The Finite Element Method for the Analysis of Non-Linear and ...

The Finite Element Method for the Analysis of Non-Linear and ...

The Finite Element Method for the Analysis of Non-Linear and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>The</strong> <strong>Finite</strong> <strong>Element</strong> <strong>Method</strong> <strong>for</strong> <strong>the</strong> <strong>Analysis</strong> <strong>of</strong><br />

<strong>Non</strong>-<strong>Linear</strong> <strong>and</strong> Dynamic Systems<br />

Pr<strong>of</strong>. Dr. Eleni Chatzi<br />

Lecture 7 - 5 November, 2010<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 1

Constitutive Relations<br />

Previously we examined <strong>the</strong> kinematic equations <strong>for</strong>mulation<br />

(displacement, strain displacement relations)<br />

<strong>The</strong> next step is to determine appropriate constitutive relationships<br />

<strong>of</strong> <strong>the</strong> <strong>for</strong>m:<br />

ex. linear analysis ⇒ σ = Eε<br />

σ = f(ε)<br />

When dealing with incremental analysis this is written in tensor<br />

<strong>for</strong>m <strong>for</strong> time t:<br />

t<br />

σ = t C ijrst ɛ rs<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 2

Constitutive Relations<br />

It is necessary that kinematic <strong>and</strong> constitutive relations are<br />

appropriate (ex. <strong>The</strong> Second Piola-Kirchh<strong>of</strong>f stress tensor is to<br />

be used with <strong>the</strong> Green Lagrange strain tensor).<br />

Ultimately, <strong>the</strong> position <strong>of</strong> <strong>the</strong> observer frame should not affect<br />

<strong>the</strong> constitutive relations <strong>of</strong> a material (material frame<br />

indifference or objectivity <strong>of</strong> <strong>the</strong> material response).<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 3

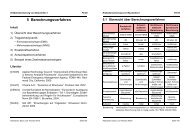

Overview <strong>of</strong> Material Descriptions<br />

We can discriminate amongst <strong>the</strong> following major classes <strong>of</strong><br />

material behavior<br />

Elastic, linear or nonlinear<br />

Hyperelastic<br />

Hypoelastic<br />

Elastoplastic<br />

Creep<br />

Viscoplastic<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 4

Solution Flowchart<br />

General Solution process in incremental nonlinear FE<br />

Known Solution at t:<br />

Stresses<br />

t σ, strains t ε,<br />

Internal material parameters t κ<br />

Known Quantities at iterations i- 1 :<br />

Nodal Displacements at first Iteration:<br />

<strong>and</strong> hence<br />

<strong>Element</strong> strains<br />

t+Δt<br />

ε i−1<br />

t+Δt<br />

U i−1<br />

Calculate at t+ Δt:<br />

t+Δt<br />

Stresses σ i−1<br />

Repat till Convergence<br />

Tangent stress strain matrix C i−1<br />

Internal material parameters<br />

t+Δt<br />

κ i−1<br />

• Elastic <strong>Analysis</strong>: directly obtain<br />

t+Δt<br />

t+Δt<br />

σ i−1 , C i−1 from ε i−1<br />

• Inelastic <strong>Analysis</strong>: Integrate to get<br />

t+Δt<br />

σ i−1<br />

t t+Δti−1<br />

= σ + ∫ dσ<br />

t<br />

Calculate:<br />

Incremental Displacement Vector ΔU i:<br />

t+Δt<br />

K i−1 ΔU i =<br />

<strong>The</strong>n,<br />

t+Δt<br />

R<br />

−<br />

t+Δt<br />

F i−1<br />

t+Δt t+Δt<br />

U i = U i−1 +<br />

ΔU i<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 5

Notation<br />

Main Stress - Strain pairs:<br />

Material <strong>Non</strong>linearity (small de<strong>for</strong>mations)<br />

