Types of Anchors for Anchoring to Concrete - Hilti

Types of Anchors for Anchoring to Concrete - Hilti

Types of Anchors for Anchoring to Concrete - Hilti

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Bonded systems use a combination <strong>of</strong><br />

adhesive bond and micro keying in<strong>to</strong> the<br />

pores <strong>of</strong> the concrete. Early systems used<br />

polyester resin, epoxies, and later, vinyl<br />

ester resins. In recent years, a larger variety<br />

<strong>of</strong> resins have been developed that<br />

have individual advantages, such as use<br />

in high temperatures, low temperatures,<br />

damp and wet holes, etc. For two component<br />

epoxy systems, the ratio <strong>of</strong> hardener<br />

<strong>to</strong> resin is critical. Prepackaged<br />

cartridge systems assure that the proper<br />

mixing is obtained. While a variety <strong>of</strong><br />

installation methods are used, most are<br />

two component resin systems that<br />

anchor threaded rod in<strong>to</strong> predrilled<br />

holes. Most will resist dynamic loads,<br />

both seismic and fatigue, but documentation<br />

in the <strong>for</strong>m <strong>of</strong> test reports should<br />

be obtained. Bonded or adhesive<br />

anchoring systems are not well suited <strong>for</strong><br />

cracked tensile zones <strong>of</strong> concrete since<br />

about 1/2 the bonding is lost, unless one<br />

uses special anchoring systems developed<br />

<strong>for</strong> use in cracked concrete. One<br />

should also use the recommended drill<br />

bit size, since many <strong>of</strong> the adhesives are<br />

sensitive <strong>to</strong> the size <strong>of</strong> the gap between<br />

the anchor rod and the concrete.<br />

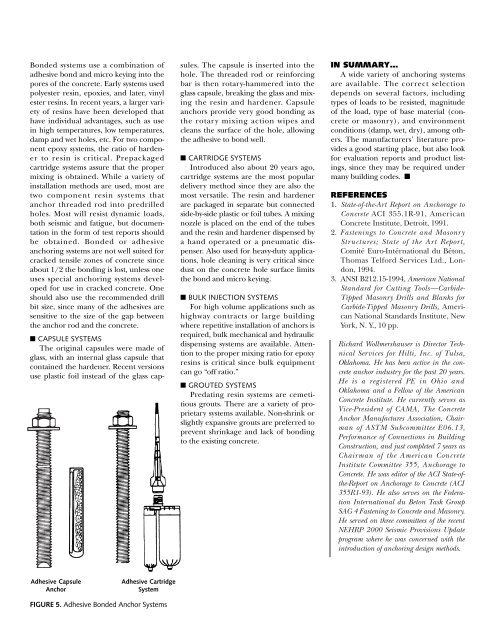

■ CAPSULE SYSTEMS<br />

The original capsules were made <strong>of</strong><br />

glass, with an internal glass capsule that<br />

contained the hardener. Recent versions<br />

use plastic foil instead <strong>of</strong> the glass capsules.<br />

The capsule is inserted in<strong>to</strong> the<br />

hole. The threaded rod or rein<strong>for</strong>cing<br />

bar is then rotary-hammered in<strong>to</strong> the<br />

glass capsule, breaking the glass and mixing<br />

the resin and hardener. Capsule<br />

anchors provide very good bonding as<br />

the rotary mixing action wipes and<br />

cleans the surface <strong>of</strong> the hole, allowing<br />

the adhesive <strong>to</strong> bond well.<br />

■ CARTRIDGE SYSTEMS<br />

Introduced also about 20 years ago,<br />

cartridge systems are the most popular<br />

delivery method since they are also the<br />

most versatile. The resin and hardener<br />

are packaged in separate but connected<br />

side-by-side plastic or foil tubes. A mixing<br />

nozzle is placed on the end <strong>of</strong> the tubes<br />

and the resin and hardener dispensed by<br />

a hand operated or a pneumatic dispenser.<br />

Also used <strong>for</strong> heavy-duty applications,<br />

hole cleaning is very critical since<br />

dust on the concrete hole surface limits<br />

the bond and micro keying.<br />

■ BULK INJECTION SYSTEMS<br />

For high volume applications such as<br />

highway contracts or large building<br />

where repetitive installation <strong>of</strong> anchors is<br />

required, bulk mechanical and hydraulic<br />

dispensing systems are available. Attention<br />

