Therma - Rad Draft.pdf - Hurlcon Heating

Therma - Rad Draft.pdf - Hurlcon Heating

Therma - Rad Draft.pdf - Hurlcon Heating

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

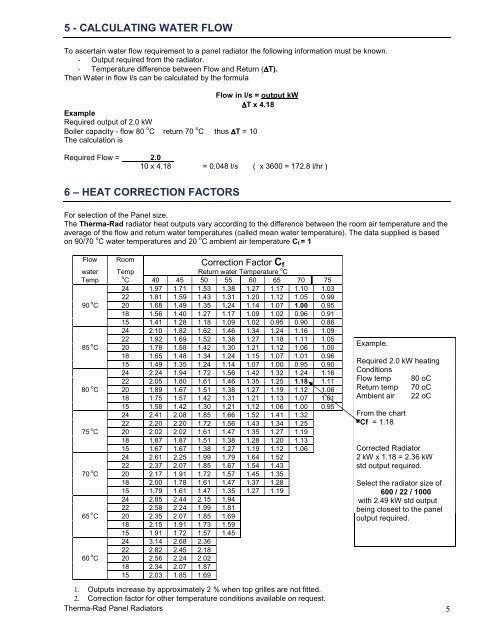

5 - CALCULATING WATER FLOW<br />

To ascertain water flow requirement to a panel radiator the following information must be known.<br />

- Output required from the radiator.<br />

- Temperature difference between Flow and Return (∆T).<br />

Then Water in flow l/s can be calculated by the formula<br />

Flow in l/s = output kW<br />

∆T x 4.18<br />

Example<br />

Required output of 2.0 kW<br />

Boiler capacity - flow 80 o C return 70 o C thus ∆T = 10<br />

The calculation is<br />

Required Flow = 2.0<br />

10 x 4.18 = 0.048 l/s ( x 3600 = 172.8 l/hr )<br />

6 – HEAT CORRECTION FACTORS<br />

For selection of the Panel size.<br />

The <strong>Therma</strong>-<strong>Rad</strong> radiator heat outputs vary according to the difference between the room air temperature and the<br />

average of the flow and return water temperatures (called mean water temperature). The data supplied is based<br />

on 90/70 o C water temperatures and 20 o C ambient air temperature C f = 1<br />

Flow Room<br />

Correction Factor C f<br />

water Temp Return water Temperature o C<br />

Temp<br />

o C 40 45 50 55 60 65 70 75<br />

24 1.97 1.71 1.53 1.38 1.27 1.17 1.10 1.03<br />

22 1.81 1.59 1.43 1.31 1.20 1.12 1.05 0.99<br />

90 o C 20 1.68 1.49 1.35 1.24 1.14 1.07 1.00 0.95<br />

18 1.56 1.40 1.27 1.17 1.09 1.02 0.96 0.91<br />

15 1.41 1.28 1.18 1.09 1.02 0.95 0.90 0.86<br />

24 2.10 1.82 1.62 1.46 1.34 1.24 1.16 1.09<br />

22 1.92 1.69 1.52 1.38 1.27 1.18 1.11 1.05<br />

85 o C 20 1.78 1.58 1.42 1.30 1.21 1.12 1.06 1.00<br />

18 1.65 1.48 1.34 1.24 1.15 1.07 1.01 0.96<br />

15 1.49 1.35 1.24 1.14 1.07 1.00 0.95 0.90<br />

24 2.24 1.94 1.72 1.56 1.42 1.32 1.24 1.16<br />

22 2.05 1.80 1.61 1.46 1.35 1.25 1.18 1.11<br />

80 o C 20 1.89 1.67 1.51 1.38 1.27 1.19 1.12 1.06<br />

18 1.75 1.57 1.42 1.31 1.21 1.13 1.07 1.01<br />

15 1.58 1.42 1.30 1.21 1.12 1.06 1.00 0.95<br />

24 2.41 2.08 1.85 1.66 1.52 1.41 1.32<br />

22 2.20 2.20 1.72 1.56 1.43 1.34 1.25<br />

75 o C 20 2.02 2.02 1.61 1.47 1.35 1.27 1.19<br />

18 1.87 1.87 1.51 1.38 1.28 1.20 1.13<br />

15 1.67 1.67 1.38 1.27 1.19 1.12 1.06<br />

24 2.61 2.25 1.99 1.79 1.64 1.52<br />

22 2.37 2.07 1.85 1.67 1.54 1.43<br />

70 o C 20 2.17 1.91 1.72 1.57 1.45 1.35<br />

18 2.00 1.78 1.61 1.47 1.37 1.28<br />

15 1.79 1.61 1.47 1.35 1.27 1.19<br />

24 2.85 2.44 2.15 1.94<br />

22 2.58 2.24 1.99 1.81<br />

65 o C 20 2.35 2.07 1.85 1.69<br />

18 2.15 1.91 1.73 1.59<br />

15 1.91 1.72 1.57 1.45<br />

24 3.14 2.68 2.36<br />

22 2.82 2.45 2.18<br />

60 o C 20 2.56 2.24 2.02<br />

18 2.34 2.07 1.87<br />

15 2.03 1.85 1.69<br />

Example.<br />

Required 2.0 kW heating<br />

Conditions<br />

Flow temp 80 oC<br />

Return temp 70 oC<br />

Ambient air 22 oC<br />

From the chart<br />

Cf = 1.18<br />

Corrected <strong>Rad</strong>iator<br />

2 kW x 1.18 = 2.36 kW<br />

std output required.<br />

Select the radiator size of<br />

600 / 22 / 1000<br />

with 2.49 kW std output<br />

being closest to the panel<br />

output required.<br />

1. Outputs increase by approximately 2 % when top grilles are not fitted.<br />

2. Correction factor for other temperature conditions available on request.<br />

<strong>Therma</strong>-<strong>Rad</strong> Panel <strong>Rad</strong>iators 5