2013 GRAND-AM Rulebook

2013 GRAND-AM Rulebook

2013 GRAND-AM Rulebook

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

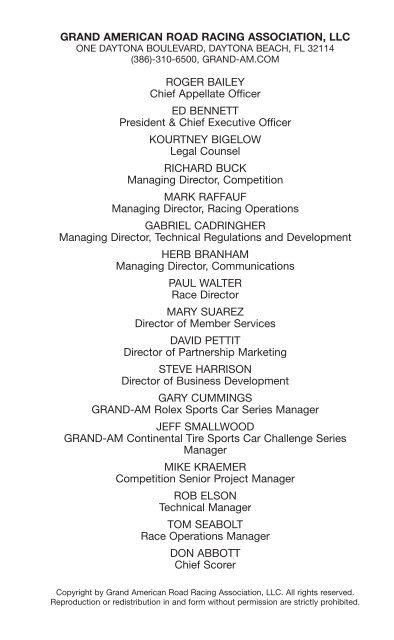

<strong>GRAND</strong> <strong>AM</strong>ERICAN ROAD RACING ASSOCIATION, LLC<br />

ONE DAYTONA BOULEVARD, DAYTONA BEACH, FL 32114<br />

(386)-310-6500, <strong>GRAND</strong>-<strong>AM</strong>.COM<br />

ROGER BAILEY<br />

Chief Appellate Officer<br />

ED BENNETT<br />

President & Chief Executive Officer<br />

KOURTNEY BIGELOW<br />

Legal Counsel<br />

RICHARD BUCK<br />

Managing Director, Competition<br />

MARK RAFFAUF<br />

Managing Director, Racing Operations<br />

GABRIEL CADRINGHER<br />

Managing Director, Technical Regulations and Development<br />

HERB BRANH<strong>AM</strong><br />

Managing Director, Communications<br />

PAUL WALTER<br />

Race Director<br />

MARY SUAREZ<br />

Director of Member Services<br />

DAVID PETTIT<br />

Director of Partnership Marketing<br />

STEVE HARRISON<br />

Director of Business Development<br />

GARY CUMMINGS<br />

<strong>GRAND</strong>-<strong>AM</strong> Rolex Sports Car Series Manager<br />

JEFF SMALLWOOD<br />

<strong>GRAND</strong>-<strong>AM</strong> Continental Tire Sports Car Challenge Series<br />

Manager<br />

MIKE KRAEMER<br />

Competition Senior Project Manager<br />

ROB ELSON<br />

Technical Manager<br />

TOM SEABOLT<br />

Race Operations Manager<br />

DON ABBOTT<br />

Chief Scorer<br />

Copyright by Grand American Road Racing Association, LLC. All rights reserved.<br />

Reproduction or redistribution in and form without permission are strictly prohibited.

<strong>GRAND</strong>-<strong>AM</strong><br />

FOREWORD<br />

These are exciting times in sports car racing.<br />

Back in September, the landmark merger of <strong>GRAND</strong>-<strong>AM</strong> Road<br />

Racing and the American Le Mans Series was announced at<br />

Daytona International Speedway. Both series will combine their<br />

banners in 2014 when we operate as a unified series, a move that<br />

has attracted the attention of the international motorsports community.<br />

With the unification as a backdrop, we are embarking on another<br />

competitive season. We look forward to competing at Circuit of The<br />

Americas, Kansas Speedway and Road Atlanta for the first time in<br />

addition to returning to many of America’s finest venues.<br />

The <strong>GRAND</strong>-<strong>AM</strong> <strong>Rulebook</strong> contains the rules and procedures<br />

governing <strong>GRAND</strong>-<strong>AM</strong>’s Rolex Sports Car Series and Continental<br />

Tire Sports Car Challenge. Revisions include the new Rolex Series<br />

GX class. We urge you to carefully study the new <strong>Rulebook</strong>, in order<br />

to familiarize yourself with these revisions as well as the rules which<br />

have not changed.<br />

<strong>GRAND</strong>-<strong>AM</strong> will continue to strive for a balanced playing field, with<br />

a full starting field of various car makes and models in each race<br />

that are as equally matched as possible. To maintain proper<br />

balance, it may be necessary to make occasional rule changes<br />

and/or modifications to ensure the proper balance in the competition<br />

arena.<br />

We all at <strong>GRAND</strong>-<strong>AM</strong> wish all of you a successful and rewarding<br />

year of racing.<br />

<strong>GRAND</strong>-<strong>AM</strong> Road Racing continues to strive to make sports car<br />

road racing highly competitive, affordable and entertaining for<br />

racing fans and competitors. One of the tools that we use for this<br />

purpose is the <strong>GRAND</strong>-<strong>AM</strong> <strong>Rulebook</strong>, which contains the rules and<br />

iii

procedures governing all <strong>GRAND</strong>-<strong>AM</strong> sanctioned on-track activities.<br />

In <strong>2013</strong>, the <strong>GRAND</strong>-<strong>AM</strong> <strong>Rulebook</strong> has been revised in several<br />

respects. We urge you to carefully study the new <strong>Rulebook</strong> in order<br />

to familiarize yourself with these revisions, as well as the rules that<br />

have not changed. If you have any questions or need rules clarifications,<br />

please contact a Senior <strong>GRAND</strong>-<strong>AM</strong> Official.<br />

In keeping with <strong>GRAND</strong>-<strong>AM</strong>’s commitment to maintain proper<br />

balance in the competition arena, it may be necessary for <strong>GRAND</strong>-<br />

<strong>AM</strong> to make rule changes and/or rule modifications from<br />

time-to-time. Such changes are designed to enhance close competition.<br />

<strong>GRAND</strong>-<strong>AM</strong>’s goal of a full starting field of various car makes<br />

and models in each race that are as equally matched as possible is<br />

in the overall best interest of the sport. That is what <strong>GRAND</strong>-<strong>AM</strong> has<br />

strived for in the past and will continue to strive for in the future.<br />

We all at <strong>GRAND</strong>-<strong>AM</strong> wish all of you a successful and rewarding<br />

year of racing.<br />

Ed Bennett<br />

President & CEO

TABLE OF CONTENTS<br />

Page<br />

SPORTING REGULATIONS<br />

SECTION 1 – GENERAL RULES PROCEDURE<br />

1-1 Applicability ......................................................................2<br />

1-2 Amendments.....................................................................2<br />

1-3 Definitions and Terms .......................................................2<br />

1-4 Interpreting and Applying the Regulations .......................5<br />

1-5 Interpretation and Application ..........................................5<br />

1-6 Principle Rule....................................................................6<br />

1-7 Submission to the Regulations.........................................6<br />

SECTION 2 – MEMBERSHIP<br />

2-1 Authority ...........................................................................6<br />

2-2 Reservation of Rights .......................................................7<br />

2-3 Membership Requirement ................................................7<br />

2-4 Application Procedure ......................................................7<br />

2-5 Eligibility Requirements ....................................................8<br />

2-6 Credentials........................................................................9<br />

2-7 Member Status .................................................................9<br />

2-8 Member Conduct............................................................11<br />

2-9 Entrant Obligations .........................................................12<br />

2-10 Substance Abuse Policy.................................................13<br />

SECTION 3 – ADMINISTRATION OF EVENTS<br />

3-1 Event ..............................................................................15<br />

3-2 Safety..............................................................................16<br />

3.3 Testing Policy..................................................................18<br />

3-3 Event Entry .....................................................................19<br />

3-4 <strong>GRAND</strong>-<strong>AM</strong> Officials ......................................................20<br />

3-5 Identification Markings ...................................................21<br />

SECTION 4 – FLAGS AND COMMUNICATION<br />

4-1 On-Track Communication...............................................22<br />

4-2 Black ...............................................................................22<br />

4-3 Black with Orange Disc ..................................................22<br />

4-4 Black & White Checkered...............................................22<br />

4-5 Blue or Blue with Orange Diagonal ................................22<br />

4-6 Green ..............................................................................23<br />

4-7 Red .................................................................................23<br />

4-8 Yellow..............................................................................23<br />

