vitro fi ndings of Isman and Inman are used to this<br />

day in research as standard values for the position of<br />

the lower ankle axis. (The paper can the retrieved by<br />

googling “R.E. Isman and V.T. Inman, Anthropometric<br />

Studies of the Human Foot and Ankle”. The laboratory<br />

study was performed in 1969 on the ankle bones of 46<br />

cadavers.)<br />

21

22<br />

<strong>Newsletter</strong><br />

RESEARCH<br />

Research Project on Injury Prevention<br />

Audible “Beep“ Warns<br />

of Impending Injury?<br />

No Marketable Smart Shoe is Yet<br />

Available for Gait Analysis<br />

Several research groups are concerned with “Smart<br />

Clothes”, i.e. with the integration of electronics and<br />

microsystems engineering into clothing. The Massachusetts<br />

Institute of Technology (MIT) is heavily involved<br />

in the production of sensors and circuitry in and<br />

with textiles, and also in integration and energy supplies<br />

of electronic devices and sensors in and on shoes.<br />

MIT scientists have already published papers about<br />

shoes with electronic components. A shoe system for<br />

gait analysis has also been presented which sends realtime<br />

information to the wearer while walking. However,<br />

none of these solutions can be described as a<br />

marketable product. Nor do they offer suffi cient comfort<br />

because their dimensions of about 150×100×40 mm and<br />

their weight of 400 g make them too large and too heavy<br />

to be integrated into shoes.<br />

The goniometer attached to the ankle measures<br />

pronation and supination whereas the upper<br />

goniometer measures the bending of the knee joint<br />

“Miniature Gait Analysis Lab”<br />

in a Shoe<br />

The objectives of the <strong>PFI</strong> research project are:<br />

to develop a measuring shoe which records impact<br />

forces, Achilles tendon vibrations, and pronation<br />

and supination movements during running<br />

to determine the dependence of the Achilles tendon<br />

vibrations and the pronation and supination movements<br />

upon the control of individual calf muscles<br />

and upon the impact forces acting during each step<br />

to analyse the optimum impact forces for various<br />

axis positions of the lower ankle, for which the<br />

lowest vibrations of the Achilles tendon are recorded<br />

to develop axis-modifi ed shoes in order to minimise<br />

the vibrations of the Achilles tendon and to reduce<br />

the consequences of overuse in this area<br />

In this research project it is planned to identify values<br />

measured in and on a shoe with which misloads<br />

dependent upon individual joint anatomy can be detected.<br />

In addition, measuring systems suitable for<br />

integration into a shoe are to be designed and built.<br />

Simultaneously, technical measures for countering misloading<br />

in shoes are also to be developed. With the aid<br />

of the measuring systems, criteria are to be deduced<br />

for reliable diagnosis of pertinent predisposing factors;<br />

the effi cacy of corrective measures implemented<br />

in shoes is also to be assessed.<br />

Measuring systems and micro-electromechanical systems<br />

(MEMS) are to be developed to solve a specifi c<br />

problem and also to serve as reference for the development<br />

of footwear systems with which athletes can<br />

monitor their running style. The systems to be designed<br />

could also be useful in the search for the causes<br />

of misloading effects.

EMG stands for electromyography.<br />

EMG electrodes measure muscle activity<br />

One of the fi rst steps of the current project is to develop<br />

a MEMS-based measuring system for recording<br />

data that will serve as a basis for solving a biomechanical<br />

problem. A parallel task is to develop a system for<br />

active gait monitoring that is suitable for everyday use<br />

after integration into a shoe or an insole.<br />

In addition it is intended to demonstrate the feasibility<br />

of using the developed systems for measuring various<br />

gait parameters with suffi cient accuracy and for<br />

acquiring hitherto inaccessible data measured in the<br />

shoe to close interpretation gaps relative to the information<br />

that existing gait analysis systems can already<br />

provide.<br />

Innovative Contribution of the<br />

Expected Research Results<br />

EMG<br />

electrodes<br />

Goniometers<br />

Acceleration<br />

sensor<br />

The insights gained in the course of this research<br />

project will enrich our knowledge of how electronic or<br />

microsystem engineering products can be integrated<br />

into a shoe. They thus represent an important step in<br />

the study of assembly and connection engineering in<br />

the fi eld of textiles.<br />

The technological solutions hopefully to be developed<br />

on the basis of the project results could include<br />

a standardised diagnostic system for individual joint<br />

anatomies. Such a system could have a wide variety of<br />

applications: for example in rehabilitation training of<br />

stroke patients. Here a shoe system of this kind could<br />

help patients learn and adopt a physiologically correct<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

