Todo List for COLTRIMS setup: - AMOS Experiment at LBNL

Todo List for COLTRIMS setup: - AMOS Experiment at LBNL

Todo List for COLTRIMS setup: - AMOS Experiment at LBNL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

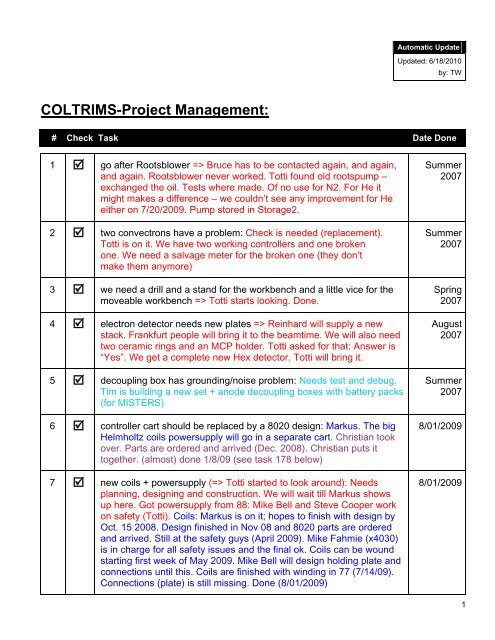

<strong>COLTRIMS</strong>-Project Management:<br />

Autom<strong>at</strong>ic Upd<strong>at</strong>e<br />

Upd<strong>at</strong>ed: 6/18/2010<br />

# Check Task D<strong>at</strong>e Done<br />

1 go after Rootsblower => Bruce has to be contacted again, and again,<br />

and again. Rootsblower never worked. Totti found old rootspump –<br />

exchanged the oil. Tests where made. Of no use <strong>for</strong> N2. For He it<br />

might makes a difference – we couldn’t see any improvement <strong>for</strong> He<br />

either on 7/20/2009. Pump stored in Storage2.<br />

2 two convectrons have a problem: Check is needed (replacement).<br />

Totti is on it. We have two working controllers and one broken<br />

one. We need a salvage meter <strong>for</strong> the broken one (they don’t<br />

make them anymore)<br />

3 we need a drill and a stand <strong>for</strong> the workbench and a little vice <strong>for</strong> the<br />

moveable workbench => Totti starts looking. Done.<br />

4 electron detector needs new pl<strong>at</strong>es => Reinhard will supply a new<br />

stack. Frankfurt people will bring it to the beamtime. We will also need<br />

two ceramic rings and an MCP holder. Totti asked <strong>for</strong> th<strong>at</strong>: Answer is<br />

“Yes”. We get a complete new Hex detector. Totti will bring it.<br />

5 decoupling box has grounding/noise problem: Needs test and debug.<br />

Tim is building a new set + anode decoupling boxes with b<strong>at</strong>tery packs<br />

(<strong>for</strong> MISTERS)<br />

6 controller cart should be replaced by a 8020 design: Markus. The big<br />

Helmholtz coils powersupply will go in a separ<strong>at</strong>e cart. Christian took<br />

over. Parts are ordered and arrived (Dec. 2008). Christian puts it<br />

together. (almost) done 1/8/09 (see task 178 below)<br />

7 new coils + powersupply (=> Totti started to look around): Needs<br />

planning, designing and construction. We will wait till Markus shows<br />

up here. Got powersupply from 88: Mike Bell and Steve Cooper work<br />

on safety (Totti). Coils: Markus is on it; hopes to finish with design by<br />

Oct. 15 2008. Design finished in Nov 08 and 8020 parts are ordered<br />

and arrived. Still <strong>at</strong> the safety guys (April 2009). Mike Fahmie (x4030)<br />

is in charge <strong>for</strong> all safety issues and the final ok. Coils can be wound<br />

starting first week of May 2009. Mike Bell will design holding pl<strong>at</strong>e and<br />

connections until this. Coils are finished with winding in 77 (7/14/09).<br />

Connections (pl<strong>at</strong>e) is still missing. Done (8/01/2009)<br />

by: TW<br />

Summer<br />

2007<br />

Summer<br />

2007<br />

Spring<br />

2007<br />

August<br />

2007<br />

Summer<br />

2007<br />

8/01/2009<br />

8/01/2009<br />

1

8 differential pumping stage: New tube (8 x 120mm ?) => Tim’s baby.<br />

Sun took over. Ken is machining parts<br />

9 repair of powersupplies, HP voltmeter, fast amplifier and CFD (Lothar<br />

will repair the CFDs once he is here): Totti is on it<br />

10 <strong>for</strong>m<strong>at</strong> d<strong>at</strong>a analysis computer, reinstall and get all the software<br />

running again => Totti will get in contact with Jim and work on it: Done<br />

11 a new 800 l turbo pump <strong>for</strong> <strong>COLTRIMS</strong> chamber is needed: Shim<strong>at</strong>su<br />

Totti: Seiko Seiki pump is repaired in time – we will use th<strong>at</strong> while we<br />

wait <strong>for</strong> the new pump<br />

12 leak test <strong>for</strong> source chamber would be nice. No leak from outside;<br />

micro leak is between last valve and chamber flange.<br />

13 check all ion gauges. They are all functioning (as well as the<br />

controller). Some filaments might be burned – so we might not have<br />

two everywhere. Sun and Totti<br />

14 marks <strong>for</strong> beamline 11 are needed => Totti will get in contact with<br />

Hendrik, Tolek and Mary (survey group). Hendrik contacted me: They<br />

will talk to the survey group but we have to check again. Scheduled <strong>for</strong><br />

January 30 th 2008. Done – marks are on the floor, but it is not clear<br />

how far the beamline has to be rot<strong>at</strong>ed.<br />

15 a new adapter flange chamber-to-differential-pumping-stage with<br />

bellow would be nice: Needs ideas and discussion. Tim found better<br />

design and is on it<br />

16 make jet-dump tube moveable => Totti has an idea. Sun is<br />

constructing. Ken is on it<br />

17 <br />

cooling of jet is mysterious: Wh<strong>at</strong> should we do ? Markus. Project<br />

postponed (new cold trap with copper rod might solve the problem)<br />

Cold trap is bad; only -115°C on copper wire, 10 cm behind trap. Most<br />

likely connection between wire and trap itself. => new trap, may be<br />

with complete rebuild of jet system<br />

18 a Drytel <strong>for</strong> the differential pumping stage is needed: Discussion open.<br />

Sun borrowed one from ALS<br />

19 a <strong>for</strong>epump <strong>for</strong> the <strong>COLTRIMS</strong> chamber is needed : Discussion open.<br />

We use a Scroll pump from ALS vacuum people (signed out by whom<br />

?)<br />

Spring<br />

2007<br />

Spring<br />

2007<br />

Spring<br />

2007<br />

Summer<br />

2007<br />

End 2008<br />

Summer<br />

2007<br />

Early<br />

spring<br />

2008<br />

Summer<br />

2007<br />

Summer<br />

2007<br />

January<br />

2009<br />

Spring<br />

2007<br />

Spring<br />

2007<br />

2

20 Chamber blind flange should turn into feedthrough flange. Totti has 4<br />

SHV 2 ¾ flange. We need an adapter to 6in. Sun is on it and found<br />

the parts<br />

Spring<br />

2007<br />

21 Oil <strong>for</strong> all turbo pumps have to be checked, e.g. replaced ! Sun did it… Summer<br />

2007<br />

22 We need a little stronger powersupply <strong>for</strong> the rainbow coils: Done by<br />

Totti<br />

23 We need a ruler on the exit slits inside the chamber: We have to find<br />

something made out of Aluminum. Sun did it<br />

24 We need two R<strong>AMOS</strong> boxes in lab 102 => Totti: Steve is on it and<br />

gets back to us. Outlets are installed.<br />

25 SAFETY: There are still chemicals in the lab: Wh<strong>at</strong> should we do ?<br />

Totti contacts Jerry….<br />

26 2 digital Frankfurt r<strong>at</strong>emeter desirable: Totti emailed to Reinhard and<br />

Lothar. Answer is “NO – not now”<br />

27 Exchange 3-fold SHV feedthrough with 4-fold SHV feedthrough: =><br />

Hunt <strong>for</strong> good one (1E-9Torr). Totti found one – hopefully it works.<br />