4-9 Yellow with Red Stripes..................................................23<br />

4-10 White...............................................................................23<br />

SECTION 5 – PADDOCK, PITS & ROAD<br />

5-1 Paddock..........................................................................23<br />

5-2 Pit Lane...........................................................................24<br />

SECTION 6 – CONDUCT OF EVENTS<br />

6-1 Technical Inspection .......................................................28<br />

6-2 Qualifying ........................................................................30<br />

v

6-3 Fan Walk .........................................................................32<br />

6-4 Pre-Race.........................................................................33<br />

6-5 Race Start and Restart Procedures................................33<br />

6-6 Race Interruption (Red Flag)...........................................34<br />

6-7 Mandatory Pit Stops.......................................................35<br />

6-8 Drive Time Restrictions...................................................35<br />

6-9 Race Completion ............................................................35<br />

6-10 On-Tracks Rules .............................................................35<br />

6-11 Safety Car.......................................................................36<br />

6-12 Standard Full Course Yellow ..........................................36<br />

6-13 Pass-Around and Pit Stops............................................36<br />

6-14 Wave-By and End of Operation......................................38<br />

6-15 Restart ............................................................................39<br />

6-16 Short Full Course Yellow ................................................39<br />

6.17 Pass-Around and Pit Stops............................................39<br />

6-18 Wave-By and End of Operation......................................40<br />

6.19 Extended Full Course Yellow..........................................40<br />

6.20 Wave-By and End of Operation......................................41<br />

6.21 Competition Penalties ....................................................41<br />

SECTION 7 – REQUIRED EQUIPMENT<br />

7-1 Fueling Rig......................................................................42<br />

7-2 Driver ID Transmitters .....................................................44<br />

7-3 Safety Light System .......................................................44<br />

SECTION 8 – DISCIPLINARY ACTION<br />

8-1 Penalty ............................................................................44<br />

8-2 General Administration ...................................................45<br />

8-3 Timing and Scoring Results ...........................................45<br />

8-4 Protest ............................................................................46<br />

8-5 Appeal.............................................................................47<br />

8-6 Appeal to the Chief Appellate Officer.............................48<br />

SECTION 9 – PRIZES, POINT FUNDS AND AWARDS<br />

9-1 Sole Authority .................................................................50<br />

9-2 Event Prizes ....................................................................50<br />

9-3 Point Funds.....................................................................50<br />

9-4 Championship.................................................................50<br />

9-5 <strong>GRAND</strong>-<strong>AM</strong> Driver Championships................................51<br />

9-6 Measurement ..................................................................52<br />

9-7 Ties .................................................................................52<br />

9-8 <strong>GRAND</strong>-<strong>AM</strong> Manufacturer Championships....................52<br />

9-9 <strong>GRAND</strong>-<strong>AM</strong> Team Championships ................................53<br />

GENERAL AUTOMOBILE REGULATIONS<br />

SECTION 1 – INTRODUCTION<br />

1-1 Eligibility .........................................................................57<br />

1-2 Measurements ............................................................... 57<br />

1-3 Equivalence Formula ..................................................... 57<br />

vi

SECTION 2 - BODYWORK REGULATIONS<br />

2-1 Bodywork .......................................................................58<br />

2-2 Rear Wing ...................................................................... 59<br />

2-3 Bodywork Pins............................................................... 59<br />

2-4 Windshield Wiper........................................................... 59<br />

2-5 Lights ............................................................................. 59<br />

2-6 Windshield/Rear Glass ...................................................59<br />

SECTION 3 - ENGINE REGULATIONS<br />

3-1 General Engine Eligibility ............................................... 60<br />

3-2 Pistons/Rods ................................................................. 61<br />

3-3 Cylinder Heads .............................................................. 61<br />

3-4 Crankshaft .................................................................... 61<br />

3-5 Camshaft, Valve Lifter and Rocker Arms ...................... 61<br />

3-6 Engine Air Restrictors .....................................................61<br />

SECTION 4 - ELECTRICAL<br />

4-1 Ignition System ..............................................................61<br />

4-2 Electrical System ........................................................... 62<br />

4-3 Traction Control ..............................................................62<br />

4-4 Traction Control ECU Control.........................................63<br />

SECTION 5 - COOLING<br />

5-1 Cooling System ..............................................................63<br />

SECTION 6 - ENGINE LUBRICATION/DRY SUMP<br />

6-1 Oil Reservoir Tank ..........................................................63<br />

SECTION 7 - EXHAUST<br />

7-1 Exhaust System..............................................................63<br />

SECTION 8 - DRIVE TRAIN<br />

8-1 Drive Train.......................................................................64<br />

8-2 AGS (Paddleshift) Systems.............................................64<br />

8-2 Artificial Heating..............................................................64<br />

SECTION 9 - WHEELS AND TIRES<br />

9-1 Official Tire - Rolex Series ..............................................64<br />

9-2 Official Tire – Continental Tire Sports Car Challenge.....64<br />

9-3 Control ............................................................................65<br />

9-4 Responsibility .................................................................65<br />

9-5 Artificial Heating..............................................................65<br />

9-6 Tire Air Pressure ............................................................65<br />

9-7 Carbon fiber wheels........................................................63<br />

9-8 Wheel Attachment ..........................................................63<br />

9-9 Wheel Diameter ............................................................. 63<br />

SECTION 10 - CHASSIS<br />

10-1 Suspension ....................................................................63<br />

10-2 Steering ......................................................................... 67<br />

10-3 Frame & Roll Cage ........................................................ 67<br />

10-4 Air Jacks ........................................................................ 68<br />

10-5 Car Weight/Ballast......................................................... 68<br />

SECTION 11 - BRAKES<br />

11-1 Brakes.............................................................................68<br />

vii

11-2 Brake Cooling System................................................... 69<br />

SECTION 12 - FUEL/FUEL CELLS<br />

12-1 Official Fuel .....................................................................69<br />

12-2 Sampling....................................................................... 69<br />

12-3 Fuel Handling................................................................. 69<br />

12-4 Fuel Cell/Fillers/Vents .................................................... 69<br />

12-5 Fuel Lines ...................................................................... 71<br />

12-6 Fuel Pumps.................................................................... 71<br />

12-7 Fuel Capacity................................................................. 71<br />

SECTION 13 - DATA ACQUISITION/RECORDING<br />

13-1 Telemetry .......................................................................71<br />

13-2 Data Acquisition ............................................................ 71<br />

13-3 Radios............................................................................ 72<br />

13-4 Transmitter..................................................................... 72<br />

13-5 Data Recording.............................................................. 72<br />

13-6 Accident Data Recorders ...............................................73<br />

SECTION 14 - IDENTIFICATION AND MARKINGS<br />

14-1 Competition Numbers ....................................................73<br />

14-2 Logos and Brand marks................................................ 74<br />

14-3 Rig Identification............................................................ 75<br />

SECTION 15 - SAFETY EQUIPMENT<br />

15-1 Driver Equipment ............................................................75<br />

15-2 Fire Extinguishers .......................................................... 77<br />

15-3 Towing Eyes....................................................................78<br />

15-4 Delphi Safety Light System ............................................78<br />

15-5 In-Car T.V. Camera..........................................................78<br />

SECTION 16 - FINAL TEXT<br />

16-1 Final Text.........................................................................79<br />

SECTION 17 - ROLL CAGE DIAGR<strong>AM</strong><br />

SECTION 18 - WINDSHIELD BRACE DIAGR<strong>AM</strong><br />

DAYTONA PROTOTYPE REGULATIONS<br />

SECTION 1 - INTRODUCTION<br />

1-1 Classifications ................................................................82<br />

1-2 Competition ....................................................................82<br />

1-3 Eligibility..........................................................................82<br />

1-4 Daytona Prototype Gen1, Gen2, and Gen3 ...................83<br />

1-5 Additional Specifications ................................................83<br />

SECTION 2 - BODYWORK<br />

2-1 Bodywork........................................................................83<br />

2-2 Headlights...................................................................... 85<br />