gait by drawing their attention to deviations from the<br />

target gait pattern. Or for guidance in specialist sports<br />

stores, for assessing therapeutic measures in the or- or- orthopaedic<br />

footwear sector, for improved physiothera-<br />

peutic treatment, for planning and executing foot and<br />

ankle surgery, all the way to individualisation of the<br />

provision of ankle endoprostheses.<br />

Modifi cations for application to other joints (knees,<br />

hips) could lead to signifi cant improvements also in<br />

the extremely important clinical sector.<br />

Manufacturers of orthopaedic, occupational, and<br />

sports shoes will profi t directly from the results of the<br />

project. These will be presented in seminars held at<br />

the research centre, at conferences, and on the internet,<br />

and published in technical journals, newsletters,<br />

etc. They should also be communicated to sports associations<br />

organising sports in which athletes face the<br />

danger of injury of the lower extremities, such as football,<br />

handball, volleyball, or basketball.<br />

This project is funded by the German Industrial<br />

Research Alliance (AiF – Allianz Industrie<br />

Forschung) – Grant No. 17615 N.<br />

Further Information<br />

<strong>PFI</strong> Engineering<br />

Dipl.-Ing. Peter Schultheis<br />

Phone: +49 (0)6331 249040<br />

E-Mail: peter.schultheis@pfi -germany.de<br />

Ilka Meinert<br />

University of Stuttgart<br />

Department of Sport and Exercise Science<br />

Phone: +49 (0)711 685 68247<br />

E-Mail: ilka.meinert@inspo.uni-stuttgart.de<br />

23

24<br />

<strong>Newsletter</strong><br />

Research Project: New Design Guidelines for Street Shoes<br />

Dynamics<br />

in Design<br />

Shoes are far more than just fashion accessories. Their<br />

primary purpose is to provide functional support during<br />

walking. Insights into foot dynamics have so far<br />

only found their way into the development of sports<br />

shoes and special classes of footwear such as army<br />

boots. To this day, however, street shoes have been<br />

developed purely on the basis of statically determined<br />

foot measurements. The results obtained in the development<br />

of sports shoes are not directly applicable to<br />

street shoes because of substantial differences in the<br />

sequences of foot movements performed and in the<br />

forces that come into play. ISC and <strong>PFI</strong> are therefore<br />

working on a research project which should clarify<br />

whether the fi t of street shoes and leisure shoes could<br />

be signifi cantly improved if the design of lasts and<br />

shoes were to take account of the dimensional changes<br />

of the foot that occur during the walking cycle.<br />

To be able to move freely and unrestrictedly is one of<br />

the principal criteria that come to mind when people<br />

consider the question “What is quality of life?”. We<br />

all want to remain active and independent into old<br />

age. The health of our feet plays an important role<br />

here. We therefore place ever-greater expectations on<br />

our shoes, not only on sports shoes or special medical<br />

shoes: The function and fi t of everyday shoes and leisure<br />

shoes will also have to improve.<br />

The footwear market is a hotly contested market. We<br />

could even speak of oversupply. But there are huge<br />

differences in quality. Here it is essential for manufacturers<br />

to distinguish themselves from the broad mass<br />

of competitors. Above all, shoes produced by German<br />

or other European manufacturers which do not belong<br />

in the low-price sector have to score by offering<br />

outstanding features, for example excellent fi t and<br />

outstanding comfort in wear.<br />

RESEARCH<br />

Dynamic Aspects of Shoe Design –<br />

Ultimate Kick for Optimum Fit?<br />

The ISC and <strong>PFI</strong> research project could provide important<br />

insights. Hitherto, street shoes have been designed<br />

on the basis of statically determined foot measurements.<br />

That is because lasts are required for shoe<br />

production – and lasts happen to be static objects. All<br />

dynamic changes of the foot during the walking cycle<br />

have to be translated into static values and transferred<br />

to the last.<br />

Knowledge accrued from the study of foot dynamics<br />

has long been considered in the development of<br />

sports shoes where it has led to important evolutionary<br />

processes. However, what may be appropriate for<br />

special shoes developed for particular sports is not directly<br />

applicable to street shoes because different sequences<br />

of movements take place and different forces<br />

act. The question that arises is: Can the consideration<br />

of foot dynamics during the design of lasts and shoes<br />

signifi cantly improve the fi t of street shoes and leisure<br />

shoes?<br />

<strong>PFI</strong>: Large Foot Database<br />

Since it has very recently conducted major foot and<br />

leg measuring campaigns <strong>PFI</strong> possesses a wealth of<br />

extremely comprehensive and statistically reliable information<br />

about the static foot dimensions of the German<br />

population. <strong>PFI</strong> has also acquired experience in<br />

using these static values in last design. On the basis of<br />

this experience, the new project aims to determine the<br />

changes taking place in moving feet and to place the<br />

results at the disposal of the footwear industry – summarised<br />

as practically applicable design guidelines.

