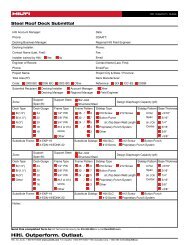

Product Submitted: Hilti MKN-FX and MN Connectors

Product Submitted: Hilti MKN-FX and MN Connectors

Product Submitted: Hilti MKN-FX and MN Connectors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

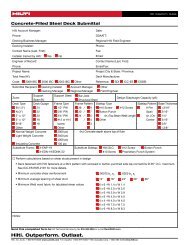

<strong>Product</strong>s <strong>Submitted</strong>:<br />

Clevis Hanger <strong>and</strong> Insulation Shields<br />

Feature/service:<br />

Size Range:<br />

Material/Finish:<br />

Use for the support of stationary pipes; use insulation shields for insulated pipes<br />

3/4" to 14" pipe sizes SDC; 2” to 8” SLC <strong>and</strong> all Insulation Shields<br />

Carbon Steel / Electro-Galvanized; PG – Pre-galvanized Insulation Shields<br />

Approvals: Factory Mutual – FM (2" to 8")<br />

Listings: Underwriters Laboratories – UL, cUL (2" to 8")<br />

Conforms to:<br />

Installation:<br />

Federal specifications WW-H-171E (Type 1 Clevis) <strong>and</strong> (Type 40 shield)<br />

Manufacturers St<strong>and</strong>ardization Society MSS-SP-58 (Type 1 Clevis) <strong>and</strong> (Type 40<br />