2-3 Aerodynamic Devices – Ducts – Vents - Louvers ........ 86<br />

SECTION 3 – WEIGHT<br />

3-1 Minimum Weight.............................................................88<br />

SECTION 4 – ENGINE ELIGIBILITY AND MODIFICATIONS<br />

4-1 Eligibility........................................................................ 89<br />

4-2 General Engine Requirements...................................... 89<br />

viii

4-3 Detailed Engine Requirements ..................................... 90<br />

SECTION 5 –DRIVETRAIN<br />

5-1 Approved Models ...........................................................91<br />

5-2 Clutch/Flywheel ..............................................................91<br />

5-3 Maximum Forward Gears ...............................................91<br />

5-4 Sequential Gear Change ................................................91<br />

5-5 Gear Ratios.................................................................... 91<br />

5-6 Bell Housing .................................................................. 91<br />

5-7 Axle Retention ................................................................91<br />

5-8 Attenuator .......................................................................92<br />

SECTION 6 – WHEELS & TIRES<br />

6-1 Official Tire......................................................................92<br />

6-2 Tire Control .....................................................................92<br />

6-3 Tire Testing......................................................................93<br />

6-4 Wheels ............................................................................93<br />

SECTION 7 –SUSPENSION<br />

7-1 Design.............................................................................94<br />

7-2 Rear Suspension ........................................................... 94<br />

7-3 Active Suspension ......................................................... 94<br />

7-4 Shock Absorbers ........................................................... 94<br />

SECTION 8 – CHASSIS/BODY DIMENSIONS<br />

8-1 Basic Dimensions ...........................................................95<br />

SECTION 9 - BRAKES<br />

9-1 Rotors .............................................................................95<br />

9-2 Calipers.......................................................................... 96<br />

9-3 Brake Hat....................................................................... 96<br />

9-4 Rolex 24 Brake Systems ................................................96<br />

9-5 DP Brake Systems..........................................................96<br />

SECTION 10 – FUEL SYSTEM<br />

10-1 Specification ...................................................................96<br />

10-2 Location......................................................................... 97<br />

10-3 Fueling ........................................................................... 97<br />

10-4 Fuel Capacity................................................................. 97<br />

SECTION 11 - TELEMETRY/DATA RECORDING<br />

11-1 Data Recorder.................................................................97<br />

SECTION 12 - IDENTIFICATION<br />

12-1 Car Identification ............................................................97<br />

12-2 Engine Identification .......................................................98<br />

SECTION 13 - SAFETY EQUIPMENT<br />

13-1 Fire Extinguishers ...........................................................98<br />

13-2 Wheel Tethers .................................................................99<br />

GT REGULATIONS<br />

SECTION 1 - General Class Explanation and Purpose<br />

1-1 Purpose .......................................................................102<br />

1-2 Specifications................................................................102<br />

1-3 Categories.....................................................................102<br />

ix

SECTION 2 - GENERAL ENGINE REGULATIONS<br />

2-1 Eligibility .......................................................................102<br />

2-2 Engine Location........................................................... 103<br />

2-3 General Engine Requirements .................................... 103<br />

2-4 Exhaust Systems......................................................... 105<br />

2-5 Cylinder Heads .............................................................105<br />

2-6 Camshaft, Valve Lifter, and Rocker Arms.....................105<br />

2-7 Intake Manifold .............................................................105<br />

2-8 Air Cleaner, and Air Intake............................................105<br />

2-9 Electrical System ..........................................................105<br />

2-10 Radiator ....................................................................... 105<br />

SECTION 3 - CAR BODY REQUIREMENTS<br />

3-1 Bodywork - (Prep 1)......................................................106<br />

3-2 Bodywork - Prep 2)...................................................... 107<br />

3-3 Dash/Installed Components......................................... 109<br />

3-4 Windows ...................................................................... 109<br />

3-5 Floor............................................................................. 110<br />

3-6 Rear Wing .................................................................... 111<br />

3-7 Front Splitter/Air Dam................................................... 111<br />

3-8 Air Inlets ....................................................................... 111<br />

3-9 Lighting......................................................................... 112<br />

SECTION 4 - DRIVE TRAIN<br />

4-1 Drive Train (Prep 1) ..................................................... 112<br />

4-2 Drive Train (Prep 2) ..................................................... 112<br />

4-3 Clutch/Flywheel.............................................................113<br />

4-4 Maximum forward gears ...............................................113<br />

4-5 Bell housing/Adapter Plate............................................113<br />

4-6 Prop/Drive Shaft............................................................113<br />

SECTION 5 – WHEELS AND TIRES<br />

5-1 Official Tire ...................................................................114<br />

5-2 Tire control ....................................................................114<br />

5-3 Testing...........................................................................114<br />

5-4 Wheels ..........................................................................115<br />

SECTION 6 - SUSPENSION AND STEERING<br />

6-1 Suspension (Prep 1) .....................................................116<br />

6-2 Suspension (Prep 2) .....................................................117<br />

SECTION 7 - BRAKES<br />

7-1 Brake Rotors ................................................................ 118<br />

7-2 Brake Calipers ............................................................. 118<br />

7-3 Brake Master Cylinders................................................ 119<br />

SECTION 8 -FUEL SYSTEM<br />

8-1 Fuel Tanks.....................................................................119<br />

8-2 Fittings and Piping ........................................................119<br />

8-3 Fuel Tank Fillers............................................................119<br />

SECTION 9 - WEIGHT<br />

9-1 Maximum permitted rear weight percentage ................120<br />

x

SECTION 10 - MANUFACTURERS<br />

10-1 Manufacturers...............................................................120<br />

GX REGULATIONS<br />

SECTION 1 - General Class Explanation and Purpose<br />

1-1 Purpose .......................................................................122<br />

1-2 Specifications................................................................122<br />

1-3 Categories.....................................................................122<br />

SECTION 2 - GENERAL ENGINE REGULATIONS<br />

2-1 Eligibility .......................................................................122<br />

2-2 Engine Location........................................................... 123<br />

2-3 General Engine Requirements .................................... 123<br />

2-4 Exhaust Systems......................................................... 125<br />

2-5 Cylinder Heads .............................................................125<br />

2-6 Camshaft, Valve Lifter, and Rocker Arms.....................125<br />

2-7 Intake Manifold .............................................................125<br />

2-8 Air Cleaner, and Air Intake............................................125<br />

2-9 Electrical System ..........................................................126<br />

2-10 Radiator ....................................................................... 126<br />

SECTION 3 - CAR BODY REQUIREMENTS<br />

3-1 Bodywork - (Prep 1)......................................................126<br />

3-2 Bodywork - (Prep 2)..................................................... 127<br />

3-3 Dash/Installed Components......................................... 130<br />

3-4 Windows ...................................................................... 130<br />

3-5 Floor............................................................................. 131<br />

3-6 Rear Wing.................................................................... 131<br />

3-7 Front Splitter/Air Dam .................................................. 132<br />

3-8 Air Inlets....................................................................... 132<br />

3-9 Lighting ........................................................................ 132<br />

SECTION 4 - DRIVE TRAIN<br />

4-1 Drive Train (Prep 1) ..................................................... 132<br />

4-2 Drive Train (Prep 2) ..................................................... 133<br />

4-3 Clutch/Flywheel.............................................................134<br />

4-4 Maximum forward gears ...............................................134<br />

4-5 Bell housing/Adapter Plate ...........................................134<br />

4-6 Prop/Drive Shaft ...........................................................134<br />

SECTION 5 – WHEELS AND TIRES<br />

5-1 Official Tire ...................................................................134<br />

5-2 Tire control ....................................................................134<br />

5-3 Testing...........................................................................135<br />

5-4 Wheels..........................................................................136<br />

SECTION 6 - SUSPENSION AND STEERING<br />

6-1 Suspension (Prep 1).....................................................136<br />

6-2 Suspension (Prep 2).....................................................137<br />

SECTION 7 - BRAKES<br />

7-1 Brake Rotors................................................................ 139<br />

7-2 Brake Calipers ............................................................. 139<br />

xi

7-3 Brake Master Cylinders ............................................... 139<br />