Engineering Stress σ<br />

Engineering Strain ε<br />

TL <strong>for</strong>mulation (large de<strong>for</strong>mations)<br />

2nd Piola-Kirchh<strong>of</strong>f Stress S<br />

Green-Lagrange Strain ɛ<br />

UL <strong>for</strong>mulation (large de<strong>for</strong>mations)<br />

Cauchy Stress τ<br />

Almansi Strain ɛ A<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 6

Elastic Material<br />

For an elastic material <strong>the</strong> stress is a function <strong>of</strong> strain only <strong>The</strong><br />

stress path is <strong>the</strong> same both in loading <strong>and</strong> unloading<br />

<strong>Linear</strong> Elastic<br />

<strong>The</strong> elasticity (constitutive)<br />

tensor components, C ijrs are<br />

constant<br />

<strong>Non</strong>linear Elastic<br />

<strong>The</strong> elasticity (constitutive)<br />

tensor components, C ijrs are<br />

a function <strong>of</strong> strain<br />

Example: Almost all materials under small stress<br />

σ<br />

ε<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 7

Elastic Material<br />

For <strong>the</strong> case <strong>of</strong> an elastic material we already saw that <strong>the</strong> TL<br />

Formulation (used <strong>for</strong> large de<strong>for</strong>mation analysis) yields:<br />

t<br />

0S ij = t t<br />

0C ijrs 0ɛ rs<br />

<strong>The</strong> elasticity tensor <strong>for</strong> 3D stress conditions is defined as:<br />

t<br />

C ijrs = λδ ij δrs + µ(δ ir δjs + δ is δjr)<br />

where λ <strong>and</strong> µ are <strong>the</strong> Lamé constants <strong>and</strong> δ ij is <strong>the</strong> Kronecker delta,<br />

Eν<br />

λ =<br />

(ν)(1 − 2ν) , µ = E<br />

2(1 + ν)<br />

{ 0 i ≠ j<br />

δ ij =<br />

1 i = j<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 8

Elastic Material<br />

Important Note<br />

“<strong>The</strong> 2nd Piola-Kirchh<strong>of</strong>f (PK2) stress <strong>and</strong> Green-Lagrange strain<br />

tensor components are invariant to rigid body motions.”<br />

For problems with small strains we can take advantage <strong>of</strong> this<br />

observation <strong>and</strong> use any constitutive relationship that has been<br />

developed <strong>for</strong> engineering stress <strong>and</strong> strain measures by just<br />

substituting with <strong>the</strong> PK2 stress <strong>and</strong> Green-Lagrange strain<br />

This observation can be extended to all problems with large<br />

de<strong>for</strong>mations but small strain conditions such as <strong>the</strong> elastic or<br />

elastoplastic buckling problem <strong>and</strong> <strong>the</strong> collapse analysis <strong>of</strong> slender<br />

structures.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 9

Elastic Material<br />

UL Formulation<br />

We now write<br />

t<br />

τ ij = t tC ∗ ijrs<br />

t tɛ A rs<br />

where <strong>the</strong> elasticity tensor components <strong>of</strong> <strong>the</strong> UL constitutive matrix<br />

C ∗ , are related to <strong>the</strong> one <strong>of</strong> <strong>the</strong> TL <strong>for</strong>mulation C, through <strong>the</strong><br />

following relationship:<br />

t<br />

tC ∗ ijrs =<br />

t<br />

ρ<br />

0<br />

ρ<br />

t<br />

0x i,m<br />

t<br />

0x j,n<br />

t<br />

0C mnpq<br />

t<br />

0x r,p<br />

t<br />

0x s,q<br />

Also <strong>the</strong> Almansi strain tensor is related to <strong>the</strong> Green-Lagrange one<br />

through<br />

t<br />

tɛ A = 0 t<br />

X T 0ɛ t 0 t<br />

X<br />

<strong>The</strong>re<strong>for</strong>e <strong>the</strong> two <strong>for</strong>mulations are equivalent <strong>and</strong> interchangeable.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 10