Sun mounted it. Gives good vacuum.<br />

28 SAFETY: Fasten the chamber to the ground. Totti: In progress…<br />

(Fred Angliss)<br />

Summer<br />

2007<br />

Summer<br />

2007<br />

Fall 2007<br />

Fall 2007<br />

Summer<br />

2007<br />

Summer<br />

2007<br />

Spring<br />

2008<br />

29 Get salvage parts from cleaning. Totti Spring<br />

2008<br />

30 Turn of the fume hood. Totti: Answer is “NO”. Hood is part of the AC<br />

system of lab 102<br />

31 Think about the use of a hex det and a 120mm <strong>for</strong> BL 10 experiment:<br />

Hex Det = Yes. Detectors have to be set-up (put together and look <strong>for</strong><br />

wiring). We have to find out how the 80mm detector can be mounted<br />

to the big spectrometer and how to lift the spectrometer or <strong>setup</strong> the<br />

big spectrometer<br />

32 Get in contact with Claude Linus and Dennis Collins <strong>at</strong> building 88:<br />

300A/30V Powersupply: Totti did it and got the powersupply<br />

Winter<br />

2007<br />

Summer<br />

2007<br />

Summer<br />

2007<br />

3

33 We need an efficient beamdump <strong>for</strong> 30 to 55 eV photons (Woods<br />

Horn): We will mount a 6in bellow <strong>at</strong> the exit of the chamber. Support<br />

rods were constructed by Totti and are in the machine shop. We need<br />

a good stand <strong>for</strong> the 6in pipe then (found something made out of<br />

steel).<br />

34 Spectrometer has to be simul<strong>at</strong>ed and designed: Need in<strong>for</strong>m<strong>at</strong>ion<br />

about KER and Electron energy first. Sun’s job and she is on it<br />

35 Get in contact with David Kilcoyne from BL 10L Fluxcurves, beam<br />

height, space constraints etc. Sun and Totti<br />

Summer<br />

2007<br />

Spring<br />

2007<br />

Spring<br />

2007<br />

36 We need a big Ethylene gas bottle. Sun Summer<br />

2007<br />

37 A computer <strong>for</strong> Acquiris: Has been ordered by Totti and M<strong>at</strong>thias – it<br />

has to be set up once it is here. Done by Totti<br />

38 We have to check with David Kilcoyne again about: Polariz<strong>at</strong>ion and<br />

gas cell in front of our <strong>setup</strong> and reloc<strong>at</strong>ion of the two cabinets <strong>at</strong> the<br />

beamline. Totti and Sun will do th<strong>at</strong><br />

Summer<br />

2007<br />

Summer<br />

2007<br />

39 Setup spectrometer: Sun did it Summer<br />

2007<br />

40 Implement bellow into differential pumping stage and test <strong>for</strong> good<br />

pressure: Sun did it<br />

41 Detectors need new cables of the right length and a coppering on the<br />

electron side: Sun and Totti did it<br />

Summer<br />

2007<br />

Summer<br />

2007<br />

42 Turn the “B<strong>at</strong>man” (machine shop work): Sun did it Summer<br />

2007<br />

43 Look <strong>for</strong> Acetylene as a backup plan and CO <strong>for</strong> calibr<strong>at</strong>ion (in<strong>for</strong>m<br />

David th<strong>at</strong> we want to use the yellow gas cabinet): Sun did it<br />

44 Construct and <strong>setup</strong> a movable table <strong>for</strong> differential stage: Totti, Sun<br />

and Felix<br />

Summer<br />

2007<br />

Summer<br />

2007<br />

45 Software <strong>for</strong> Acquiris is missing: Frankfurt Fall 2007<br />

46 Preanalysis routine <strong>for</strong> C2H4 (PAW): Sun is on it Fall 2007<br />

47 Get Telescope from building 88 (Bob Shannon): Totti got it Spring<br />

2008<br />

4

End of 2-Bunch-Run 8/2007<br />

48 Replace 4 to 2¾in adapter on collim<strong>at</strong>or cross (put new aperture<br />

inside): Felix<br />

Winter<br />

2007<br />

49 Exchange 4-fold BNC feedthrough with 4-fold SHV-feedthrough: Felix Winter<br />

2007<br />

50 SAFETY: Build gas manifold (bypass to Scroll pump and convectron<br />

needed, <strong>at</strong> least three inputs desirable): Felix and Totti<br />

51 SAFETY: Exhaust <strong>for</strong> diaphragm pump needs connection to KF: Felix<br />

and Totti<br />

52 Repair decoupling cylinders (note, there are 100 instead of 150 Ohm<br />

in one of them) and b<strong>at</strong>tery boxes: Josh and Felix<br />

53 Check tools <strong>for</strong> missing parts: For instance small round files are<br />

needed. Felix and Sun<br />

Spring<br />

2008<br />

Spring<br />

2008<br />

Summer<br />

2008<br />

Spring<br />

2008<br />

54 Check and order Lemo cables: Felix and Totti Spring<br />

2008<br />

55 Check and make short (3in) SHV cables: Felix Spring<br />

2008<br />

56 Check and order Lemo adapters, T’s, 50 Ohm….: Felix and Totti Spring<br />

2008<br />

57 Check digital scope (one channel might be broken <strong>at</strong> low amplific<strong>at</strong>ion;<br />

ask Tim): Tim and Felix. Channel 1 below 100mV does not work –<br />

repair is too expensive<br />

58 Think about rainbow coils: How can we increase the current going<br />

through ? Felix and Totti: New computer cables in parallel<br />

59 Change the offset flange <strong>at</strong> chamber entrance (according to new<br />

spectrometer): Felix<br />

60 Get adapter <strong>for</strong> new turbo pump and mount it: Totti got it/mounting<br />

postponed<br />

61 Arms and their Mounting pl<strong>at</strong>es <strong>for</strong> Helmholtz-coils have to be<br />

changed to 8020 design: Felix<br />

Spring<br />

2008<br />

Spring<br />

2008<br />

Spring<br />

2008<br />

Summer<br />

2008<br />

Summer<br />

2008<br />

62 Organize a Drytell and the rebuilt Scroll pump from Evan: Sun Spring<br />

2008<br />

5

63 Check <strong>for</strong> Alc<strong>at</strong>el ACP20 (found in the dumpster) with Evan again:<br />

Totti – can not be repaired ;-(<br />

64 <br />

Software upgrades on computers: COBOLD, SIMION and Compilers:<br />

Markus orders; hopefully done by Oct. 15. Compiler arrived and was<br />

installed on Markus and Christians computer.<br />

65 Check and get Kwikflange (Hoses, clamps, rings…) and Swagelok<br />

(valves, bending tool…): Felix and Totti<br />

66 Connect printer to acquisition computer and get new cartridges: Felix<br />

and Totti. Totti installed the printer; cartridges are new but print heads<br />

are bad. Too expensive to replace. Buying a new printer (150$) is<br />

cheaper (low priority)<br />

Spring<br />

2008<br />

Winter<br />

2008<br />

Spring<br />

2008<br />

Summer<br />

2008<br />

67 Put pumps on wheels: Felix Spring<br />

2008<br />

68 Make a jet test with the roots pump: Felix and Totti Spring<br />

2008<br />

69 Repair chamber ion gauge and cable: Felix and Sun Spring<br />

2008<br />

End of 2-Bunch-Run 3/2008<br />

70 Get Electronics Rack from ALS (sector 10): Sun, Totti and Steve<br />

Cooper<br />

71 Get electronics (Powersupply, CFD, NIM bins) from repair: Totti (one<br />

CFD is still in repair). Done<br />

Spring<br />

2008<br />

Summer<br />

2008<br />

72 New phosphor screen: Sun and Felix Summer<br />

2008<br />

73 Mark more tools with pink dot: Sun, Totti and Felix Summer<br />

2008<br />

74 Wh<strong>at</strong> should we do with the Hex-Anode ? Totti, Reinhard, Lothar. Has<br />

to be replaced with new one. Markus brought it.<br />

75 Adapters <strong>for</strong> differential stage need taped holes <strong>for</strong> center piece of the<br />

tube. Sun and Felix<br />

Summer<br />

2008<br />

Summer<br />

2008<br />

6

76 New 2 nd (and 3 rd ?) harddrive <strong>for</strong> D<strong>at</strong>a acquisition computer has to be<br />

ordered and mounted (SATA): M<strong>at</strong>thias ordered two and installed<br />

them.<br />

77 SAFETY: Connection <strong>for</strong> 300A power supply (208VAC/50A) plus<br />

safety shield around electrodes: Totti, Evan and Steve Cooper. Device<br />

is in EI shop<br />

Spring<br />

2008<br />

Summer<br />

2008<br />

78 On/Off switch <strong>for</strong> scroll pump is needed: Totti and Steve Cooper Spring<br />

2008<br />

79 Need convectron <strong>for</strong> 1 st stage: Felix and Totti Spring<br />

2008<br />

80 Need convectron <strong>for</strong> gas manifold: Felix and Totti Spring<br />

2008<br />

81 W<strong>at</strong>er connection in 102: Felix and Sun Spring<br />

2008<br />

82 Need gases and regul<strong>at</strong>ors <strong>for</strong> N2, CO, CO2, Ne: Felix and Sun Summer<br />

2008<br />

83 80mm detectors have to be reassembled: Felix and Sun (+Totti) Summer<br />

2008<br />

84 Stabilized Jet-he<strong>at</strong>ing; need controller, power supply and test<br />

Irina works on it<br />

6/17/2010<br />

85 SAFETY: Order Earmuffs: Felix Spring<br />

2008<br />

86 Coldtrap lids should be higher and might need holes: Felix Spring<br />

2008<br />

87 Mount CF150 cross <strong>for</strong> long spectrometer: Felix and Sun Spring<br />

2008<br />

88 Lab improvement list: All. Totti - no input from other team members Summer<br />

2008<br />

End of 2-Bunch-Run 8/2008<br />

89 Makeover of the differential pumping stage: Tube has to be part of the<br />

stage not of the chamber. postponed<br />

7

6 New controller cart needed (8020): Markus. Christian took over; parts<br />

are ordered and arrived (Dec. 2008). Some parts are still missing and<br />

have to be ordered. Stuff arrived. Christian puts things together. Alupl<strong>at</strong>es<br />