SECTION 8 -FUEL SYSTEM<br />

8-1 Fuel Tanks.....................................................................139<br />

8-2 Fittings and Piping ........................................................140<br />

8-3 Fuel Tank Fillers............................................................140<br />

SECTION 9 - WEIGHT<br />

9-1 Maximum permitted rear weight percentage ................140<br />

SECTION 10 - MANUFACTURERS<br />

10-1 Manufacturers...............................................................140<br />

CONTINENTAL TIRE SPORTS CAR CHALLENGE<br />

SECTION 1 - PURPOSE<br />

1-1 Purpose .......................................................................142<br />

SECTION 2 - ELIGIBILITY<br />

2-1 Eligibility....................................................................... 142<br />

2-2 Classes ........................................................................ 142<br />

2-3 Recognition/Configuration........................................... 143<br />

SECTION 3 - CHASSIS/BODYWORK REGULATIONS<br />

3-1 Drive and Steering .......................................................144<br />

3-2 Added car weight ........................................................ 144<br />

SECTION 4 - FUEL/FUEL CELLS<br />

4-1 Fuel Tank/Cell .............................................................. 144<br />

4-2 Fuel Fillers/Vents ......................................................... 144<br />

4-3 Fuel Lines .................................................................... 145<br />

4-4 Fuel Capacity............................................................... 145<br />

SECTION 5 - MANDATORY SAFETY EQUIPMENT/<br />

MODIFICATIONS<br />

5-1 Roll Cage .....................................................................145<br />

5-2 Glass............................................................................ 146<br />

5-3 Other Safety Modifications.......................................... 146<br />

SECTION 6 - AUTHORIZED MODIFICATIONS<br />

6-1 Standard Components ................................................ 146<br />

6-2 Brakes.......................................................................... 146<br />

6-3 Shocks, Springs, Suspension ..................................... 147<br />

6-4 Lights ........................................................................... 148<br />

6-5 Exhaust System........................................................... 148<br />

6-6 Turbocharging/Supercharging ..................................... 149<br />

6-7 Other Items Which May Be Substituted...................... 150<br />

6-8 Engine.......................................................................... 151<br />

6-9 Steering Wheel/Steering System................................. 152<br />

6-10 Doors/Hood/Body Shell............................................... 152<br />

6-11 Ride Height/Track ........................................................ 152<br />

6-12 Items That May Be Removed...................................... 153<br />

6-13 Gearbox, Differential, Drivetrain .................................. 153<br />

6-14 Tires ............................................................................. 153<br />

SECTION 7 - VEHICLE ELIGIBILITY AND NOTES<br />

xii

PREFACE<br />

The Grand American Road Racing Association LLC (“<strong>GRAND</strong>-<strong>AM</strong>”)<br />

<strong>Rulebook</strong> is designed to provide for the orderly conduct of all <strong>GRAND</strong>-<br />

<strong>AM</strong> sports car sanctioned activities and takes effect immediately upon<br />

publication.<br />

The <strong>Rulebook</strong> consists of the following 3 Articles:<br />

1. Article 1 - The General Sporting Regulations (“GSR”). The<br />

GSR contains the basic rules and Regulations under which<br />

<strong>GRAND</strong>-<strong>AM</strong> and its Series are organized under. Where no<br />

other section of the Regulations addresses an issue, the GSR<br />

governs.<br />

2. Article 2 - The General Automobile Regulations (“GAR”). The<br />

GAR provides the general technical and safety specifications<br />

of the Car and equipment. Where no other section of the<br />

Regulations addresses an issue, the GAR governs.<br />

3. Article 3 - The General Class Regulations (“GCR”). The GCR<br />

provides the technical specifications for each class of Cars:<br />

(“DP-GCR”), (“GT-GCR”) and (Continental: (GS/ST-GCR”).<br />

Where the GAR and a GCR conflict, the GCR prevails.<br />

In addition to the <strong>Rulebook</strong>, <strong>GRAND</strong>-<strong>AM</strong> may issue:<br />

1. Specific Car Regulations (“SCR”) that provide technical<br />

specifications for a specific make and model of Car (such as<br />

the constructor and engine for the DP Cars). Where the<br />

<strong>Rulebook</strong> and the SCR conflict, the SCR governs.<br />

2. Supplementary Regulations (“SR”) that provide rules and<br />

specifications specific to an Event. Where the Supplementary<br />

Regulations are in conflict with the <strong>Rulebook</strong> or the SCR, the<br />

Supplementary Regulations govern.<br />

Finally, <strong>GRAND</strong>-<strong>AM</strong> communicates to its Members through<br />

Bulletins, through its Director of Competition and through Officials.<br />

Such communication may amplify, amend, clarify or modify the<br />

<strong>Rulebook</strong>, SCR and/or SR.<br />

All together, these publications and any amendments, along with<br />

any applicable agreements to which <strong>GRAND</strong>-<strong>AM</strong> is a party, form the<br />

“Regulations” for <strong>GRAND</strong>-<strong>AM</strong> and its Members. The purpose of the<br />

Regulations is to: (i) promote safety, the sport of automotive compe-<br />

xiii

tition and <strong>GRAND</strong>-<strong>AM</strong>, (ii) enhance competition, (iii) ensure the<br />

quality, fairness and integrity of the <strong>GRAND</strong>-<strong>AM</strong> programs and<br />

operations and (iv) achieve prompt finality in the competition results<br />

(“the Purpose”).<br />

It is ultimately the obligation of each Member to ensure their<br />

conduct and equipment comply with all applicable Regulations. No<br />

express or implied warranty of safety shall result from publication<br />

of, or compliance with, the Regulations. They are intended as a<br />

guide for the conduct of automobile racing and are in no way a<br />

guarantee against injury or death to participants, spectators, or<br />

others.<br />

xiv

<strong>2013</strong><br />

SPORTING REGULATIONS<br />

1

SPORTING REGULATIONS<br />

SECTION 1 – GENERAL RULES PROCEDURE<br />

1.1 Applicability. The Regulations apply to all Events. For all<br />

Members, the <strong>Rulebook</strong>, as part of the Regulations, establishes<br />

the foundation for the organization and conduct of all<br />

Events.<br />

1.2 Amendments. <strong>GRAND</strong>-<strong>AM</strong> reserves the right to amend, or<br />

modify, the Regulations at any time in furtherance of “the<br />

Purpose”. Such amendments become effective upon publication<br />

by <strong>GRAND</strong>-<strong>AM</strong>, in the manner of its choice, regardless<br />

of when a Member receives actual notice.<br />

1.3 Definitions and Terms. The following terms, appearing periodically<br />

throughout the Regulations, have the following<br />

meanings:<br />

• Car means an automobile approved for racing competition.<br />

• Commitment Line means where the start of the pit lane<br />

speed limit begins, normally indicated by cones at pit<br />

entrance.<br />

• Competitor means Member, Entrant, Driver, Car owner,<br />

team manager, Crewmember or any other person (other<br />

than an Official) who participates competitively in an<br />

Event. Whenever the words Competitor, Entrant, Driver,<br />

Car owner, team manager, mechanic, team member or<br />

Crewmember are used, unless the context indicates<br />

otherwise, the term used is interpreted to include any<br />

Driver, Entrant, Car owner, team manager, mechanic,<br />

team member or Crewmember assigned to or a member<br />

of the same racing team.<br />

• Conclusive means that such action, inaction, and/or decision<br />

are final and not subject to protest, appeal and/or<br />

litigation.<br />

• Continental Tire Sports Car Challenge (CTSCC) denoted<br />

in parentheses and italicized where Regulations differ<br />

from the Rolex Series.<br />

• DP means a Daytona Prototype Car or the Daytona<br />

Prototype class.<br />

• Event means an entire program of Grand-Am sanctioned<br />

competitions.<br />

• FIA (Federation Internationale de I’Automobile) means the<br />

International Federation of National Automobile Clubs.<br />

2

• Finish(ing) Line means the point on-track where timing<br />

and scoring ends.<br />

• <strong>GRAND</strong>-<strong>AM</strong> means the national sanctioning organization<br />