shield)<br />

Install in accordance with MSS-SP-69

Ordering <strong>and</strong> Technical Information for SLC:<br />

Allowable loads use a safety factor of 3<br />

Clevis Hanger SLC<br />

Old<br />

Item<br />

No.<br />

Item<br />

No.<br />

Clevis Description<br />

Box<br />

Qty<br />

Allowable<br />

Load (lb)<br />

Item<br />

No.<br />

Insulation Sheild<br />

Description<br />

Box Qty<br />

334700 2008782 MH-SLC 2" EG 1 610 2008613 MH-SLIS 2" PG 50<br />

337250 3475949 50 610<br />

NEW! 2008783 MH-SLC 2 1/2" EG 1 1130 2008614 MH-SLIS 2 1/2" PG 50<br />

NEW! 3475950 50 1130<br />

334701 2008784 MH-SLC 3" EG 1 1130 2008615 MH-SLIS 3" PG 25<br />

337251 3475951 50 1130<br />

334702 2008785 MH-SLC 4" EG 1 1130 2008616 MH-SLIS 4" PG 25<br />

337252 3475952 20 1130<br />

334703 2008786 MH-SLC 5" EG 1 1430 2008617 MH-SLIS 5" PG 25<br />

337253 3475953 20 1430<br />

334704 2008787 MH-SLC 6" EG 1 1940 2008618 MH-SLIS 6" PG 10<br />

337254 3475954 10 1940<br />

334705 2008788 MH-SLC 8" EG 1 2000 2008619 MH-SLIS 8" PG 10<br />

337255 3475955 10 2000<br />

Dimension<br />

Dia.<br />

(in)<br />

RS Rod<br />

Size<br />

(in)<br />

MRI<br />

Min. Rod<br />

Insertion<br />

(in)<br />

Material<br />

Thickness<br />

Gauge<br />

A<br />

(in)<br />

S<br />

(in)<br />

H<br />

(in)<br />

W<br />

(in)<br />

CL<br />

(in)<br />

ID<br />

(in)<br />

L<br />

(in)<br />

2 3/8 5/16 1 1/8 5/16 5 3 9/16 3 5/8 2 3/8 12 18<br />

2 1/2 1/2 7/16 1 3/16 7/16 6 4 5/8 4 7/16 3 12 18<br />

3 1/2 7/16 1 5/16 7/16 6 7/8 5 1/16 4 13/16 3 5/8 12 18<br />

4 5/8 7/16 1 5/8 7/16 8 1/2 6 1/8 5 7/8 4 9/16 12 18<br />

5 5/8 9/16 1 3/4 9/16 9 3/4 7 5/16 6 9/16 5 2/3 12 18<br />

6 3/4 11/16 1 13/16 11/16 11 1/4 8 15/16 7 7/16 6 3/4 12 16<br />

8 3/4 11/16 2 3/16 11/16 13 13/16 11 3/16 8 15/16 8 7/8 12 16

Ordering <strong>and</strong> Technical Information for SDC:<br />

Allowable loads use a safety factor of 3<br />

Old<br />

Item<br />

No.<br />

Item<br />

No.<br />

Description<br />

Box<br />

Qty<br />

Allowable<br />

Load (lb)<br />

RS<br />

Rod<br />

Size<br />

(in)<br />

MRI<br />

Min. Rod<br />

Insertion<br />

(in)<br />

Dimensions<br />

Material<br />

Thickness<br />

Gauge<br />

A<br />

(in)<br />

H<br />

(in)<br />

CL<br />

(in)<br />

L<br />

(in)<br />

n.a. 333236 SDC-EG 3/4" 50 610 3/8 9/16 1/4 2 3/8 1 3/16<br />

n.a. 333237 SDC-EG 1" 50 610 3/8 9/16 5/16 2 3/4 1 1/2<br />

n.a. 424206 SDC-EG 1-1/4" 25 610 3/8 9/16 1/2 3 5/16 1 13/16<br />

n.a. 333239 SDC-EG 1-1/2" 25 610 3/8 9/16 7/8 3 15/16 2 3/8<br />

n.a. 425681 SDC-EG 2” 1 610 3/8 9/16 15/16 4 1/2 2 11/16 12 18<br />

n.a. 333240 SCD-EG 2-1/2" 25 1130 1/2 3/4 3/4 5 1/4 3 12 18<br />

n.a. 425682 SDC-EG 3” 1 1130 1/2 3/4 15/16 6 3 3/8 12 18<br />

n.a. 425683 SDC-EG 4” 1 1130 5/8 15/16 1 3/8 7 3/4 4 7/16 12 16<br />

n.a. 424209 SDC-EG 5” 1 1430 5/8 15/16 1 13/16 9 3/4 5 7/8 12 16<br />

n.a. 306594 SDC-EG 6” 1 1940 3/4 1 1/16 2 5/16 11 3/4 7 3/16 12 16<br />

n.a. 306595 SDC-EG 8” 1 2000 3/4 1 1/16 2 3/4 14 8 7/16 12 16<br />

n.a. 424210 SDC-EG 10" 1 3600 7/8 1 5/16 2 5/16 16 1/2 9 9/16<br />

n.a. 424211 SDC-EG 12" 1 3800 7/8 1 5/16 2 11/16 18 5/8 1011/16<br />

n.a. 424212 SDC-EG 14" 1 4200 1 1 1/2 4 3/16 21 3/4 13<br />

Item No.<br />

Insulation Sheild<br />

Description<br />

L<br />

Dimensio<br />

n<br />

(in)<br />

Material<br />

Thickness<br />

Gauge<br />

424197 Insulation Shield 2” PG 12 18<br />

424198 Insulation Shield 2-1/2” PG 12 18<br />

424199 Insulation Shield 3” PG 12 18<br />

424200 Insulation Shield 4” PG 12 16<br />

424202 Insulation Shield 5” PG 12 16<br />

424203 Insulation Shield 6” PG 12 16<br />

424204 Insulation Shield 8” PG 12 16

Installation instructions for SLC – Speed Lock Clevis<br />

Installation instructions for SLIS insulation shield

<strong>Product</strong> <strong>Submitted</strong>: Riser Clamps:<br />

8/30/2011<br />

MH-SLR-LH<br />

Speed Lock Riser Clamp – Long Hinge<br />

MH-CSLR-LR<br />

Copper Speed Lock Riser Clamp – Long Hinge<br />

_________________________________________________________________________<br />

MH-SLR-S<br />

Speed Lock Riser Clamp – Short<br />

MH-SLR-LS<br />

Speed Lock Riser Clamp – Long Slotted<br />

Feature/service: For supporting vertical steel pipe risers or copper tubing types K or L. Riser clamps<br />

typically utilize the structure to support the legs of the clamp. The clamp typically rests on top of the<br />

concrete floor which the pipe riser passes through. Additionally the riser clamp is attached to a wall using<br />

threaded rods bolted to the riser clamp through the holes provided.<br />

Size Range:<br />

1” - 10” pipe sizes; see tables for range by clamp type.<br />

Material: Carbon Steel S235JRG1 (ASTM A 1011 or A 1008, SS GR. 33)<br />

Finish: Copper Color Plated 5 µm, Galvanized to ASTM A 653 G60 or B 633<br />

Copper clamps are not designed for electrolysis or corrosion resistance, but for<br />

identification purposes only.<br />

Conforms with: Federal specification WW-H-171 (Type 8)<br />

Manufacturers St<strong>and</strong>ardization Society MSS-SP-58 (Type 8)<br />

Installation to be in accordance with ANSI / MSS-SP-69

Ordering <strong>and</strong> Technical Information for MH-SLR-LH:<br />

Allowable loads use a safety factor of 3<br />

Riser Clamp - Long Hinge<br />

Old<br />

Item<br />

No.<br />

Item No. Description<br />

Box<br />

Qty<br />

Allowable<br />

Load (lb)<br />

Tightening<br />

torque<br />

(ft-lb)<br />

Set Screw diameter<br />

x length<br />

Wrench<br />

Size<br />

336347 2007545 MH-SLR-LH 1" PG 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

336348 2007546 MH-SLR-LH 1 1/4" PG 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

336649 2007547 MH-SLR-LH 1 1/2" PG 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

2007548 MH-SLR-LH 2" PG 1 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

424225 3475936 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

2007549 MH-SLR-LH 2 1/2" PG 1 390 3/8"-16 UNC x 1 1/2" 9/16 19<br />

336351 3475937 25 390 3/8"-16 UNC x 1 1/2" 9/16 19<br />

2007550 MH-SLR-LH 3" PG 1 530 1/2"-13 UNC x 2" 3/4 50<br />

3475938 25 530 1/2"-13 UNC x 2" 3/4 50<br />

2007551 MH-SLR-LH 4" PG 1 810 1/2"-13 UNC x 2" 3/4 50<br />

3475939 20 810 1/2"-13 UNC x 2" 3/4 50<br />

Height<br />

dimension<br />

(in)<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

D<br />

dimension<br />

(in)<br />

Material<br />

Thickness<br />

Gauge<br />

Description<br />

MH-SLR-LH 1" PG 1 9.0 1.8 1.3 2.5 14<br />

MH-SLR-LH 1 1/4" PG 1 9.4 2.1 1.5 2.7 14<br />

MH-SLR-LH 1 1/2" PG 1 9.7 2.4 1.6 2.8 14<br />

MH-SLR-LH 2" PG 1-3/16" 10.3 3.0 1.9 3.1 12<br />

MH-SLR-LH 2 1/2" PG 1-3/16" 10.9 3.5 2.2 3.4 12<br />

MH-SLR-LH 3" PG 1-1/2" 12.1 4.2 2.7 4.1 11<br />

MH-SLR-LH 4" PG 1-1/2" 13.2 5.2 3.2 4.6 11

Ordering <strong>and</strong> Technical Information for MH-CSLR-LH:<br />

Allowable loads use a safety factor of 3<br />

Riser Clamp - Copper Long Hinge<br />

Old<br />

Item<br />

No.<br />

Item No. Description<br />

Box<br />

Qty<br />

Allowable<br />

Load (lb)<br />

Tightening<br />

torque<br />

(ft-lb)<br />

Set Screw diameter<br />

x length<br />

Wrench<br />

Size<br />

424231 2007555 MH-CSLR-L 1" Copper 25 120 3/8"-16 UNC x 1 1/2" 9/16 19<br />

424232 2007556 MH-CSLR-L 1 1/4" Copper 25 150 3/8"-16 UNC x 1 1/2" 9/16 19<br />

424233 2007557 MH-CSLR-L 1 1/2" Copper 25 150 3/8"-16 UNC x 1 1/2" 9/16 19<br />

2007558 MH-CSLR-L 2" Copper 1 150 3/8"-16 UNC x 1 1/2" 9/16 19<br />

424234 3475945 25 150 3/8"-16 UNC x 1 1/2" 9/16 19<br />

2007559 MH-CSLR-L 2 1/2" Copper 1 300 3/8"-16 UNC x 1 1/2" 9/16 19<br />

424235 3475946 25 300 3/8"-16 UNC x 1 1/2" 9/16 19<br />

2007560 MH-CSLR-L 3" Copper 1 300 1/2"-13 UNC x 2" 3/4 50<br />

424236 3475947 25 300 1/2"-13 UNC x 2" 3/4 50<br />

2007561 MH-CSLR-L 4" Copper 1 300 1/2"-13 UNC x 2" 3/4 50<br />

424237 3475948 25 300 1/2"-13 UNC x 2" 3/4 50<br />

Description<br />

Height<br />

dimensi<br />

on (in)<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

D<br />

dimension<br />

(in)<br />

Material<br />

Thickness<br />

Gauge<br />

MH-CSLR-L 1" Copper 1 9.0 1.6 1.3 2.5 14<br />

MH-CSLR-L 1 1/4" Copper 1 9.3 1.9 1.4 2.6 14<br />

MH-CSLR-L 1 1/2" Copper 1 9.6 2.1 1.6 2.8 14<br />

MH-CSLR-L 2" Copper 1-3/16" 10.3 2.8 1.9 3.1 12<br />

MH-CSLR-L 2 1/2" Copper 1-3/16" 10.9 3.3 2.2 3.4 12<br />

MH-CSLR-L 3" Copper 1-1/2" 12.1 3.9 2.7 4.1 11<br />

MH-CSLR-L 4" Copper 1-1/2" 13.2 4.9 3.2 4.6 11

Ordering <strong>and</strong> Technical Information for MH-SLR-S:<br />

Allowable loads use a safety factor of 3<br />

Riser Clamp - Short<br />

Old<br />

Item<br />

Item<br />

Description<br />

No.<br />

No.<br />

Box<br />

Qty<br />

Allowable<br />

Load (lb)<br />

Tightening<br />

torque<br />

(ft-lb)<br />

Set Screw diameter x<br />

length<br />

Wrench<br />

Size<br />

NEW! 2007398 MH-SLR-S 1" PG 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