Example<br />

Consider <strong>the</strong> four node element shown below. Examine <strong>the</strong> effect <strong>of</strong> using two<br />

different stress measures <strong>and</strong> <strong>the</strong> same constitutive matrix on <strong>the</strong> Cauchy stresses.<br />

2<br />

1<br />

3 4<br />

A. TL <strong>for</strong>mulation Using <strong>the</strong> PK2 stress measure <strong>and</strong> <strong>the</strong> Green-Lagrange strain<br />

tensor we have:<br />

t<br />

0S ij = t t<br />

0C ijrs 0 ɛ rs (1)<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 11

Example<br />

In order to define <strong>the</strong> required stresses <strong>and</strong> strains we need to determine <strong>the</strong> de<strong>for</strong>mation<br />

gradient t 0S, which in 2D is written as:<br />

⎡<br />

∂ t x 1 ∂ t ⎤<br />

x 1<br />

t<br />

0 X = ⎢ ∂ 0 x 1 ∂ 0 x 2<br />

⎣ ∂ t x 2 ∂ t ⎥<br />

x 2 ⎦ (2)<br />

∂ 0 x 1 ∂ 0 x 2<br />

<strong>The</strong> coordinates <strong>of</strong> a r<strong>and</strong>om point within <strong>the</strong> element are given as <strong>the</strong> weighted sum <strong>of</strong><br />

<strong>the</strong> nodal coordinates, where <strong>the</strong> weights are <strong>the</strong> shape functions. However, <strong>the</strong> shape<br />

functions are written with respect to <strong>the</strong> r, s system (isoparametric representation) as:<br />

N 1 = 1 4 (1 + r)(1 + s) N 2 = 1 (1 − r)(1 + s)<br />

4<br />

N 3 = 1 4 (1 − r)(1 − s) N 4 = 1 (3)<br />

4 (1 + r)(1 − s)<br />

From <strong>the</strong> given figure however we see that <strong>the</strong> 0 x 1 , 0 x 2 system is related to <strong>the</strong> r, s<br />

system through:<br />

0 x 1 = r + 1<br />

0 x 2 = s + 1 ⇒<br />

N 1 = 1 4 0 x 1 0 x 2 N 2 = 1 4 (2 − 0 x 1 )( 0 x 2 )<br />

(4)<br />

N 3 = 1 4 (2 − 0 x 1 )(2 − 0 x 2 ) N 4 = 1 4 0 x 1 (2 − 0 x 2 )<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 12

Example<br />

<strong>The</strong>re<strong>for</strong>e, we ultimately have:<br />

∂ t x i<br />

∂ 0 x j<br />

=<br />

<strong>The</strong> nodal coordinates at time t are:<br />

4∑<br />

k=1<br />

( ) ∂Nk t x k<br />

∂ 0 i (5)<br />

x j<br />

( t x 1<br />

1<br />

, t x 1 2) = (2 + 4t, 2) ( t x 2 1, t x 2 2) = (4t, 2)<br />

( t x 3 1, t x 3 2) = (0, 0) ( t x 4 1, t x 4 2) = (2, 0)<br />

(6)<br />

By substituting (4), (5) <strong>and</strong> (6) into Eqn (2) we obtain:<br />

[ ]<br />

t 1 2t<br />

0X =<br />

0 1<br />

From Lecture 4 we know that <strong>the</strong> Green-Langrange strain tensor will <strong>the</strong>n be:<br />

t<br />

0ɛ = 1 2 (t 0X T t 0X − I) ⇒<br />

[ ]<br />

t 0 t<br />

0ɛ =<br />

t 2t 2<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 13

Example<br />

Also, <strong>for</strong> plane strain strain conditions <strong>the</strong> constitutive tensor is:<br />