formed to promote sports car road racing and the trade<br />

name and registered service mark of Grand American<br />

Road Racing Association, LLC.<br />

• (Continental: GS means a Grand Sport Car or the Grand<br />

Sport class.)<br />

• GT means a Grand Touring Car or the Grand Touring<br />

class.<br />

• Headquarters means the principal office of <strong>GRAND</strong>-<strong>AM</strong>,<br />

located at One Daytona Boulevard, Daytona Beach,<br />

Florida, 32114.<br />

• Member means an individual or entity accepted by<br />

<strong>GRAND</strong>-<strong>AM</strong> as a Member pursuant to the Regulations<br />

whose membership is not expired, suspended, canceled<br />

or terminated.<br />

• OE means original equipment as delivered on a Car built<br />

by a recognized automobile manufacturer and delivered<br />

via a regular retail sales outlet.<br />

• Paddock means the area within the facility where Entrants<br />

park their transporters and work on the Car between<br />

Sessions.<br />

• Pit Stall means the working area along pit lane assigned<br />

to an Entrant during a Session, in which the Competitors<br />

may place their equipment and service the Car.<br />

• Promoter means an individual, partnership, corporation,<br />

joint venture or other legal entity that, in connection with<br />

the Event, is designated as the “Promoter” in the<br />

executed Sanction Agreement for the Event.<br />

• Race means the Car competition during an Event, listed<br />

on the <strong>GRAND</strong>-<strong>AM</strong> season schedule, for which championship<br />

points and awards are distributed based upon<br />

finishing position.<br />

• Race Equipment means a Car, Car part, engine, engine<br />

component, tires, fuel, support equipment and/or any<br />

other part or related equipment.<br />

• Race Procedure means the manner in which an Event is<br />

conducted. It includes, but is not limited to, determinations<br />

regarding the eligibility of Cars for competition,<br />

qualifying procedures, the line-up of the Cars, the start of<br />

the Race, the control of Cars throughout the Race by<br />

flags, lights, or other direct communication, the election<br />

to stop or delay a Race, control of pit activity, flagging,<br />

the positioning of Cars at any time, the assessment of lap<br />

and time penalties, and the completion of the Race. It<br />

3

does not include the assessment of penalties (disqualification,<br />

suspension or fine) except lap and/or time<br />

penalties imposed during a Race or immediately after a<br />

Race.<br />

• Regulations mean the rules and Regulations governing<br />

the organization, sanctioning and conduct of Events. This<br />

includes but is not limited to, the <strong>Rulebook</strong>,<br />

Supplementary Regulations and Bulletins.<br />

• Safety Car means a non-competition vehicle used during<br />

the exploratory laps prior to the start of the Race and<br />

during a Race to collect the field of Cars during an intervention.<br />

• Sanction Agreement means the documentary authority,<br />

granted by <strong>GRAND</strong>-<strong>AM</strong>, to organize and hold a competition.<br />

• Series means the individual series sanctioned by<br />

<strong>GRAND</strong>-<strong>AM</strong>.<br />

• Session means the time from the official start of the<br />

Session as determined by the Official Schedule and<br />

Timing and Scoring, through the official time of the end of<br />

the Session as determined by the Official Schedule or<br />

adjusted by Race Control until the last running Car exits<br />

the racing surface and the Cars have cleared pit lane.<br />

• Single File means a line of Cars arranged one behind<br />

another without overtaking.<br />

• Start(ing) Line means the point on-track where timing and<br />

scoring begins.<br />

• (Continental: ST means Street Tuner Car or the Street<br />

Tuner Class.)<br />

• Supervisory Officials means the officers, employees or<br />

agents of <strong>GRAND</strong>-<strong>AM</strong> as designated by <strong>GRAND</strong>-<strong>AM</strong>.<br />

The Supervisory Officials for <strong>2013</strong> include:<br />

• Ed Bennett, President & Chief Executive Officer<br />

• Richard Buck, Managing Director, Competition<br />

• Gabriel Cadringher, Managing Director, Technical<br />

Regulations and Development<br />

• Mark Raffauf, Managing Director of Racing Operations<br />

• Gary Cummings, <strong>GRAND</strong>-<strong>AM</strong> Rolex Sports Car Series<br />

Manager<br />

• Jeff Smallwood, <strong>GRAND</strong>-<strong>AM</strong> Continental Tire Sports<br />

Car Challenge Series Manager<br />

• Mike Kraemer, Competition Senior Project Manager<br />

• Rob Elson, Technical Manager<br />

• Tom Seabolt, Race Operations Manager<br />

• Don Abbott, Chief Scorer<br />

• Mary Suarez, Director of Member Services<br />

4

• Supplementary Regulations (SR) means additional rules<br />

specific to an Event.<br />

• Test(ing) means all forms of Testing on or off-track.<br />

• Tire Set means two front tires and two rear tires.<br />

1.4 Interpreting and Applying the Regulations.<br />

1.4.1 Pronouns. The pronouns “he”, “his”, and “him” are<br />

generic and not intended to indicate gender.<br />

1.4.2 Money. All monetary amounts specified are in US<br />

Dollars.<br />

1.4.3 Forms and Information. All forms and information<br />

referred to in the Regulations can be obtained from<br />

Headquarters and/or <strong>GRAND</strong>-<strong>AM</strong>.com.<br />

1.4.4 Notice. Receipt is determined by the date<br />

contained in the U.S. postal mark (if mailed),<br />

<strong>GRAND</strong>-<strong>AM</strong> recognized courier receipt, or the<br />

<strong>GRAND</strong>-<strong>AM</strong> date or fax time code stamp (if delivered<br />

in person or sent by fax).<br />

1.5 Interpretation and Application. In any dispute regarding the<br />

Regulations, the interpretation and application of the Officials<br />

shall prevail. Notwithstanding the foregoing or any other<br />

provision in the Regulations, Supervisory Officials may review<br />

an Official’s interpretation or application of the Regulations<br />

where such Supervisory Officials deem such review to be<br />

appropriate. The interpretation and application of the<br />

Regulations by the Officials (or by a Supervisory Official) are<br />

Conclusive, except as provided for in the Regulations. In<br />

furtherance of “the Purpose”, all Members, including but not<br />

limited to, Competitors, expressly agree that:<br />

1.5.1 NON-LITIGABLE. DETERMINATIONS MADE BY<br />

<strong>GRAND</strong>-<strong>AM</strong> AS TO THE APPLICABILITY AND<br />

INTERPRETATION OF THE REGULATIONS ARE<br />

NON-LITIGABLE, AND THEY WILL NOT INITIATE<br />

OR MAINTAIN LITIGATION OF ANY KIND AGAINST<br />

<strong>GRAND</strong>-<strong>AM</strong> OR ANYONE ACTING ON BEHALF OF<br />

<strong>GRAND</strong>-<strong>AM</strong>, TO REVERSE OR MODIFY SUCH<br />

APPLICATION AND/OR INTERPRETATION OR TO<br />

RECOVER D<strong>AM</strong>AGES OR TO SEEK ANY OTHER<br />

KIND OF RELIEF AS A RESULT OF SUCH DETER-<br />

MINATIONS. IF THE LITIGATION IS NOT<br />

DISMISSED PURSUANT TO THIS COVENANT,<br />

THE MATTER WILL BE TRIED BEFORE A JUDGE<br />

OF COMPETENT JURISDICTION AND THE<br />

MEMBER HEREBY WAIVES ANY RIGHT TO TRIAL<br />

BY JURY IN SUCH ACTION. <strong>GRAND</strong>-<strong>AM</strong><br />

5

RESERVES THE RIGHT TO TAKE ANY OTHER<br />

ACTION HEREUNDER, INCLUDING SUSPENSION<br />

OR TERMINATION OF MEMBERSHIP, FOR VIOLA-<br />

TION OF THIS SECTION.<br />

1.5.2 Reimbursement of Legal Fees. Any Member that<br />

initiates or maintains litigation in violation of this<br />

provision agrees to reimburse <strong>GRAND</strong>-<strong>AM</strong> for all<br />