NEW! 2007399 MH-SLR-S 1 1/4" PG 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

NEW! 2007540 MH-SLR-S 1 1/2" PG 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

NEW! 2007541 MH-SLR-S 2" PG 1 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

NEW! 3475772 25 255 3/8"-16 UNC x 1 1/2" 9/16 19<br />

NEW! 2007542 MH-SLR-S 2 1/2" PG 1 390 3/8"-16 UNC x 1 1/2" 9/16 19<br />

NEW! 3475933 25 390 3/8"-16 UNC x 1 1/2" 9/16 19<br />

NEW! 2007543 MH-SLR-S 3" PG 1 530 1/2"-13 UNC x 2" 3/4 50<br />

NEW! 3475934 25 530 1/2"-13 UNC x 2" 3/4 50<br />

NEW! 2007544 MH-SLR-S 4" PG 1 810 1/2"-13 UNC x 2" 3/4 50<br />

NEW! 3475935 20 810 1/2"-13 UNC x 2" 3/4 50<br />

Description<br />

Height<br />

dimension<br />

(in)<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

D<br />

dimension<br />

(in)<br />

Material<br />

Thickness<br />

Gauge<br />

MH-SLR-S 1" PG 1 4.2 1.8 1.5 n.a. 14<br />

MH-SLR-S 1 1/4" PG 1 4.6 2.1 1.7 n.a. 14<br />

MH-SLR-S 1 1/2" PG 1 4.9 2.4 1.8 n.a. 14<br />

MH-SLR-S 2" PG 1-3/16" 5.6 3.0 2.1 n.a. 12<br />

MH-SLR-S 2 1/2" PG 1-3/16" 6.1 3.5 2.4 n.a. 12<br />

MH-SLR-S 3" PG 1-1/2" 7.4 4.2 2.9 n.a. 11<br />

MH-SLR-S 4" PG 1-1/2" 8.4 5.2 3.4 n.a. 11

Ordering <strong>and</strong> Technical Information for MH-SLR-LS:<br />

Allowable loads use a safety factor of 3<br />

Riser Clamp - Long Slotted<br />

Old<br />

Item<br />

Item<br />

Description<br />

No.<br />

No.<br />

Box<br />

Qty<br />

Allowable<br />

Load (lb)<br />

Tightening<br />

torque<br />

(ft-lb)<br />

Set Screw diameter x<br />

length<br />

Wrench<br />

Size<br />

424226 2016765 MH-SLR-LS 3" EG 1 530 3/8"-16 UNC x 1 1/2" 9/16 19<br />

3475940 25 530 3/8"-16 UNC x 1 1/2" 9/16 19<br />

424227 2016766 MH-SLR-LS 4” EG 1 810 1/2"-13 UNC x 2" 3/4 50<br />

3475941 20 810 1/2"-13 UNC x 2" 3/4 50<br />

424228 2007552 MH-SLR-LS 6" EG 1 1570 1/2"-13 UNC x 2" 3/4 50<br />

3475942 10 1570 1/2"-13 UNC x 2" 3/4 50<br />

424229 2007553 MH-SLR-LS 8" EG 1 2500 5/8"-11 UNC x 2 1/2" 15/16 75<br />

3475943 5 2500 5/8"-11 UNC x 2 1/2" 15/16 75<br />

2007554 MH-SLR-LS 10" EG 1 2500 5/8"-11 UNC x 2 1/2" 15/16 75<br />

3475944 5 2500 5/8"-11 UNC x 2 1/2" 15/16 75<br />

Description<br />

Height<br />

dimension<br />

(in)<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

D<br />

dimension<br />

(in)<br />

Material<br />

Thickness<br />

(in)<br />

MH-SLR-LS 3" EG 1 3/16 11 3/4 3 7/8 3 4 5/8 3/16<br />

MH-SLR-LS 4” EG 1 1/2 13 5 3 3/4 5 1/4 1/4<br />

MH-SLR-LS 6" EG 2 16 7 1/8 6 6 3/4 1/4<br />

MH-SLR-LS 8" EG 2 18 1/4 9 3/8 6 7 7/8 3/8<br />

MH-SLR-LS 10" EG 2 20 5/8 11 1/2 7 3/16 9 3/8

<strong>Product</strong> <strong>Submitted</strong>: Strut Clamps:<br />

Date: 9/27/2011<br />

MH-UB<br />

MH-CB<br />

MH-RBA<br />

SC SS316<br />

(Universal Break Apart)<br />

(Copper Break Apart)<br />

(Rigid Break Apart)<br />

(Rigid SS316 Clamp)<br />

_________________________________________________________________________<br />

MH-R45<br />

(Rigid w/45º bolt)<br />

_________________________________________________________________________<br />

MH-EMTV<br />

(EMT w/vertical bolt)<br />

MH-EMT45 (EMT w/45º bolt)<br />

Feature/service:<br />

Size Range:<br />

Material:<br />

Finish:<br />

Strut clamps for rigid or EMT pipes <strong>and</strong> conduits on strut.<br />

Copper color plated strut clamps for copper tubing diameters.<br />

Universal strut clamps for rigid or EMT pipes <strong>and</strong> conduits.<br />

3/8” - 8” pipe sizes; see tables for range by clamp type.<br />

Carbon Steel S235JRG1 (ASTM A 653 SS GR. 33), 316SS (stainless steel)<br />

Copper Color Plated 5 µm, Galvanized to ASTM A653 (G60)