⎡<br />

1 ν 0<br />

C =<br />

E<br />

⎢ ν 1 0<br />

1 − ν 2 ⎣<br />

1 − ν<br />

0 0<br />

2<br />

⎤<br />

⎡<br />

E=5000,ν=0.3<br />

⎥<br />

⎢<br />

⎦ → ⎣<br />

6731 2885 0<br />

2885 6731 0<br />

0 0 1923<br />

Now, using <strong>the</strong> assumption <strong>of</strong> small strain we can use <strong>the</strong> above constitutive<br />

tensor <strong>for</strong> <strong>the</strong> relationship between <strong>the</strong> PK2 stress <strong>and</strong> <strong>the</strong> Green-Lagrange strain.<br />

Hence from Eqn (1):<br />

⎡<br />

⎢<br />

⎣<br />

S 11<br />

S 22<br />

S 12<br />

⎤<br />

⎡<br />

⎥ ⎢<br />

⎦ = ⎣<br />

5770t 2<br />

13462t 2<br />

3846t<br />

⎤<br />

⎥<br />

⎦<br />

⎤<br />

⎥<br />

⎦<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 14

Example<br />

<strong>The</strong>n, <strong>the</strong> Cauchy stress at time t can be obtained from <strong>the</strong> PK2<br />

stress as (Lecture 4):<br />

t ρ t<br />

0 ρ<br />

t τ = 0X t 0S t 0X T ⇒<br />

⎡ ⎤ ⎡<br />

τ 11 21000t 2 + 54000t 4 ⎤<br />

⎢ ⎥ ⎢<br />

⎣ τ 22 ⎦ = ⎣ 13000t 2 ⎥<br />

⎦<br />

τ 12 3800t + 27000t 3<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 15

Example<br />

B. Jaumann stress rate <strong>for</strong>mulation<br />

This <strong>for</strong>mulation uses <strong>the</strong> following constitutive relationship:<br />

t˜τ ij = t C ijrs t D rs (7)<br />

where <strong>the</strong> velocity strain tensor t D is computed using <strong>the</strong> velocity gradient L (see<br />

Lecture 4) :<br />

[ ]<br />

0 2<br />

L = ẊX −1 =<br />

0 0<br />

L can be decomposed to s symmetric part D = D T (<strong>the</strong> velocity strain tensor) <strong>and</strong> a<br />

skew symmetric part W = −W T (<strong>the</strong> spin tensor):<br />

L = D + W<br />

[<br />

0 1<br />

D =<br />

1 0<br />

which in this case yields<br />

] [ ]<br />

0 1<br />

, W =<br />

−1 0<br />

Now we use <strong>the</strong> same constitutive matrix C <strong>and</strong> Eqn (7) to obtain <strong>the</strong> Jaumann stress at<br />

time t:<br />

⎡ ⎤ ⎡ ⎤<br />

˜τ 11 0<br />

⎢ ⎥ ⎢ ⎥<br />

⎣ ˜τ 22 ⎦ = ⎣ 0 ⎦<br />

˜τ 12<br />

3846<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 16

Example<br />

<strong>The</strong> Jaumann stress is connected to <strong>the</strong> Cauchy stress through:<br />

˜τ ij = ˙τ ij + τ ip W pj + τ jp W pi<br />

which from <strong>the</strong> above yields <strong>the</strong> follwoing <strong>for</strong>mula <strong>for</strong> <strong>the</strong> Cauchy components τ ij<br />

⎡<br />

⎢<br />

⎣<br />

˙τ 11<br />

˙τ 22<br />

˙τ 12<br />

⎤ ⎡<br />

⎥ ⎢<br />

⎦ = ⎣<br />

2τ 12<br />

⎤<br />

−2τ 12<br />

⎥<br />

⎦<br />

<strong>The</strong> above system <strong>of</strong> ordinary differential equations can be solved to finally get:<br />

