Types of Anchors for Anchoring to Concrete - Hilti

Types of Anchors for Anchoring to Concrete - Hilti

Types of Anchors for Anchoring to Concrete - Hilti

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PART TWO...<br />

<strong>Types</strong> <strong>of</strong> <strong>Anchors</strong> <strong>for</strong><br />

<strong>Anchoring</strong> <strong>to</strong> <strong>Concrete</strong><br />

Everything you wanted <strong>to</strong> know about types <strong>of</strong> anchors<br />

<strong>for</strong> use in concrete (well almost everything)<br />

by Richard E. Wollmershauser, P.E., FACI<br />

Designers and installers <strong>of</strong> anchors<br />

<strong>for</strong> fastening attachments and structural<br />

components <strong>to</strong> concrete face a seemingly<br />

unlimited variety <strong>of</strong> anchoring products.<br />

How is one supposed <strong>to</strong> know<br />

which is the “right” anchor <strong>for</strong> a given<br />

application? This article gives a brief<br />

overview <strong>of</strong> the types <strong>of</strong> anchors available,<br />

how they develop the capacity <strong>to</strong><br />

resist loads, and some general comments<br />

about appropriateness <strong>of</strong> these anchors<br />

<strong>for</strong> different applications.<br />

<strong>Anchors</strong> can be separated in<strong>to</strong> two<br />

major categories, those that are placed<br />

be<strong>for</strong>e the concrete is cast, known as<br />

cast-in-place anchors, and those that are<br />

installed in<strong>to</strong> hardened concrete, known<br />

as post-installed or drilled-in anchors.<br />

Each <strong>of</strong> these two categories is composed<br />

<strong>of</strong> a variety <strong>of</strong> different anchors, all <strong>of</strong><br />

which transfer loads from the attachment<br />

<strong>to</strong> the concrete in a variety <strong>of</strong> ways<br />

depending on their individual designs.<br />

LOADS AND LOAD-TRANSFER<br />

MECHANISMS<br />

Be<strong>for</strong>e reviewing the various types <strong>of</strong><br />

anchors, it is appropriate <strong>to</strong> present the<br />

types <strong>of</strong> loads that anchors must resist<br />

and mechanisms <strong>for</strong> load-transfer from<br />

anchor <strong>to</strong> concrete.<br />

The primary types <strong>of</strong> loads <strong>to</strong> be<br />

resisted in normal construction are static<br />

and dynamic. Load fac<strong>to</strong>rs are spelled<br />

out in the applicable building codes. Static<br />

loads can be tension, shear, or combinations<br />

<strong>of</strong> both. Dynamic loads can be<br />

seismic, fatigue, wind, and shock. The<br />

many types <strong>of</strong> anchors available have<br />

characteristics that make them suitable<br />

<strong>for</strong> or unsuitable <strong>for</strong> use under these various<br />

