Here - PFI Group

Here - PFI Group

Here - PFI Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

When Does a Shoe Fit?<br />

How is Chromium(VI) Formed<br />

in Leather and Leather Goods?<br />

Mould Resistance<br />

of Leathers and Intermediate Products<br />

Still Just a Dream?<br />

The Eco Shoe<br />

Newsletter<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens

2<br />

Newsletter<br />

Contents<br />

Contents<br />

Contents<br />

................................................................... 02<br />

Editorial ................................................................... 04<br />

News<br />

Radioactive Contamination<br />

of Goods from Asia? .................................................. 05<br />

Point of Shoes Well Received .................................... 06<br />

International Footwear Trade Expert ....................... 08<br />

Kai Tinschert Joins Physics Section ............................. 09<br />

Professor Klaus Mattil Turns 75 ................................. 09<br />

DSF Alumni Reunion in August ................................. 10<br />

Biotechnology<br />

The Eco Shoe – Still Just a Dream? ............................ 12<br />

Pirmasens Energy Park All Set to Go ......................... 16<br />

<strong>PFI</strong> Expands International<br />

Research Activities ...................................................... 18<br />

Research<br />

01.2011<br />

01.2011<br />

When Does a Shoe Fit? .............................................. 20

Chemistry<br />

How is Chromium(VI) Formed<br />

in Leather and Leather Goods? ................................ 24<br />

Microbiology<br />

Mould Resistance of Leathers<br />

and Intermediate Products ....................................... 28<br />

Changes to ASTM E2149 /<br />

Challenge Test Method ............................................. 30<br />

Physics<br />

Shoe Accessory with Core Strength .......................... 36<br />

Masthead<br />

Publisher: <strong>PFI</strong> Test and Research Institute Pirmasens<br />

Prüf- und Forschungsinstitut Pirmasens e. V.<br />

Member of <strong>PFI</strong> <strong>Group</strong><br />

Director of Institute: Dr. Gerhard Nickolaus<br />

Address: Marie-Curie-Straße 19<br />

66953 Pirmasens / Germany<br />

Phone: +49 6331 2490 0<br />

Fax: +49 6331 2490 60<br />

E-Mail: info@pfi-germany.de<br />

Internet: www.pfi-germany.de<br />

Editor: Elisabeth Rouiller<br />

Translation: Tony Rackstraw<br />

Design Concept and Layout:<br />

Konzept fünf - Agentur für Werbung und Design<br />

Internet: www.konzept-fuenf.de<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Pictures:<br />

Fotolia (p. 5),<br />

August Herzog Maschinenfabrik GmbH & Co KG (p. 38),<br />

<strong>PFI</strong>, ISC<br />

Reprint – extracts included – only with authorisation<br />

of the <strong>PFI</strong>.<br />

The online-version of the <strong>PFI</strong>-Newsletter is available<br />

under www.pfi-group.org/newsletter.html<br />

3

4<br />

Editorial<br />

Newsletter<br />

Dear Readers,<br />

The latest issue of the <strong>PFI</strong> Newsletter has now been<br />

published. We trust that it will again provide you<br />

with a wealth of valuable and interesting information<br />

about the research activities and services offered by<br />

<strong>PFI</strong>. Like any other dynamic organisation, <strong>PFI</strong> is in a<br />

state of constant flux; traditional areas of activity are<br />

contracting, new areas are expanding.<br />

EDIToRIAL<br />

Thus our Biotechnology Department is currently moving<br />

ahead under full steam, undoubtedly having received<br />

an additional boost from recent events in Japan.<br />

Alternative approaches to power generation, decentralised<br />

solutions for conservation of fossil resources<br />

and reduction of effective CO emissions, as well as the<br />

2<br />

synthesis of raw materials and plastics from renewable<br />

resources are all much in demand. We have our eye on<br />

the ball. Of course, we cannot claim to be able to solve<br />

the fundamental problems of energy generation, but<br />

we can make an important contribution to the mosaic<br />

of future energy supplies. For our original area of core<br />

competence, the footwear industry, attractive possibilities<br />

resulting from use of biodegradable polymers<br />

produced from renewable resources can open up new<br />

markets.<br />

We greatly appreciate your interest in current developments<br />

and projects undertaken at <strong>PFI</strong>. Do not hesitate<br />

to contact us if you have any questions or suggestions.<br />

Contact details of our department heads will be found<br />

in this publication. And, of course, I am also glad to be<br />

of assistance wherever I can.<br />

Yours Dr. Gerhard Nickolaus<br />

<strong>PFI</strong> <strong>Group</strong>

NEWS<br />

The accident at the Fukushima nuclear power station<br />

in Japan and the subsequent escape of radioactive<br />

nuclides, which have been and still are at the centre<br />

of world-wide attention, are a cause for concern for<br />

companies which manufacture goods in the Far East<br />

or import goods produced in factories located in that<br />

region. After all, those persons who place products on<br />

the market are ultimately responsible for them. The<br />

question arises whether the goods are radioactively<br />

contaminated, and if so to what extent. It is also necessary<br />

to establish whether, and if so which, safety<br />

measures are appropriate, for example whether tests<br />

for radioactive contamination prior to shipment are<br />

advisable.<br />

In the estimation of the German Federal Institute for<br />

Risk Assessment and the Federal Ministry of the Environment,<br />

Nature Conservation, and Reactor Safety,<br />

goods from other Asian countries (such as China or<br />

India) were not subject to any specific threat of radioactive<br />

contamination at the time of going to press.<br />

Hence footwear manufacturers with production facilities<br />

in Asian countries other than Japan need not expect<br />

any such risks and therefore need not adopt any<br />

additional precautionary measures. It is difficult to assess<br />

the situation regarding goods from Japan itself.<br />

Shipping companies and airlines have adopted appropriate<br />

measures and have avoided or continue to<br />

avoid the area.<br />

Goods entering Germany from Japan are subjected<br />

to random testing for radioactivity by the customs<br />

authorities. EU-wide fast-track legislation has been<br />

enacted and direct safety precautions introduced for<br />

foods imported from Japan, which pose a significantly<br />

greater risk of radioactive contamination and an associated<br />

health hazard for the consumer.<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Possible Consequences of the Nuclear Accident at Fukushima<br />

Radioactive Contamination<br />

of Goods from Asia?<br />

A direct threat of radioactive contamination in and for<br />

Germany is ruled out by experts. However, the situation<br />

regarding consumer goods may change at short notice<br />

in view of the dynamic course of developments.<br />

Current information about the situation both in general<br />

and with regard to the consequences, particularly<br />

in Germany, can be found at: http://www.bfr.bund.de<br />

or http://www.bmu.de.<br />

Further information:<br />

Dipl.-Biologin Michaela Würtz<br />

Phone: +49 6331 2490 550,<br />

E-Mail: michaela.wuertz@pfi-germany.de<br />

5

6<br />

Newsletter<br />

The third Point of Shoes – International Fair for Fashion,<br />

Materials and Production (PoS), which took place<br />

at Pirmasens on 19 and 20 April, got off to a resounding<br />

start. Although the event took place during the Easter<br />

holiday period, almost 450 visitors were present on<br />

both days of the show and displayed an avid interest<br />

in the offerings of the 77 exhibitors. “Almost all the<br />

German footwear manufacturers were represented,<br />

meaning that we have attained the important goal of<br />

again attracting the domestic companies en bloc to<br />

Pirmasens”, summarised PoS organiser Uwe Thamm.<br />

Shoe machines were a special feature of this PoS; 15<br />

companies showcased their innovations. This technology<br />

platform will be featured every two years. And<br />

the PoS lecture programme, devoted this time to the<br />

Keynote Topic of sustainability, generated keen interest.<br />

“According to the latest available statistics dating from<br />

2009, the German footwear industry comprises 45 companies<br />

with more than 50 employees – and the registration<br />

data clearly show that the PoS attendees represent<br />

the entire domestic footwear sector”, says Uwe Thamm.<br />

“Companies which for many years have only travelled<br />

to Bologna are now coming back to Pirmasens. And<br />

most importantly: The decision makers are coming.”<br />

NEWS<br />

High Level of Visitor Acceptance, Top-Quality Lectures<br />

Point of Shoes<br />

Well Received<br />

“We were surprised by the quality of the discussions<br />

and were able to establish new contacts”, said<br />

Christopher Thornhill of Molina & Bianchi.<br />

Confirmation comes from the exhibitors: “The delegations<br />

coming to the show are generally made up of just<br />

two or three people, but they are very knowledgeable<br />

experts who are authorised to make decisions. Window<br />

shoppers and gawkers, on the lookout for cookies<br />

and ball-point pens, don’t come here”, according<br />

to Sam Neuer of the Zweibrücken-based company Innovatec.<br />

“We were surprised by the quality of the discussions<br />

and were able to establish new contacts; our<br />

expectations were thus surpassed”, said Christopher<br />

Thornhill of Molina & Bianchi. A hint of reservation<br />

was nevertheless expressed by some of the exhibitors:<br />

“It could all be somewhat more international.”

