You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LASERTECHNIK / LASER TECHNOLOGY<br />

Dank besonderem Engagement aller Mitarbeiter<br />

konnte der Bereich Lasertechnik <strong>2005</strong> trotz der<br />

verschärften Situation bei den öffentlichen Fördermitteln<br />

und des allgemein geringen Wirtschaftswachstums<br />

sein Niveau bei den Drittmittelprojekten,<br />

Veröffentlichungen und Patenten wenigstens<br />

in etwa halten. Das Drittmittelaufkommen von rund<br />

1,0 Mio “ liegt merklich unter dem Niveau des Vorjahres<br />

(1,2 Mio “). Insgesamt haben jedoch die<br />

mit dem Umzug erreichten kurzen Wege zu den<br />

anderen <strong>IPHT</strong>-Forschungsbereichen einen deutlichen<br />

Zuwachs bei der bereichsübergreifenden<br />

Zusammenarbeit bewirkt.<br />

generally poor rate of economic growth. The project<br />

funds in <strong>2005</strong> of about 1.0 Mio are close to<br />

the amount of 2004 (1.2 Mio “). Overall the move<br />

to the Beutenberg campus yielded, however, a<br />

considerable strengthening of trans-divisional<br />

cooperation due to the short distances to the<br />

other <strong>IPHT</strong> research divisions.<br />

4.2 Selected Results<br />

4.2.1 Laser chemistry<br />

Laser chemistry at <strong>IPHT</strong> is essentially concerned<br />

with the deposition of thin films and thin film systems,<br />

their physicochemical modification (particularly<br />

laser crystallisation) and some special<br />

items like spectroscopic diagnostics of thin film<br />

processing, nanowire preparation, and fs laser<br />

micromachining.<br />

Laser crystallisation<br />

(Gudrun Andrä, Joachim Bergmann,<br />

Arne Bochmann, Fritz Falk, Annett Gawlik,<br />

Ekkehardt Ose)<br />

For several years, <strong>IPHT</strong> has been aiming at the<br />

preparation of thin film solar cells consisting of<br />

large grained crystalline silicon on glass. The<br />

development of this new cell type is based on the<br />

deposition of amorphous silicon either by plasma<br />

CVD from SiH 4 (13.6 MHz) or by electron beam<br />

evaporation of bulk silicon and its in situ laser<br />

crystallisation. In a first step large crystal grains<br />

are obtained from 300–500 nm thick amorphous<br />

silicon layers by cw laser crystallisation (seed<br />

layer formation). Subsequently the seed layer<br />

undergoes epitaxial thickening by pulsed Layered<br />

Laser Crystallisation (LLC), an <strong>IPHT</strong> patented<br />

method. So far laboratory cells with an open circuit<br />

voltage of 510 mV and a conversion efficiency<br />

of 4.8% based on an absorber thickness of<br />

5 µm were obtained. Recent work addressed the<br />

acceleration (industrial application) and optimisation<br />

of the seed layer formation by applying a<br />

700 W diode laser focused to a line and scanned<br />

across the substrates to achieve crystallite sizes<br />

of 0.1 to several mm (cf. coloured page). Additional<br />

progress for the solar cell performance is<br />

expected from improving light trapping, improving<br />

contact and shunt resistances as well as minimising<br />

charge carrier recombination. The related<br />

work benefits from the discussions and cooperation<br />

with the Hahn-Meitner-Institute (HMI) at<br />

Berlin, Solar-Zentrum Erfurt at CiS, Ersol company<br />

at Erfurt, and INPUT Solar, a Thuringian association<br />

of photovoltaic industrial companies and<br />

R&D institutes.<br />

Thin film deposition and nanowire growth<br />

(Gudrun Andrä, Fritz Falk, Herbert Stafast,<br />

Thomas Stelzner)<br />

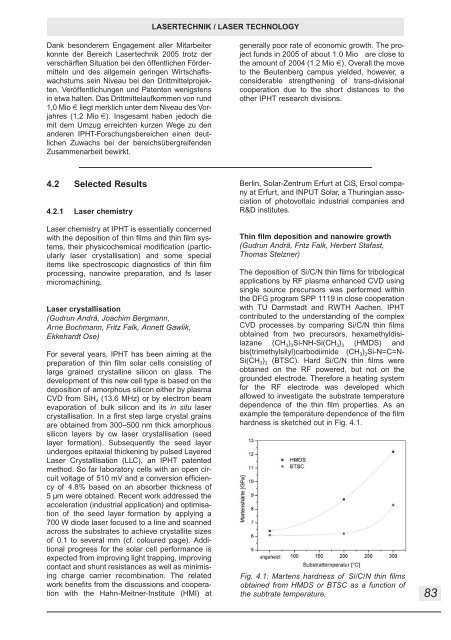

The deposition of Si/C/N thin films for tribological<br />

applications by RF plasma enhanced CVD using<br />

single source precursors was performed within<br />

the DFG program SPP 1119 in close cooperation<br />

with TU Darmstadt and RWTH Aachen. <strong>IPHT</strong><br />

contributed to the understanding of the complex<br />

CVD processes by comparing Si/C/N thin films<br />

obtained from two precursors, hexamethyldisilazane<br />

(CH 3 ) 3 Si-NH-Si(CH 3 ) 3 (HMDS) and<br />

bis(trimethylsilyl)carbodiimide (CH 3 ) 3 Si-N=C=N-<br />

Si(CH 3 ) 3 (BTSC). Hard Si/C/N thin films were<br />

obtained on the RF powered, but not on the<br />

grounded electrode. Therefore a heating system<br />

for the RF electrode was developed which<br />

allowed to investigate the substrate temperature<br />

dependence of the thin film properties. As an<br />

example the temperature dependence of the film<br />

hardness is sketched out in Fig. 4.1.<br />

Fig. 4.1: Martens hardness of Si/C/N thin films<br />

obtained from HMDS or BTSC as a function of<br />

the subtrate temperature.<br />

83