types <strong>of</strong> loads. Two state-<strong>of</strong>-the-art<br />

documents, references 1 and 2, give<br />

much more detailed in<strong>for</strong>mation. Especially<br />

good are approval agency evaluation<br />

reports such as ICBO ES, BOCA,<br />

and SBCCI or product listings <strong>for</strong> specific<br />

use as issued by listing agencies (e.g.<br />

UL and FM). Manufacturers’ literature<br />

may specify the applications <strong>for</strong> which<br />

anchors are qualified and if test reports<br />

are available <strong>to</strong> document capacities.<br />

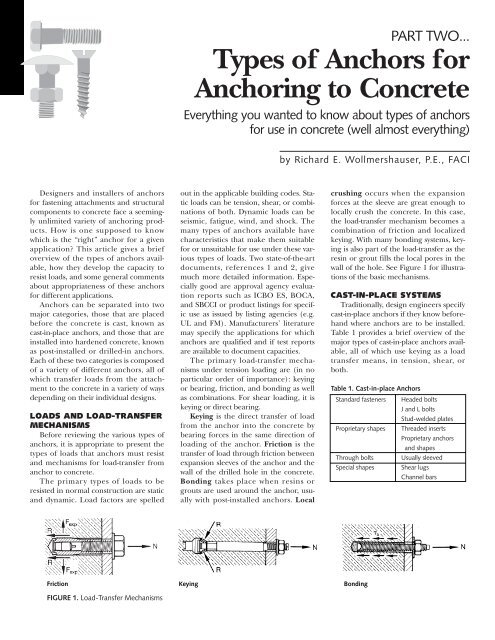

The primary load-transfer mechanisms<br />

under tension loading are (in no<br />

particular order <strong>of</strong> importance): keying<br />

or bearing, friction, and bonding as well<br />

as combinations. For shear loading, it is<br />

keying or direct bearing.<br />

Keying is the direct transfer <strong>of</strong> load<br />

from the anchor in<strong>to</strong> the concrete by<br />

bearing <strong>for</strong>ces in the same direction <strong>of</strong><br />

loading <strong>of</strong> the anchor. Friction is the<br />

transfer <strong>of</strong> load through friction between<br />

expansion sleeves <strong>of</strong> the anchor and the<br />

wall <strong>of</strong> the drilled hole in the concrete.<br />

Bonding takes place when resins or<br />

grouts are used around the anchor, usually<br />

with post-installed anchors. Local<br />

crushing occurs when the expansion<br />

<strong>for</strong>ces at the sleeve are great enough <strong>to</strong><br />

locally crush the concrete. In this case,<br />

the load-transfer mechanism becomes a<br />

combination <strong>of</strong> friction and localized<br />

keying. With many bonding systems, keying<br />

is also part <strong>of</strong> the load-transfer as the<br />

resin or grout fills the local pores in the<br />

wall <strong>of</strong> the hole. See Figure 1 <strong>for</strong> illustrations<br />