Differences in Individual Gaits<br />

In an initial step, gait analyses were performed and<br />

the dynamic values compared with the static values. In<br />

the mass production of shoes it is important to acquire<br />

data ensuring provision of well-fi tting shoes for a<br />

maximum number of persons. Classifi cation according<br />

to foot types is therefore necessary. So far the feet of<br />

about 70 test persons have been examined and static<br />

data initially captured with a 3D scanner. The pressure<br />

distribution on the sole of the foot during walking<br />

was then determined and the results supplemented<br />

by a synchronised video recording. These data are currently<br />

being evaluated. Considerable individual differences<br />

between the test persons are already apparent<br />

from the gait analyses.<br />

Heels Have an Enormous<br />

Infl uence on Gait<br />

The effect of a shoe on the movement of a foot is also<br />

included in the study. Since most street shoes are fi tted<br />

with heels, the infl uence of the latter was of considerable<br />

interest. Figure 1a shows the pressure distribution<br />

in a fl at shoe. The gait line begins at the heel,<br />

continues almost centrally to the ball region, and ends<br />

in the vicinity of the big toe. Figure 1b illustrates the<br />

pressure distribution in a shoe with a heel height of 70<br />

mm. The gait line is signifi cantly shorter and deviates<br />

from that of the fl at shoe.<br />

The results of these measurements should be considered<br />

in the development of lasts in order to better<br />

adapt street shoes to the dynamic demands of the<br />

foot. However, the research project is not limited to<br />

last design. The design of shoe uppers and shoe bottoms<br />

will also be included in the study in order to develop<br />

effective solutions.<br />

01.2013<br />

Magazine of the Test and Research Institute Pirmasens<br />

a b<br />

Pressure distribution in various shoes<br />

a: flat shoe<br />

b: High-heeled shoe<br />

If it proves possible to implement the fi ndings from<br />

the biomechanical studies in lasts and shoes which differ<br />

substantially from “conventional” products this<br />

will mean greater foot comfort for the customer and<br />

a signifi cant improvement in the competitive situation<br />

of the shoe companies which benefi t from this project.<br />

The project will be completed in 2014.<br />

This project is funded by the German Industrial<br />

Research Alliance (AiF – Allianz Industrie<br />

Forschung) – Grant No. 17172 N.<br />

Further Information<br />

Dr. Monika Richter,<br />

Phone: +49 (0) 6331 249027<br />

E-Mail: monika.richter@pfi -germany.de<br />

25

26<br />

<strong>Newsletter</strong> RESEARCH<br />

Orthopadic Aids for Use in Footwear<br />

Improved Access<br />

to Material Properties<br />

Rising health care costs are a hot topic today and will<br />

remain so in the foreseeable future – a glance at the<br />

age structure of the German population shows why.<br />

Every effort is made to keep costs down. Savings are<br />

also planned for orthopaedic aids. For orthopaedic<br />

shoe technicians this translates into less money for<br />

each individual prescription. The question arises as to<br />

how orthopaedic aids can be designed more effectively.<br />

This in turn requires comprehensive information<br />

about important material parameters, but such information<br />

is not readily accessible. This defi cit should be<br />

rectifi ed by a <strong>PFI</strong> research project to compile a comprehensive<br />

database containing information about<br />

the parameters of materials used in orthopaedic footwear.<br />

The nature and structure of insoles and footbeds have<br />

to be individually adapted to the clinical picture presented<br />

by the foot of the patient to be treated. Choice<br />

of the right materials plays a key role here. Knowledge<br />

of the material properties is growing all the more important<br />

since the range of available materials has increased<br />

dramatically in recent years. Recent additions<br />

include, above all, synthetic materials designed specifi -<br />

cally for use in orthopaedic footwear. Which orthopaedic<br />

shoemaker uses what materials for which purpose<br />

nowadays depends almost entirely upon professional<br />

experience. A generally accessible database providing<br />

clear and comparable information about material<br />

properties simply does not exist.<br />

Dearth of Comprehensive<br />

Information about Materials<br />

The only material parameter hitherto generally available<br />

is the Shore hardness. But this parameter says<br />

nothing about the durability of the material, its shock<br />

absorption properties, its damping behaviour, or its resilience.<br />

Sports-medical studies have shown that it is precisely<br />

this kind of information that is important if a medical<br />

aid is to achieve the desired biomechanical effect.<br />

The material properties should also remain unchanged<br />

throughout the entire lifetime of the product. Information<br />

about this aspect has also so far been lacking.<br />

Lack of Information<br />

about Hygienic Properties<br />

And yet another shortcoming should be rectifi ed: Materials<br />

for orthopaedic aids are often selected without<br />

precise knowledge of hygienic aspects. Strictly speaking<br />

this knowledge is absolutely essential in view of<br />

the fact that such products are worn for prolonged<br />

periods and, depending upon the clinical picture, may<br />

also come into contact with infectious wound secretions.<br />

This implies a high risk of colonisation by bacteria<br />

and other microorganisms. On the one hand,<br />