<strong>for</strong> the top and bottom are designed and have to go into the<br />

machine shop. They are now mounted. Frame is rein<strong>for</strong>ced. Still some<br />

brackets are missing. Feet got altered (4/12/09). Got plexi glass lips<br />

on top. Frame is assembled. First modules went in (5/1/09). Feet are<br />

ready to be <strong>at</strong>tached (5/19/09). Modules have to go up to make a<br />

complete unit fit <strong>at</strong> the bottom (6/2/09). Folder boxes needed <strong>for</strong> safety<br />

and emergency shutdown list: Totti ordered something and mounted it<br />

(6/9/09). Labels on Power cords are needed. Power has to be<br />

redistributed evenly. Brackets are needed to <strong>at</strong>tach chain <strong>for</strong> seismic<br />

safety (chains and quick connectors have to be found and cut: Totti<br />

found something <strong>for</strong> a start). Totti did it (6/4/09). Totti ordered double<br />

8020 brackets <strong>for</strong> feet and installed them 9/18/09.<br />

91 Aluminum pl<strong>at</strong>es (mesh-holders) <strong>for</strong> spectrometers need holes and<br />

threads to take detector + new Aluminum arms are needed (to replace<br />

the broken ones; done by Felix). Markus; scheduled <strong>for</strong> end of Nov.<br />

Still have to go in the machine shop. Done<br />

92 <br />

93 <br />

SAFETY: Complete check on all regul<strong>at</strong>ors <strong>for</strong> all gases and pressure<br />

ranges: Markus + Christian; scheduled <strong>for</strong> Dec. => Regul<strong>at</strong>ors <strong>for</strong><br />

flammable gases (H2, CO, CmHn) tested and ok (3 x 60 psi, 2 x 600<br />

psi); Rare gases, N2 (4 x 60 psi, 1 x 1200 psi). Have couple of broken<br />

or unknown ones (will repair when needed). Look out <strong>for</strong> spare one<br />

with high pressure (1000psi, rare gases). Good regul<strong>at</strong>ors are labeled<br />

now.<br />

New/big coils may need new 8020 arms (longer and perhaps<br />

stronger): Totti (has to wait on Markus to finish designing and<br />

construction of the coils first; 8020 profiles are available and need to<br />

be cut then). Checked: Old arms do the job<br />

94 Check LEMO, BNC, SHV cables, Ts, barrels and adapters: Markus +<br />

Christian. SHV and Lemo cables, Ts and adapters checked and bad<br />

ones rejected<br />

95 Check the anode cylinders + new (universal) voltage divider or b<strong>at</strong>tery<br />

boxes are needed (perhaps with potis). Think of 6 SHV connectors…:<br />

Josh and Felix are on it. They put voltage divider in cylinders – works<br />

well…<br />

96 New voltage divider boxes are needed <strong>for</strong> the detectors (to have potis<br />

would be nice): Felix is on it<br />

97 2 more decoupling boxes <strong>for</strong> the spectrometer are needed: Felix is on<br />

it<br />

7/20/2009<br />

+<br />

9/18/2009<br />

1/30/2009<br />

01/26/2009<br />

05/11/2009<br />

January<br />

2009<br />

Summer<br />

2008<br />

Summer<br />

2008<br />

Summer<br />

2008<br />

8

98 Moveable Scintill<strong>at</strong>or going inside the spectrometer of any size has to<br />

be constructed (<strong>at</strong>tached to the chamber – not to the spectrometer):<br />

Totti started looking around. Josh is building the support arm – did not<br />

work; needs improvement: Totti took over and reconstructed some<br />

parts and made a new rail system. Parts are ready, installed and work<br />

“ok” (not perfect). Push-pull and 4xSHV feedthroughs got switched.<br />

Arm <strong>for</strong> front phosphor is adjusted. Phosphor or Szintill<strong>at</strong>or is still<br />

missing and Vacuum test is needed (Markus)… See 138<br />

99 Nozzle was clogged – we cleaned it but a jet test is necessary:<br />

Markus. Nozzle is free – cooling remains a problem<br />

100 <br />

SAFETY: Pumps on wheels: Get rid of the wooden boards (fire<br />

hazards) and replace with Aluminum: Markus + Christian; projected <strong>for</strong><br />

January 2009.<br />

101 Measure the convectron gauges: There has to be 20 Ohm between<br />

pin 1 and 2 (if not it is likely to be broken). One can clean a convectron<br />

with Alcohol or Acetone cautiously<br />

=> moved down<br />

102 We need a new MCP holder <strong>for</strong> 80mm pl<strong>at</strong>es th<strong>at</strong> fit the 120mm Quad<br />

Anode plus a ceramic ring with a big copper pl<strong>at</strong>e/ring on the front to<br />

compens<strong>at</strong>e fringe fields (recoil det): Markus, Sven and Ottmar<br />

103 Electronic Rack: Rack blower in the middle has a damaged fan on the<br />

right. Replace. Totti looked <strong>at</strong> it and cleaned a little with pressurized<br />

air. Does not run gre<strong>at</strong> but is ok <strong>for</strong> now.<br />

8/30/2008<br />

Spring<br />

2008<br />

01/25/2009<br />

Summer<br />

2008<br />

8/15/2008<br />

104 SAFETY: Rainbow coils: Replace orange plug. Totti did it 8/20/2008<br />

105 SAFETY: We need more little electronic boxes with grounding (robust<br />

style): Load Resistors, Voltage divider (<strong>for</strong> Grid or Copperpl<strong>at</strong>e)…<br />

Especially 1:10 and 1:20 voltage divider are needed <strong>for</strong> monitoring<br />

Voltages up to 1000 or 2000 V (Totti got input from EM shop: SHV-<br />

Banana is not available – voltage dividers with output of max 100V are<br />

okay in order to bring it to BNC). Totti ordered 20 boxes (<strong>for</strong><br />

<strong>COLTRIMS</strong> and MISTERS). Christian will build them and is on it.<br />

Almost finished – tests would be desirable.<br />

106 Decoupling boxes need mechanical support: Christian + Totti. 4<br />

pieces are machined in the shop <strong>for</strong> <strong>COLTRIMS</strong>. If it works we will<br />

order 4 more <strong>for</strong> MISTERS. Totti gave drawings to Rene. Christian will<br />

order threaded rods and nuts.<br />

2/20.2009<br />

11/08/2008<br />

9

107 Check the very short SHV-SHV cables <strong>for</strong> damage: They are poorly<br />

made – very unreliable. Complain <strong>at</strong> EI shop (see 94): Markus +<br />

Christian. 4 SHV bad cables found (still working, but plastic insul<strong>at</strong>ion<br />

<strong>at</strong> connector damaged) => put in “useful broken cable”-box<br />

1/30/2009<br />

108 Manifold: Replace one valve with a lockable one. Totti did it. 8/15/2008<br />

109 Phosphor: Front phosphor was weak and peeling off in vacuum (too<br />

much glue ?). Totti spoke to David K. about flaking phosphor: We<br />

made the layer too thick. He will help with air brushing phosphor on<br />

glass pl<strong>at</strong>es – Totti and David did it. Small Phosphor or Scintill<strong>at</strong>or <strong>for</strong><br />

spectrometer arm is still missing – Totti did it. See also 123 and 138<br />

92 <br />

SAFETY: Check regul<strong>at</strong>ors <strong>for</strong> leaks and appropri<strong>at</strong>e range (high<br />

pressure). Markus + Christian<br />

111 Rods <strong>for</strong> anode cylinders are still missing. Ken is on it. Totti will check.<br />

Done and installed. Needed rewiring. Test would be good…<br />

112 SAFETY: Check crane post <strong>for</strong> missing screws. Replace broken<br />

brackets. Totti did it – not all the screws are in but it seems ok.<br />

113 SAFETY: Check crane wheel <strong>at</strong> the tip. Totti did it and gener<strong>at</strong>ed a<br />

required crane log book<br />

114 We need a NIM-NIM power cable – 10 feet long<br />

115 Oil <strong>for</strong> the small 4 turbo pumps needs to be ordered from Pfeiffer:<br />

Totti. Ordered 8/20/09. Arrived 9/3/09. Inserted 9/8/09.<br />

116 Redesign MCP Holder pl<strong>at</strong>e <strong>for</strong> Hexdetector and Quad 80 (similar to<br />

DLD120). Markus; will be finished by end of Oct. Still in machine shop.<br />

(Jan 2009)<br />

117 Ion Gauge in Source Chamber: Replace broken filament (David K.<br />

might help us out). New filament available in ALS shop ($70) but we<br />

might be able to use a filament from the old ion gauges. Totti did it,<br />

see below.<br />

118 SAFETY: Replace the 30 year old ion gauges with new ones. Cables<br />

to connect to the old controllers have to be fabric<strong>at</strong>ed though (EM<br />