<strong>of</strong> the basic mechanisms.<br />

CAST-IN-PLACE SYSTEMS<br />

Traditionally, design engineers specify<br />

cast-in-place anchors if they know be<strong>for</strong>ehand<br />

where anchors are <strong>to</strong> be installed.<br />

Table 1 provides a brief overview <strong>of</strong> the<br />

major types <strong>of</strong> cast-in-place anchors available,<br />

all <strong>of</strong> which use keying as a load<br />

transfer means, in tension, shear, or<br />

both.<br />

Table 1. Cast-in-place <strong>Anchors</strong><br />

Standard fasteners Headed bolts<br />

J and L bolts<br />

Stud-welded plates<br />

Proprietary shapes Threaded inserts<br />

Proprietary anchors<br />

and shapes<br />

Through bolts Usually sleeved<br />

Special shapes Shear lugs<br />

Channel bars<br />

Friction Keying Bonding<br />

FIGURE 1. Load-Transfer Mechanisms

1.5<br />

Traditionally, design<br />

engineers specify<br />

cast-in-place anchors if<br />

they know be<strong>for</strong>ehand<br />

where anchors are <strong>to</strong><br />

be installed.<br />

Headed Bolt L-Bolt J-Bolt Stud-welded Plate<br />

FIGURE 2. Cast-in-place <strong>Anchors</strong><br />

Many <strong>of</strong> these types <strong>of</strong> anchors have<br />

special uses. Shear lugs and stud-welded<br />

plates provide large shear resistance,<br />

while channel bars give specific attachment<br />

capability. J and L bolts are typically<br />

used <strong>for</strong> anchoring sill plates <strong>to</strong><br />

foundations, but have a tendency <strong>to</strong><br />

straighten and pull out under high tension<br />

loading. Headed bolts under<br />

ASTM A 490 and F 1554 specifications<br />

are veritable workhorses <strong>for</strong> structural<br />

engineers.<br />

But what if the cast-in-place anchor is<br />

mislocated, or if the location <strong>of</strong> the<br />

anchor is not known be<strong>for</strong>e construction,<br />

or additional anchorages need <strong>to</strong><br />

be made after the concrete is cast? The<br />

post-installed anchor industry has developed<br />

a wide variety <strong>of</strong> products <strong>for</strong> these<br />

situations.<br />

POST-INSTALLED ANCHORS<br />

With the development and improvements<br />

<strong>of</strong> rotary hammer drills and carbide-tipped<br />

bits, the user has the<br />

capability <strong>to</strong> install many different kinds<br />

<strong>of</strong> post-installed anchors in hardened<br />

concrete virtually anywhere that is accessible<br />

<strong>to</strong> the drills.<br />

Post-installed anchors can be divided<br />

in<strong>to</strong> two major types, depending on the<br />

method <strong>of</strong> transferring load in<strong>to</strong> the<br />

concrete. They are mechanical systems<br />

and bonded or adhesive systems.<br />

<strong>Anchors</strong> can also be cross-classified<br />

according <strong>to</strong> their load carrying capability;<br />

heavy-duty, medium-duty and lightduty.<br />

Table 2 provides an overview <strong>of</strong> the<br />

major types <strong>of</strong> post-installed anchors currently<br />

available as well as a generalized<br />

load categorization.<br />

Table 2. Post-Installed <strong>Anchors</strong><br />

MECHANICAL SYSTEMS HEAVY- MEDIUM- LIGHT-<br />

DUTY DUTY DUTY<br />

Undercut <strong>Anchors</strong><br />

•<br />

Torque-controlled expansion anchors<br />

Heavy duty sleeve anchor • •<br />

Wedge anchors • • x<br />

Coil anchors • • x<br />

Screw anchors • • •<br />

Sleeve anchors • •<br />

Light duty metal anchors<br />

•<br />

Plastic anchors<br />

•<br />

Displacement-controlled expansion anchors<br />

Drop-in x • x<br />

Self-drilling x • x<br />

BONDED OR ADHESIVE SYSTEMS<br />

Using threaded rods or rein<strong>for</strong>cing bars<br />

Capsule systems • • x<br />

Cartridge systems • • x<br />

Bulk-injection systems • • x<br />

Cemetitious or epoxy grouted systems • • x<br />

• Indicates normal category<br />

x Indicates possible but not primary category<br />

MECHANICAL<br />

ANCHORING SYSTEMS<br />

While mechanical anchors have been<br />

available <strong>for</strong> several decades, there have<br />

been significant advances in the types<br />

and capabilities <strong>of</strong> these systems. They<br />

cover the range from heavy duty <strong>to</strong> light<br />

duty capacities. The major concern is <strong>to</strong><br />

select the appropriate anchors that will<br />

resist the expected loads <strong>for</strong> the given<br />

application. Is the anchor expected <strong>to</strong><br />

experience seismic or fatigue loads, or<br />

merely static loads? While some anchors<br />

will withstand all <strong>of</strong> these types <strong>of</strong> loads,<br />

others may fail abruptly under dynamic<br />

loading at a load level less than the static<br />

capacity.<br />

■ UNDERCUT ANCHORS<br />

These anchors have been on the market<br />

<strong>for</strong> about 20 years. They are excellent<br />

<strong>for</strong> use under both static and<br />

dynamic loads. They obtain their holding<br />

capacity through keying, that is,<br />

direct bearing on the concrete, and,<br />

under proper installation, can withstand<br />

very high loads without slipping out <strong>of</strong><br />

the drilled hole. They are the preferred<br />

anchors <strong>for</strong> use where cracks in tension<br />

zones <strong>of</strong> the concrete can be expected <strong>to</strong><br />

occur.

