Types of Anchors for Anchoring to Concrete - Hilti

Types of Anchors for Anchoring to Concrete - Hilti

Types of Anchors for Anchoring to Concrete - Hilti

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

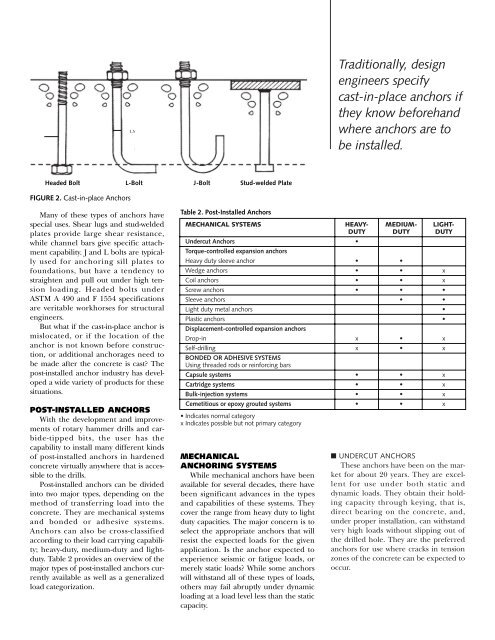

1.5<br />

Traditionally, design<br />

engineers specify<br />

cast-in-place anchors if<br />

they know be<strong>for</strong>ehand<br />

where anchors are <strong>to</strong><br />

be installed.<br />

Headed Bolt L-Bolt J-Bolt Stud-welded Plate<br />

FIGURE 2. Cast-in-place <strong>Anchors</strong><br />

Many <strong>of</strong> these types <strong>of</strong> anchors have<br />

special uses. Shear lugs and stud-welded<br />

plates provide large shear resistance,<br />

while channel bars give specific attachment<br />

capability. J and L bolts are typically<br />

used <strong>for</strong> anchoring sill plates <strong>to</strong><br />

foundations, but have a tendency <strong>to</strong><br />

straighten and pull out under high tension<br />

loading. Headed bolts under<br />

ASTM A 490 and F 1554 specifications<br />

are veritable workhorses <strong>for</strong> structural<br />

engineers.<br />

But what if the cast-in-place anchor is<br />

mislocated, or if the location <strong>of</strong> the<br />

anchor is not known be<strong>for</strong>e construction,<br />

or additional anchorages need <strong>to</strong><br />

be made after the concrete is cast? The<br />

post-installed anchor industry has developed<br />

a wide variety <strong>of</strong> products <strong>for</strong> these<br />

situations.<br />

POST-INSTALLED ANCHORS<br />

With the development and improvements<br />

<strong>of</strong> rotary hammer drills and carbide-tipped<br />

bits, the user has the<br />

capability <strong>to</strong> install many different kinds<br />

<strong>of</strong> post-installed anchors in hardened<br />

concrete virtually anywhere that is accessible<br />

<strong>to</strong> the drills.<br />

Post-installed anchors can be divided<br />

in<strong>to</strong> two major types, depending on the<br />

method <strong>of</strong> transferring load in<strong>to</strong> the<br />

concrete. They are mechanical systems<br />

and bonded or adhesive systems.<br />

<strong>Anchors</strong> can also be cross-classified<br />

according <strong>to</strong> their load carrying capability;<br />

heavy-duty, medium-duty and lightduty.<br />

Table 2 provides an overview <strong>of</strong> the<br />

major types <strong>of</strong> post-installed anchors currently<br />

available as well as a generalized<br />

load categorization.<br />

Table 2. Post-Installed <strong>Anchors</strong><br />

MECHANICAL SYSTEMS HEAVY- MEDIUM- LIGHT-<br />

DUTY DUTY DUTY<br />

Undercut <strong>Anchors</strong><br />

•<br />

Torque-controlled expansion anchors<br />

Heavy duty sleeve anchor • •<br />

Wedge anchors • • x<br />

Coil anchors • • x<br />

Screw anchors • • •<br />

Sleeve anchors • •<br />

Light duty metal anchors<br />

•<br />

Plastic anchors<br />

•<br />

Displacement-controlled expansion anchors<br />

Drop-in x • x<br />

Self-drilling x • x<br />

BONDED OR ADHESIVE SYSTEMS<br />

Using threaded rods or rein<strong>for</strong>cing bars<br />

Capsule systems • • x<br />

Cartridge systems • • x<br />

Bulk-injection systems • • x<br />

Cemetitious or epoxy grouted systems • • x<br />

• Indicates normal category<br />

x Indicates possible but not primary category<br />

MECHANICAL<br />

ANCHORING SYSTEMS<br />

While mechanical anchors have been<br />

available <strong>for</strong> several decades, there have<br />

been significant advances in the types<br />

and capabilities <strong>of</strong> these systems. They<br />

cover the range from heavy duty <strong>to</strong> light<br />

duty capacities. The major concern is <strong>to</strong><br />

select the appropriate anchors that will<br />

resist the expected loads <strong>for</strong> the given<br />

application. Is the anchor expected <strong>to</strong><br />

experience seismic or fatigue loads, or<br />

merely static loads? While some anchors<br />

will withstand all <strong>of</strong> these types <strong>of</strong> loads,<br />

others may fail abruptly under dynamic<br />

loading at a load level less than the static<br />

capacity.<br />

■ UNDERCUT ANCHORS<br />

These anchors have been on the market<br />

<strong>for</strong> about 20 years. They are excellent<br />

<strong>for</strong> use under both static and<br />

dynamic loads. They obtain their holding<br />

capacity through keying, that is,<br />

direct bearing on the concrete, and,<br />

under proper installation, can withstand<br />

very high loads without slipping out <strong>of</strong><br />

the drilled hole. They are the preferred<br />

anchors <strong>for</strong> use where cracks in tension<br />

zones <strong>of</strong> the concrete can be expected <strong>to</strong><br />

occur.