Here - PFI Group

Here - PFI Group

Here - PFI Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

36<br />

Newsletter<br />

By No Means Trivial<br />

Shoe Accessory with Core Strength<br />

Everybody is familiar with them. Everybody uses<br />

them. Even oetzi, the famous glacier mummy, is considered<br />

to have been aware of their great advantages<br />

and every child has to laboriously learn how to tie<br />

them. We are talking shoelaces. Yet although it is hard<br />

to imagine everyday life without shoelaces, only few<br />

people have probably ever asked how they are actually<br />

made. Since this question has been put to us, we<br />

would like to provide an insight into shoelace production.<br />

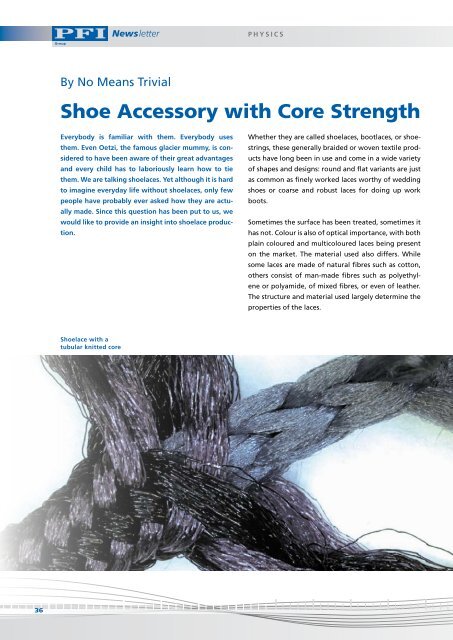

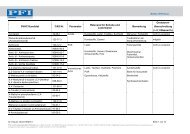

Shoelace with a<br />

tubular knitted core<br />

PHYSICS<br />

Whether they are called shoelaces, bootlaces, or shoestrings,<br />

these generally braided or woven textile products<br />

have long been in use and come in a wide variety<br />

of shapes and designs: round and flat variants are just<br />

as common as finely worked laces worthy of wedding<br />

shoes or coarse and robust laces for doing up work<br />

boots.<br />

Sometimes the surface has been treated, sometimes it<br />

has not. Colour is also of optical importance, with both<br />

plain coloured and multicoloured laces being present<br />

on the market. The material used also differs. While<br />

some laces are made of natural fibres such as cotton,<br />

others consist of man-made fibres such as polyethylene<br />

or polyamide, of mixed fibres, or even of leather.<br />

The structure and material used largely determine the<br />

properties of the laces.