Pilatus PC-21 Depron-Version - HT-Modellbau

Pilatus PC-21 Depron-Version - HT-Modellbau

Pilatus PC-21 Depron-Version - HT-Modellbau

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Recommended general procedures warranting best results of kit assembly:<br />

Polystyrene parts should be handled with care, do not put down heavy objects on them, do not put them on sharp edges, so that<br />

you would not damage their surface (by impact, too high finger pressure, etc.). These damages could be repaired by hair dryer or<br />

steam (it should be tested on a material sample!).<br />

Fit up parts for one operation on the desk without gluing. If necessary modify them and when they fit perfectly glue them<br />

in correct position.<br />

The parts are painted with alcohol-based paints, which are not resistant to paint thinners. In such areas where glue has to be<br />

applied, use the glue sparingly so that it would not flow out and with extreme care as not to damage the paint.<br />

Cut all PSH parts out with small overlap (cca 1 mm), modify them by grinding before gluing. Repair edges by a paint.<br />

Make the openings in PP parts with a safety razor, sharp knife or a scalpel. Blunt knife tears edges, the cut is not smooth!<br />

Glue the PP parts together with the UHU-por glue (or LA glue if necessary). Apply thin layer, spread well, let dry for a while and<br />

press parts together. Excessive UHU-por glue can be washed by gasoline (does not damage alcohol based paint). Glue strength<br />

joints with EPOXY. Tack the PSH parts (not PP parts!) with instant glue (CyA glue in the guide). Recommended type of glue is<br />

mentioned in the assembly illustrations.<br />

Clean milled edges of wooden parts by grinding with sandpaper before assembly.<br />

Assembly of Scale Model of<br />

"<strong>Pilatus</strong> <strong>PC</strong>-<strong>21</strong>"<br />

1) Before assembly application of decals on fuselage, wings and tail is recommended.<br />

The set of landing gear parts is not part of the kit, it is supplied separately.<br />

Connection of electric accessories "on the desk" is necessary!<br />

Optional parts:<br />

2x microservo 8g<br />

2x microservo 12g<br />

1x motor + regulator, Mega<br />

1x receiver, 5 channels<br />

2x extension cables of servos, 30 cm<br />

2x extension cables of servos for tail, 15cm<br />

1x battery 3 cell Li-Pol 1500 mAh<br />

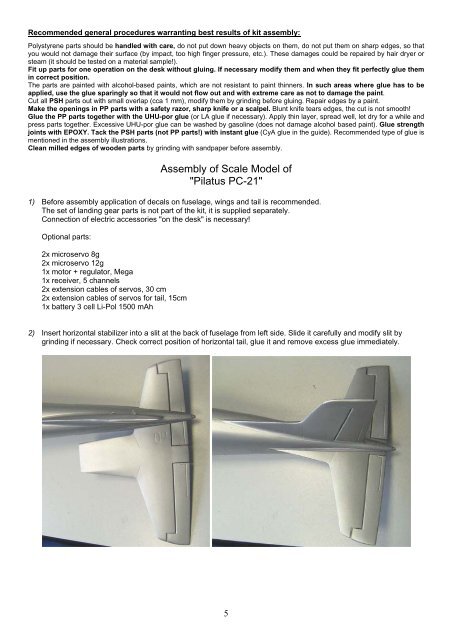

2) Insert horizontal stabilizer into a slit at the back of fuselage from left side. Slide it carefully and modify slit by<br />

grinding if necessary. Check correct position of horizontal tail, glue it and remove excess glue immediately.<br />

5

3) Install rod pins on levers of servos. Pass rods through bowdens in fuselage. Install servos into plywood plate in<br />

fuselage from below. Connect rods with servos and levers of rudder and elevator.<br />

4) Screw the motor with connected regulator to the bulkhead, pass it through the opening in bulkhead into fuselage.<br />

