The items listed below are all included in TRD's ... - Fluidraulics Inc

The items listed below are all included in TRD's ... - Fluidraulics Inc

The items listed below are all included in TRD's ... - Fluidraulics Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BSPT British Standard Pipe Taper<br />

British Standard Pipe Taper (BSPT) threads have the same taper<br />

as American NPT tapered threads, but use a 55° Whitworth<br />

thread form and different diameters. (Not <strong>in</strong>terchangeable with NPT)<br />

BSPP<br />

British Standard Pipe Par<strong>all</strong>el<br />

British Standard Pipe Par<strong>all</strong>el (BSPP), also referred to as BSP<br />

“Straight” Thread. (Not <strong>in</strong>terchangeable with NPT)<br />

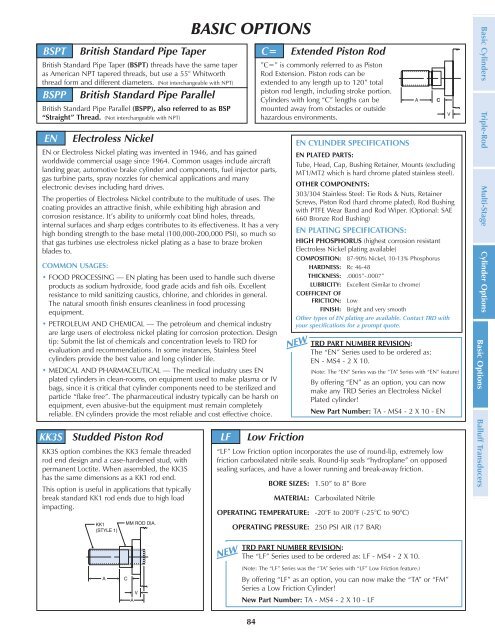

BASIC OPTIONS<br />

EN or Electroless Nickel plat<strong>in</strong>g was <strong>in</strong>vented <strong>in</strong> 1946, and has ga<strong>in</strong>ed<br />

worldwide commercial usage s<strong>in</strong>ce 1964. Common usages <strong>in</strong>clude aircraft<br />

land<strong>in</strong>g gear, automotive brake cyl<strong>in</strong>der and components, fuel <strong>in</strong>jector parts,<br />

gas turb<strong>in</strong>e parts, spray nozzles for chemical applications and many<br />

electronic devises <strong>in</strong>clud<strong>in</strong>g hard drives.<br />

<strong>The</strong> properties of Electroless Nickel contribute to the multitude of uses. <strong>The</strong><br />

coat<strong>in</strong>g provides an attractive f<strong>in</strong>ish, while exhibit<strong>in</strong>g high abrasion and<br />

corrosion resistance. It’s ability to uniformly coat bl<strong>in</strong>d holes, threads,<br />

<strong>in</strong>ternal surfaces and sharp edges contributes to its effectiveness. It has a very<br />

high bond<strong>in</strong>g strength to the base metal (100,000-200,000 PSI), so much so<br />

that gas turb<strong>in</strong>es use electroless nickel plat<strong>in</strong>g as a base to braze broken<br />

blades to.<br />

COMMON USAGES:<br />

• FOOD PROCESSING — EN plat<strong>in</strong>g has been used to handle such diverse<br />

products as sodium hydroxide, food grade acids and fish oils. Excellent<br />

resistance to mild sanitiz<strong>in</strong>g caustics, chlor<strong>in</strong>e, and chlorides <strong>in</strong> general.<br />

<strong>The</strong> natural smooth f<strong>in</strong>ish ensures cleanl<strong>in</strong>ess <strong>in</strong> food process<strong>in</strong>g<br />

equipment.<br />

• PETROLEUM AND CHEMICAL — <strong>The</strong> petroleum and chemical <strong>in</strong>dustry<br />

<strong>are</strong> large users of electroless nickel plat<strong>in</strong>g for corrosion protection. Design<br />

tip: Submit the list of chemicals and concentration levels to TRD for<br />

evaluation and recommendations. In some <strong>in</strong>stances, Sta<strong>in</strong>less Steel<br />

cyl<strong>in</strong>ders provide the best value and long cyl<strong>in</strong>der life.<br />