NEWS<br />

“We shall gladly pursue that point”, was the response<br />

of Uwe Thamm. “Now that we have attained our<br />

first objective, that of bringing the German footwear<br />

manufacturers back to Pirmasens, and now that Italian,<br />

Spanish, Portuguese, Czech, and even Chinese<br />

companies number among the exhibitors at PoS, we<br />

shall initially concentrate on attracting visitors from<br />

neighbouring countries. However, we should not expect<br />

miracles: Attracting international visitors will<br />

take time. But we are working on it.”<br />

The concluding discussion, chaired by Petra Salewski,<br />

Editor-in-Chief of the trade journals Schuhkurier and<br />

Steptechnik, has meanwhile become a traditional<br />

feature of PoS. The conclusion to be drawn from this<br />

discussion, attended mainly by exhibitors, was that no<br />

consensus can be reached in the matter of dates: The<br />

proponents of an earlier date and of a later date split<br />

into two fairly irreconcilable groups. And then there<br />

are additional constraints imposed by space allocation<br />

in the exhibition halls and public holidays. “The next<br />

PoS will take place on 3 and 4 November 2011, as was<br />

decided on the basis of exhibitor and visitor questionnaires<br />

in September 2010. In November we shall know<br />

the key data for 2012 and again strive to find ‘ideal’<br />

dates”, explained Thamm.<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

PoS organiser and ISC Head<br />

Uwe Thamm gave a positive assessment<br />

of the April Point of Shoes<br />

It has already been decided that the November PoS<br />

Fair will close at 2 p.m. on the second day. The second<br />

day of the event is still necessary, even if there are not<br />

so many visitors as on the first day: After all, about one<br />

third of the attendees only came on the second day.<br />

It has also been decided to move the open discussion<br />

session with exhibitors and visitors forward to 5 p.m.<br />

on the first day.<br />

The New Keynote Topic for the November PoS will be<br />

“Ten Years into the Future. Global Scenarios for the<br />

European Footwear Industry 2021”.<br />

“And another matter of great concern to us is the provision<br />

of a WLAN connection in the exhibition halls”,<br />

was Uwe Thamm’s final observation. “We sincerely<br />

hope that the City of Pirmasens can arrange for its installation<br />

between now and the next PoS.”<br />

Contact<br />

Point of Shoes contact partner at ISC is Steffen Korf.<br />

E-Mail: steffen.korf@isc-germany.com<br />

Phone: +49 (0)6331 145334-17<br />

Fax: +49 (0)6331 145334-30<br />

Further information can be found at<br />

www.point-of-shoes.com.<br />

PoS is organised by:<br />

International Shoe Competence Center<br />

Pirmasens gGmbH<br />

Director: Dipl.-Ing. (FH) Uwe Thamm<br />

Marie-Curie-Straße 20<br />

66953 Pirmasens / Germany<br />

Phone: +49 6331 145334-0<br />

E-Mail: info@isc-germany.com<br />

Internet: www.isc-germany.com<br />

7

8<br />

Newsletter<br />

The Chamber of Industry and Commerce (Industrieund<br />

Handelskammer, IHK) and the International<br />

Shoe Competence Center Pirmasens have together<br />

launched a new certification course: Qualification as<br />

“International Footwear Trade Expert” meets a real<br />

demand and can be completed over a period of nine<br />

weekends.<br />

The “International Footwear Trade Expert” course is<br />

designed for employees of footwear manufacturers,<br />

suppliers to the footwear industry, and footwear dealers<br />

without a background in footwear. The participants<br />

acquire the general and footwear-specific know-how<br />

necessary for a job in the international shoe trade.<br />

72 Hours Packed Full of Challenges<br />

The new course can be completed on nine Saturdays<br />

by persons in regular employment and concludes with<br />

a certification exam. The participants will spend six of<br />

the nine Saturdays at ISC Germany, where they can<br />

benefit from the facilities of the ISC “training factory”,<br />

and three at the Chamber of Industry and Commerce<br />

in Pirmasens. The course covers the following topics:<br />

International trade and customs procedures<br />

Logistics<br />

Quality demands placed on footwear<br />

Certificates of origin<br />

Makes, production methods<br />

Footwear terminology and footwear English<br />

Business fundamentals<br />

Complaints management<br />

Hazardous substances<br />

NEWS<br />

New IHK / ISC Certification Course<br />

International<br />

Footwear Trade Expert<br />

Future footwear trade experts will be able to begin<br />

their training at ISC Germany in the course of 2011<br />

“Today’s footwear industry is totally internationalised,<br />

which also means that the procurement chains<br />

are becoming ever longer and more complex”, according<br />

to Uwe Thamm, Head of ISC Germany. “The new<br />

certification course fills a training gap by providing,<br />

in compact and highly practical manner, the specialist<br />

knowledge necessary to confidently cope with all<br />

aspects of procurement.”<br />

The first footwear trade experts can start the course in<br />

the fourth quarter of 2011 and receive their certificate<br />

in the first quarter of 2012. The course will cost approximately<br />

1700 Euro.<br />

Contact:<br />

Dipl.-Ing. Uwe Thamm<br />

International Shoe Competence<br />

Center Germany gGmbH<br />

Marie-Curie-Straße 20<br />

66953 Pirmasens / Germany<br />

Phone: +49 6331 14 53 34 0<br />

E-Mail: info@isc-germany.com´<br />

Internet: www.isc-germany.com

NEWS<br />

Welcome to the Team<br />

Kai Tinschert<br />

Joins Physics Section<br />

Kai Tinschert completed his studies for a Diplom-Ingenieur<br />

degree in textile engineering specialising in<br />

surface engineering at the Pirmasens Campus of the<br />

Kaiserslautern University of Applied Sciences in August<br />

2009. He went on to gain practical experience at<br />

a leading manufacturer of special elastic fabrics for<br />

medical products.<br />

In January 2011 he joined the Physical Materials Testing<br />

and Research team at <strong>PFI</strong>. After first familiarising himself<br />

with all areas of activity and procedures, his main<br />

field of work will be in research and testing of textiles.<br />

Congratulations<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Professor Klaus Mattil Turns 75<br />