Put plastic motor hood on and check if shaft of the carrier passes through bonnet center and modify position of<br />

motor if necessary. Stick motor cover either to fuselage or fix it to inside spruce braces of fuselage using two<br />

screws.<br />

6

5) Cut a pad from balsa sheet according to battery size and cut out part of cockpit floor of the same size. You may<br />

make the pad longer so that you can move battery and modify the center of gravity. Glue balsa pad to fuselage.<br />

At the same time glue velcro to the pad and to the battery. Cut another pad from balsa for the receiver, fix it in<br />

front of batteries using velcro. Pass the antenna through fuselage and take it out through a small opening made at<br />

the back of fuselage.<br />

6) Remove carefully servo covers from wings and make slits for servo levers in them. Cut out opening for servos.<br />

Connect extension cables 30 cm to servos and pass them through the wing. Insert servos to prepared openings<br />

and stick bases of servos with a drop of glue. Glue servo covers in. Make links of aileron and servo levers from<br />

steel wire 0.8 mm and secure them with a drop of glue or with a piece of spaghetti.<br />

7) Cut and glue flap mechanism covers. Prepare openings in wings for their installation.<br />

WARNING! If you install landing gear, glue the covers into openings after installation of gear locks.<br />

If you are going to fly without landing gear, glue covers into slits and represent wheel tires using black paint.<br />

7

8) Make two parts from polypropylene strip 820 mm long and two 760 mm long. Glue the shorter parts to sides of<br />

front cockpit and longer parts to rear cockpit. Cut instrument panels out, paint them a glue them in. Assemble pilot<br />

seats, blind rear parts with parts cut from PP. Cut out parts of pilots, glue them together and caulk the seams.<br />

Paint pilots with light green-ochre paint, helmets with white paint. You can prepare oxygen mask tubes from<br />

pieces of spaghetti. Stick pilots to seats, you can prepare seat belts for better look. Install seats into fuselage.<br />

Assemble dial sight and glue it. Glue the cockpit.<br />

8

9) Assemble the spinner, propeller and install it. You can glue front part of the spinner or fix it with two screws.<br />

10) Deflections setting - ailerons can have slightly negative angle in basic position, max. 1 mm. Elevator slightly up at<br />

basic position, cca 1 mm.<br />

11) Insert batteries, install wing and verify correct position of the center of gravity. Modify it using batteries movement.<br />

67 - 72 mm from center leading edge at fuselage. Fix the wing with a plastic screw when connectors from<br />

receiver to aileron servos are connected. Be aware of a reaction moment of propeller when you launch model<br />

from the hand. It causes model tilting to left. Do not decrease throttle rapidly, make landing maneuver with<br />

running motor.<br />

12) Landing gear assembly<br />

Assemble the lock of nose gear from supplied parts and spruce lath so that steel wire would be inserted tightly to<br />

prepared opening. Prepare locks of main landing gear in the same way. Cut covers of landing gear wells and glue<br />

the lock of nose gear in. Locks of main landing gear will be glued to the lower wing covering. Assemble landing<br />

gear legs from supplied parts, glue shock absorbers from supplied parts to main legs, glue door rods and struts.<br />

Bend carefully nose gear cover and insert it into well. Modify main gear covers by bending ends to angle 90 o and<br />

by gluing bends, slide landing gear legs into locks, insert covers into locks and press legs to locks. Landing gear<br />

and wells are white.<br />

9

<strong>Pilatus</strong> <strong>PC</strong>-<strong>21</strong> Produce:<br />

<strong>HT</strong> <strong>Modellbau</strong><br />

Rebensweg 35<br />

CH-3293 Dotzingen<br />

Switzerland<br />

www.ht-modellbau.ch<br />

and<br />

FLYING STYRO KIT, spol. s r.o.<br />

J. Faimonové 11a, 628 00 BRNO, Czech Republic<br />

Tel.: 544<strong>21</strong>5000<br />

Fax: 544<strong>21</strong>0176<br />

e-mail: info@flyingstyrokit.cz<br />

www.flyingstyrokit.cz<br />

11