⎡<br />

⎢<br />

⎣<br />

τ 11<br />

τ 22<br />

τ 12<br />

⎤ ⎡<br />

⎥ ⎢<br />

⎦ = ⎣<br />

1900(1 − cos2t)<br />

−1900(1 − cos2t)<br />

1900sin2t<br />

⎤<br />

⎥<br />

⎦<br />

<strong>The</strong> results from methods A <strong>and</strong> B are ra<strong>the</strong>r close <strong>for</strong> small values <strong>of</strong> <strong>the</strong> de<strong>for</strong>mation<br />

measure t but grow quite different as t gets larger than 0.1, indicating that <strong>the</strong> same C<br />

can no longer be used.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 17

Hyperelastic Material<br />

Hyperelastic (rubberlike) materials<br />

exhibit an incompressible response,<br />

path independence <strong>and</strong> no energy<br />

dissipation.<br />

<strong>The</strong> stress is now calculated through<br />

<strong>the</strong> strain energy functional W<br />

t<br />

0S ij = ∂W<br />

∂ t 0ɛ ij<br />

Figure: Stress-strain curves <strong>for</strong> various<br />

hyperelastic material models.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 18

Hyperelastic Material<br />

Hyperelastic Material Models<br />

Saint Venant-Kirchh<strong>of</strong>f model<br />

W (ɛ) = λ 2 [tr(ɛ)]2 + µtr(ɛ 2 )<br />

<strong>and</strong> <strong>the</strong> second Piola-Kirchh<strong>of</strong>f stress can be derived as<br />

S = λ[tr(ɛ)]I + 2µɛ<br />

λ, µ are <strong>the</strong> Lamé constants<br />

Mooney-Rivlin model<br />

W (ɛ) = C 1 (I 1 − 3) + C 2 (I 2 − 3)<br />

where C1 <strong>and</strong> C2 are empirically determined material constants <strong>and</strong><br />

I 1 = tr(C) = C 11 + C 22 + C 33<br />

where C is <strong>the</strong> Cauchy-Green de<strong>for</strong>mation tensor (see Lecture 4) <strong>and</strong><br />

I 2 = 1 2 [(I 1) 2 − tr(C) 2 ]<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 19

Hypoelastic Material<br />

In this case, stress increments are calculated from strain increments<br />

dσ ij = C ijrs dɛ rs<br />

<strong>The</strong> material moduli C ijrs are defined as functions <strong>of</strong><br />

stress<br />

strain<br />

fracture criteria<br />

loading <strong>and</strong> unloading parameters<br />

maximum strains reached <strong>and</strong> so on<br />

Example Concrete models<br />

(*Hypoelasticity is not an elastic type <strong>of</strong> behavior in <strong>the</strong> sense that it<br />

does not exhibit path independence)<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 20

Inelasticity<br />

Elastoplasticity, Creep <strong>and</strong> Viscoplasticity are types <strong>of</strong> Inelastic<br />

behavior<br />

Elastic behavior ⇒ stresses can be directly calculated from <strong>the</strong> strain<br />

Inelastic behavior ⇒ <strong>the</strong> stress at time t depends on <strong>the</strong> stress strain<br />

history<br />

In <strong>the</strong> incremental analysis <strong>of</strong> inelastic response we had three main scenarios<br />

Small displacements-rotations / small strains ⇒ use linear elastic<br />

solution, engineering stress <strong>and</strong> strain measures<br />

Large displacements-rotations / small strains ⇒ use TL <strong>for</strong>mulation<br />

by substituting <strong>the</strong> appropriate stress - strain measures (PK2,<br />

Green-Lagrange) in <strong>the</strong> place <strong>of</strong> <strong>the</strong> engineering stress <strong>and</strong> strain<br />

measures<br />

Large displacements-rotations / large strains ⇒ use ei<strong>the</strong>r TL or UL<br />

<strong>for</strong>mulation, more complex constitutive laws<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 21

Elastoplasticity<br />

In this <strong>for</strong>mulation we encounter a linearly elastic behavior until yield<br />