■ EXPANSION ANCHORS<br />

Expansion anchors have been available<br />

<strong>for</strong> at least 30 years. There are two<br />

basic types that are distinguished by their<br />

operating principles. The first, <strong>to</strong>rquecontrolled<br />

expansion anchors, are<br />

installed by inserting the anchor in<strong>to</strong> the<br />

drilled hole, and applying the prescribed<br />

setting <strong>to</strong>rque <strong>to</strong> the head or nut. A cone<br />

at the bot<strong>to</strong>m <strong>of</strong> the anchor is pulled up<br />

in<strong>to</strong> an expansion sleeve that expands<br />

in<strong>to</strong> the concrete with local crushing,<br />

and providing both friction and localized<br />

keying as load-transfer mechanisms.<br />

Most have a beneficial follow-up expansion<br />

characteristic that under tension<br />

loading, the more the anchor bolt displaces<br />

upward out <strong>of</strong> the hole, the<br />

greater the expansion <strong>for</strong>ces.<br />

There are several types available that<br />

vary significantly in their ability <strong>to</strong> resist<br />

static and dynamic loads. The heavy-duty<br />

sleeve anchor (not <strong>to</strong> be confused with<br />

the light duty sleeve anchor composed <strong>of</strong><br />

a sheet metal sleeve around a cone) can<br />

resist dynamic loads as well as function<br />

well in expected cracks in concrete.<br />

Wedge anchors are the most common<br />

type <strong>of</strong> <strong>to</strong>rque-controlled expansion<br />

anchor. Many have been tested <strong>for</strong> resisting<br />

seismic loads and have received<br />

ICBO ES Evaluation Report listings <strong>for</strong><br />

such service.<br />

Sleeve anchors are generally considered<br />

light duty, and rely more on friction<br />

and less on local crushing and keying <strong>of</strong><br />

the concrete. They can be used in hollow<br />

masonry.<br />

The second major type <strong>of</strong> expansion<br />

anchor is the displacement-controlled<br />

expansion anchor. Two primary examples<br />

are the drop-in and the self-driller.<br />

Drop-in anchors are installed in the<br />

predrilled hole by use <strong>of</strong> a setting <strong>to</strong>ol<br />

that drives a plug in<strong>to</strong> the expansion<br />

portion <strong>of</strong> the anchor. The lower section<br />

<strong>of</strong> the anchor is expanded in<strong>to</strong> the concrete,<br />

which experiences local crushing.<br />

The second type has cutting teeth on the<br />

lower end and drills its own hole. The<br />

anchor is driven on<strong>to</strong> an expansion plug<br />

that expands the lower portion <strong>of</strong> the<br />

anchor in<strong>to</strong> the concrete. These anchors<br />

derive their holding capacity from friction<br />

and keying. The drawback is that<br />

they do not have any follow-up expansion.<br />

Once set, they do not expand further<br />

under loading. If the plug is not<br />

Sleeve Anchor<br />

FIGURE 3. Mechanical <strong>Anchors</strong><br />

Torque-controlled<br />

Expansion Anchor<br />

sufficiently set, the anchor may experience<br />

reduced capacity.<br />

■ OTHER TYPES OF<br />

MECHANICAL ANCHORS<br />

Screw anchors <strong>of</strong> smaller diameters<br />

and used <strong>for</strong> light duty applications have<br />

been available <strong>for</strong> many years. They are<br />

installed in<strong>to</strong> holes drilled with matched<strong>to</strong>lerance<br />