A thoroughbred shoemaker, exceptionally gifted engineer<br />

and teacher, ever-helpful colleague, and dyedin-the-wool<br />

native of the Palatinate is how we can<br />

best describe Professor Klaus Mattil. over the 30-year<br />

period from 1969 to 1999 he headed the Technical Department<br />

of <strong>PFI</strong>. on 3 May 2011 he celebrated his 75th<br />

birthday. The entire staff at <strong>PFI</strong> joins together in congratulating<br />

him on this occasion.<br />

This living idea generator Klaus Mattil has instigated<br />

innumerable projects and developments, and he continues<br />

to work with an enormous level of commitment<br />

to this day – far beyond the usual age of retirement.<br />

Particularly impressive is the energy he invested in his<br />

pioneering and trend-setting activities at <strong>PFI</strong>, and subsequently<br />

as <strong>PFI</strong> consultant and professor at Kaiserslautern<br />

University of Applied Sciences, where he continues<br />

to communicate his profound knowledge to students.<br />

“My wish for the footwear world is that Professor Mattil<br />

will long continue to place his knowledge and his energy<br />

in its service”, is how <strong>PFI</strong> Director Dr. Gerhard Nickolaus<br />

expressed his sentiments. “Congratulations, Professor<br />

Mattil, and long may you carry on the good work!”<br />

9

10<br />

Newsletter<br />

German College of Footwear Design and Technology<br />

DSF Alumni Reunion<br />

in August<br />

Just over two years ago, students and members of the<br />

teaching staff of the German College of Footwear Design<br />

and Technology (Deutsche Schuhfachschule, DSF)<br />

undertook a study trip to Portugal to visit a number of<br />

footwear factories. The trip was, of course, interesting<br />

and informative. However, among the highlights<br />

of the excursion, top place went to the discussions<br />

held with DSF alumni who now live and work in Portugal.<br />

In fact, these meetings were so interesting that<br />

the wish arose to pursue exchange of information<br />

and experience with other DSF alumni, wherever they<br />

might be in the world. Thus the idea of organising an<br />

inter-year reunion for DSF graduates was born.<br />

open-ended clicking presses<br />

at the Footwear College<br />

in the mid-1950s<br />

NEWS<br />

A date has now been set for this meeting: Alumni of all<br />

entry years of the German College of Footwear Design<br />

and Technology as well as friends and sponsors of the<br />

college are cordially invited to the grand reunion starting<br />

at 5 p.m. on 20 August 2011. The meeting points<br />

are located on the premises of the German College of<br />

Footwear Design and Technology at the International<br />

Shoe Competence Center (ISC Germany, Marie-Curie-<br />

Str. 20, 66953 Pirmasens) and at the Pirmasens Festival<br />

Hall from 7 p.m. onwards.<br />

The new premises of the Footwear College at ISC can<br />

be viewed during a champagne reception starting at<br />

5 p.m. A photo exhibition will tell the history of the<br />

Footwear College from its foundation in 1927 right<br />

up to the present day. The pictures illustrate everyday<br />

aspects and highlights in the life of the Footwear College<br />

and also track changes in the facilities and equipment<br />

at the school in the course of time. Of course,<br />

class photos of all the graduation years are an absolutely<br />

essential component of any such exhibition. Numerous<br />

exhibits will also relate individual stories from<br />

the long history of our College. All participants will<br />

receive a brochure showing highlights of this exhibition.<br />

Anybody who has additional photos or materials<br />

is kindly asked to make these documents available for<br />

20 August.

The response of alumni has been so overwhelming<br />

that the main celebration originally planned to take<br />

place on the premises of ISC had to be relocated to the<br />

Pirmasens Festival Hall. Graduates are eagerly anticipating<br />

this evening and meeting and conversing with<br />

former students and teachers. In order to facilitate<br />

planning of the event, all interested persons should<br />

register as soon as possible and inform the Footwear<br />

College of their contact details by e-mail or letter. A<br />

registration form can be found at www.bbspirmasens.<br />

de. Further information will be distributed prior to the<br />

meeting on 20 August. And do not forget to inform all<br />

alumni with whom you have kept in touch!<br />

Contact<br />

Deutsche Schuhfachschule<br />

at BBS Pirmasens<br />

Adlerstraße 31<br />

66955 Pirmasens / Germany<br />

Phone: +49 (0)6331-24010<br />

Fax: +49 (0)6331-240120<br />

Internet: www.bbspirmasens.de<br />

E-Mail: schuhfachschule@freenet.de<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Modern clicking presses and cutting tables<br />

in the well-equipped machine shop of ISC,<br />

the new home of the German College of<br />

Footwear Design and Technology<br />

11

12<br />

Newsletter BIoTECHNoLoGY<br />

Joint Project of <strong>PFI</strong> and Kaiserslautern University of Applied Sciences<br />

The Eco Shoe – Still<br />

Just a Dream?<br />

Just imagine there were such a thing, a 100 percent<br />

eco shoe … no recycling problems, great consumer<br />

acceptance, tomorrow’s ultimate product. Today’s<br />

reality looks very different: up to the present shoes<br />

remain a disposal nightmare. The situation is untenable<br />

and that is why <strong>PFI</strong>’s Biotechnology Department<br />

and Kaiserslautern University of Applied Sciences are<br />

planning a joint project with the principal goal of developing<br />

a shoe that can be bio-recycled.<br />

Two facts are indisputable: Consumer demand for ecofriendly<br />

products is steadily increasing and regulatory<br />

demands are becoming ever more stringent. For this<br />

reason <strong>PFI</strong> has set up a research project bearing the<br />

name “Development of Shoe Production Based on Renewable<br />

and Fermentable Materials”. The declared<br />

aim is 100 % bio-recycling of footwear at the end of<br />

its product life cycle together with all waste from the<br />

production process, with complete utilisation of all the<br />

material and energetic resources present in the materials.<br />

Another aim of the project is to promote sales of<br />

ecologically valuable footwear in Germany and thus<br />

to open up a new market for SMEs belonging to the<br />

footwear industry and its suppliers.<br />

Greater Environmental<br />

Consciousness<br />

More and more enquiries about eco-friendly products<br />

are reaching footwear manufacturers and <strong>PFI</strong>; a sure<br />

indication that the ecological awareness of consumers<br />

is on the increase. Topics such as sustainable material<br />

and product development, energy efficiency,<br />

and conservation of resources are of interest to everincreasing<br />

numbers of consumers or to that steadily<br />

growing group of person who consciously strive<br />

to pursue an eco-friendly lifestyle. Whether or not a<br />

product has been sustainably developed and produced<br />

clearly influences purchasing decisions made by these<br />

consumers. At the same time, manufacturing industry<br />

has understood – not least because of increasing material<br />

and energy prices – that sustainable operation<br />

and effective, and where possible waste-free, utilisation<br />

of resources are worthwhile. While earth-muffiny<br />

niche products have long been available, the footwear<br />

industry has now begun large scale use of materials<br />

which fulfil two principal purposes: On the one hand,<br />

they yield products of excellent ecological value manufactured<br />

by sustainable production processes wherever<br />

possible; on the other, they permit recycling of as<br />

many as possible of the raw materials and components<br />

used in production which are still present at the end<br />

of the product life cycle. In a parallel development, increasingly<br />

stringent regulations are compelling companies<br />

to recycle ever greater proportions of their<br />

waste and to design their products in compliance with<br />

ecological standards.

THE ECo SHoE - STILL JUST A DREAM?<br />

Footwear Problems:<br />

Material Diversity and Composites<br />

The footwear industry faces the particularly challenging<br />

task of offering ecologically valuable products in<br />

combination with efficient utilisation of resources, because<br />

a shoe represents a combination of widely differing<br />

materials. Furthermore, only limited use is presently<br />

made of ecologically valuable materials.<br />

An automated separation unit for all materials would<br />

give rise to certain ecological burdens. It would also<br />

significantly increase disposal costs. Unlike in the electrical<br />

and electronics industry, for example, which<br />

processes noble metals whose recycling is definitely<br />

worthwhile, footwear does not contain any high-price<br />

materials. It is therefore questionable whether such<br />

a sorting unit would be really worthwhile. If such a<br />

separation unit for shoes were to operate profitably,<br />

it could only do so by processing comparatively large<br />

amounts of waste. That would create disposal problems,<br />

above all for SMEs. In addition, only thermoplastics<br />

and metals would be to some degree recyclable,<br />

all the other waste could only be utilised thermally. It<br />

would also be necessary to demonstrate that the energy<br />

generated exceeds the amount of energy invested<br />

in the separation process.<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Project partner of <strong>PFI</strong> is the Western Palatinate Institute<br />

of Plastics Engineering on the Pirmasens Campus<br />

of Kaiserslautern University of Applied Sciences<br />

Conventional approaches to the recycling of industrial<br />

wastes from footwear production are based either on<br />

the principle of reutilising certain classes of substances,<br />

which can be admixed to a certain extent with new<br />

material, or on the principle of thermal utilisation.<br />

However, the (largely fossil) material resources would<br />

be lost on combustion. At the same time, residues<br />

proving difficult to dispose of, such as slag or spent<br />

combustion plant filters, would also arise.<br />

13

14<br />

Newsletter<br />

Joint Project of <strong>PFI</strong> and Kaiserslautern University of Applied Sciences<br />