shop). Totti is on it and bought 3 gauges. Gauges are installed and the<br />

broken one is repaired with a filament of an old ion gauge. NOTE: We<br />

are not oper<strong>at</strong>ional because of the cables! EI people will order 4 “pigtails”<br />

and modify our old cables. Work in progress. Done – test needed<br />

(Markus who has to per<strong>for</strong>m the vacuum test: 1/16/09 test done –<br />

cable were wired the wrong way by EI shop). Now everything is ok.<br />

12/01/2008<br />

January<br />

2009<br />

9/1/2008<br />

8/17/2008<br />

11/30/2008<br />

9/8/2009<br />

2/18/2009<br />

8/16/2008<br />

10/1/2008<br />

10

119 <br />

Convectron gauge in Manifold has problem: Try to readjust or replace.<br />

Markus + Christian; starts with 17 and 123. Oct. 15. => Manifold<br />

convectron gauge shows right pressure.<br />

120 Repair Phillips CFD 715: Center channel jumps in time (seen on<br />

computer, it is not a cable delay problem). Give to Eric Henson. Totti<br />

did it<br />

January<br />

2009<br />

8/15/2008<br />

121 Repair Ortec 441 R<strong>at</strong>emeter. Give to Eric Henson. Totti did it 8/15/2008<br />

122 Powersupply of Helmholtz coils: Display is broken; maybe more. Give<br />

to EM shop. Totti did it. Back from repair. Should work.<br />

123 Open the jet which got clogged during summer beamtime: Clean the<br />

nozzle. Get new Swagelok filter. Remove mesh in front of nozzle !?<br />

Totti prepared dismount of turbo pump. Markus + Christian. Markus<br />

cleaned nozzle and put stuff back together. Jettest and vacuum test<br />

(also of the phosphor feedthrough) is still needed. First test gave<br />

factor too small rise in jetdump. Reopened and reduced the distance<br />

to skimmer from 11 to 5 mm. Now jet is working fine (no new filter was<br />

implemented though).<br />

8/15/2008<br />

1/21/2009<br />

124 Check all 5 NIM bins (each slot) <strong>for</strong> voltages. Totti did it 8/16/2008<br />

125 Pin <strong>at</strong> 120mm quad anode fell off. Solder…. Totti did it 8/16/2008<br />

126 Re-center the Chamber on the frame. Adjust the little frame <strong>for</strong> the<br />

differential pumping stage. Totti did it<br />

127 SAFTEY: Earthquake brackets <strong>for</strong> Chambers in 102 and 104 are not<br />

safe. Redesign needed. Totti did it – prototype will be made by Rene.<br />

Prototype is now revised. Rene is making 12 stereotypes. Done and<br />

installed<br />

128 Harddrives in d<strong>at</strong>a acquisition and d<strong>at</strong>a analysis computer have to be<br />

replaced. Perhaps order four 500 GB HDs (check if BIOS would be<br />

happy with th<strong>at</strong>). Think of the possible options. M<strong>at</strong>thias ordered HDs<br />

and they arrived. However, there are not mounted yet. Markus will<br />

replace some: see 148.<br />

129 Monitor of d<strong>at</strong>a analysis computer has a problem. Might be still under<br />

warranty. Totti is on it. Sent it out <strong>for</strong> repair. Came back and was also<br />

broken. Send out again. Came back and works.<br />

130 SAFETY: Multiple outlets near w<strong>at</strong>er lines (within 6 feet) need plastic<br />

box: Totti did it<br />

8/16/2008<br />

9/9/2008<br />

12/01/2008<br />

9/11/2008<br />

8/22/2008<br />

11

131 SAFETY: As found during summer beamtime lid needs support<br />

threaded rods (+cylinders with delrin ends) to take the load in case we<br />

open the chamber and work under the lid: Markus. Rods were<br />

designed and machine in cooper<strong>at</strong>ion with machinist (Rene Delano)<br />

and engineer. Parts in machine shop. Only 3 instead of 4 rods were<br />

done. Test needed. Done: 3 rods are strong enough.<br />

132 SAFETY: We have to find a way to get the LN2 out of the trap fast<br />

and safe in case we have to open the chamber: Sun will ask Frank<br />

Zucca. Markus will sketch a delrin lid with inlet <strong>for</strong> pressurized air and<br />

an outlet <strong>for</strong> LN2 (+ pressure relief valve maybe). Totti took over:<br />

Sketch was presented to Jim Floyd. He will think about it and get back<br />

to us… Vacuum cleaner in combin<strong>at</strong>ion with dewar might do the job.<br />

Lid <strong>for</strong> dewar was constructed and machined with Rene (safety<br />

aspects taken into account). Vacuum cleaner war ordered and arrived.<br />

Test with w<strong>at</strong>er worked ok. Test with LN2 failed: The hose was too<br />

small. Totti “organized” bigger hose (LN2 certific<strong>at</strong>ed) and insul<strong>at</strong>ed it<br />

with foam. Test was positive. Rene makes new handle. Done – will<br />

work.<br />

133 Jetdump endpl<strong>at</strong>e and nut have to be milled down to gain some<br />

clearance between the spectrometer and the Jetdump: Totti made a<br />

drawing. It is in the machine shop. Done and installed. Jetdump tube<br />

needs adjustment: see 137<br />

134 SAFETY: Electronic rack has a broken wheel. Needs replacement<br />

wheels (with brakes). Chamber wheels don’t look so well either (Totti<br />

replaced them)… Markus; order goes out with 6 and 7. Markus and<br />

Christian replaced the wheel.<br />

135 D<strong>at</strong>a acquisition computer has a driver problem with the DVD writer. It<br />

can not burn DVDs. Totti tried to upd<strong>at</strong>e the driver (but there are no<br />

newer versions out there) and upd<strong>at</strong>ed NERO. Still no success. Help<br />

from somebody else is needed. M<strong>at</strong>thias did it: Cable was loose due<br />

to transport<strong>at</strong>ion from and to the ALS.<br />

136 SAFETY: ALS wooden roll stoppers need rubber pads. Sun ordered<br />

parts. Totti cut rubber pads and improved 30 wooden brackets (we are<br />

out of rubber pads and silicon glue again). Sun ordered more.<br />

137 Jetdump tube in Jetdump-cylinder needs adjustment. Markus +<br />

Christian + Sun<br />

10/1/2008<br />

1/19/2009<br />

8/27/2008<br />

11/20/2008<br />

9/5/2008<br />

9/8/2008<br />

2/25/2009<br />

12

138 We need 5mm wide and 5cm long glass pl<strong>at</strong>es <strong>for</strong> the phosphor and<br />

help from David Kilcoyne with airbrushing. Totti ordered new glass<br />

cutter. Sun cut the class pl<strong>at</strong>es. Totti and Sun will approach David and<br />

Hendrik. Phosphor is on pl<strong>at</strong>es (thanks to David). Pl<strong>at</strong>es were tested<br />

<strong>at</strong> HH Laser in 458. We saw something and taking in account th<strong>at</strong> this<br />

was 10Hz it might work <strong>at</strong> the ALS. Totti remains skeptical…<br />

139 Helmholtz Powersupplies need place to store them. Ask in building 2<br />

and so on…: Markus. One powersupply (800 A / 20 V) got stored in<br />

storage (warehouse). No place <strong>for</strong> the PowerTen powersupply has<br />

been found yet (Feb. 2009). Put Powerten Powersupply in the back of<br />

building 7 and labeled it 9/30/09.<br />

140 SAFETY: New Helmholtz coils need save cable and w<strong>at</strong>er hose<br />

connection. Plastic box is needed or similar. Markus will check back<br />

on EI shop. => Plastic box is fine, still waiting <strong>for</strong> official safety<br />

inspectors (April. 2009). M. Bell: “No w<strong>at</strong>er leak detection needed but<br />

flow controller is desirable” (March. 2009). Temper<strong>at</strong>ure sensor would<br />

be a good idea as well. Mike Bell took over. Done 7/31/09.<br />

141 SAFETY: Administr<strong>at</strong>ive lockout procedure <strong>for</strong> gas manifold + labels +<br />

swagelok cap are needed. Rene put cap on a chain, Totti made Alu<br />

labels and wrote the admin. Procedure (which was <strong>for</strong>warded to the<br />