Application Chart<br />

Continued on next page

Application Chart - continued<br />

Pipe/ Rigid<br />

Conduit<br />

Size<br />

Copper<br />

Pipe<br />

Size<br />

Flexible<br />

conduit<br />

size<br />

EMT<br />

Family Item # Item Description Quantity<br />

Size<br />

EMT Conduit Clamps 2008821 MH-EMT45 1/2" PG 100 1/2"<br />

2008822 MH-EMT45 3/4" PG 100 3/4"<br />

2008823 MH-EMT45 1" PG 100 1"<br />

2008824 MH-EMT45 1 1/4" PG 50 1 1/4"<br />

2008825 MH-EMT45 1 1/2" PG 50 1 1/2"<br />

2008826 MH-EMT45 2" PG 50 2"<br />

2008827 MH-EMTV 1/2" PG 100 1/2" 1/2"<br />

2008828 MH-EMTV 3/4" PG 100 1/2" 3/4" 3/4"<br />

2008829 MH-EMTV 1" PG 50 3/4" 1" 1"<br />

2008830 MH-EMTV 1 1/4" PG 50 1" 1 1/4" 1 1/4"<br />

2008831 MH-EMTV 1 1/2" PG 50 1 1/4" 1 1/2" 1 1/2"<br />

2008832 MH-EMTV 2" PG 25 1 1/2" 2"<br />

2016764 MH-EMTV 2" FLEX 25 2" 2"<br />

2008833 MH-EMTV 2 1/2" PG 25 2 1/2" 2 1/2" 2 1/2"<br />

2008834 MH-EMTV 3" PG 10 3" 3" 3"<br />

2008835 MH-EMTV 4" PG 10 4" 4" 4"

Ordering <strong>and</strong> Technical Information for MH-UB:<br />

Allowable loads use a safety factor of 3<br />

Strut Clamp - Universal for EMT, Rigid or Conduit Pipes<br />

Old Item<br />

No.<br />

Item No. Description Box Qty<br />

Allowable<br />

Load 1 (lb)<br />

Ultimate<br />

Shear Load 2<br />

(lb)<br />

Ultimate<br />

Slip Load 3<br />

(lb)<br />

371574 2008846 MH-UB 1/2" PG 100 200 75 50<br />

371575 2008847 MH-UB 3/4" PG 100 200 75 50<br />

371576 2008848 MH-UB 1" PG 50 200 75 50<br />

371577 2008849 MH-UB 1 1/4" PG 50 200 75 50<br />

371578 2008850 MH-UB 1 1/2" PG 50 200 100 50<br />

371579 2008851 MH-UB 2" PG 50 200 100 50<br />

Tightening<br />

torque<br />

(in-lb)<br />

Material<br />

Thickness<br />

Gauge<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

Description Set Screw<br />

diameter x length<br />

Wrench<br />

Size<br />

MH-UB 1/2" PG 5/16"-18 UNC x 3/4" 1/2" 60 16 1.96 0.68 0.96-0.82<br />

MH-UB 3/4" PG 5/16"-18 UNC x 3/4" 1/2" 60 16 2.19 0.79 1.17-1.04<br />

MH-UB 1" PG 5/16"-18 UNC x 3/4" 1/2" 60 14 2.47 0.91 1.46-1.31<br />

MH-UB 1 1/4" PG 5/16"-18 UNC x 1" 1/2" 60 14 2.84 1.09 1.81-1.66<br />

MH-UB 1 1/2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.08 1.20 2.05-1.89<br />

MH-UB 2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.56 1.44 2.52-2.35

Ordering <strong>and</strong> Technical Information for MH-CB:<br />

Allowable loads use a safety factor of 3<br />

Strut Clamp - Copper-Plated for Copper Pipe or Tubing<br />

Old<br />

Item<br />

Item<br />

Description<br />

Box Qty<br />

No.<br />

No.<br />

Allowable<br />

Load 1 (lb)<br />

Ultimate<br />

Shear Load 2<br />

(lb)<br />

Ultimate<br />

Slip Load 3<br />

(lb)<br />

371545 2008836 MH-CB 3/8" 100 400 75 50<br />

371546 2008837 MH-CB 1/2" 100 400 75 50<br />

371547 2008838 MH-CB 3/4" 100 400 75 50<br />

371548 2008839 MH-CB 1" 100 600 75 50<br />

371549 2008840 MH-CB 1 1/4" 100 600 75 50<br />

371550 2008841 MH-CB 1 1/2" 100 600 100 50<br />

371551 2008842 MH-CB 2" 50 600 100 50<br />

371552 2008843 MH-CB 2 1/2" 50 800 200 75<br />

371553 2008844 MH-CB 3" 25 800 200 75<br />

371554 2008845 MH-CB 4" 25 800 200 75<br />

Tightening<br />

Torque<br />

(in-lb)<br />

Material<br />

Thickness<br />

Gauge<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

Description Set Screw diameter<br />

x length<br />

Wrench<br />

Size<br />

MH-CB 3/8" 5/16"-18 UNC x 1" 1/2" 60 16 1.73 0.54 0.62<br />

MH-CB 1/2" 5/16"-18 UNC x 1" 1/2" 60 16 1.87 0.61 0.74<br />

MH-CB 3/4" 5/16"-18 UNC x 1" 1/2" 60 16 2.07 0.73 0.99<br />

MH-CB 1" 5/16"-18 UNC x 1" 1/2" 60 14 2.35 0.85 1.27<br />

MH-CB 1 1/4" 5/16"-18 UNC x 1" 1/2" 60 14 2.62 0.98 1.52<br />

MH-CB 1 1/2" 5/16"-18 UNC x 1" 1/2" 60 14 2.88 1.11 1.77<br />

MH-CB 2" 5/16"-18 UNC x 1" 1/2" 60 14 3.40 1.35 2.27<br />

MH-CB 2 1/2" 3/8"-16 UNC x 1-1/4" 9/16" 60 12 3.94 1.61 2.84<br />

MH-CB 3" 3/8"-16 UNC x 1-1/4" 9/16" 60 12 4.45 1.85 3.34<br />

MH-CB 4" 3/8"-16 UNC x 1-1/4" 9/16" 60 12 5.46 2.35 4.34

Ordering <strong>and</strong> Technical Information MH-RBA:<br />

Allowable loads use a safety factor of 3<br />

Strut Clamp - Rigid for Rigid Conduit or Pipes<br />

Old Item<br />

No.<br />

Item No. Description Box Qty<br />

Allowable<br />

Load 1<br />

(lb)<br />

Ultimate<br />

Shear Load 2<br />

(lb)<br />

Ultimate<br />

Slip Load 3<br />

(lb)<br />

371557 2008800 MH-RBA 1/2" PG 100 400 50 40<br />

371558 2008801 MH-RBA 3/4" PG 100 400 50 40<br />

371559 2008802 MH-RBA 1" PG 100 600 75 50<br />

371560 2008803 MH-RBA 1 1/4" PG 50 600 75 50<br />

371561 2008804 MH-RBA 1 1/2" PG 50 600 100 50<br />

371562 2008805 MH-RBA 2" PG 50 600 100 60<br />

371563 2008806 MH-RBA 2 1/2" PG 25 800 100 60<br />

371564 2008807 MH-RBA 3" PG 25 800 200 150<br />

371565 2008808 MH-RBA 4" PG 25 800 200 150<br />

424213 2008809 MH-RBA 6" PG 10 1000 200 150<br />

Tightening<br />

torque<br />

(in-lb)<br />

Material<br />

Thickness<br />

Gauge<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

Description Set Screw diameter<br />

x length<br />

Wrench<br />

Size<br />

MH-RBA 1/2" PG 5/16"-18 UNC x 1" 1/2" 60 16 2.02 0.70 0.96<br />

MH-RBA 3/4" PG 5/16"-18 UNC x 1" 1/2" 60 16 2.25 0.81 1.17<br />

MH-RBA 1" PG 5/16"-18 UNC x 1" 1/2" 60 14 2.55 0.94 1.46<br />

MH-RBA 1 1/4" PG 5/16"-18 UNC x 1" 1/2" 60 14 2.91 1.11 1.81<br />

MH-RBA 1 1/2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.16 1.23 2.05<br />