The Eco Shoe – Still<br />

Just a Dream?<br />

New hydrothermal and enzymatic digestion plant<br />

in the <strong>PFI</strong> engineering lab<br />

BIoTECHNoLoGY<br />

New Materials<br />

and Recycling Methods<br />

The joint project of <strong>PFI</strong> Biotechnology Department and<br />

Kaiserslautern University of Applied Sciences envisages<br />

that development and selection of special materials<br />

(cellulose, starch blends, as well as other biopolymers)<br />

and processing methods will enable all the materials<br />

used in footwear together with the waste generated<br />

during production first to be comminuted and<br />

then merged together. Hydrothermal and enzymatic<br />

digestion cleave the substances into smaller building<br />

blocks and the resulting monomers or oligomers can<br />

be transformed by microorganisms into new starting<br />

materials such as biopolymers in a fermentation process.<br />

Any remaining components that cannot be put to<br />

material use are converted into biomethane (methane<br />

produced from biomass). The objective is optimum<br />

utilisation of all the energy and material resources<br />

present in the footwear materials. Headed by Professor<br />

Dr.-Ing. Jens Schuster, the Western Palatinate Institute<br />

of Plastics Engineering (Institut für Kunststofftechnik<br />

Westpfalz, IKW) on the Pirmasens Campus of Kaiserslautern<br />

University of Applied Sciences serves as second<br />

research establishment for the polymeric components<br />

of footwear. In the course of the project it is intended<br />

to develop an outsole material which has the rubberyelastic<br />

properties of a conventional sole material while<br />

also fulfilling all biodegradability criteria.

THE ECo SHoE - STILL JUST A DREAM?<br />

Material Database<br />

Depending upon their field of use in footwear, the<br />

newly developed materials are tested for their suitability<br />

for footwear manufacture in the Physical Materials<br />

Testing Department of <strong>PFI</strong>. The neighbouring<br />

ISC subsequently produces sample shoes in close cooperation<br />

with shoe manufacturers and suppliers to the<br />

footwear industry. The data collected in the course of<br />

the research project, concerning, for example, the fermentability<br />

or the mechanical properties of the biodegradable<br />

materials, are to be compiled in a database<br />

and subsequently published. This information provides<br />

footwear manufacturers with an opportunity to<br />

increasingly attune their products to ecological needs<br />

and future regulatory requirements. The knowledge<br />

gained, together with the database for all materials<br />

used in footwear production, should open the door<br />

to ecologically appropriate footwear production by<br />

making components such as linings, upper materials,<br />

or adhesives biodegradable. The results of outsole development<br />

illustrate the huge development potential<br />

of biodegradable elastic polymers. They also provide<br />

a basis for further projects focussing on the development<br />

of ecologically valuable hard-wearing footwear.<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

<strong>PFI</strong> Combines Footwear Competence<br />

with Biotechnology<br />

With this project <strong>PFI</strong> intends to establish a link between<br />

the original core competence of the organisation, i.e.<br />

footwear engineering, and the relatively young <strong>PFI</strong><br />

Biotechnology Department, gain further experience<br />

in the area of biopolymers, and demonstrate practical<br />

applications of developments ensuing from the on-going<br />

project concerning production of PHB undertaken<br />

together with the Johannes Gutenberg University at<br />

Mainz (Report: Newsletter 1.2010 – pp. 7 et seqq.).<br />

The research project has already received a favourable<br />

response. A 2011 project starting date is envisaged.<br />

Further information:<br />

Dipl.-Ing. (FH) Christian Schadewell<br />

Phone: +49 6331 2490 - 843<br />

E-Mail: christian.schadewell@pfi-germany.de<br />

15

16<br />

Newsletter<br />

Pirmasens Energy Park All Set to Go<br />

Purchase of a site in the Winzeln industrial zone of Pirmasens<br />

by <strong>PFI</strong> has set the scene for practice-oriented<br />

international research into material and energetic utilisation<br />

of biomass.<br />

The Biotechnology Department came into existence<br />

when <strong>PFI</strong> moved to the Husterhöhe area of Pirmasens<br />

in 2003. From the very beginning, research focussed<br />

on the fast and efficient digestion of biomass. And<br />

work was by no means limited to production of biogas<br />

as an energy source; the goal was also to produce<br />

high-value fermentation products with the aid of biotechnological<br />

processes. Thus the production of xylose<br />

from straw and its microbiological transformation into<br />

xylitol was initially optimised. Other target products<br />

followed, such as lactic acid and polyhydroxybutyric<br />

acid (PHB) which can be used for biopolymer production.<br />

In the course of time it became apparent that<br />

economic production of energy and raw materials<br />

from biomass is possible only if the necessary production<br />

processes performed in decentralised facilities are<br />

properly matched to one another, thus resulting in<br />

synergy effects. It is also necessary to intensify the use<br />

of lignocellulose-containing residual biomass such as<br />

straw as co-substrate in order to conserve agricultural<br />

land for food production.<br />

BIoTECHNoLoGY<br />

<strong>PFI</strong> Invests in Pilot Plant<br />

for Biomass Fermentation<br />

The scientific and technical basis for practical implementation<br />

of the idea has been established in various<br />

individual projects. Thus thermal pressure hydrolysis<br />

for activated sludge was tested on an industrial scale<br />

at the Blümelstal sewage plant in Pirmasens and was<br />

found to increase biogas production by up to 25 percent.<br />

“Process-controlled enzymatic hydrolysis” (PEH)<br />

is used to accelerate the degradation of cellulose in an<br />

agricultural biogas plant at Wallhalben near Pirmasens<br />

in order to double the throughput of the plant without<br />

detrimental effects on the process biology. Other<br />

experimental units for straw digestion were also tested<br />

in the <strong>PFI</strong> engineering laboratory. In spite of the success<br />

of individual projects, it has so far proved impossible<br />

to integrate all the technical developments accomplished<br />

by the Biotechnology Department into a single<br />

practically functioning plant in order to scrutinise the<br />

expected synergy effects. Such scrutiny should become<br />

possible and a basis created for further research<br />

projects and technical developments on construction<br />

of a demonstration plant.<br />

The projected fermentation plant is intended to process<br />

5,000 t of sugar beet, 3,000 t of maize silage, 1,000<br />

t of straw, and 500 t each of whole-crop cereal silage<br />

(WCCS) and grass silage per year. Annual production<br />

of 100 t of xylitol and 400 t PHB is the set goal. In addition,<br />

the plant will generate 500 kW of electrical energy<br />

to be fed into the grid and 500 kW of thermal<br />

energy for the provision of process heat. This corresponds<br />

to an efficiency of over 80 percent in terms of<br />

the biomass consumed. On average only about 40 to<br />

60 percent of the biomass used is currently converted<br />

into electrical and thermal energy.