costs of such litigation, including travel expenses<br />

and attorney’s fees.<br />

1.6 Principal Rule. On occasion, circumstances are presented,<br />

either unforeseen or otherwise extraordinary, in which strict<br />

application of the Regulations may not achieve “the Purpose.”<br />

In such rare circumstances, Officials, as a practical matter,<br />

may make a determination that is not contemplated by or is<br />

inconsistent with the Regulations. Such determinations are<br />

reviewable by Supervisory Officials. All such determinations<br />

are Conclusive, except as provided for in the Regulations.<br />

1.7 Submission to the Regulations. No express or implied<br />

warranty of safety shall result from the publication and/or<br />

compliance with the Regulations. Every person, entity, group<br />

of persons, or Promoter, and any person who receives a<br />

Membership, warrants that (i) he agrees without reservation<br />

to know and abide by the Regulations, (ii) he renounces the<br />

right to have legal recourse, except with the written consent<br />

of <strong>GRAND</strong>-<strong>AM</strong>, to any arbitrator or tribunal not provided for<br />

in the Regulations.<br />

SECTION 2 - <strong>GRAND</strong>-<strong>AM</strong> MEMBERSHIP<br />

2.1 Authority. <strong>GRAND</strong>-<strong>AM</strong> may, but is not required to, accept as<br />

a Member any individual or entity, as long as the applicant<br />

submits a properly executed Membership Application with<br />

the appropriate fee and meets the required qualifications.<br />

<strong>GRAND</strong>-<strong>AM</strong> is dedicated to the highest degree of professionalism,<br />

sportsmanship and integrity. For that reason,<br />

<strong>GRAND</strong>-<strong>AM</strong> at its sole discretion, may reject the application<br />

of an otherwise qualified applicant if it is in the interest of<br />

<strong>GRAND</strong>-<strong>AM</strong> or the sport of automobile racing, for reasons<br />

including but not limited to, the applicant’s participation or<br />

involvement in conduct inconsistent with “the Purpose”,<br />

whether in the course of racing activity or not, and whether<br />

or not the applicant was a Member or applicant at the time<br />

of such conduct. The affected Member may appeal such<br />

determination directly to the Chief Appellate Officer, in accor-<br />

6

dance with the Regulations. Notwithstanding the foregoing,<br />

all decisions as to an applicant’s driving ability and/or physical<br />

condition are Conclusive.<br />

2.2 Reservation of Rights. <strong>GRAND</strong>-<strong>AM</strong> reserves the right to<br />

deny entry to any Event to any Member or to revoke any<br />

Membership or credential previously issued by <strong>GRAND</strong>-<strong>AM</strong><br />

for any reason or no reason, except that <strong>GRAND</strong>-<strong>AM</strong> will not<br />

deny or revoke a Membership or credential solely on the<br />

basis of race, creed, color, sex, or national origin.<br />

2.3 Membership Requirement. Any person or entity desiring to<br />

participate in <strong>GRAND</strong>-<strong>AM</strong> as a Driver, Entrant, Crewmember,<br />

permanent media, Industry Representative, partner or<br />

Official must be a current Member of <strong>GRAND</strong>-<strong>AM</strong> in the<br />

capacity in which they wish to participate.<br />

2.3.1 Exception. A competition license issued by the FIA<br />

as a Driver or Entrant for persons who reside internationally<br />

is recognized for participation in an Event<br />

listed on the FIA calendar but does not include a<br />

<strong>GRAND</strong>-<strong>AM</strong> Membership or any benefits or privileges<br />

of such Membership, including but not limited<br />

to point awards, point fund awards or participant<br />

accident insurance:<br />

2.3.2 FIA Membership. Every Driver in a FIA-listed Race<br />

must possess a current FIA Driver License regardless<br />

of other licensing. Every Car entered in a<br />

FIA-listed Race must be entered by someone<br />

possessing a current FIA Entrant License regardless<br />

of other licensing. Applications for FIA licenses<br />

may be obtained from <strong>GRAND</strong>-<strong>AM</strong>.<br />

2.4 Application Procedure. An applicant must submit a fully<br />

completed and properly signed Annual Membership<br />

Application (waiver) accompanied by the appropriate<br />

Membership fee to Headquarters. The receipt of an applicant’s<br />

Annual Membership Application and/or fee does not<br />

constitute the issuance of, or approval by <strong>GRAND</strong>-<strong>AM</strong> of<br />

such Annual Membership Application. An applicant is notified<br />

in writing by <strong>GRAND</strong>-<strong>AM</strong> whether their application has<br />

been approved.<br />

2.4.1 Minors. All applicants 16, 17 or 18 years old at the<br />

time of application and not legally emancipated,<br />

must include with their Annual Membership<br />

Application and fee, a fully complete Minor<br />

Participant Waiver signed by the applicant and the<br />

7

applicant’s father, mother, and/or legal guardian. All<br />

signatures on the Minor Participant Waiver must be<br />

notarized unless the minor applicant is applying in<br />

person at Registration during a <strong>GRAND</strong>-<strong>AM</strong> Event<br />

and his father, mother and/or legal guardian is<br />

present, in which case all parties must sign before<br />

a <strong>GRAND</strong>-<strong>AM</strong> Official. An applicant 16, 17 or 18<br />

years old and emancipated, must include with their<br />

Annual Membership Application and fee, a copy of<br />

the emancipation order. Specific Events may have<br />

additional requirements for minors that must be<br />

fulfilled prior to participation in such Event.<br />

2.4.2 Business Entities. If applicant is a partnership,<br />

corporation or other legal entity, the person responsible<br />

for all communication and contact with<br />

<strong>GRAND</strong>-<strong>AM</strong> regarding the entity must fill out the<br />

Annual Membership Application and such person<br />

must meet the eligibility requirements for the<br />

capacity in which the entity wishes to participate.<br />

2.5 Eligibility Requirements.<br />

2.5.1 Driver. To secure and maintain Membership in the<br />

capacity of Driver, an applicant must at minimum: (i)<br />

Be 16 years of age; (ii) If requested, submit to and<br />

pass a driving ability test(s) conducted by and at<br />

the discretion of <strong>GRAND</strong>-<strong>AM</strong>; and (iii) Be physically<br />

fit as determined at the sole discretion of <strong>GRAND</strong>-<br />

<strong>AM</strong>. In this regard, <strong>GRAND</strong>-<strong>AM</strong> may require an<br />

applicant to pass one or more physical examination(s)<br />

by a qualified physician(s).<br />

2.5.2 Entrant. To secure and maintain a Membership in<br />

the capacity of Entrant, an applicant must, at<br />

minimum, be 21 years of age.<br />

2.5.3 Crewmember. To secure and maintain<br />

Membership in the capacity of Crew member, an<br />

applicant must at minimum: (i) Be 16 years of age<br />

and (ii) Be physically fit as determined in the sole<br />

discretion of <strong>GRAND</strong>-<strong>AM</strong>. In this regard, <strong>GRAND</strong>-<br />

<strong>AM</strong> may require an applicant to pass one or more<br />

physical examination(s) by a qualified physician(s).<br />

2.5.4 Official. To secure and maintain Membership in the<br />

capacity of Official, an applicant must at minimum:<br />

(i) Be 18 years of age; (ii) Possess, in the sole<br />

discretion of <strong>GRAND</strong>-<strong>AM</strong>, the necessary qualifications<br />

and abilities to carry out the duties of an<br />

Official; and (iii) Be physically fit as determined in<br />

8

the sole discretion of <strong>GRAND</strong>-<strong>AM</strong>. In this regard,<br />