MH-RBA 2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.64 1.47 2.52<br />

MH-RBA 2 1/2" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 12 4.19 1.72 3.09<br />

MH-RBA 3" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 12 4.81 2.03 3.71<br />

MH-RBA 4" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 12 5.82 2.53 4.71<br />

MH-RBA 6" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 10 7.97 3.59 6.89

Ordering <strong>and</strong> Technical Information for SC Rigid SS316:<br />

Allowable loads use a safety factor of 3<br />

Strut Clamp - SS316 Rigid for Stainless Steel Pipes<br />

Old<br />

Item<br />

No.<br />

Item<br />

No.<br />

Description<br />

Box<br />

Qty<br />

Allowable<br />

Load 1<br />

(lb)<br />

Ultimate<br />

Shear<br />

Load 2<br />

(lb)<br />

Ultimate<br />

Slip Load<br />

3 (lb)<br />

n.a. 3445360 Strut Clamp Rigid 1/2" SS316 50 400 75 50<br />

n.a. 3445361 Strut Clamp Rigid 3/4" SS316 50 400 75 50<br />

n.a. 3445362 Strut Clamp Rigid 1" SS316 50 600 75 50<br />

n.a. 3445363 Strut Clamp Rigid 1-1/4" SS316 25 600 75 50<br />

n.a. 3445364 Strut Clamp Rigid 1-1/2" SS316 25 600 75 50<br />

n.a. 3445365 Strut Clamp Rigid 2" SS316 25 600 75 50<br />

n.a. 3445366 Strut Clamp Rigid 2-1/2" SS316 10 800 75 50<br />

n.a. 3445367 Strut Clamp Rigid 3" SS316 10 800 75 50<br />

n.a. 3445368 Strut Clamp Rigid 4" SS316 10 1000 75 50

Ordering <strong>and</strong> Technical Information for MH-R45:<br />

Allowable loads use a safety factor of 3<br />

Strut Clamp - Rigid 45 for Rigid Conduit or Pipes<br />

Old Item<br />

No.<br />

Item No. Description Box Qty<br />

Allowable<br />

Load 1 (lb)<br />

Ultimate<br />

Shear Load 2<br />

(lb)<br />

Ultimate Slip<br />

Load 3 (lb)<br />

NEW! 2008810 MH-R45 1/2" PG 100 400 50 40<br />

NEW! 2008811 MH-R45 3/4" PG 100 400 50 40<br />

NEW! 2008812 MH-R45 1" PG 100 600 75 50<br />

NEW! 2008813 MH-R45 1 1/4" PG 50 600 75 50<br />

NEW! 2008814 MH-R45 1 1/2" PG 50 600 100 50<br />

NEW! 2008815 MH-R45 2" PG 50 600 100 60<br />

NEW! 2008816 MH-R45 2 1/2" PG 25 800 100 60<br />

NEW! 2008817 MH-R45 3" PG 25 800 200 150<br />

NEW! 2008818 MH-R45 4" PG 25 800 200 150<br />

NEW! 2008819 MH-R45 6" PG 10 1000 200 150<br />

424214 2008820 MH-R45 8" PG 10 1000 200 150<br />

Tightening<br />

torque<br />

(in-lb)<br />

Material<br />

Thickness<br />

Gauge<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

Description Set Screw diameter<br />

x length<br />

Wrench<br />

Size<br />

MH-R45 1/2" PG 5/16"-18 UNC x 3/4" 1/2" 60 16 2.10 0.71 0.96<br />

MH-R45 3/4" PG 5/16"-18 UNC x 3/4" 1/2" 60 16 2.30 0.82 1.17<br />

MH-R45 1" PG 5/16"-18 UNC x 3/4" 1/2" 60 14 2.62 0.95 1.46<br />

MH-R45 1 1/4" PG 5/16"-18 UNC x 1" 1/2" 60 14 2.97 1.12 1.81<br />

MH-R45 1 1/2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.21 1.24 2.05<br />

MH-R45 2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.68 1.48 2.52<br />

MH-R45 2 1/2" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 12 4.23 1.73 3.09<br />

MH-R45 3" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 12 4.86 2.04 3.71<br />

MH-R45 4" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 12 5.88 2.54 4.71<br />

MH-R45 6" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 10 7.89 3.55 6.73<br />

MH-R45 8" PG 3/8"-16 UNC x 1-1/4" 9/16" 60 10 9.89 4.54 8.75

Ordering <strong>and</strong> Technical Information MH-EMT45:<br />

Allowable loads use a safety factor of 3<br />

Strut Clamp - EMT for EMT Pipe<br />

Old<br />

Item<br />

No.<br />

Item No. Description Box Qty<br />

Allowable<br />

Load 1 (lb)<br />

Ultimate<br />

Shear Load 2<br />

(lb)<br />

Ultimate<br />

Slip Load 3<br />

(lb)<br />

371568 2008821 MH-EMT45 1/2" PG 100 200 50 30<br />

371569 2008822 MH-EMT45 3/4" PG 100 200 50 30<br />

371570 2008823 MH-EMT45 1" PG 100 200 75 40<br />

371571 2008824 MH-EMT45 1 1/4" PG 50 200 75 40<br />

371572 2008825 MH-EMT45 1 1/2" PG 50 200 100 40<br />

371573 2008826 MH-EMT45 2" PG 50 200 100 50<br />

Tightening<br />

torque<br />

(in-lb)<br />

Material<br />

Thickness<br />

Gauge<br />

A<br />

dimension<br />

(in)<br />

B<br />

dimension<br />

(in)<br />

C<br />

dimension<br />

(in)<br />

Description<br />

Set Screw<br />

diameter x length<br />

Wrench<br />

Size<br />

MH-EMT45 1/2" PG 5/16"-18 UNC x 3/4" 1/2" 60 16 1.98 0.65 0.82<br />

MH-EMT45 3/4" PG 5/16"-18 UNC x 3/4" 1/2" 60 16 2.20 0.75 1.04<br />

MH-EMT45 1" PG 5/16"-18 UNC x 3/4" 1/2" 60 14 2.47 0.87 1.31<br />

MH-EMT45 1 1/4" PG 5/16"-18 UNC x 1" 1/2" 60 14 2.81 1.05 1.66<br />

MH-EMT45 1 1/2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.05 1.17 1.89<br />