ALS safety staff by Dec. 18). Input from Donna Hamamoto and Will<br />

Thur are expected <strong>for</strong> January 2009. No feedback to two more emails<br />

– case closed <strong>for</strong> now.<br />

142 Ne spectrometer has to be simul<strong>at</strong>ed (Allen) and constructed and<br />

fitted to the chamber + the right offset flange has to be found and<br />

mounted (Markus).<br />

143 SAFETY: Portable box with Personal Protective Equipment <strong>for</strong> the<br />

ALS beamtimes is needed (containing gloves, earplugs, earmuffs,<br />

glasses, goggles…). Totti and Sun put something together. Wrong<br />

earmuffs were delivered (RMA in process). Box still needs some<br />

labels about the contents on the outside (Totti did it – waiting <strong>for</strong><br />

Earmuffs: Sun got them).<br />

144 Spare blue HP NIM bin with broken 12V and a silver Tenelec NIM bin<br />

with broken 6V was found <strong>at</strong> salvage area. Totti gave it to Eric Henson<br />

(who is in the hospital <strong>for</strong> some weeks) <strong>for</strong> repair around Dec. 18 and<br />

Jan. 22/08. Eric is out <strong>for</strong> a couple of months (3/31/09). Eric is back<br />

but hasn’t started yet (9/10/09). Totti picked them up and brought<br />

them to the ALS (3/21/10).<br />

=> moved down<br />

12/06/2008<br />

9/30/2009<br />

7/31/2009<br />

1/22/2009<br />

2/20/2009<br />

1/12/2008<br />

13

145 Gases have to be ordered: Ne, He, CO (gas cabinet). Markus. Gases<br />

ordered (CO lecture bottle UHP, Neon bottle 80 research grade)<br />

146 CF150 cross with turbo pump has to be mounted on recoil ion side.<br />

Markus<br />

147 8020 support of differential pumping stage is weak. 1530 Profiles<br />

would be stronger. Totti ordered some stuff from 8020 (9/10/09).<br />

Arrived 9/18/09. Needs to be mounted. Totti did it 9/25/09<br />

1/10/2009<br />

2/3/2009<br />

9/25/2009<br />

148 Mount two new Hard Drives into D<strong>at</strong>a Analysis Computer. Markus 2/26/2009<br />

149 Attaching hex80 to 80 Spectrometer has to be solved. Markus has an<br />

idea and designs parts.<br />

150 SAFETY: Quartz glass protection cover <strong>for</strong> CF40 glass flange on<br />

Jetdump. Markus got one.<br />

2/26/2009<br />

2/5/2009<br />

End of 2-Bunch-Run 3/2009<br />

151 SAFETY: Thin green grounding cable on chamber frame (electron<br />

side) needs to be replaced + there is another one with a loose<br />

connection <strong>at</strong> the lug. We need more grounding cables as back-up<br />

Christian + Totti replaced the bad and three short ones 3/26/09. We<br />

now have some short spares (not really good ones). It’s still a good<br />

idea to have about 5 good spares (AWG14, 1.25m long or so). Totti<br />

took care of it.<br />

152 SAFETY: Chamber needs motorcycle jack or something like th<strong>at</strong> to<br />

position it while it is elev<strong>at</strong>ed Totti thinks of transfer pl<strong>at</strong>es from<br />

McMaster instead. Ordered. Is in 77 <strong>for</strong> welding (5/12/09)… Parts are<br />

done (5/21/09). Test needed with new electronic rack <strong>for</strong> instance.<br />

Have to wait on Christian to finish it first. Test done (5/22/09). Will<br />

work but we need scissor jacks to stabilize chamber and take the<br />

weight once we put the pl<strong>at</strong>es under the feet. Totti ordered two jacks<br />

(arrived 5/26/09). Put a box together with transfer pl<strong>at</strong>es and scissor<br />

jacks (under the workbench). Depending on the height of the chamber<br />

wooden blocks might be needed too – we should look out <strong>for</strong><br />

something (building 7 and 79).<br />

153 SAFETY: Last lockable valve on manifold was missing: Totti ordered<br />

it; arrived 3/11; replaced it + changed admin lockout procedure.<br />

3/31/2009<br />

5/26/0209<br />

3/18/2009<br />

14

154 SAFETY: Anchor bolts in 102 were pulled out of the floor. Totti filed in<br />

work order 3/18/2009 and got in contact with Monroe Thomas. Hope<br />

to get got more help <strong>for</strong>m James Mankini… Mankini contacted Fred<br />

Angliss (he will stop by 4/1/09). Steve Cooper stepped in and<br />

contacted Tom Reese: Deeper drilling is necessary. Th<strong>at</strong> requires<br />

floor scanning. Steve Cooper arranged <strong>for</strong> floor scanning (4/1/09). The<br />

scanning report will be sent to James Mankini in the near future <strong>for</strong><br />

completion of the drill permit. In the meantime Fred Angliss took a look<br />

<strong>at</strong> the floor and concluded the following: A) the wrong anchor bolts<br />

were installed (they were not in agreement with his calcul<strong>at</strong>ions). B)<br />

The concrete is busted <strong>at</strong> two places, thus the tiles should come out in<br />

order to take a closer look. C) He recommends replacing all 8 anchor<br />

bolts with 3/8in HILTI KB-TZ, 2.5in embedded. The tiles have to be<br />

removed wherever the concrete is busted in order to conclude<br />

(together with Fred) if a deeper drilling would fix the problem or if the<br />

concrete needs to be fixed first (Carpenters do th<strong>at</strong> 4/2/09). Totti<br />

moved the chamber <strong>for</strong> this purpose. Tom Reese will then send<br />

somebody to take all 8 anchor bolts out. Done: Anchor bolts installed<br />

by carpenter (Warren Elliot). Chamber back in place.<br />

155 SAFETY: Main grounding cables have to remain with frame, pump<br />

cart or electronic rack. Totti put labels on except controller cart (we<br />

wait <strong>for</strong> the new cart here – done: Totti put label on 5/28/09)<br />

156 Electronic/Detector tests: a) test new decoupling boxes and voltage<br />

divider, b) lens potis, c) spectrometer voltage dividers, d) old<br />

decoupling cylinders (150 Ohm, contacts, cable configur<strong>at</strong>ion…), e)<br />

fast amplifier (need labels <strong>for</strong> polarity, amp. Factor) Christian.<br />

Everything soldered and ready to be tested 7/10/09 (we need a<br />

detector and spectrometer in vacuum). Done<br />

157 Spectrometer voltmeter (on the right hand side of the rack) has bad<br />

switch: fix it Totti. Took the front panel out and filed the slot <strong>for</strong> the<br />

button a little bigger. Works better but not gre<strong>at</strong>.<br />

158 MISTERS decoupling cylinders have to be modified as a back-up<br />

Christian. Done 7/10/09. Test is still needed.<br />

159 We have to buy more meshes (80%, 200 micron). We lost 7 sheets<br />

Markus. Quote requested (4/14/08). Ordered (4/20/09). Arrived and<br />

cut. Stuff was pretty crumpled on roll. Loss is estim<strong>at</strong>ed to 50%.<br />

Markus complained <strong>at</strong> TWP Inc. but they don’t care…<br />

160 We need a KF, CF and screw supply suitcase <strong>for</strong> the beamtime. Totti<br />

found something 3/25/09. Nuts & Bolts supply is fine. We need more<br />

supplies to fill the CF/KF suitcase. Totti bought some stuff, but KF25<br />

o-rings are missing <strong>for</strong> instance (ALS shop is out of it)… got some<br />

4/14/09. We now have the minimum equipment.<br />

4/7/2009<br />

3/31/2009<br />

7/28/2009<br />

3/24/2009<br />

7/28/2009<br />

4/30/2009<br />

4/14/2009<br />

15

161 SHV-whip needs new label Totti did it. Decoupling boxes and<br />

cylinders + voltage divider need labels and drawings etc. Markus did it<br />

162 D<strong>at</strong>a analysis computer is getting too slow: We should use Sun’s or<br />

M<strong>at</strong>thias’ computer. Ali offered his PC and Monitor… We will use<br />

M<strong>at</strong>thias computer as analysis computer. Needs re<strong>for</strong>m<strong>at</strong>ting since it<br />

is fubar software wise. With IT service (8/24/09). Totti brought it back<br />

from IT service and <strong>setup</strong> the accounts and put IT security software<br />

on it (8/31/09). Needs ROOT, PAW, COBOLD, Background, R<strong>at</strong>e<br />

Alarm, Backup Programs, Compiler, Origin, GS, Acrob<strong>at</strong>… Totti<br />

started putting stuff on 9/17/09 (Cobold, Background, R<strong>at</strong>e Alarm,<br />