<strong>to</strong> the proper mixing ratio <strong>for</strong> epoxy<br />

resins is critical since bulk equipment<br />

can go “<strong>of</strong>f ratio.”<br />

■ GROUTED SYSTEMS<br />

Predating resin systems are cemetitious<br />

grouts. There are a variety <strong>of</strong> proprietary<br />

systems available. Non-shrink or<br />

slightly expansive grouts are preferred <strong>to</strong><br />

prevent shrinkage and lack <strong>of</strong> bonding<br />

<strong>to</strong> the existing concrete.<br />

IN SUMMARY…<br />

A wide variety <strong>of</strong> anchoring systems<br />

are available. The correct selection<br />

depends on several fac<strong>to</strong>rs, including<br />

types <strong>of</strong> loads <strong>to</strong> be resisted, magnitude<br />

<strong>of</strong> the load, type <strong>of</strong> base material (concrete<br />

or masonry), and environment<br />

conditions (damp, wet, dry), among others.<br />

The manufacturers’ literature provides<br />

a good starting place, but also look<br />

<strong>for</strong> evaluation reports and product listings,<br />

since they may be required under<br />

many building codes. ■<br />

REFERENCES<br />

1. State-<strong>of</strong>-the-Art Report on Anchorage <strong>to</strong><br />

<strong>Concrete</strong> ACI 355.1R-91, American<br />

<strong>Concrete</strong> Institute, Detroit, 1991.<br />

2. Fastenings <strong>to</strong> <strong>Concrete</strong> and Masonry<br />

Structures; State <strong>of</strong> the Art Report,<br />

Comité Euro-Intérnational du Bé<strong>to</strong>n,<br />

Thomas Tel<strong>for</strong>d Services Ltd., London,<br />

1994.<br />

3. ANSI B212.15-1994, American National<br />

Standard <strong>for</strong> Cutting Tools—Carbide-<br />

Tipped Masonry Drills and Blanks <strong>for</strong><br />

Carbide-Tipped Masonry Drills, American<br />

National Standards Institute, New<br />

York, N. Y., 10 pp.<br />

Richard Wollmershauser is Direc<strong>to</strong>r Technical<br />

Services <strong>for</strong> <strong>Hilti</strong>, Inc. <strong>of</strong> Tulsa,<br />

Oklahoma. He has been active in the concrete<br />

anchor industry <strong>for</strong> the past 20 years.<br />

He is a registered PE in Ohio and<br />

Oklahoma and a Fellow <strong>of</strong> the American<br />

<strong>Concrete</strong> Institute. He currently serves as<br />

Vice-President <strong>of</strong> CAMA, The <strong>Concrete</strong><br />

Anchor Manufactures Association, Chairman<br />

<strong>of</strong> ASTM Subcommittee E06.13,<br />

Per<strong>for</strong>mance <strong>of</strong> Connections in Building<br />

Construction, and just completed 7 years as<br />

Chairman <strong>of</strong> the American <strong>Concrete</strong><br />

Institute Committee 355, Anchorage <strong>to</strong><br />

<strong>Concrete</strong>. He was edi<strong>to</strong>r <strong>of</strong> the ACI State-<strong>of</strong>the-Report<br />

on Anchorage <strong>to</strong> <strong>Concrete</strong> (ACI<br />

355R1-93). He also serves on the Federation<br />

International du Be<strong>to</strong>n Task Group<br />

SAG 4 Fastening <strong>to</strong> <strong>Concrete</strong> and Masonry.<br />

He served on three committees <strong>of</strong> the recent<br />

NEHRP 2000 Seismic Provisions Update<br />

program where he was concerned with the<br />

introduction <strong>of</strong> anchoring design methods.<br />

Adhesive Capsule<br />

Anchor<br />

Adhesive Cartridge<br />

System<br />

FIGURE 5. Adhesive Bonded Anchor Systems