MH-EMT45 2" PG 5/16"-18 UNC x 1" 1/2" 60 14 3.50 1.39 2.35

Ordering <strong>and</strong> Technical Information MH-EMTV:<br />

Allowable loads use a safety factor of 3<br />

Strut Clamp - EMTV for EMT, Flexible <strong>and</strong> Mechanical Pipes<br />

Old<br />

Box Allowable<br />

Item Item No. Description<br />

Qty Load 1 (lb)<br />

No.<br />

Ultimate Shear<br />

Load 2 (lb)<br />

Ultimate<br />

Slip Load 3<br />

(lb)<br />

n.a. 2008827 MH-EMTV 1/2" PG 100 200 50 30<br />

n.a. 2008828 MH-EMTV 3/4" PG 100 200 50 30<br />

n.a. 2008829 MH-EMTV 1" PG 50 200 75 40<br />

n.a. 2008830 MH-EMTV 1 1/4" PG 50 200 75 40<br />

n.a. 2008831 MH-EMTV 1 1/2" PG 50 200 100 40<br />

n.a. 2008832 MH-EMTV 2" PG 25 200 100 50<br />

n.a. 2016764 MH-EMTV 2" FLEX 25 200 100 50<br />

n.a. 2008833 MH-EMTV 2 1/2" PG 25 350 100 50<br />

n.a. 2008834 MH-EMTV 3" PG 10 350 100 50<br />

n.a. 2008835 MH-EMTV 4" PG 10 350 100 50<br />

Description<br />

Tightening<br />

Torque<br />

(in-lb)<br />

Strut<br />

Clamp<br />

Material<br />

Thickness<br />

Gauge<br />

Pipe<br />

Clamp<br />

Material<br />

Thickness<br />

Gauge<br />

Set Screw<br />

diameter x length<br />

Wrench<br />

Size<br />

A<br />

(in)<br />

B<br />

(in)<br />

C<br />

(in)<br />

D<br />

(in)<br />

MH-EMTV 1/2" 1/4"-20 UNC x 7/8 3/8" 30 16 18 1.75 2.50 0.57 1.14<br />

MH-EMTV 3/4" 1/4"-20 UNC x 7/8 3/8" 30 16 18 1.99 0.71 0.53 1.32<br />

MH-EMTV 1" 1/4"-20 UNC x 7/8 3/8" 30 14 18 2.35 0.67 0.49 1.53<br />

MH-EMTV 1 1/4" 1/4"-20 UNC x 7/8 3/8" 30 14 18 2.65 0.73 0.55 1.87<br />

MH-EMTV 1 1/2" 1/4"-20 UNC x 7/8 3/8" 30 14 18 2.87 0.73 0.55 2.11<br />

MH-EMTV 2" 1/4"-20 UNC x 1 3/8" 30 14 18 3.34 0.87 0.70 2.47<br />

MH-EMTV 2" FLEX 1/4"-20 UNC x 7/8 3/8" 30 14 16 3.58 4.30 0.54 2.73<br />

MH-EMTV 2 1/2" 1/4"-20 UNC x 1 3/8" 30 12 16 4.36 5.17 0.64 3.34<br />

MH-EMTV 3" 1/4"-20 UNC x 1 3/8" 30 12 16 4.87 5.68 0.63 3.91<br />

MH-EMTV 4" 1/4"-20 UNC x 1 3/8" 30 12 16 5.81 6.62 0.63 4.93

<strong>Product</strong> <strong>Submitted</strong>:<br />

<strong>Hilti</strong> Strut<br />

Feature/service:<br />

• C-profile with serrated edges for greater hold <strong>and</strong> stability<br />

• Scaled tick marks every 2" to assist with measurement, cutting <strong>and</strong> installation<br />

• Slots for greater flexibility<br />

• Longitudinal swaging for greater strength<br />

Size Range:<br />

Material:<br />

Finish:<br />

See subsequent tables<br />

Metal framing strut shall be C-profile channel with serrated rolled edges, fabricated from<br />

structural grade steel conforming to one of the following specifications ASTM A570<br />

GR33, or ASTM A653 GR 33.<br />

Nominal thickness of 12-gauge strip steel is 0.101 inches (2.57mm); 14-gauge is 0.075<br />

inches (1.9mm).<br />

Allowable design stress is 25000 psi (172 MPa = 172 N/mm²)<br />

Pre-Galvanized<br />

Pre-galvanized strut shall be zinc coated by hot dip process prior to roll forming. The<br />

zinc weight shall be G90 in accordance with ASTM A653. (PG)<br />

Electro-Deposition Coating<br />

Electro-Deposition Coating or "E-Coating" uses electricity to deposit a smooth, thin<br />

uniform layer of plastic coating on the surface of the steel channel. The epoxy-coated<br />

strut is then cured in an oven at approximately 400°F for at least 20 minutes. Salt spray<br />

(fog) testing has been conducted to verify the performance of the finish - the plastic<br />

coating withstood 1000 hours in a salt spray chamber, when tested in accordance with<br />

ASTM B1117-95 specification. Since the coating is applied as a liquid, the epoxy<br />

travels into crevices <strong>and</strong> trouble spaces so that outside moisture is less able to invade<br />

