Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Die nachfolgend präsentierten Ergebnisse in diesem<br />

Jahresbericht machen die hohe Attraktivität<br />

der Forschung zu optischen Fasern und Faseranwendungen<br />

deutlich und bieten in Kombination<br />

mit dem komplementären Arbeitsgebiet zur<br />

photonischen Instrumentierung im <strong>IPHT</strong> breite<br />

zukünftige Anwendungsmöglichkeiten.<br />

OPTIK / OPTICS<br />

40<br />

2.2. Scientific Results<br />

2.2.1 Flame hydrolysis technique (FHD)<br />

for the preparation of advanced<br />

optical materials<br />

(C. Aichele, St. Grimm, M. Köhler,<br />

K. Schuster)<br />

The flame hydrolysis technique allows the production<br />

of highest quality silica. This material is<br />

primarily used for planar optical waveguide<br />

devices and components or for the deposition of<br />

substrate tubes by OVD (Outside Vapor Deposition).<br />

To utilize the potential of this technology we<br />

are engaged in new applications.<br />

The recent concentration of microlithography on<br />

an excitation wavelength of 193 nm requires an<br />

improvement of the optical materials and devices<br />

used.<br />

For high power density and excellent replication<br />

quality, materials are necessary which provide<br />

special, very well-defined properties in terms of<br />

optical quality as well as type and distribution of<br />

the dopant hydrogen. The flame hydrolysis technique<br />

enables the preparation of a high-quality<br />

quartz glass material combined with the implementation<br />

of different dopant distributions in a<br />

wide range.<br />

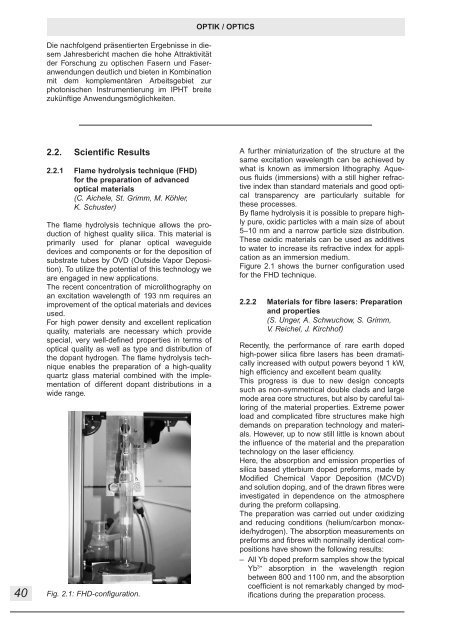

Fig. 2.1: FHD-configuration.<br />

A further miniaturization of the structure at the<br />

same excitation wavelength can be achieved by<br />

what is known as immersion lithography. Aqueous<br />

fluids (immersions) with a still higher refractive<br />

index than standard materials and good optical<br />

transparency are particularly suitable for<br />

these processes.<br />

By flame hydrolysis it is possible to prepare highly<br />

pure, oxidic particles with a main size of about<br />

5–10 nm and a narrow particle size distribution.<br />

These oxidic materials can be used as additives<br />

to water to increase its refractive index for application<br />

as an immersion medium.<br />

Figure 2.1 shows the burner configuration used<br />

for the FHD technique.<br />

2.2.2 Materials for fibre lasers: Preparation<br />

and properties<br />

(S. Unger, A. Schwuchow, S. Grimm,<br />

V. Reichel, J. Kirchhof)<br />

Recently, the performance of rare earth doped<br />

high-power silica fibre lasers has been dramatically<br />

increased with output powers beyond 1 kW,<br />

high efficiency and excellent beam quality.<br />

This progress is due to new design concepts<br />

such as non-symmetrical double clads and large<br />

mode area core structures, but also by careful tailoring<br />

of the material properties. Extreme power<br />

load and complicated fibre structures make high<br />

demands on preparation technology and materials.<br />

However, up to now still little is known about<br />

the influence of the material and the preparation<br />

technology on the laser efficiency.<br />

Here, the absorption and emission properties of<br />

silica based ytterbium doped preforms, made by<br />

Modified Chemical Vapor Deposition (MCVD)<br />

and solution doping, and of the drawn fibres were<br />

investigated in dependence on the atmosphere<br />

during the preform collapsing.<br />

The preparation was carried out under oxidizing<br />

and reducing conditions (helium/carbon monoxide/hydrogen).<br />

The absorption measurements on<br />

preforms and fibres with nominally identical compositions<br />

have shown the following results:<br />

– All Yb doped preform samples show the typical<br />

Yb 3+ absorption in the wavelength region<br />

between 800 and 1100 nm, and the absorption<br />

coefficient is not remarkably changed by modifications<br />

during the preparation process.