• MEDICAL AND PHARMACEUTICAL — <strong>The</strong> medical <strong>in</strong>dustry uses EN<br />

plated cyl<strong>in</strong>ders <strong>in</strong> clean-rooms, on equipment used to make plasma or IV<br />

bags, s<strong>in</strong>ce it is critical that cyl<strong>in</strong>der components need to be sterilized and<br />

particle “flake free”. <strong>The</strong> pharmaceutical <strong>in</strong>dustry typic<strong>all</strong>y can be harsh on<br />

equipment, even abusive-but the equipment must rema<strong>in</strong> completely<br />

reliable. EN cyl<strong>in</strong>ders provide the most reliable and cost effective choice.<br />

84<br />

C= Extended Piston Rod<br />

”C=” is commonly referred to as Piston<br />

Rod Extension. Piston rods can be<br />

extended to any length up to 120” total<br />

piston rod length, <strong>in</strong>clud<strong>in</strong>g stroke portion.<br />

Cyl<strong>in</strong>ders with long “C” lengths can be<br />

mounted away from obstacles or outside<br />

hazardous environments.<br />

EN Electroless Nickel EN CYLINDER SPECIFICATIONS<br />

KK3S Studded Piston Rod<br />

KK3S option comb<strong>in</strong>es the KK3 female threaded<br />

rod end design and a case-hardened stud, with<br />

permanent Loctite. When assembled, the KK3S<br />

has the same dimensions as a KK1 rod end.<br />

This option is useful <strong>in</strong> applications that typic<strong>all</strong>y<br />

break standard KK1 rod ends due to high load<br />

impact<strong>in</strong>g.<br />

EN PLATED PARTS:<br />

Tube, Head, Cap, Bush<strong>in</strong>g Reta<strong>in</strong>er, Mounts (exclud<strong>in</strong>g<br />

MT1/MT2 which is hard chrome plated sta<strong>in</strong>less steel).<br />

OTHER COMPONENTS:<br />

303/304 Sta<strong>in</strong>less Steel: Tie Rods & Nuts, Reta<strong>in</strong>er<br />

Screws, Piston Rod (hard chrome plated), Rod Bush<strong>in</strong>g<br />

with PTFE Wear Band and Rod Wiper. (Optional: SAE<br />

660 Bronze Rod Bush<strong>in</strong>g)<br />

EN PLATING SPECIFICATIONS:<br />

HIGH PHOSPHORUS (highest corrosion resistant<br />

Electroless Nickel plat<strong>in</strong>g available)<br />

COMPOSITION: 87-90% Nickel, 10-13% Phosphorus<br />

HARDNESS: Rc 46-48<br />

THICKNESS: .0005”-.0007”<br />

LUBRICITY: Excellent (Similar to chrome)<br />

COEFFICENT OF<br />

FRICTION: Low<br />

FINISH: Bright and very smooth<br />

Other types of EN plat<strong>in</strong>g <strong>are</strong> available. Contact TRD with<br />

your specifications for a prompt quote.<br />

NEW<br />

LF Low Friction<br />

TRD PART NUMBER REVISION:<br />

<strong>The</strong> “EN” Series used to be ordered as:<br />

EN - MS4 - 2 X 10.<br />

(Note: <strong>The</strong> “EN” Series was the “TA” Series with “EN” feature)<br />

By offer<strong>in</strong>g “EN” as an option, you can now<br />

make any TRD Series an Electroless Nickel<br />

Plated cyl<strong>in</strong>der!<br />

New Part Number: TA - MS4 - 2 X 10 - EN<br />

“LF” Low Friction option <strong>in</strong>corporates the use of round-lip, extremely low<br />

friction carboxilated nitrile seals. Round-lip seals “hydroplane” on opposed<br />

seal<strong>in</strong>g surfaces, and have a lower runn<strong>in</strong>g and break-away friction.<br />

BORE SIZES: 1.50” to 8” Bore<br />

MATERIAL: Carboxilated Nitrile<br />

OPERATING TEMPERATURE: -20°F to 200°F (-25°C to 90°C)<br />

NEW<br />

OPERATING PRESSURE: 250 PSI AIR (17 BAR)<br />

TRD PART NUMBER REVISION:<br />

<strong>The</strong> “LF” Series used to be ordered as: LF - MS4 - 2 X 10.<br />

(Note: <strong>The</strong> “LF” Series was the “TA” Series with “LF” Low Friction feature.)<br />

By offer<strong>in</strong>g “LF” as an option, you can now make the “TA” or “FM”<br />

Series a Low Friction Cyl<strong>in</strong>der!<br />

New Part Number: TA - MS4 - 2 X 10 - LF<br />

Basic Options B<strong>all</strong>uff Transducers<br />

Basic Cyl<strong>in</strong>ders Triple-Rod Multi-Stage Cyl<strong>in</strong>der Options