<strong>PFI</strong> INVESTS IN PILoT PLANT<br />

The following plant components newly developed by<br />

<strong>PFI</strong> and its partner organisations will be installed to<br />

implement the innovative concept:<br />

Lagoons holding liquid sugar beet silage for<br />

automatic charging of the fermenters<br />

Digestion unit for hydrothermal degradation<br />

of lignocelluloses<br />

PEH reactor for mixing and liquefying the richly<br />

structured biomass and acceleration of cellulose<br />

degradation<br />

Fixed-bed fermenter for lactic acid production<br />

and acceleration of the biogas process<br />

Evaporation unit for concentration of the hydro-<br />

lysis and fermentation digestates<br />

Cogeneration unit for energetic utilisation of<br />

hydrogen-rich biogas<br />

High-temperature heat pump for generation<br />

of process heat for the evaporation process<br />

Digestate processing plant for fixation of<br />

ammoniacal nitrogen in the fermentation residue<br />

A central building at the demonstration plant is to<br />

house a training room and a control centre from which<br />

the various processes can be controlled and optimised<br />

under the supervision of engineers and scientists.<br />

Practical information and training sessions can also be<br />

offered. The premises will also accommodate members<br />

of various international research establishments<br />

working as teams on multi-year research projects. In<br />

particular, close scientific collaboration in the area of<br />

biomass utilisation is planned between Rhineland-<br />

Palatinate and Lorraine. Being so close to France, the<br />

projected demonstration plant should also help intensify<br />

collaboration between farmers and companies<br />

from the two regions. Supporting roles are envisaged<br />

for agricultural associations and the chambers of industry<br />

and commerce. Pro-rata funding for the projected<br />

demonstration plant is expected from the Life+<br />

Programme of the European Union. Applications for<br />

funding of cross-border cooperation between Rhineland-Palatinate<br />

and Lorraine are to be submitted via<br />

the Interreg IV programme.<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Now that the plot has been purchased, <strong>PFI</strong> can proceed<br />

with permit planning. This will be undertaken in close<br />

consultation with the City of Pirmasens and Bioenergie<br />

Pirmasens, a subsidiary of the Pirmasens municipal<br />

utility company. In total, three plants are planned for<br />

the Pirmasens Energy Park: a steam gasification unit<br />

for wood, a methanisation plant for biogenic municipal<br />

waste, and the above fermentation plant for agricultural<br />

biomass. Construction of the last-mentioned<br />

demonstration plant is scheduled to begin in mid-<br />

2012.<br />

Silo for maize<br />

and grass silage<br />

Straw storage<br />

Fermentation technology<br />

and product preparation<br />

Storage tank<br />

Straw digestion<br />

plant<br />

Projected <strong>PFI</strong> demonstration plant at the<br />

Pirmasens-Winzeln energy park<br />

Further information:<br />

Dipl.-Ing. (FH) Benjamin Pacan<br />

Phone: +49 6331 2490 - 840<br />

E-Mail: benjamin.pacan@pfi-biotechnology.de<br />

Control center and<br />

training room<br />

PEH reactor<br />

CHP container<br />

Lagoon for liquid<br />

sugar beet silage<br />

Methane<br />

digester<br />

Fixed-bed<br />

fermenter<br />

17

18<br />

Newsletter<br />

In past years <strong>PFI</strong> has repeatedly initiated EU projects<br />

related to its core competence of footwear engineering.<br />

It is no secret that the level of funding in this area<br />

has meanwhile started to fall owing to the transfer of<br />

footwear production to Asia. The alternative is to acquire<br />

EU funding for <strong>PFI</strong>’s new key research activities<br />

biotechnology and regenerative energies. To achieve<br />

this goal the Engineering and Biotechnology Departments<br />

will be collaborating even more closely.<br />

Owing to the expected participation of more than six<br />

countries and bureaucratic hurdles in the application<br />

phase, many of the funding possibilities set out in the<br />

7th EU Framework Research Programme require a<br />

high commitment of human resources. The low success<br />

rate, which often lies below 15 percent, also poses<br />

a considerable financial risk for the applicant. In order<br />

to minimise expenditure of effort and risks, submission<br />

of applications for transnational projects involving<br />

only two to three European partners was first considered.<br />

In response to the current call for proposals,<br />

a CORNET project on the topic «Upgrading of Waste<br />

Heat to Process Heat for Different Industries» (for<br />

short «From Waste Heat to Process Heat») was submitted<br />

by <strong>PFI</strong> together with Papiertechnische Stiftung of<br />

Munich (coordinator), University College of West Flanders,<br />

Ghent University, Université de Liège, and the<br />

Flemish User <strong>Group</strong>.<br />

BIoTECHNoLoGY<br />

New EU Project Proposals Submitted<br />

<strong>PFI</strong> Expands International<br />

Research Activities<br />

CORNET stands for Collective Research Networking, i.e.<br />

networking of national and regional programmes of<br />

community research in Europe. The ERA-NET CORNET<br />

coordinated by the German Federation of Industrial<br />

Research Associations involves participation of 21 ministries<br />

and lead partners from 17 countries and regions<br />

of Europe. The objective is to intensify European coordination<br />

between national and regional programmes<br />

of community research. CORNET organises two rounds<br />

of calls for proposals per year for jointly funded community<br />

research projects.<br />

The high-temperature heat pump to be developed in<br />

this project is an important technical aid for concentration<br />

of sugar solutions by two-stage vacuum evaporators<br />

prior to fermentation. In addition, process water<br />

can also be recovered for straw digestion. Improved<br />

utilisation of waste heat from the cogeneration unit<br />

permits use of more straw as substrate for the fermentation<br />

plant. After determination of the thermal<br />

energy required for the various sub-processes of the<br />

innovative biomass processing plants, the <strong>PFI</strong> Engineering<br />

Department will develop an intelligent control<br />

system for heat management in connection with<br />

the high temperature heat pump. The Biotechnology<br />

Department will undertake practical tests and develop<br />

optimisation proposals. The SMEs participating in the<br />

project (for example, a biogas plant operator) should<br />

be placed in a position to better utilise the waste heat<br />

from cogeneration plants. Furthermore, economic aspects<br />

are to be considered and design parameters determined<br />

for the use of high temperature heat pumps.

NEW EU-PRoJECT PRoPoSALS SUBMITTED<br />

In view of the European Union’s aims of raising the<br />

contribution of renewable energy sources to power<br />

generation to over 20 percent by 2020 and of doubling<br />

the current eight to ten percent market share of<br />

bio-based products by 2020, <strong>PFI</strong> is expecting a significant<br />

increase in research funding in these areas in the<br />

coming years. The nuclear catastrophe at Fukushima<br />

and increasing oil prices will certainly further boost<br />

this trend.<br />

A planned Interreg IV project should serve as an introduction<br />

to transnational collaboration in the increased<br />

use of biomass. <strong>Here</strong> <strong>PFI</strong> wishes to cooperate with the<br />

Lorca Agricultural Cooperative, the Lorraine Farmers’<br />

Association, and the “Ecole Nationale Supérieure<br />

d'Agronomie” as well as SMEs in Rhineland-Palatinate<br />

and Lorraine. The planned project encompasses the<br />

following tasks:<br />

Advice on plant cultivation, harvesting, and<br />

transportation logistics<br />

Cultivation, supply, and preservation of energy crops<br />

Construction, operation, and development of<br />

digestion and fermentation plants<br />

Optimisation of the fertilising action of digestion<br />

residues<br />

Waste Biomass<br />

Digester<br />

Xylitol<br />

as a Sugar Substitute<br />

Biogas<br />

Waste Heat<br />

Residual Biomass<br />

Electrical<br />

Energy<br />

Combined Heat<br />

and Power Plant<br />

Engine Cooling System<br />

High-temperature<br />

Heat Pump<br />

Fermentation<br />

Plant<br />

Biotechnological<br />

Conversion<br />

Projected use of a high-temperature heat pump in a biomass processing plant<br />

Organisation of information events and seminars<br />

Exhaust Heat<br />

Process Heat<br />

Waste Heat<br />

Lignocellulosic<br />

Biomass<br />

TPH<br />

Vacuum<br />

Evaporator<br />

Hydrolyzate Concentrate<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Biopolymers as Polyhydroxyalkanoates<br />