bits. Recently, manufacturers<br />

have been introducing larger diameter<br />

screw anchors in the heavy-duty range,<br />

either installed in<strong>to</strong> holes drilled with<br />

matched-<strong>to</strong>lerance bits or using bits<br />

meeting the requirements <strong>of</strong> ANSI<br />

B212.15. They distribute the load in<strong>to</strong><br />

the concrete through load transfer from<br />

the threads <strong>to</strong> the concrete (keying).<br />

Coil anchors have also been introduced<br />

in<strong>to</strong> the market in the heavy-duty<br />

Heavy-duty<br />

Sleeve Anchor<br />

Undercut<br />

Anchor<br />

Drop-in Anchor Self-drilling Anchor Stud Anchor<br />

FIGURE 4. Displacement-controlled Expansion <strong>Anchors</strong><br />

load range. A coil anchor is composed <strong>of</strong><br />

a coil near the end <strong>of</strong> a specially<br />

designed lag bolt. As the bolt is <strong>to</strong>rqued,<br />

the screw advances through the coil,<br />

which expands in<strong>to</strong> the concrete. High<br />

load capacities can be developed.<br />

■ LIGHT DUTY ANCHORS<br />

There are many light duty anchors<br />

available, made <strong>of</strong> metals and plastics.<br />

They function in a variety <strong>of</strong> base materials,<br />

concrete, masonry, wood, drywall,<br />

etc. Manufacturers publish test data <strong>to</strong><br />

document their capacities in these base<br />

materials.<br />

BONDED ANCHOR SYSTEMS<br />

Bonded resin or adhesive anchors<br />

were generally introduced in<strong>to</strong> the construction<br />

market about twenty years ago.