<strong>GRAND</strong>-<strong>AM</strong> may require an applicant to pass one<br />

or more physical examination(s) by a qualified<br />

physician(s).<br />

2.5.5 Partner. To secure and maintain Membership in the<br />

capacity of Partner, an applicant must at minimum:<br />

(i) Be 21 years of age; and (ii) Be an employee<br />

or agent of an entity which has a direct contractual<br />

relationship with <strong>GRAND</strong>-<strong>AM</strong> (Sponsor, Contin -<br />

gency Partner, OEM, Series Sponsor, Promoter,<br />

etc.)<br />

2.5.6 Industry Representative. To secure and maintain<br />

Membership in the capacity of Industry<br />

Representative, an applicant must at minimum:<br />

(i) Be 19 years of age; and (ii) Be an employee or<br />

agent of a company that supplies products or services<br />

to Competitors. Annual credentials are not<br />

available to Industry Representatives.<br />

2.5.7 Media. To secure and maintain Membership in the<br />

capacity of Media Representative, an applicant<br />

must at minimum: (i) Be 19 years of age; and (ii) Be<br />

assigned to cover <strong>GRAND</strong>-<strong>AM</strong> Event(s).<br />

2.6 Credentials. Only persons approved by <strong>GRAND</strong>-<strong>AM</strong> are<br />

permitted to enter restricted areas (i.e., garage areas, pits,<br />

racing surface and similar areas) after they have personally<br />

signed all required entry forms, waiver and release of liability<br />

forms and pit permits applicable to the particular Event and<br />

obtain a credential. Persons are prohibited from signing at<br />

any time, for any reason, any entry form, waiver and release<br />

of liability form or pit permit for anyone other than themselves.<br />

Credentials must be displayed at all times during an<br />

Event. Competitors must not enter Race Control, timing and<br />

scoring and/or the broadcast compound during any Session<br />

unless permitted or directed by an Official.<br />

2.6.1 Eligibility. Annual credentials are available for<br />

Members in the capacity of: Entrant, Driver, Partner,<br />

Crew member, Media, Official and VIP upon execution<br />

and acceptance by <strong>GRAND</strong>-<strong>AM</strong> of an Annual<br />

Credential Application. <strong>GRAND</strong>-<strong>AM</strong> single Event<br />

licenses are available in the capacity of: Entrant,<br />

Driver, Partner, Crew member, Official, VIP and<br />

Industry Representative.<br />

2.7 Member Status. All Membership cards and credentials<br />

issued by <strong>GRAND</strong>-<strong>AM</strong> remain the property of <strong>GRAND</strong>-<strong>AM</strong><br />

9

and expire December 31st of the year of issue. Privileges<br />

may be revoked at any time for non-compliance with the<br />

Regulations. All Members of <strong>GRAND</strong>-<strong>AM</strong> must, willingly and<br />

without reservation, present their Membership card and/or<br />

credential to Officials upon request. <strong>GRAND</strong>-<strong>AM</strong> in its sole<br />

discretion may review the qualifications of any Member at<br />

any time and may require such Member to submit to additional<br />

physical examination(s) Driver ability test(s), provide a<br />

resume to include Driver information and record of competition<br />

and/or take any other action or require the Member to<br />

take any action, as <strong>GRAND</strong>-<strong>AM</strong> deems appropriate, to determine<br />

whether the Member continues to qualify in the<br />

appropriate capacity, as set forth in the Regulations.<br />

2.7.1 Independent Contractor. Members are independent<br />

contractors who assume and take full<br />

accountability for reporting and paying to the<br />

appropriate authorities all charges, premiums and<br />

taxes, if any, due and payable on any funds<br />

Members may receive as a result of their participation<br />

in Events, including but not limited to Social<br />

Security taxes, unemployment insurance taxes,<br />

workman’s compensation insurance, income taxes<br />

and withholding taxes. A Member is not an agent,<br />

servant or employee of <strong>GRAND</strong>-<strong>AM</strong> by virtue of<br />

such Membership. Each Member is responsible for<br />

compensating their employees and/or agents and<br />

assumes all responsibility for the actions of the<br />

Member’s employees and/or agents.<br />

2.7.2 Revocation. <strong>GRAND</strong>-<strong>AM</strong> may suspend a Member<br />

for a definite or indefinite period of time or terminate<br />

such Membership indefinitely, in the interest of<br />

<strong>GRAND</strong>-<strong>AM</strong> or the sport of automobile racing.<br />

Upon suspension or revocation, the Member must<br />

promptly forward the Membership card and any<br />

credentials to Headquarters. If the Member fails to<br />

do so, the Membership becomes inoperative and<br />

invalid, unless the Member has been suspended, in<br />

which case the Membership becomes inoperative<br />

and invalid until the lifting of the suspension.<br />

<strong>GRAND</strong>-<strong>AM</strong> will return the Membership card and<br />

credential (if applicable) to the Member upon the<br />

lifting of the suspension. Such Member has no right<br />

to receive, and <strong>GRAND</strong>-<strong>AM</strong> is not obligated to<br />

refund, any part or all of the fees paid by Member.<br />

The affected Member may appeal such suspension<br />

10

or termination directly to the Chief Appellate Officer,<br />

in accordance with the Regulations.<br />

2.7.3 Voluntary Termination. A Member may terminate<br />

his Membership at any time by providing a letter of<br />

resignation and their Membership card and credentials<br />

to Headquarters. Such Member shall have no<br />

right to receive, and <strong>GRAND</strong>-<strong>AM</strong> is not obligated to<br />

refund, any part or all of the fees paid by Member.<br />

2.7.4 Non-Transferable. A Membership and/or credential<br />

is non-transferable and non-assignable. It must<br />

only be used by the person to whom it is issued.<br />

Any attempt to transfer, lend, or permit any other<br />

person or entity to use it shall result in a penalty. IF<br />

FOR ANY REASON, WHETHER INTENTIONAL OR<br />

UNINTENTIONAL, A MEMBERSHIP AND/OR<br />

CREDENTIAL IS USED BY ANY OTHER PERSON,<br />

SUCH MEMBER(S) SHALL INDEMNIFY <strong>GRAND</strong>-<br />

<strong>AM</strong> AND ALL RELATED PARTIES FOR ANY<br />

D<strong>AM</strong>AGES ARISING FROM SUCH USE.<br />

2.8 Member Conduct. Each Member is expected to conduct<br />

themselves in a professional and sportsmanlike manner.<br />

Persons whose appearance, associations or affiliations at or<br />

away from an Event are deemed inappropriate or who exhibit<br />

conduct which is offensive, abrasive, in bad taste, or otherwise<br />

inappropriate or who have been convicted of criminal<br />

activity, may be denied Membership or may have their<br />

existing Membership suspended or revoked by <strong>GRAND</strong>-<strong>AM</strong>.<br />

Such conduct may also result in penalties at the discretion of<br />

<strong>GRAND</strong>-<strong>AM</strong>.<br />

2.8.1 Fan Engagement. Members may be required to<br />

take part in certain fan and media activities<br />

including, but not limited to, autograph sessions,<br />

television interviews, fan forums, tech talks, pit lane<br />

or Paddock fan walks. Failure or refusal to participate<br />

as directed, once scheduled and notified,<br />

arriving late, or departing early without the permission<br />

of <strong>GRAND</strong>-<strong>AM</strong>, may result in the imposition of<br />

penalties.<br />

2.8.2 Disparagement. Any Member that publicly criticizes<br />

<strong>GRAND</strong>-<strong>AM</strong>, its employees or its Officials<br />

may be considered to be acting in an unsports -<br />

manlike manner prejudicial or detrimental to<br />

<strong>GRAND</strong>-<strong>AM</strong> or the sport of automobile racing and<br />

may be subject to penalties.<br />

11

2.8.3 Payment. Failure to pay all sums due to <strong>GRAND</strong>-<br />

<strong>AM</strong> or its contractors, agents, affiliated companies<br />

or Promoters may result in penalties.<br />

2.9 Entrant Obligations. It is the responsibility of the Entrant,<br />

wishing to participate in an Event, to obtain the appropriate<br />

Official Entry Form and to ascertain and abide by all applicable<br />

deadlines and instructions. Such Entrant or his<br />

nominated designee is the sole spokesperson for its<br />

Competitors in any and all competition matters pertaining to<br />

the Event.<br />

2.9.1 Car Registration. All Entrants must register their<br />

Car(s) with <strong>GRAND</strong>-<strong>AM</strong> by completing the necessary<br />

application forms and paying the appropriate<br />

fees.<br />

2.9.2 Competition Numbers. Competition numbers are<br />

assigned by <strong>GRAND</strong>-<strong>AM</strong> following the completion<br />

of the registration process and are non-assignable<br />

and non-transferable, except by <strong>GRAND</strong>-<strong>AM</strong>. The<br />