the coated area <strong>and</strong> cause corrosion. (EC)<br />

Hot-Dip Galvanized<br />

Hot-dip galvanized strut according to ASTM A123 (HDG)<br />

Stainless Steel<br />

316 Ti Stainless Steel strut (SS)

Ordering/Technical Information:<br />

13/16’’ - 12 Gauge 13/16’’ - 14 Gauge<br />

Item #<br />

Description<br />

Slot<br />

Weight/Piece<br />

Finish Package Qty.<br />

Configuration<br />

(lbs)<br />

3424461 1316-12/PG 10’ 2-1/2” x 9/16” PG 1 12.2<br />

3424462 1316-12/PG 10’ VIP 2-1/2” x 9/16” PG 50 12.2<br />

3424483 1316-12/PG 20’ 2-1/2” x 9/16” PG 1 24.3<br />

3424484 1316-12/PG 20’ VIP 2-1/2” x 9/16” PG 50 24.3<br />

3424457 1316-12/PG 10’ SOLID Solid PG 1 15.4<br />

3424458 1316-12/PG 10’ SOLID VIP Solid PG 50 15.4<br />

3424459 1316-12/PG 20’ SOLID Solid PG 1 30.8<br />

3424460 1316-12/PG 20’ SOLID VIP Solid PG 50 30.8<br />

3424485 1316-12/HDG 10’ 2-1/2” x 9/16” HDG 1 12.2<br />

3424486 1316-12/HDG 10’ VIP 2-1/2” x 9/16” HDG 50 12.2<br />

3424487 1316-12/SS 316 Ti 3m (10’-1“) 2-1/2” x 9/16” SS 1 12.5<br />

3424488 1316-12/SS 316 Ti 3m (10’-1“) VIP 2-1/2” x 9/16” SS 12 12.5<br />

Item #<br />

Description<br />

Slot<br />

Weight/Piece<br />

Finish Package Qty.<br />

Configuration<br />

(lbs)<br />

3424493 1316-14/PG 10’ 2-1/2” x 9/16” PG 1 8.7<br />

3424494 1316-14/PG 10’ VIP 2-1/2” x 9/16” PG 50 8.7<br />

3424495 1316-14/PG 20’ 2-1/2” x 9/16” PG 1 17.4<br />

3424496 1316-14/PG 20’ VIP 2-1/2” x 9/16” PG 50 17.4<br />

3424491 1316-14/PG 10’ SOLID Solid PG 1 9.7<br />

3424492 1316-14/PG 10’ SOLID VIP Solid PG 50 9.7<br />

3422497 1316-14/GR E-COAT 10’ 2-1/2” x 9/16” EC 1 8.7<br />

3422498 1316-14/GR E-COAT 10’ VIP 2-1/2” x 9/16” EC 50 8.7

1-5/8’’ - 12 Gauge<br />

Item #<br />

Description<br />

Slot<br />

Configuration<br />

Finish Package Qty.<br />

Weight/Piece<br />

(lbs)<br />

3424499 158-12/PG 10’ SOLID Solid PG 1 18.5<br />

3424500 158-12/PG 10’ SOLID VIP Solid PG 50 18.5<br />

3424501 158-12/PG 20’ SOLID Solid PG 1 37<br />

3424502 158-12/PG 20‘ SOLID VIP Solid PG 50 37<br />

3424503 158-12/PG 2’ 2-1/2” x 9/16” PG 1 3.6<br />

3424504 158-12/PG 2’ VIP 2-1/2” x 9/16” PG 50 3.6<br />

3424505 158-12/PG 4’ 2-1/2” x 9/16” PG 1 7.2<br />

3424506 158-12/PG 4’ VIP 2-1/2” x 9/16” PG 50 7.2<br />

3424507 158-12/PG 6’ 2-1/2” x 9/16” PG 1 10.8<br />

3424508 158-12/PG 6’ VIP 2-1/2” x 9/16” PG 50 10.8<br />

3424509 158-12/PG 6’-8” 2-1/2” x 9/16” PG 1 12<br />

3424510 158-12/PG 6’-8” VIP 2-1/2” x 9/16” PG 50 12<br />

3424511 158-12/PG 10’ 2-1/2” x 9/16” PG 1 18<br />

3424512 158-12/PG 10’ VIP 2-1/2” x 9/16” PG 50 18<br />

3424513 158-12/PG 20’ 2-1/2” x 9/16” PG 1 36<br />

3424514 158-12/PG 20‘ VIP 2-1/2” x 9/16” PG 50 36<br />

3424519 158-12/PG 10’ 11/16” Slot 2-5/8” x 11/16” PG 1 18<br />

3424520 158-12/PG 10’ 11/16” Slot VIP 2-5/8” x 11/16” PG 50 18<br />

3424521 158-12/HDG 10’ 2-1/2” x 9/16” HDG 1 18<br />

3424522 158-12/HDG 10’ VIP 2-1/2” x 9/16” HDG 50 18<br />

3424523 158-12GR /E-COAT 10’ 2-1/2” x 9/16” EC 1 18<br />

3424524 158-12/GR E-COAT 10’ VIP 2-1/2” x 9/16” EC 50 18<br />

3424525 158-12/GR E-COAT 20’ 2-1/2” x 9/16” EC 1 36<br />

3424526 158-12/GR E-COAT 20’ VIP 2-1/2” x 9/16” EC 50 36<br />

3424527 158-12/SS 316 Ti 3m (10’-1“) 2-1/2” x 9/16” SS 1 18.5<br />

3424528 158-12/SS 316 Ti 3m (10’-1“) VIP 2-1/2” x 9/16” SS 12 18.5

1-5/8’’ - 14 Gauge<br />

Item # Description<br />

Slot<br />

Configuration Finish Package Qty. Weight/Piece<br />

(lbs)<br />

3424531 158-14/PG 10’ 2-1/2” x 9/16” PG 1 13.6<br />

3424532 158-14/PG 10’ VIP 2-1/2” x 9/16” PG 50 13.6<br />

3424533 158-14/PG 20’ 2-1/2” x 9/16” PG 1 27.2<br />

3424534 158-14/PG 20‘ VIP 2-1/2” x 9/16” PG 50 27.2<br />

3428084 158-14/PG 10’ SOLID Solid PG 1 14.5<br />

3428085 158-14/PG 10‘ SOLID VIP Solid PG 50 14.5<br />

2-7/16’’ - 12 Gauge<br />

Description<br />

Slot<br />

Configuration Finish Package Qty. Weight/Piece<br />

(lbs)<br />

3424535 2716-12/PG 10’ 2-1/2” x 9/16” PG 1 24.5<br />

3424536 2716-12/PG 10’ VIP 2-1/2” x 9/16” PG 40 24.5<br />

3424537 2716-12/PG 20’ 2-1/2” x 9/16” PG 1 49<br />

3424538 2716-12/PG 20‘ VIP 2-1/2” x 9/16” PG 40 49<br />

3424086 2716-12/PG 20’ 11/16” SLOT 2-5/8” x 11/16” PG 1 49

13/16’’ Back to back - 12 Gauge<br />

Item # Description<br />

Slot<br />

Configuration Finish Package Qty. Weight/Piece<br />

(lbs)<br />

3424489 1316-12/PG 3m (10’-1“) B2B 1-9/16” X 9/16” PG 1 23.6<br />

3424490 1316-12/PG 3m (10’-1“) B2B VIP 1-9/16” X 9/16” PG 25 23.6<br />

1-5/8’’ Back to back - 12 Gauge<br />

Item #<br />

Description<br />

Slot<br />

Configuration<br />

Finish<br />

Package<br />

Qty.<br />

Weight/Piece<br />

(lbs)<br />

3424515 158-12/PG 3m (10’-1“) B2B 1-9/16” X 9/16” PG 1 36.8<br />

3424516 158-12/PG 3m (10’-1“) B2B VIP 1-9/16” X 9/16” PG 25 36.8<br />

3424517 158-12/PG 6m (19’-11”) B2B 1-9/16” X 9/16” PG 1 72.7<br />

3424518 158-12/PG 6m (19’-11”) B2B VIP 1-9/16” X 9/16” PG 25 72.7<br />

3424529 158-12/SS 316 Ti 3m (10’-1“) B2B 1-9/16” X 9/16” SS 1 36.8<br />

3424530 158-12/SS 316 Ti 3m (10’-1“) B2B VIP 1-9/16” X 9/16” SS 6 36.8

<strong>Product</strong> <strong>Submitted</strong>:<br />

Threaded Rod<br />

Size Range:<br />

Material:<br />

Finish:<br />

1/4”-3/4” in 6’ <strong>and</strong> 10’ lengths<br />

AISI 1008 - 1010 or ASTM A36 Steel<br />

Plain Oil or Zinc Plated<br />

Ordering/Technical Information:<br />

Item No.<br />

00257963<br />