Bonded systems use a combination <strong>of</strong><br />

adhesive bond and micro keying in<strong>to</strong> the<br />

pores <strong>of</strong> the concrete. Early systems used<br />

polyester resin, epoxies, and later, vinyl<br />

ester resins. In recent years, a larger variety<br />

<strong>of</strong> resins have been developed that<br />

have individual advantages, such as use<br />

in high temperatures, low temperatures,<br />

damp and wet holes, etc. For two component<br />

epoxy systems, the ratio <strong>of</strong> hardener<br />

<strong>to</strong> resin is critical. Prepackaged<br />

cartridge systems assure that the proper<br />

mixing is obtained. While a variety <strong>of</strong><br />

installation methods are used, most are<br />

two component resin systems that<br />

anchor threaded rod in<strong>to</strong> predrilled<br />

holes. Most will resist dynamic loads,<br />

both seismic and fatigue, but documentation<br />

in the <strong>for</strong>m <strong>of</strong> test reports should<br />

be obtained. Bonded or adhesive<br />

anchoring systems are not well suited <strong>for</strong><br />

cracked tensile zones <strong>of</strong> concrete since<br />

about 1/2 the bonding is lost, unless one<br />

uses special anchoring systems developed<br />

<strong>for</strong> use in cracked concrete. One<br />

should also use the recommended drill<br />

bit size, since many <strong>of</strong> the adhesives are<br />

sensitive <strong>to</strong> the size <strong>of</strong> the gap between<br />

the anchor rod and the concrete.<br />

■ CAPSULE SYSTEMS<br />

The original capsules were made <strong>of</strong><br />

glass, with an internal glass capsule that<br />

contained the hardener. Recent versions<br />

use plastic foil instead <strong>of</strong> the glass capsules.<br />

The capsule is inserted in<strong>to</strong> the<br />

hole. The threaded rod or rein<strong>for</strong>cing<br />

bar is then rotary-hammered in<strong>to</strong> the<br />

glass capsule, breaking the glass and mixing<br />

the resin and hardener. Capsule<br />

anchors provide very good bonding as<br />

the rotary mixing action wipes and<br />

cleans the surface <strong>of</strong> the hole, allowing<br />

the adhesive <strong>to</strong> bond well.<br />

■ CARTRIDGE SYSTEMS<br />

Introduced also about 20 years ago,<br />

cartridge systems are the most popular<br />

delivery method since they are also the<br />

most versatile. The resin and hardener<br />

are packaged in separate but connected<br />

side-by-side plastic or foil tubes. A mixing<br />

nozzle is placed on the end <strong>of</strong> the tubes<br />

and the resin and hardener dispensed by<br />

a hand operated or a pneumatic dispenser.<br />

Also used <strong>for</strong> heavy-duty applications,<br />

hole cleaning is very critical since<br />

dust on the concrete hole surface limits<br />

the bond and micro keying.<br />

■ BULK INJECTION SYSTEMS<br />

For high volume applications such as<br />

highway contracts or large building<br />

where repetitive installation <strong>of</strong> anchors is<br />

required, bulk mechanical and hydraulic<br />

dispensing systems are available. Attention<br />

<strong>to</strong> the proper mixing ratio <strong>for</strong> epoxy<br />

resins is critical since bulk equipment<br />

can go “<strong>of</strong>f ratio.”<br />

■ GROUTED SYSTEMS<br />

Predating resin systems are cemetitious<br />

grouts. There are a variety <strong>of</strong> proprietary<br />

systems available. Non-shrink or<br />

slightly expansive grouts are preferred <strong>to</strong><br />

prevent shrinkage and lack <strong>of</strong> bonding<br />

<strong>to</strong> the existing concrete.<br />

IN SUMMARY…<br />

A wide variety <strong>of</strong> anchoring systems<br />

are available. The correct selection<br />

depends on several fac<strong>to</strong>rs, including<br />

types <strong>of</strong> loads <strong>to</strong> be resisted, magnitude<br />

<strong>of</strong> the load, type <strong>of</strong> base material (concrete<br />

or masonry), and environment<br />

conditions (damp, wet, dry), among others.<br />

The manufacturers’ literature provides<br />

a good starting place, but also look<br />

<strong>for</strong> evaluation reports and product listings,<br />

since they may be required under<br />

many building codes. ■<br />

REFERENCES<br />

1. State-<strong>of</strong>-the-Art Report on Anchorage <strong>to</strong><br />

<strong>Concrete</strong> ACI 355.1R-91, American<br />

<strong>Concrete</strong> Institute, Detroit, 1991.<br />

2. Fastenings <strong>to</strong> <strong>Concrete</strong> and Masonry<br />

Structures; State <strong>of</strong> the Art Report,<br />

Comité Euro-Intérnational du Bé<strong>to</strong>n,<br />

Thomas Tel<strong>for</strong>d Services Ltd., London,<br />

1994.<br />

3. ANSI B212.15-1994, American National<br />

Standard <strong>for</strong> Cutting Tools—Carbide-<br />

Tipped Masonry Drills and Blanks <strong>for</strong><br />

Carbide-Tipped Masonry Drills, American<br />

National Standards Institute, New<br />

York, N. Y., 10 pp.<br />

Richard Wollmershauser is Direc<strong>to</strong>r Technical<br />

Services <strong>for</strong> <strong>Hilti</strong>, Inc. <strong>of</strong> Tulsa,<br />

Oklahoma. He has been active in the concrete<br />

anchor industry <strong>for</strong> the past 20 years.<br />

He is a registered PE in Ohio and<br />

Oklahoma and a Fellow <strong>of</strong> the American<br />

<strong>Concrete</strong> Institute. He currently serves as<br />

Vice-President <strong>of</strong> CAMA, The <strong>Concrete</strong><br />

Anchor Manufactures Association, Chairman<br />

<strong>of</strong> ASTM Subcommittee E06.13,<br />

Per<strong>for</strong>mance <strong>of</strong> Connections in Building<br />

Construction, and just completed 7 years as<br />

Chairman <strong>of</strong> the American <strong>Concrete</strong><br />

Institute Committee 355, Anchorage <strong>to</strong><br />

<strong>Concrete</strong>. He was edi<strong>to</strong>r <strong>of</strong> the ACI State-<strong>of</strong>the-Report<br />

on Anchorage <strong>to</strong> <strong>Concrete</strong> (ACI<br />

355R1-93). He also serves on the Federation<br />

International du Be<strong>to</strong>n Task Group<br />

SAG 4 Fastening <strong>to</strong> <strong>Concrete</strong> and Masonry.<br />

He served on three committees <strong>of</strong> the recent<br />

NEHRP 2000 Seismic Provisions Update<br />

program where he was concerned with the<br />

introduction <strong>of</strong> anchoring design methods.<br />

Adhesive Capsule<br />

Anchor<br />

Adhesive Cartridge<br />

System<br />

FIGURE 5. Adhesive Bonded Anchor Systems