Entrant must use the assigned competition number<br />

on the Car registered by the Entrant. During an<br />

Event, the Entrant must use the competition<br />

number to identify a particular Car and it must not<br />

be transferred to another Car during the Event,<br />

except with <strong>GRAND</strong>-<strong>AM</strong> approval. At subsequent<br />

Events, the Entrant may use the competition<br />

number to identify a different Car registered by the<br />

Entrant. Points and other prizes are awarded to the<br />

Entrant for the performance of the Car identified by<br />

the competition number assigned to the Entrant. If<br />

<strong>GRAND</strong>-<strong>AM</strong> changes an Entrant’s competition<br />

number, <strong>GRAND</strong>-<strong>AM</strong>, at its sole discretion, may<br />

transfer the Entrant’s championship points to the<br />

new competition number. <strong>GRAND</strong>-<strong>AM</strong> reserves the<br />

right to revoke, reassign or transfer competition<br />

numbers at any time.<br />

2.9.3 Responsibility. Entrants are at all times responsible<br />

for the conduct of their Competitors. An offense<br />

committed by a Competitor may be charged to the<br />

Entrant. Unpaid fines of the Entrant, its designee<br />

and/or Competitors may be collected by deducting<br />

the amount from the purse or point fund earnings of<br />

the Entrant.<br />

2.9.4 Entrant Representative. When the Entrant cannot<br />

be present at an Event or is otherwise unavailable,<br />

he must designate a Member to be the Entrant’s<br />

12

epresentative in regards to all actions that an<br />

Entrant may take under the Regulations for such<br />

Event.<br />

2.9.5 Change in Ownership. With respect to an Entrant<br />

that is a business entity, the Entrant must inform<br />

Headquarters in writing promptly if the entity is<br />

altered in any material manner or the entity’s stock<br />

or assets are sold (other than routine daily stock<br />

sales) or becomes the subject of a merger or the<br />

entity’s ownership interest materially changes.<br />

When informed of such a change, <strong>GRAND</strong>-<strong>AM</strong> in its<br />

sole discretion may revoke the entity’s<br />

Membership. If the new entity submits a new<br />

Annual Membership Application, <strong>GRAND</strong>-<strong>AM</strong> may<br />

assign the previous competition number(s) to the<br />

new Entrant or may assign different competition<br />

number(s). <strong>GRAND</strong>-<strong>AM</strong> in its sole discretion may<br />

assign to the new Entrant the championship points<br />

earned by the former Entrant and such other determinations<br />

regarding scoring, point funds and the<br />

distribution of the purse or prize monies if doing so<br />

is in the furtherance of “the Purpose”.<br />

2.9.6 Competitive Analysis. <strong>GRAND</strong>-<strong>AM</strong> may require<br />

Entrants to submit Race Equipment for analysis of<br />

performance capabilities in order to promote closer<br />

competition. Entrants must take all necessary steps<br />

to enable such tests. <strong>GRAND</strong>-<strong>AM</strong> is not responsible<br />

for any payment, reimbursement, damage or loss<br />

as a result of such analysis.<br />

2.10 Substance Abuse Policy. <strong>GRAND</strong>-<strong>AM</strong>’s Substance Abuse<br />

Policy (“Policy”) prohibits the misuse of alcohol, prescription<br />

drugs and/or any other substance used in a manner that<br />

affects the safety of competition, including but not limited to,<br />

illegal substances. As part of the Regulations, Members are<br />

subject to the Policy, which can be found in its entirety on<br />

<strong>GRAND</strong>-<strong>AM</strong>.com.<br />

2.10.1 Reasonable Suspicion. <strong>GRAND</strong>-<strong>AM</strong> may require a<br />

Member to submit to a test(s) if an Official has<br />

reasonable suspicion that (i)the Member has<br />

violated any part of the Policy as a result of using<br />

any prohibited substance, or (ii) has diminished<br />

ability to perform as a result of using any prohibited<br />

substance. Some conditions, observations and/or<br />

reports that may cause such reasonable suspicion<br />

are, without limitation, as follows:<br />

13

• Being found or observed in possession of<br />

illegal substances or illegal drug paraphernalia,<br />

at any time.<br />

• Observation of signs, symptoms and/or<br />

behaviors generally understood to accompany<br />

the use of prohibited substances including,<br />

without limitation, physical signs of red or<br />

droopy eyes, dilated or constricted pupils,<br />

constant running nose, red appearance in the<br />

face, persistent sniffing, slurred speech, stumbling,<br />

hyperactivity, needle marks, repeated<br />

unexplained disappearances from an Event,<br />

time distortion including repeated tardiness<br />

and missed appointments, chronic forgetfulness<br />

or broken promises, accidents during an<br />

Event(s), inability to concentrate or remember<br />

or to maintain attention, mental confusion,<br />

paranoia, presence of abnormal thoughts or<br />

ideas, violent tendencies, loss of temper, irritability,<br />

extreme personality change or mood<br />

swings, deteriorating personal hygiene or<br />

appearance, violation of safety precautions or<br />

careless acts during an Event.<br />

• An arrest or conviction for driving while under<br />

the influence of alcohol or drugs, or a drug<br />

related conviction.<br />

• Receipt of a report from a reliable source that<br />

a Member is under the influence of prohibited<br />

substances or is using, possessing or selling<br />

illegal drugs or substances.<br />

• The results of an examination or test, as<br />

provided by the Regulations, which shows<br />

evidence of use of a prohibited substance,<br />

alcohol abuse or of adulteration or manipulation<br />

of the specimen.<br />

• The odor or aroma of an alcoholic beverage on<br />

or about the breath or body of a Member<br />

consistent with use of such a substance or<br />

alcoholic beverage on the day of an Event.<br />

2.10.2 Refusal. If a Member refuses to consent to and<br />

participate in a test within the time period designated<br />

by an Official, the Member may be removed<br />

from the Event by the Race Director and may be<br />

subject to other emergency action as may be<br />

appropriate, including penalties.<br />

14

SECTION 3 - ADMINISTRATION OF EVENTS<br />

3.1 Event. <strong>GRAND</strong>-<strong>AM</strong> approves an annual calendar of Events.<br />

An Event or a competition forming part of an Event may be<br />

canceled, rescheduled, or postponed by <strong>GRAND</strong>-<strong>AM</strong> for<br />

reasons of safety, or forces beyond <strong>GRAND</strong>-<strong>AM</strong>’s control. If<br />

an entire Event is canceled prior to its commencement,<br />

<strong>GRAND</strong>-<strong>AM</strong> will make every effort to notify all parties<br />

concerned, but accepts NO responsibility for such cancellation,<br />

or failure to notify.<br />

3.1.1 Advertising and Promotion Release. Each<br />

Competitor by entering an Event, grants to<br />

<strong>GRAND</strong>-<strong>AM</strong>, its duly authorized agents, assigns<br />

and licensees, including but not limited to the<br />

Series sponsor and Promoters, on an exclusive<br />

basis, the right to use and sublicense, Competitor’s<br />

name, likeness and performance, in and out of<br />

uniform, including photographs, images and<br />

sounds of Competitor, any Crewmember and/or<br />

any Car(s) with respect to which Competitor participates<br />

in the Event(s), in any way, material or<br />

medium (including but not limited to print, broadcasts<br />

by and through television, cable television,<br />

radio, pay-per-view, closed circuit television, satellite<br />

signal, digital signal, film productions, audiotape<br />

productions, transmissions over the Internet, public<br />

and private online services authorized by <strong>GRAND</strong>-<br />

<strong>AM</strong>, sales, other commercial projects and/or the<br />

like) for promoting, advertising, or reporting<br />

<strong>GRAND</strong>-<strong>AM</strong> racing generally, the <strong>GRAND</strong>-<strong>AM</strong><br />

Series in which Competitor participates, and/or any<br />