(PHA) from Glucose and organic Acids<br />

The planned transnational research projects should<br />

provide a basis for further European research activities.<br />

In the future, <strong>PFI</strong> plans to submit several project<br />

proposals yearly in the 7th EU Framework Research<br />

Programme. Staff members of various European research<br />

institutions will spend time working at <strong>PFI</strong> in<br />

order to establish an appropriate network. A European<br />

research and development manager will be appointed<br />

at <strong>PFI</strong> to coordinate these activities. Small and<br />

medium-sized enterprises are invited to participate.<br />

<strong>PFI</strong> will be glad to help with preparation of the necessary<br />

project documentation.<br />

Further information:<br />

Dipl.-Ing. (FH) Benjamin Pacan<br />

Phone: +49 6331 2490 - 840<br />

E-Mail: benjamin.pacan@pfi-biotechnology.de<br />

19

20<br />

Newsletter<br />

Innovative Method for Fitting Shoes<br />

When Does a Shoe Fit?<br />

Fortunately, proper fit has returned to the focus of attention<br />

of footwear manufacturers, retailers, and customers.<br />

This interest was rekindled by the results of a<br />

Germany-wide foot measuring campaign undertaken<br />

in an AiF research project (the results are to be found<br />

in a German-language publication entitled “The Foot<br />

Report” which can be ordered from the address given<br />

at the end of this article). AiF is the German Association<br />

of Industrial Research organisations. This study<br />

showed that properly fitting shoes are hard to find<br />

by conventional methods of shoe selection. A further<br />

AiF research project was therefore launched in order<br />

to develop an innovative and economically practicable<br />

shoe selection method permitting choice of better<br />

fitting shoes.<br />

Cumulative frequency in %<br />

Fig. 1:<br />

Level of provision<br />

of different widths<br />

for women<br />

Availability<br />

of a width<br />

19%<br />

4 Widths<br />

6 Widths<br />

8 Widths<br />

Women<br />

Width according to FAGUS 52<br />

(Frequency of widths in all sizes)<br />

RESEARCH<br />

The foot is a part of the body and by its very nature<br />

three dimensional. Hitherto, however, selection of<br />

shoes has been based almost exclusively on shoe size,<br />

a one-dimensional measure of foot length. The width,<br />

i.e. a measure of ball girth, is given for only few shoes.<br />

In addition, no uniform set of tables exists for determining<br />

the width; instead, there are many tables<br />

which also differ from one another – albeit only slightly<br />

in most cases. Most people are unaware of their foot<br />

width. Of course, customers generally know whether<br />

they have wide or very narrow feet, if only because<br />

they have serious problems in finding properly fitting<br />

shoes.<br />

In order to supply 90 percent of the population with<br />

properly fitting shoes, each shoe size would have to<br />

be available in eight widths. But the costs would be<br />

prohibitive. If every shoe size were available in four<br />

widths, then 60 percent of customers could be properly<br />

provided for (Fig. 1). Yet even then, there would<br />

still be a substantial risk that shoes would not fit. Additional<br />

foot measurements should be introduced to<br />

facilitate correct choice, but that would drive up costs<br />

out of all proportion.<br />

Anatomical<br />

ball circumference<br />

260<br />

250<br />

240<br />

230<br />

220<br />

210<br />

200<br />

190<br />

Anatomical ball circumference<br />

Women (age dependent)<br />

15-20 21-30 31-40<br />

Age group (years)<br />

51-50 51-60 61-70<br />

- Sigma Mean value + Sigma<br />

Fig. 2: Variation of the anatomical ball girths<br />

of women

WHEN DoES A SHoE FIT?<br />

Search for Correlations<br />

Investigations for the new project were undertaken<br />

on the basis of the foot measurements recorded during<br />

the foot measuring campaign. To this end, the foot<br />

measurements were analysed and any correlations<br />

were sought which could be of value for improved<br />

shoe selection. Apart from circumference measurements,<br />

width and height also appeared to be of interest.<br />

However, these investigations did not lead to any<br />

useful solution because the measurements showed a<br />

huge range of variation but no unequivocal correlations.<br />

The anatomical ball girth, measured over the big<br />

toe and little toes joints, is mentioned as example: The<br />

mean value for women was 231.3 mm, but the variation<br />

was large for all age groups (see Fig. 2).<br />

In summary, it was concluded that all combinations<br />

of measurements can occur in feet. No foot types can<br />

be deduced from the measurements. This finding was<br />

considered unsatisfactory, especially since different<br />

foot shapes became apparent on evaluation of the<br />

measurements, as can be seen in Fig. 3.<br />

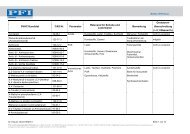

Table 1: Foot types<br />

Variant Limit of<br />

heel-instep<br />

width<br />

difference<br />

in mm<br />

Limit of<br />

instep-ball<br />

widht<br />

difference<br />

in mm<br />

Percentage<br />

of foottype<br />

A1<br />

Percentage<br />

of foottype<br />

A2<br />

Percentage<br />

of foottype<br />

B1<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

Defining Different Foot Shapes<br />

A different approach to examination of the<br />

foot measurements was therefore adopted.<br />

The question posed was: What makes the<br />

difference between the individual foot<br />

shapes? The answer lies in the differences<br />

between the width measurements. These<br />

obvious differences were therefore studied.<br />

The measurements used were the maximum<br />

heel width at 20 percent of the foot length,<br />

the instep width at 50 percent of the foot<br />

length, and projected maximum ball width<br />

(Fig. 4).<br />

The difference between the individual measurements<br />

was calculated and the feet assigned to certain foot<br />

types (see Table 1). Foot types A1, A2, B1, were B2 defined.<br />

The letter of the alphabet describes the backfoot<br />

and the numeral the forefoot. Among the female test<br />

persons, a difference between heel width and instep<br />

width smaller than or equal to 17 mm classified the foot<br />

as type A. If the difference was greater than 17 mm, the<br />

foot corresponded to type B. At a difference between<br />

the projected ball width and the instep width less than<br />

or equal to 11 mm, the foot was of type 1; at a difference<br />

greater than 11 mm the foot was of type 2.<br />

Percentage<br />

of foottype<br />

16_9 16 9 5% 31% 20% 44%<br />

16_11 16 11 10% 25% 35% 30%<br />

16_12 16 12 14% 21% 42% 23%<br />

16_13 16 13 18% 17% 49% 16%<br />

14_11 14 11 5% 15% 40% 40%<br />

15_11 15 11 7% 20% 38% 36%<br />

16_11 16 11 10% 25% 35% 30%<br />

17_11 17 11 14% 31% 31% 25%<br />

18_11 18 11 19% 36% 26% 19%<br />

B2<br />

Fig. 3: Various foot shapes<br />

21

22<br />

Newsletter<br />

Innovative Method for Fitting Shoes<br />

This assignment procedure is illustrated by a number<br />

of examples:<br />

For a given foot the maximum heel width was 61 mm,<br />

the maximum instep width 77 mm, and the projected<br />

ball width 86 mm. The difference between the instep<br />

width and the heel width is then 77 – 61 = 16 mm, i.e. the<br />

difference is smaller than 17 mm; the<br />

backfoot is of type A.<br />

The difference between the projected<br />

ball width and the instep width<br />

is 86 – 77 = 9 mm, i.e. the difference<br />

is smaller than 11; the forefoot is of<br />

type 1. The complete foot was classified<br />

as type A1 (example in Fig. 4).<br />

In the case of another foot the<br />

maximum heel width was 64 mm,<br />

the maximum instep width 88 mm,<br />

and the projected ball width 104<br />

mm. The difference between the<br />

instep width and the heel width is<br />

then 88 – 64 = 24 mm, i.e. the difference<br />

is greater than 17 mm; the<br />

backfoot is of type B (see Fig. 5).<br />

The difference between the projected ball width and<br />

the instep width is 104 – 88 = 16 mm, i.e. the difference<br />

is greater than 11; the forefoot is of type 2. The<br />

complete foot was classified as type B2 (see Fig. 6).<br />

These different foot types cannot be obtained by conventional<br />

grading because the heel would be scaled<br />

up or down in proportion to the ball measurement.<br />

RESEARCH<br />

When Does a Shoe Fit?<br />

Fig. 4:<br />

Test person of<br />

foot type A1<br />

Fig. 5:<br />

Test person of<br />

foot type B2<br />

Last Development<br />

The foot measurements for all shoes sizes were subsequently<br />

sorted according to these foot types and the<br />

distribution of the various other foot measurements<br />

examined in order to be able to assign further measurements<br />

to these types. On the basis of these results<br />

the measurements were determined for lasts for closed<br />

street shoes with a flat toe spring. For sample size 37<br />

a heel width of 58 mm was assigned to the sole of the<br />

type A last, and one of 55 mm in the case of the type<br />

B last. A medium width, width number 5, corresponding<br />

to a girth of 215 mm was selected for the type A1<br />

foot, width number 6 (220 mm girth) for types A2 and<br />

B1, and width number 7 (225 mm girth) for type B2.<br />

Comparison of the types showed that types A2 and B1<br />

differed only in the heel width. For the tests a further<br />

last was produced as a combination of these two. Accordingly,<br />

type A2B1 differs only in the heel width of<br />

the last sole, which is 57 mm. The instep height was<br />

the same for all types at 65 mm.<br />

The same was done for court shoe lasts, for which<br />

somewhat different, narrower values were selected<br />

for the heel width. Type A had a heel width of 54 mm<br />

and type B a width of 50 mm. The court shoes had a<br />

heel pitch of 60 mm. No A2B1 combination last was<br />

made in this case because the more stringent fitting<br />

demands on this kind of shoe allow no room for compromises.<br />

Fig. 6: Test person with shoe type B2

WHEN DoES A SHoE FIT?<br />

Wearing Tests<br />

The lasts were used to make shoes for wearing tests.<br />

The feet of the test persons were measured and assigned<br />

to the corresponding foot type. All the shoes<br />

were tried on for evaluation, or, in the case of a readily<br />

recognisable foot type, the appropriate shoe was immediately<br />

selected. Evaluation was undertaken both<br />

by the test person and by the person carrying out the<br />

tests.<br />

The wearing tests showed that, in addition to the<br />

width, the fit of the heel is very important. Shoes of<br />

type B fitted test persons with a slender heel more<br />

comfortably than those of type A. In contrast, test persons<br />

with a wide heel felt better in shoes of type A.<br />

However, the test persons included a number of people<br />

for whom the available widths did not come into<br />

question because their feet required an even narrower<br />

width. Combination of the results of this project and<br />

greater gradation steps (see final report of AiF Research<br />

Project 14993) can assure a significantly better<br />

supply of correctly fitting shoes.<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