Backup Programs, GS, PAW, ROOT, Compiler). Totti moved<br />

computer to 2-102 and put it in gear 9/23/09. Markus put more<br />

programs on it 3/10/10<br />

163 Work on Jet: Cooling (new coldtrap), nozzle cleaning or new nozzle<br />

design. Jet test with Roots pump <strong>for</strong> He (it might help) Markus. New<br />

nozzle and holding parts designed and in machine shop with Rene<br />

(4/9/09). First approach (using old coldtrap). New coldtrap is designed<br />

and in machine shop with Rene (4/21/09). CF35 pipe was ordered<br />

and arrived (4/29/09). Filter and gold gasket brought from Frankfurt<br />

(6/03/09). Everything put together 7/13/09. Jettest on 7/14/09 without<br />

and with Roots Forepump. Analysis of the results shows th<strong>at</strong> rootspump<br />

does not help. Per<strong>for</strong>mance with respect to the old design =<br />

??? New coldtrap is still in shop and needs to be mounted (8/2/09).<br />

Totti and Rene decided on the length and welding procedure of cold<br />

trap. M<strong>at</strong>erial got ordered. Totti spoke to Bob Conroy how to <strong>at</strong>tach<br />

the copper braid. Rene drilled the holes in the rod and in the newly<br />

designed clamp. Rene points out th<strong>at</strong> knife edge on CF100 flange is<br />

not wonderful – could be polished !? Copper bottom and CF100 top<br />

flange is done. Next step: Cut the stainless tube by 6.5mm, weld cold<br />

trap (Rene). Weld copper braid to clamp and rod (Bob) 10/29/09.<br />

Copper rod + braid + clamp done and shaped down. Coldtrap<br />

completely welded 11/20/09. Resistor needs to be <strong>at</strong>tached and<br />

jetflange on chamber rot<strong>at</strong>ed + new gas inlet + makeover of rainbow<br />

coils (see 198).<br />

164 D<strong>at</strong>a acquisition computer needs recovery Markus brought it to IT<br />

Service 3/20/2009; we might need to replace the harddrive. Totti<br />

picked it up. New Seag<strong>at</strong>e HD was installed. Upd<strong>at</strong>ed XP, Symantec<br />

and Spybot + defragmented C and D drive. Got rid of Spybot and<br />

Symantec and put Sophos on acqu. and analysis computer.<br />

165 New 120 spectrometer (copper pl<strong>at</strong>es + drift tube needed) Markus.<br />

Spectrometer parts and det. mounting in machine shop. Alu pipe<br />

ordered and arrived (4/29/09). Parts are in machine shop: copper<br />

pl<strong>at</strong>e in 80, drift tube etc. with Rene… Core is assembled by Christian.<br />

Drift follows… Resistors connected (06/25/09), Drift still missing. Done<br />

7/10/09 (incl. mesh in front of Recoil Ion Det).<br />

4/14/2009<br />

3/10/2010<br />

2/17/2010<br />

3/23/2009<br />

7/10/2009<br />

16

166 Long CF150 spool + bello <strong>for</strong> spectrometer + frame or stand has to be<br />

in place Markus. Parts designed and machine shop. Vacuum parts<br />

found – some need testing (see 175). Need to order 8020 parts: goes<br />

out with stuff <strong>for</strong> Christian <strong>for</strong> cart (4/24/09). Assembled (5/5/09).<br />

Vacuum test needed. Vacuum is fine (7/14/09)<br />

167 Rail <strong>for</strong> phosphor screen needs makeover Totti took it out of the<br />

chamber and brought it to the machine shop. Rene is on it 3/30/09.<br />

Totti fi(l)ne tuned the rail system and did a first adjustment. Should<br />

work a little better now. Totti noticed th<strong>at</strong> the black handle <strong>at</strong> the end<br />

got loose a little bit and tighten it again using both little setscrews<br />

(weak point)…<br />

168 One more layer of phosphor on the glasses would be nice Totti +<br />

David. More tests in the meantime shows th<strong>at</strong> it works the way it is <strong>for</strong><br />

now<br />

169 SAFETY: CSD guest procedure, Gasmanifold, JHA, AHD, OJT,<br />

Emergency Shutdown <strong>List</strong> have to be in place Totti (is in contact with<br />

Tracey Bigelow from HR; goes very slowly). Looks like EID can be<br />

issued perhaps 2 to 3 weeks in advance. PGI <strong>for</strong>m has to be filled out<br />

be<strong>for</strong>e by every guest by all means 4/14/09. W<strong>at</strong>ch out: There is a<br />

new PGI <strong>for</strong>m (un<strong>for</strong>tun<strong>at</strong>ely write protected). Because of th<strong>at</strong> and a<br />

missing internet interface <strong>at</strong> CSD we go via ALS again. We added a<br />

new AHD like document <strong>for</strong> people to read be<strong>for</strong>e they work with the<br />

<strong>COLTRIMS</strong> appar<strong>at</strong>us. The <strong>LBNL</strong> JHA system will face an overhaul<br />

within 6 to 12 months. We have to wait <strong>for</strong> this outcome.<br />

170 Apertures insets <strong>for</strong> slits in chamber needed Markus made one.<br />

Daniel may makes a better version (no not really).<br />

171 Program <strong>for</strong> autom<strong>at</strong>ic Backup (like FileSync) is needed Christian<br />

installed it. It should be implemented in the red background box. Totti<br />

put something together <strong>for</strong> coltrims/lbl and local account…<br />

172 Spectrometer simul<strong>at</strong>ions <strong>for</strong> He experiment Markus is on it. Done:<br />

Total spectrometer length 1.5 m<br />

173 SAFETY: Noise exposure in labs 102 and 104. Totti is in contact with<br />

Herb Toor and Rich Mc Clure from facilities <strong>for</strong> tests (Herb will show<br />

up in 104 Mar. 23; <strong>for</strong> 102 we have to give him a holler once the<br />

appar<strong>at</strong>us is running again). According to Herb: no probs (72 to 77db)<br />

in 104 and 106. Herb stopped by July 14, 09 to check the noise level<br />

in 102. It came out to 79db, which is no problem.<br />

Herb measured the compressed air nozzles (9/24/09). The have<br />

100dB – thus hearing protection is highly recommended. Totti put<br />

warning signs in the three labs.<br />

7/14/2009<br />

3/31/2009<br />

6/17/2010<br />

7/10/2009<br />

8/1/2009<br />

3/30/2009<br />

4/12/2009<br />

7/14/2009<br />

9/24/2009<br />

17

174 Get quote <strong>for</strong> modifying CF200 pipe by adding 2x CF35 flanges (77<br />

machine shop). Markus: 1000 $. Different solution found (see 175).<br />

175 Check recycled vacuum parts (bello and CF200 spool) <strong>for</strong> recoil ion<br />

spectrometer arm with Frank Zucca. Markus. Equipment is <strong>at</strong> pl<strong>at</strong>ing<br />

shop <strong>for</strong> UHV cleaning (4/21/09). With Frank <strong>for</strong> UHV test (4/24/09). 2<br />

out of 3 bellos are okay (bad one has label).<br />

176 Get compass to check magnetic field orient<strong>at</strong>ion of Helmholtz coils.<br />

Markus. Ordered <strong>at</strong> McMaster; arrived – is in toolbox<br />

177 SAFETY: New Controller Cart needs seismic safety <strong>at</strong> least <strong>for</strong> 102.<br />

Totti made drawings <strong>for</strong> the 8020 feet like <strong>at</strong> the chamber and gave<br />

them to Ken Shiler (5/28/09) – done (6/9/09). We need a unistrut bar<br />

and two long threaded rods <strong>for</strong> the ALS. Totti found unistrut bar and<br />

rods + nuts and washers (5/28/09). Bar and Rod need to be cut. Totti<br />

cut everything and assembled a bracket and labeled it (5/29/09).<br />

Christian needs to <strong>at</strong>tach 8020 brackets <strong>for</strong> <strong>at</strong>taching a chain (see 6):<br />

Did it (6/4/09). Totti found chain and quick connectors as well as<br />

shackles and bolted on some 8020 brackets: Might work – need<br />

second opinion (6/3/09). New McMaster feet and threaded rods have<br />

to be ordered – done and installed (6/18/09). Brackets are ready to be<br />

drilled to the floor – need to know position first (have to wait on<br />

Markus and Christian). Totti is in contact with Fred Angliss and James<br />

Mankini. Fred Angliss approved 3/8" Hilti HIS inserts with RE-500<br />

epoxy and 3/8" A193 grade B7 threaded rods installed with a hammer<br />

drill and carbide bit in accordance with ICC ESR-2322 (see<br />

http://www.icc-es.org/reports/pdf_files/ICC-ES/ESR-2322.pdf) and<br />

special inspection during install<strong>at</strong>ion. Contact Johnny Johnson x5371<br />

to schedule the inspection. Position <strong>for</strong> cart found and marked. New<br />

floor scanning is needed (HIS inserts go 5 in deep) – done 9/10/09.<br />

Monroe Thomas asked <strong>for</strong> Drill Permit. Monroe also has the epoxy<br />

glue which is needed <strong>for</strong> the HIS inserts (9/17/09). Everything drilled<br />

and glued 9/24/09. Totti and Rene drilled 0.5in holes in the brackets –<br />

everything fits.<br />

178 SAFETY: Totti got copper grounding pl<strong>at</strong>e from Steve Cooper <strong>for</strong> the<br />

new controller cart (7/14/09). Christian will get screws and mount it:<br />

Done. Diaphragm pumps need good grounding cable: Done. Strain<br />

relief on one pump and plug on the other one have to be fixed: Still<br />

has to go to Steve Cooper. Christian brought both pumps to Steve<br />

(8/20/09). Totti got them and reinstalled them in the cart.<br />

4/20/2009<br />

4/24/2009<br />

4/15/2009<br />

9/25/2009<br />

8/31/2009<br />

End of 2-Bunch-Run 8/2009<br />

18

179 (8/2/09) Ion getter pump <strong>at</strong> BL 11 has to be moved out of the way.<br />

