GL – Mapping the Future in Offshore Wind - Germanischer Lloyd

GL – Mapping the Future in Offshore Wind - Germanischer Lloyd

GL – Mapping the Future in Offshore Wind - Germanischer Lloyd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The <strong>GL</strong> Group <strong>–</strong> a synergy of global knowledge and local expertise<br />

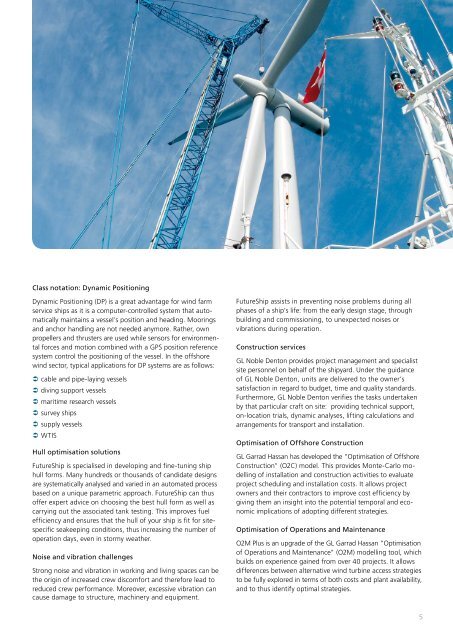

Class notation: Dynamic Position<strong>in</strong>g<br />

Dynamic Position<strong>in</strong>g (DP) is a great advantage for w<strong>in</strong>d farm<br />

service ships as it is a computer-controlled system that automatically<br />

ma<strong>in</strong>ta<strong>in</strong>s a vessel’s position and head<strong>in</strong>g. Moor<strong>in</strong>gs<br />

and anchor handl<strong>in</strong>g are not needed anymore. Ra<strong>the</strong>r, own<br />

propellers and thrusters are used while sensors for environmental<br />

forces and motion comb<strong>in</strong>ed with a GPS position reference<br />

system control <strong>the</strong> position<strong>in</strong>g of <strong>the</strong> vessel. In <strong>the</strong> offshore<br />

w<strong>in</strong>d sector, typical applications for DP systems are as follows:<br />

ÂÂcable and pipe-lay<strong>in</strong>g vessels<br />

ÂÂdiv<strong>in</strong>g support vessels<br />

ÂÂmaritime research vessels<br />

ÂÂsurvey ships<br />

ÂÂsupply vessels<br />

ÂÂWTIS<br />

Hull optimisation solutions<br />

<strong>Future</strong>Ship is specialised <strong>in</strong> develop<strong>in</strong>g and f<strong>in</strong>e-tun<strong>in</strong>g ship<br />

hull forms. Many hundreds or thousands of candidate designs<br />

are systematically analysed and varied <strong>in</strong> an automated process<br />

based on a unique parametric approach. <strong>Future</strong>Ship can thus<br />

offer expert advice on choos<strong>in</strong>g <strong>the</strong> best hull form as well as<br />

carry<strong>in</strong>g out <strong>the</strong> associated tank test<strong>in</strong>g. This improves fuel<br />

efficiency and ensures that <strong>the</strong> hull of your ship is fit for sitespecific<br />

seakeep<strong>in</strong>g conditions, thus <strong>in</strong>creas<strong>in</strong>g <strong>the</strong> number of<br />

operation days, even <strong>in</strong> stormy wea<strong>the</strong>r.<br />

Noise and vibration challenges<br />

Strong noise and vibration <strong>in</strong> work<strong>in</strong>g and liv<strong>in</strong>g spaces can be<br />

<strong>the</strong> orig<strong>in</strong> of <strong>in</strong>creased crew discomfort and <strong>the</strong>refore lead to<br />

reduced crew performance. Moreover, excessive vibration can<br />

cause damage to structure, mach<strong>in</strong>ery and equipment.<br />

<strong>Future</strong>Ship assists <strong>in</strong> prevent<strong>in</strong>g noise problems dur<strong>in</strong>g all<br />

phases of a ship’s life: from <strong>the</strong> early design stage, through<br />

build<strong>in</strong>g and commission<strong>in</strong>g, to unexpected noises or<br />

vibrations dur<strong>in</strong>g operation.<br />

Construction services<br />

<strong>GL</strong> Noble Denton provides project management and specialist<br />

site personnel on behalf of <strong>the</strong> shipyard. Under <strong>the</strong> guidance<br />

of <strong>GL</strong> Noble Denton, units are delivered to <strong>the</strong> owner’s<br />

satisfaction <strong>in</strong> regard to budget, time and quality standards.<br />

Fur<strong>the</strong>rmore, <strong>GL</strong> Noble Denton verifies <strong>the</strong> tasks undertaken<br />

by that particular craft on site: provid<strong>in</strong>g technical support,<br />

on-location trials, dynamic analyses, lift<strong>in</strong>g calculations and<br />

arrangements for transport and <strong>in</strong>stallation.<br />

Optimisation of <strong>Offshore</strong> Construction<br />

<strong>GL</strong> Garrad Hassan has developed <strong>the</strong> "Optimisation of <strong>Offshore</strong><br />

Construction" (O2C) model. This provides Monte-Carlo modell<strong>in</strong>g<br />

of <strong>in</strong>stallation and construction activities to evaluate<br />

project schedul<strong>in</strong>g and <strong>in</strong>stallation costs. It allows project<br />

owners and <strong>the</strong>ir contractors to improve cost efficiency by<br />

giv<strong>in</strong>g <strong>the</strong>m an <strong>in</strong>sight <strong>in</strong>to <strong>the</strong> potential temporal and economic<br />

implications of adopt<strong>in</strong>g different strategies.<br />

Optimisation of Operations and Ma<strong>in</strong>tenance<br />

O2M Plus is an upgrade of <strong>the</strong> <strong>GL</strong> Garrad Hassan "Optimisation<br />

of Operations and Ma<strong>in</strong>tenance" (O2M) modell<strong>in</strong>g tool, which<br />

builds on experience ga<strong>in</strong>ed from over 40 projects. It allows<br />

differences between alternative w<strong>in</strong>d turb<strong>in</strong>e access strategies<br />

to be fully explored <strong>in</strong> terms of both costs and plant availability,<br />

and to thus identify optimal strategies.<br />

5