The detailed results can be found in <strong>PFI</strong>’s final report<br />

on AiF Project 15857. The research project was funded<br />

by the Federal German Ministry of Economics and<br />

Technology via the German Association of Industrial<br />

Research Organisations (AiF) in accordance with a resolution<br />

adopted by the German Parliament.<br />

Contact:<br />

Dr. Monika Richter<br />

<strong>PFI</strong> Pirmasens e.V.<br />

Phone: +49 6331 - 249027<br />

E-Mail: monika.richter@pfi-germany.de<br />

23

24<br />

Newsletter<br />

Joint <strong>PFI</strong> and LGR Research Project<br />

The pronounced toxicity of chromium(VI) and the introduction<br />

of a limit value for chromium(VI) in leather<br />

articles of daily use have made elucidation of the<br />

mechanisms of chromium(VI) formation in leather a<br />

matter of prime concern. In a joint research project,<br />

the Test and Research Institute Pirmasens (Prüf- und<br />

Forschungsinstitut Pirmasens, <strong>PFI</strong>) and the Tanning<br />

School Leather Institute Reutlingen (Lederinstitut<br />

Gerberschule Reutlingen, LGR) have investigated<br />

how total chromium, soluble total chromium, and the<br />

substances naturally present in hides are interrelated<br />

with chromium(VI) formation in leather und leather<br />

goods.<br />

CHEMISTRY<br />

How is Chromium(VI) Formed<br />

in Leather and Leather Goods?<br />

Tests for contaminants in footwear and leather goods<br />

repeatedly reveal the presence of highly hazardous<br />

chromium(VI). In a recent laboratory study on<br />

60 shoes of various kinds, some of which contained<br />

several different kinds of leather, six were found to<br />

contain high levels of chromium(VI). Among the other<br />

54 shoes without conspicuous initial chromium(VI) values,<br />

chromium(VI) could be detected in 11 after they<br />

had been subjected to an ageing process in which the<br />

leathers were incubated for 24 hours at 80 °C. The<br />

German Federal Institute for Risk Assessment had<br />

long recommended a ban on leather goods with a<br />

chromium(VI) content exceeding 3 mg/kg. The eighteenth<br />

amendment to the German Consumer Goods<br />

Ordinance of 3 August 2010 therefore includes a provision<br />

for chromium(VI). Consumer goods exceeding<br />

the chromium(VI) limit value may no longer be placed<br />

on the market and must be removed from the market.<br />

This can mean serious economic damage for manufacturers<br />

and the trade.<br />

Chromium as Tanning Agent<br />

Tanning with chromium(III) salts is the principal<br />

method of leather tanning. Chrome-tanned leather<br />

is characteristically strong and supple. Its properties<br />

make it suitable for use in numerous products: for<br />

footwear and apparel, and also for furniture and<br />

car interiors.<br />

What is the Function<br />

of Chromium in Tanning?<br />

Leather is a product derived from animal hides preserved<br />

by tanning. During the tanning process the<br />

tanning agent chromium binds to the collagen in the

JoINT <strong>PFI</strong> AND LGR RESEARCH PRoJECT<br />

The Project and Its objectives<br />

The complete title of the research project is “Studies to<br />

Determine the Relations between Soluble Total Chromium<br />

as well as Hide Constituents and Chromium(VI)<br />

Formation in Leather and Leather Goods”. It was funded<br />

as IGF Project No. 15845 N of the Leather Research<br />

Association (Forschungsvereinigung Leder, FGL) by<br />

the German Federal Ministry of Economics and Technology<br />

through the German Federation of Industrial<br />

Research Associations (AiF) within the IGF programme<br />

for promoting industrial cooperative research and development.<br />

The objective of the joint research project undertaken<br />

by <strong>PFI</strong> and the Tanning School Leather Institute was to<br />

elucidate the interrelations between total chromium<br />

content, soluble total chromium content, the hide<br />

constituents, and the formation of chromium(VI) and<br />

to understand the mechanisms involved.<br />

hides. The leather thus does not shrink; it remains<br />

supple and retains its strength. The chromium(III)<br />

salts used in chrome tanning are only very slightly<br />

toxic since they are only poorly absorbed by the body.<br />

Chromium(III) can cause local skin irritation in sensitive<br />

persons. Extremely hazardous chromium(VI)<br />

can be formed from chromium(III) in reactions favoured<br />

by oxidation processes and alkaline pH<br />

values. According to our current state of knowledge,<br />

chromium(VI), in contrast to chromium(III),<br />

can penetrate the cell membrane. Chromium(VI)<br />

is highly toxic, allergenic, and carcinogenic.<br />

Procedure<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

In order to undertake the project, various upper and<br />

lining leathers were first produced: leathers with high<br />

and with low chrome tanning agent contents; with and<br />

without fixation; with various fatting agents; leathers<br />

of high layer thickness; and leathers with a high<br />

chromium(VI) content. Total chromium, total soluble<br />

chromium, and chromium(VI) were measured. What<br />

information is provided by these measured values?<br />

Total chromium refers to the total amount of chromium<br />

present in a leather. Its determination requires<br />

destruction of the leather by action of acid.<br />

Total soluble chromium designates that chromium<br />

fraction of a leather which can be dissolved out of<br />

the leather by the action of aqueous salt solutions resembling<br />

human perspiration without destroying the<br />

leather. This simulates the possible chromium exposure<br />

of a person that can result on wearing of leather<br />

products.<br />

Chromium(VI) is also dissolved out of leather by the<br />

action of aqueous salt solutions. The difference is that<br />

only chromium in the +6 oxidation state is determined<br />

in this case. The principal question is whether the three<br />

measured values are correlated, and if so, how? Laboratory<br />

tests for chromium(VI) are generally performed<br />

prior to or at the beginning of footwear production. It<br />

was therefore important to include the effects of storage,<br />

heat, light, and adhesives in the investigations.<br />

Chrome III<br />

oxidation<br />

Reduction<br />

Simplified representation of transformation<br />

of chromium(III) into chromium(VI)<br />

Chrome VI<br />

25

26<br />

Newsletter<br />

Joint <strong>PFI</strong> and LGR Research Project<br />

Results for Different Leathers<br />

Fatting and Amount of Chrome Tanning<br />

Agent Used<br />

The choice of fatting agent was crucial for chromium(VI)<br />

formation during leather production. In contrast, the<br />

animal hide constituents present in leather have no<br />

influence on the chromium(VI) values. Use of greater<br />

quantities of chrome tanning agent led to high contents<br />

of total chromium and soluble total chromium in<br />

leather. The amount of soluble total chromium could<br />

be reduced by fixation of the leather with dicarboxylic<br />

acids. No correlation could be seen between high total<br />

chromium contents or high soluble total chromium<br />

contents and the chromium(VI) content of the leathers.<br />

Ageing and UV Irradiation<br />

A considerable influence on chromium(VI) formation<br />