Talk to Hendrik. Totti + Markus + Support<br />

9/29/09 Remind Hendrik again end of November, begin December<br />

(Shutdown in December). Totti writes email to Hendrik & Tolek<br />

10/28/09. Did it: got positive reply on this.<br />

12/07/09 Ion getter pump will not be moved away, but whole chamber<br />

disconnected from beamline. Center pipe will also be dismounted.<br />

180 (8/2/09) BL 11 needs glass valve <strong>for</strong> speeding up alignment process.<br />

Talk to Hendrik. Totti + Markus + Support. Bruce Rude has thicker<br />

glass window <strong>for</strong> VAT g<strong>at</strong>e valve to comply with safety standard. Tony<br />

Warwick has to be contacted and involved <strong>for</strong> the safety issues <strong>at</strong> the<br />

ALS. Totti spoke to Tony and Jim Floyd: No radi<strong>at</strong>ion problem just<br />

mechanical stability. Bruce Rude can give us the right window (he<br />

also has the tool to mount it). Totti writes email to Hendrik & Tolek<br />

10/28/09. Did it: got neg<strong>at</strong>ive reply on this. Wh<strong>at</strong> now ?<br />

= moved down<br />

181 (8/3/09) the new Helmholtz coils need two separ<strong>at</strong>e w<strong>at</strong>erlines to be<br />

reserved <strong>at</strong> BL 11. Talk to Hendrik. Totti + Markus + Support. Markus<br />

let w<strong>at</strong>erlines hanging <strong>at</strong> BL. Totti put remark on beamtime<br />

prepar<strong>at</strong>ion list (8/25/09):<br />

http://amo-csd.lbl.gov/downloads/Checklist%20<strong>for</strong>%20Beamtime.pdf<br />

182 (8/2/09) New Helmholtz coils need fix<strong>at</strong>ions: 8020 clamp on top and<br />

8020 (with brackets) <strong>at</strong> chamber frame (left and right post). Totti +<br />

Markus. 8020 brackets determined to be 5.5in long. Totti found 8020<br />

m<strong>at</strong>erial, cut it and mounted the pieces. We need to order brackets<br />

and plastic end caps from 8020 plus more Velcro straps from<br />

McMasters… (8/26/09). Totti orders from 8020. Markus orders from<br />

McMaster (9/10/09). 8020 arrived 9/19/09. Totti put plastic caps +<br />

brackets + velcro on 9/23/09. Test mount 8/25/09: works<br />

12/07/2009<br />

8/25/2009<br />

9/23/2009<br />

19

183 (8/2/09) New Helmholtz coils need makeover: Connectors, tie raps, …<br />

8020 arms need en<strong>for</strong>cement on the top part. Totti cut the w<strong>at</strong>er<br />

hoses short. Totti ordered some 8020 stuff – 9/10/09. 8020 stuff<br />

arrived and Totti put brackets on arms (not recommended to open)<br />

9/18/09. Totti cut plastic hose and put the screws on the Coils. Totti<br />

flipped the 8 Alu brackets to reverse up and down 9/21/09. Arms and<br />

coils were aligned and test-mounted 9/23/09. Totti and Markus put<br />

sleeve (McMaster 1459T17) around the power supply cables 9/24/09.<br />

6 feet are missing. Markus orders more… W<strong>at</strong>er hoses were cut short<br />

9/30/09. SAFETY: Need new cover (Totti got rid of the sharp edges of<br />

the interim cover). More sleeve arrived and Totti put it + low profile tie<br />

wraps + yellow tape on the cables <strong>at</strong> the power supply and the coils.<br />

Totti fixed the loose clamps on one coil 10/6/09. Markus designed<br />

cover and ordered m<strong>at</strong>erial; stuff is with Ken Shiler. Totti got parts and<br />

gave it a shot – doesn’t fit; brought it back to Ken Shiler. 10/28/09<br />

Covers are back. Totti found screws and assembled everything. Fits,<br />

but we need to close the big holes on the bottom. (Old covers are kept<br />

as spares in storage 2). Totti came up with sketch. With Ken Shiler<br />

10/29/09. Cover is done and fits 11/10/09<br />

184 (8/2/09) New controller cart should have rot<strong>at</strong>able wheels on backside<br />

too <strong>for</strong> better maneuverability. Markus will order from McMaster<br />

(30305T811); ordered 8/24/09. Wheels arrived and Totti mounted<br />

them 8/26/09.<br />

185 (8/2/09) 70l turbo pump (Alc<strong>at</strong>el) needs new place/mount <strong>at</strong> chamber<br />

frame (8020). Totti came up with idea and brought sketch + turbo +<br />

8020 (60x60) to Ken Shiler (8/26/09). Parts done 9/17/09. Totti got<br />

them and installed everything on <strong>COLTRIMS</strong> frame. Shorter KF25<br />

hose + curve and longer KF40 hose needed. Totti got everything and<br />

installed it.<br />

115 (8/2/09) Oil change <strong>for</strong> turbo pumps after beamtime (also the big<br />

guy?): Totti. Ordered <strong>for</strong> the 4 small turbo pumps (8/20/09) – the big<br />

guy looks ok, but second opinion is needed. Arrived 9/3/09. Installed<br />

by Totti (9/8/09).<br />

186 (8/2/09) Grounding pl<strong>at</strong>e on one side of the frame has to be moved to<br />

the other corner. Longer grounding cable desirable. Put back the<br />

grounding cable borrowed from MISTERS. Markus (8/26/09). Totti<br />

removed the grounding pl<strong>at</strong>e from inappropri<strong>at</strong>e position (pushed<br />

upwards and flipped to the inside) – 8/32/09.<br />

187 SAFETY: (8/2/09) more and longer plastic exhaust hoses are needed<br />

(order <strong>for</strong> MISTERS as well). Markus. Ordered. Arrived 3/9/09. Totti<br />

cut it and installed KF flanges.<br />

11/10/2009<br />

8/26/2009<br />

9/17/2009<br />

9/8/2009<br />

8/26/2009<br />

8/31/2009<br />

9/4/2009<br />

20

188 (8/2/09) labels are missing: @ mult. outlets of the controller cart and<br />

NIM rack (“Requires separ<strong>at</strong>e Fuse”); @ fan in controller cart (“start<br />

fan be<strong>for</strong>e switching on the controllers”) and fans in NIM rack. Totti did<br />

it (8/24/09).<br />

189 (8/4/09) Bring back Alc<strong>at</strong>el turbo pump to Frank Zucca after run.<br />

Markus<br />

190 (8/13/09) Transport<strong>at</strong>ion cart <strong>for</strong> new Helmholtz Coils needed. Markus<br />

put it together. Needs some more parts - Ken Shiler is on it (9/3/09).<br />

Markus put it together 9/23/09.<br />

191 (8/15/09) All cables (Lemo, BNC, SHV, controller cables) need check<br />

<strong>for</strong> bad shielding etc.<br />

=> moved down<br />

192 (8/15/09) Storage and Backup solution needed <strong>for</strong> analysis and<br />

backup PC’s (+ Server). Totti found “StarTech.com 3.5in Silver 4<br />

Drive eSATA Multi Raid External Hard Drive Encl.” in eBuy (CDW-G).<br />

Will order 2 of them after input from Frankfurt experts (Till + Jan).<br />

Ordered two towers (incl. controller card) plus one additional controller<br />

card (8/24/09)<br />

Parts: StarTech.com 3.5in Silver 4 Drive eSATA Multi RAID External<br />

Hard Drive Encl, Mfg. Part: SAT3540ER, CDW Part: 1584610,<br />

UNSPSC: 43201802, Hard drive array - 4 bays ( SATA-300 ) - 0 x HD<br />

- Serial ATA-300 (external), $226.00<br />

1 Port PCI Express es<strong>at</strong>a II controller card, StarTech.com ID:<br />

PEXESATA1, $23<br />

Stuff arrived and has been tested (9/4/09). Works fine <strong>for</strong> the most<br />

