Here - PFI Group

Here - PFI Group

Here - PFI Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The various colour and structural effects of shoelaces<br />

are determined by the number and nature of the flyer<br />

wheels and the yarn, among other factors. Whether<br />

round or flat braids are produced is also decided at<br />

this point.<br />

Round shoelaces have yet another special feature: In<br />

addition to their visible braiding, forming the sleeve,<br />

they often have a core concealed in their interior. This<br />

usually consists of other textile materials. e.g. yarns,<br />

ply yarns, or tubular knitted material. Core material<br />

is fed into the machine separately during production<br />

and is enclosed by a braided sleeve made up of the<br />

subsequently visible yarns. But why take all the trouble?<br />

Because the core endows shoelaces with additional<br />

desired properties: they weigh more, exhibit a<br />

greater tensile strength, or have better extensibility<br />

than those without a core.<br />

The braided cords of several metres length are clearly<br />

much too long for use as shoelaces. They are therefore<br />

cut to length. The tips have to be fixed in a plastic<br />

or metal sheath, known as an aglet, to prevent them<br />

from unravelling. In the case of synthetic fibres, the<br />

ends can be welded together ultrasonically to form<br />

a moulded tip aglet. Alternatively, aglets can be produced<br />

by crimping a piece of metal onto the shoelace<br />

or by forming a plastic sleeve directly on the lace. The<br />

aglets serve not only to protect the tips but also as an<br />

aid in threading the laces through the eyelets. Oetzi<br />

can only have dreamed of such convenience!<br />

01.2011<br />

Magazine of the Test and Research Institute Pirmasens<br />

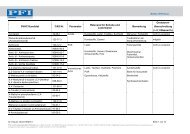

Tests<br />

for Shoelaces at <strong>PFI</strong><br />

<strong>PFI</strong> offers the following standard tests<br />

for shoelaces:<br />

Abrasion (according to DIN EN ISO 22774)<br />

- laces abrading against each other<br />

- laces abrading against eyelets<br />

Tensile strength and elongation<br />

(based on DIN EN ISO 18691)<br />

- testing in as-received condition<br />

- testing after abrasive wear<br />

Pull-out strength for aglets<br />

Moreover, <strong>PFI</strong> can perform other, albeit<br />

non-standard tests in special cases:<br />

Water fastness<br />

Mass per unit length<br />

Further information:<br />

Dipl.-Ing. (FH) Kai Tinschert<br />

Phone: +49 6331 2490 - 16<br />

E-Mail: kai.tinschert@pfi-germany.de<br />

39