00257964<br />

00257965<br />

00257966<br />

00257967<br />

00257968<br />

00257969<br />

00257970<br />

00309386<br />

00309387<br />

00309388<br />

00309389<br />

00309390<br />

00309391<br />

00309392<br />

00309393<br />

00309394<br />

00309395<br />

Description<br />

1/4”-6’ THREADED ROD-<br />

ZINC<br />

3/8”-6’ THREADED ROD-<br />

ZINC<br />

1/2”-6’ THREADED ROD-<br />

ZINC<br />

5/8”-6’ THREADED ROD-<br />

ZINC<br />

3/4”-6’ THREADED ROD-<br />

ZINC<br />

1/4”-6’ THREADED ROD-<br />

PLAIN<br />

3/8”-6’ THREADED ROD-<br />

PLAIN<br />

1/2”-6’ THREADED ROD-<br />

PLAIN<br />

1/4”-10’ THREADED ROD-<br />

ZINC<br />

3/8”-10’ THREADED ROD-<br />

ZINC<br />

1/2”-10’ THREADED ROD-<br />

ZINC<br />

5/8”-10’ THREADED ROD-<br />

ZINC<br />

3/4”-10’ THREADED ROD-<br />

ZINC<br />

1/4”-10’ THREADED ROD-<br />

PLAIN<br />

3/8”-10’ THREADED ROD-<br />

PLAIN<br />

1/2”-10’ THREADED ROD-<br />

PLAIN<br />

5/8”-10’ THREADED ROD-<br />

PLAIN<br />

3/4”-10’ THREADED ROD-<br />

PLAIN<br />

Tube<br />

Qty<br />

Weight<br />

Lb/ft<br />

Wt. (lbs)<br />

per pkg.<br />

** Per MSS SP-58, the maximum allowable tensile loads are based on an allowable tensile stress of 12,000 psi reduced by 25%<br />

resulting in 9,000 psi. The 12,000 psi allows for the interchangeability of the referenced rod materials. The 25% reduction is to<br />

allow for normal installation <strong>and</strong> service conditions.<br />

Diam.<br />

In.<br />

Pitch<br />

Diameter<br />

In.<br />

Major<br />

Diameter<br />

In.<br />

Material<br />

Max allow<br />

tensile<br />

load (lb)**<br />

50 .12 35.70 1/4-20 .2164-.2108 .2489-.2367<br />

AISI 1008-<br />

1010<br />

240<br />

25 .30 42.60 3/8-16 .3331-.3266 .3737-.3595<br />

AISI 1008-<br />

1010<br />

610<br />

12 .50 38.80 1/2-13 .4485-.4411 .4985-.4822<br />

AISI 1008-<br />

1010<br />

1130<br />

8 .84 39.80 5/8-11 .5644-.5561 .6234-.6052<br />

AISI 1008-<br />

1010<br />

1810<br />

5 1.20 36.20 3/4-10 .6832-.6744 .7482-.7288 ASTM A36 2710<br />

50 .12 35.70 1/4-20 .2164-.2108 .2489-.2367<br />

AISI 1008-<br />

1010<br />

240<br />

25 .30 42.60 3/8-16 .3331-.3266 .3737-.3595<br />

AISI 1008-<br />

1010<br />

610<br />

12 .50 38.80 1/2-13 .4485-.4411 .4985-.4822<br />

AISI 1008-<br />

1010<br />

1130<br />

50 .12 59.50 1/4-20 .2164-.2108 .2489-.2367<br />

AISI 1008-<br />

1010<br />

240<br />

25 .30 71.30 3/8-16 .3331-.3266 .3737-.3595<br />

AISI 1008-<br />

1010<br />

610<br />

12 .50 61.40 1/2-13 .4485-.4411 .4985-.4822<br />

AISI 1008-<br />

1010<br />

1130<br />

8 .84 66.50 5/8-11 .5644-.5561 .6234-.6052<br />

AISI 1008-<br />

1010<br />

1810<br />

5 1.20 60.00 3/4-10 .6832-.6744 .7482-.7288 ASTM A36 2710<br />

50 .12 59.50 1/4-20 .2164-.2108 .2489-.2367<br />

AISI 1008-<br />

1010<br />

240<br />

25 .30 71.30 3/8-16 .3331-.3266 .3737-.3595<br />

AISI 1008-<br />

1010<br />

610<br />

12 .50 61.40 1/2-13 .4485-.4411 .4985-.4822<br />

AISI 1008-<br />

1010<br />

1130<br />

8 .84 66.50 5/8-11 .5644-.5561 .6234-.6052<br />

AISI 1008-<br />

1010<br />

1810<br />

5 1.20 60.00 3/4-10 .6832-.6744 .7482-.7288 ASTM A36 2710

<strong>Product</strong> <strong>Submitted</strong>:<br />

BC Beam Clamp<br />

Feature/service:<br />

Size Range:<br />

Material:<br />

Finish:<br />

Approvals:<br />

Listings:<br />

Conforms with:<br />

Installation:<br />

Structural attachment (with infinite adjustment) to top or bottom of metal beams, purlins,<br />

channel or angle iron to support hanger rod.<br />

1/4” through 3/4” rod sizes<br />

Malleable iron casting with a hardened cup point set screw <strong>and</strong> locknut<br />

Plain or EG (Electro-Galvanized)<br />

Factory Mutual - FM (3/8” thru 3/4” only)<br />

Underwriter Laboratories - UL, cUL (3/8” thru 1/2” only)<br />

Federal specification WW-H-171 (Type 19) <strong>and</strong> Manufacturers St<strong>and</strong>ardization Society<br />

MSS-SP-58 (Type 19)<br />

Install in accordance with ANSI/MSS-SP-69<br />

Ordering/Technical Information:<br />

Item #<br />

Description<br />

Box<br />

Qty<br />

Minimum setscrew<br />

torque (ft-lb)<br />

Max set-screw<br />

torque (ft-lb)<br />

Rod<br />

Size<br />

"A"<br />

Max<br />

Pipe<br />

Size<br />

Dim<br />

"B"<br />

Dim<br />

"C"<br />

Dim<br />

"D"<br />

Dim<br />

"E"<br />

Max allow load<br />

(lb)*<br />

Top Bottom<br />

00257366 BC 3/8" 100 5 (60 in-lb) 7.5 (90 in-lb) 3/8" 4" 0.906" 1.732" 1.520" 3/8" 500 250<br />

00257367 BC 1/2" 50 5 (60 in-lb) 7.5 (90 in-lb) 1/2" 8" 0.906" 1.89" 1.575" 3/8" 950 760<br />

00257368 BC 5/8" 50 10 (120 in-lb) 15 (180 in-lb) 5/8" 8" 0.906" 2.087" 1.654" 1/2" 950 760<br />

00257369 BC 3/4" 50 10 (120 in-lb) 15 (180 in-lb) 3/4" 8" 1.024" 2.283" 1.654" 1/2" 950 760<br />

00258002 BC-EG 1/4" 100 3.5 (40 in-lb) 5 (60 in-lb) 1/4" NA 0.827" 1.614" 1.496" 1/4" 350 NA<br />

00306600 BC-EG 3/8" 100 5 (60 in-lb) 7.5 (90 in-lb) 3/8" 4" 0.906" 1.732" 1.52" 3/8" 500 250<br />

00306601 BC-EG 1/2" 50 5 (60 in-lb) 7.5 (90 in-lb) 1/2" 8" 0.906" 1.89" 1.575" 3/8" 950 760<br />

CAUTION! Correct torquing is essential for proper clamp performance.<br />

Note: In the absence of a torque wrench:<br />

a. The set-screw should be finger tightened to the I-Beam <strong>and</strong> then an additional one-half turn<br />

applied to the set-screw.<br />

*Based on a safety factor of 3.