in leathers could be ascribed to ageing and UV irradiation.<br />

This is also apparent from studies on the different<br />

layers of leather. To this end, the leathers were split<br />

into four layers. The chromium(VI) contents proved to<br />

be higher in the outer layers directly exposed to the<br />

environment than in the inner layers.<br />

CHEMISTRY<br />

How is Chromium(VI) Formed<br />

in Leather and Leather Goods?<br />

Adhesives and Heat<br />

Furthermore, the effect of three different adhesives<br />

on chromium(VI) formation was also examined. Thus<br />

the leathers were treated with a natural latex adhesive,<br />

a synthetic latex adhesive, and a PU dispersion<br />

adhesive. The leathers were additionally subjected to<br />

heating to simulate the footwear production process.<br />

Application of adhesive led to significantly higher<br />

chromium(VI) contents in some of the tested lining<br />

leathers, whereas upper leathers showed hardly any<br />

increase in chromium(VI) levels. Adhesive treatment<br />

and heat tended to slightly reduce the chromium(VI)<br />

levels in leathers with a high initial chromium(VI) concentration.<br />

A slight increase in chromium(VI) levels<br />

was noted in the case of low initial chromium(VI) contents.<br />

Reducing Agents<br />

In addition, the effect of reducing agents on the<br />

chromium(VI) contents of leathers was also investigated,<br />

both in a vat process and after spray application.<br />

On the one hand, reducing agents prevent the formation<br />

of chromium(VI); on the other, they lower the<br />

concentration of existing chromium(VI). Use of reducing<br />

agents consistently leads to lower chromium(VI)<br />

contents of leathers. The reducing action also withstood<br />

treatment with heat and adhesives.<br />

Leather lining<br />

attached to shoe upper

JoINT <strong>PFI</strong> AND LGR RESEARCH PRoJECT<br />

The leather was split fourfold<br />

in order to examine the<br />

individual layers<br />

Tests on Footwear<br />

In addition to the studies on leather samples, items of<br />

footwear were also produced and the leathers subsequently<br />

examined in the laboratory. Upper and lining<br />

leathers with different contents of chrome tanning<br />

agent were selected for shoe production and two different<br />

adhesives were used. Four upper leathers and<br />

four lining leathers were used in one shoe, for the toe,<br />

the heel, the left side, and the right side, respectively.<br />

None of the leathers used had a chromium(VI) content<br />

exceeding 3.0 mg/kg prior to shoe production. In total,<br />

32 upper leathers and 32 lining leathers from the shoes<br />

were examined for their chromium(VI) content. None<br />

of the upper leathers used in the shoes showed increased<br />

chromium(VI) levels. Five of the lining leathers<br />

were found to have chromium(VI) values exceeding 3.0<br />

mg/kg. A long-term test of the shoes over a period of<br />

three months showed a slight increase of chromium(VI)<br />

values depending upon the amount of chrome tanning<br />

agent used. The increased chromium(VI) levels in the<br />

shoes could be greatly lowered by spray application<br />

of reducing agents. After a four-week treatment of<br />

the shoes with reducing agents, the individual leathers<br />

of the shoes were again examined with regard to<br />

their chromium(VI) contents. The reducing agent lost<br />

some of its potential, but the chromium(VI) levels of<br />

the leathers of the shoes still lay below the legal limit<br />

value for chromium(VI) of 3.0 mg/kg.<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

The findings demonstrate that adoption of specific<br />

measures can minimise the risk of chromium(VI) formation<br />

in leather products – in the interests of preventative<br />

consumer health care. The complete research<br />

report is available from the contact address.<br />

Contact:<br />

Dr. Kerstin Schulte<br />

Head of Chemical Analysis and Research<br />

Prüf- und Forschungsinstitut Pirmasens<br />

Marie-Curie-Straße 19<br />

66953 Pirmasens<br />

Phone: +49 6331 2490 712<br />

Fax: +49 6331 2490 60<br />

E-Mail: kerstin.schulte@pfi-germany.de<br />

27

28<br />

Newsletter<br />

<strong>PFI</strong> Participates in Wet-White Round-Robin Test<br />

Mould Resistance of Leathers<br />

and Intermediate Products<br />

Mould infestation of raw materials and finished products<br />

repeatedly gives rise to considerable financial<br />

losses and may also adversely affect the health of employees.<br />

Such infestation is frequently triggered by a<br />

high water or moisture content of intermediate products<br />

that are susceptible to microbial attack and/or<br />

adverse climatic conditions (rainy season) in the production<br />

centres of the Far East. For this reason, tests<br />

for mould resistance of leather intermediate products<br />

are not only helpful but absolutely essential features<br />

of quality control. In this way, substandard materials<br />

can be eliminated and possible infestation and further<br />

spread of mould can be effectively prevented.<br />

MICRoBIoLoGY<br />

Tegewa (an association of manufacturers of textile,<br />

paper, leather, and fur auxiliaries and colourants, surfactants,<br />

complexing agents, antimicrobial agents,<br />

polymeric flocculants, cosmetic raw materials, pharmaceutical<br />

excipients, and allied products) addresses<br />

current topics relating to the above areas with the aim<br />

of offering its members and the market appropriate<br />

practical solutions.<br />

Last summer the leather auxiliary section of Tegewa<br />

set up the “Mould Resistance” Project <strong>Group</strong> which is<br />

concerned with questions surrounding this topic. The<br />

members of the Project <strong>Group</strong> come from industry and<br />

from research institutes.<br />

Over the years, there have been changes in the preservation<br />

methods used for leather products and intermediates.<br />

The question thus arises whether the reliable<br />

yet relatively straightforward laboratory method<br />

for testing the mould resistance of so-called wet-blue<br />

(chrome-tanned leather products) published in 1996<br />

by the above Section is also applicable to wet-white<br />

(glutaraldehyde-tanned leather products).<br />

To this end a round-robin test was carried out by five<br />

participants, including <strong>PFI</strong>, at the close of 2010.

Round-Robin Test Methodology<br />

The method is based on an agar diffusion test. Punched<br />

out specimens are placed with both the flesh side and<br />

the grain side in contact with an agar plate uniformly<br />

inoculated with spores of a given test organism and<br />

incubated at elevated temperature and moisture levels.<br />

The test organism, a mould fungus, then grows<br />

initially on the agar and, depending upon the state of<br />

preservation, possibly also on the specimen. The condition<br />

of the sample is evaluated on a weekly basis.<br />

Any inhibition zone appearing around the specimen is<br />

recorded and measured.<br />

If there is a lack of mould resistance (evaluation 1/A, A<br />

= growth area) mould growth generally begins at the<br />

outer edge and gradually proceeds over the test sample;<br />

the extent of growth was also measured.<br />

If preservation is adequate the samples will show no<br />