part. The SiI Manager software on the computer with the non original<br />

controller cart did not see the storage tower device. Totti called<br />

startech and fixed it (see below).<br />

If there is trouble with the non original controller card and “SiI<br />

Manager 4726” software download the l<strong>at</strong>est software from<br />

http://www.startech.com/. Search <strong>for</strong> Product “SAT3540ER” on the<br />

upper right hand of the webpage, download and unzip. Deinstall old<br />

drivers and manager software. Reboot. Then go “start”, “settings”,<br />

“control panel”, “add new hardware” and browse <strong>for</strong> the new “*.inf” file<br />

of the download while installing the driver. Then install new manager.<br />

There is a folder called “SAT3540ER” on the c:\ of TWeber-x09 with<br />

the files. (controller card can stay installed in the computer while doing<br />

all th<strong>at</strong>). [Altern<strong>at</strong>ive suggested by Startech support: PEXESATA2 as<br />

controller card instead of PEXESTA1; it runs the Sil3132.]<br />

8/26/2009<br />

9/23/2009<br />

9/04/2009<br />

21

193 SAFETY: (8/31/09) Electrical Inventory Inspection (Steve Chow et al.)<br />

• HP Duo Power Supply (<strong>for</strong> rainbow coils) needs strain relief in<br />

the back. EI-shop. Totti brought it to EI shop 9/21/09. Done<br />

9/23/09.<br />

• Keithley Voltmeter needs either a handle or a cover <strong>for</strong> the<br />

holes. Totti fixed it 8/31/09.<br />

• Seiko Seiki Turbo Pump Controller needs strain relief <strong>for</strong> AC<br />

power. Totti did it 8/31/09.<br />

• Belkacem power supply needs new terminal, fuse box, and AC<br />

power cover. EI-shop. Totti brought it to EI shop 9/23/09. Done<br />

9/23/09.<br />

• Variag needs new powercord. EI-shop. Totti brought it to EI<br />

shop 9/21/09. Done 9/23/09.<br />

• Small NIM bin needs powercord to be cut and hole closed. Totti<br />

did it 8/31/09.<br />

• Ion gauge cable has no strain relief. Totti fixed it 8/31/09.<br />

• Turbo pump controller cable has broken strain relief. Totti fixed<br />

it 8/31/09.<br />

• Thermovac controller cables have no strain relief. Totti fixed it<br />

8/31/09.<br />

• Nim Fan AC cord is frayed. EI-shop. Totti brought it to EI shop<br />

9/21/09. Done 9/23/09.<br />

• PicoAmp Meter needs new AC power cord. EI-shop. Totti<br />

brought it to EI shop 9/23/09. Done 11/16/09<br />

• MH Prior power supply has two prong AC power cable. Needs<br />

replacement. EI-shop. Totti brought it to EI shop 9/21/09. Done<br />

9/23/09.<br />

• Broken He<strong>at</strong>ing tapes. EI-shop. Totti brought one (new plug) to<br />

EI shop 9/23/09. The other one perhaps can be fixed with a<br />

Luesterklemme ? NO – got fixed with shrink hose (9/29/09)<br />

•<br />

2 Blue Diaphragm pumps need new power cords. Totti brought<br />

them to EI shop 11/12/09. Done 11/17/09<br />

Mike Bell has been contacted. Stacked all the devices in 106 <strong>for</strong> pick<br />

up by some EI shop guy. Have to check back on EI shop. They don’t<br />

pick it up – Totti brings it to EI shop in two loads (see above).<br />

11/17/2009<br />

194 Handle Bars <strong>for</strong> Controller cart would be nice. Totti ordered from 9/30/2009<br />

McMasters 9/29/09. Arrived 9/30/09 and were mounted.<br />

195 Safety (Security): Server Backup Computer needs new power<br />

supply. Totti did it 9/29/09. Server got new hard drives after boot<br />

sector problems 12/22/09.<br />

9/29/2009<br />

12/22/2009<br />

22

196 11/17/09 Fast Lothar NIM CFD’s need test <strong>for</strong> time jitter or walk<br />

problem according to Markus’ analysis. Markus runs test and is in<br />

contact with Lothar – might exchange or repair them over Christmas.<br />

Lothar things it was a bad walk and threshold adjustment. No test<br />

were done.<br />

197 <br />

12/15/09 Look <strong>for</strong> CO and order, also talk to Donna. Markus ordered 2<br />

midsize bottles. Bottle arrived and is outside building 7 (locked).<br />

Bottles labeled<br />

and put in ALS gas storage.<br />

198 12/15/09 Resize Helmholtz cage after moving? May be needs to be a<br />

little bigger. Markus: New Cable/Clamps and Rods are ordered and<br />

arrived. Cage posts need to be further apart + old and new rods need<br />

to be cut + install new cable. 1/7/10 Totti made new stand-offs in<br />

machine shop and mounted them. Exchanged Al rods <strong>at</strong> the vertical<br />

side. New horizontal rods need to be measured, cut and mounted:<br />

Done 1/8/10. Florian and Totti adjusted height (1/20/10). Florian and<br />

Irina installed computer cable. Resistance checked. Should work.<br />

Some cables still need to be fastened to the frame.<br />

199 <br />

12/1/09 CO spectrometer simul<strong>at</strong>ion: Design is almost finished<br />

(12/20/09). Drift tube needs to be cut + tapped holes <strong>for</strong> feet installed.<br />

CF 150-250 Adapter is needed. 8020 support <strong>for</strong> CF250<br />

spool needs<br />

to be built. Check CF250 spool (is out of the dumpster). Markus brings<br />

hexanode and mesh from Frankfurt. Totti borrowed 13 ¼ to 8 in flange<br />

(Frank Zucca) and 13 ¼ to 2 ¾ flange (Eli Rothenburg); a second 13<br />

¼ to 8 in flange would be better – got it from Bruce Rude (1/14/10).<br />

Florian and Markus build spectrometer and fitted it into chamber<br />

(3/10/10)<br />

163 12/1/09 Jet cooling still needs to be put together and tested. Gas inlet<br />

is missing. Glands have to be ordered and welded to new stainless<br />

steel tube – Glands arrived 1/710. Florian brought it to 77 (1/22/10).<br />

Parts came back and were installed. Leak found on nozzle to copper<br />

block connection (insert was tightened). Works but no big<br />

improvement <strong>for</strong> cold jet (-125C <strong>at</strong> Nozzle, -153C <strong>at</strong> Coldtrap Copper<br />

rod, ideal would be -196C).<br />

200 1/19/10 D<strong>at</strong>a acquisition computer crashed with blue screen<br />

and was<br />

unstable after reboot. Totti imaged oper<strong>at</strong>ing system to a new<br />

harddrive with IT service and exchanged SATA cable.<br />

201 1/26/10 Connectors <strong>for</strong> 12pin feedthrough (anode) and perhaps <strong>for</strong><br />

SHV feedthroughs are needed. Florian found pins <strong>at</strong> http://www.multicontact-usa.com<br />

– part-number 41.6000, type B1-TH (1/26/10).<br />

Orderd and arrived. Florian made new cables<br />

20/12/2009<br />

2/11/2010<br />

3/12/2010<br />

3/10/2010<br />

2/17/10<br />

1/20/10<br />

2/5/2010<br />

23

202 SAFETY: (2/17/10) Jet cold trap sends condens<strong>at</strong>e w<strong>at</strong>er on rainbow<br />

coils, Helmholtz coils, floor and perhaps a pump if loc<strong>at</strong>ed<br />

underne<strong>at</strong>h. Foam or w<strong>at</strong>er collector is needed. Markus ordered three<br />

sponges and some absorbent m<strong>at</strong>erial (3/5/10) . Test needed.<br />

Absorbent m<strong>at</strong>erial didn’t help much. Totti installed some sponges.<br />

Test needed (4/2/10)<br />

203 <br />

New spectrometer pl<strong>at</strong>es m<strong>at</strong>e from phosphor bronze – ordered <strong>at</strong><br />

McMaster. They were supposed to be fl<strong>at</strong> (not from a coil), but have<br />

still been curved too much. Even with putting <strong>for</strong>ce on the mounted<br />

spectrometer stack, the<br />

distance between two pl<strong>at</strong>es can exceed 30<br />

%. -> Don’t take phosphor bronze from McMaster <strong>for</strong><br />

spectrometer pl<strong>at</strong>es!!! Markus<br />

4/2/2010<br />

2/26/2010<br />

204 (3/9/10) Allen and Markus gave feedback about drifting and jumping<br />

spectrometer voltage: Totti ordered two Stand<strong>for</strong>d PS325 and a<br />

rackmount (3/9/10)<br />

3/9/2010<br />

115 Oil <strong>for</strong> big turbo pump needed: Markus ordered from Pfeiffer (2/15/10). 6/10/2010<br />

Arrived 3/10/10. Needs to be filled in… Done 6/10/10<br />

End of 2-Bunch-Run 4/2010<br />

24