<strong>and</strong> usually a gardening post yield behavior<br />

Examples Metals, soild <strong>and</strong> Rocks when subjected to high stresses<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 22

Elastoplasticity<br />

<strong>The</strong> strain <strong>and</strong> stress increments are given by:<br />

dɛ rs = dɛ E rs + dɛ P rs<br />

dσ ij = C E ijrs (dɛ rs − dɛ P rs)<br />

where C E ijrs are <strong>the</strong> components <strong>of</strong> <strong>the</strong> elastic constitutive tensor <strong>and</strong> dɛ rs, dɛ E rs,<br />

dɛ P rs are <strong>the</strong> components <strong>of</strong> <strong>the</strong> total strain increment.<br />

To calculate <strong>the</strong> plastic strains we use <strong>the</strong> following three properties:<br />

Yield Function f y(σ, ɛ P )<br />

f y < 0 ⇒ Elastic behavior<br />

f y = 0 ⇒ Plastic behavior<br />

f y > 0 ⇒ Inadmissible<br />

Flow rule<br />

<strong>The</strong> yield function is used in <strong>the</strong> flow rule in order to obtain <strong>the</strong> plastic<br />

strain increments<br />

λ is a scalar to be determined<br />

dɛ P ij = λ ∂fy<br />

∂σ ij<br />

Hardening rule<br />

This specifies how <strong>the</strong> yield function is modified during plastic flow<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 23

Elastoplasticity<br />

Example: Von Mises yield criterion (in 3D):<br />

f y = 0 ⇒ (σ 11 − σ 22) 2 + (σ 22 − σ 33) 2 + (σ 11 − σ 33) 2 + 6(σ 2 12 + σ 2 23 + σ 2 31) − 2σ 2 y = 0<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 24

Elastoplasticity<br />

Isotropic & Kinematic hardening Rules<br />

In <strong>the</strong> case <strong>of</strong> isotropic hardening, <strong>the</strong> yield surface exp<strong>and</strong>s<br />

uni<strong>for</strong>mly.<br />

In <strong>the</strong> case <strong>of</strong> kinematic hardening, <strong>the</strong> size <strong>of</strong> <strong>the</strong> yield surface<br />

remains unchanged <strong>and</strong> <strong>the</strong> center location <strong>of</strong> <strong>the</strong> yield surface<br />

is shifted.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 25

Elastoplasticity<br />

Response <strong>for</strong> cyclic loading<br />

Isotropic hardening: <strong>the</strong> yield stress is higher as <strong>the</strong> cyclic loading progresses<br />

Kinematic hardening: <strong>the</strong> difference between unloading stress <strong>and</strong> new yield<br />

stress in <strong>the</strong> opposite direction <strong>of</strong> loading is constant <strong>and</strong> equal to 2σ y.<br />

Figure: isotropic hardening in tension<br />

Figure: kinematic hardening<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 26

<strong>The</strong>rmoelastoplasticity <strong>and</strong> Creep<br />

This behavior exhibits <strong>the</strong> time effect <strong>of</strong> increasing strains under constant<br />

loads or decreasing stress under constant de<strong>for</strong>mations (relaxation)<br />

Typical examples <strong>of</strong> such behavior are metals at high temperatures<br />

<strong>The</strong> <strong>the</strong>rmal strain(ɛ = α∆T ) <strong>and</strong> <strong>the</strong> creep strain now enter <strong>the</strong><br />

<strong>for</strong>mulation <strong>of</strong> <strong>the</strong> stress strain relationships.<br />

Creep<br />

Creep is <strong>the</strong> tendency <strong>of</strong> a solid material to slowly move or de<strong>for</strong>m<br />

permanently under constant stresses. Creep tests measure <strong>the</strong> strain<br />

response due to a constant stress. <strong>The</strong> classical creep curve represents <strong>the</strong><br />

evolution <strong>of</strong> strain as a function <strong>of</strong> time in a material subjected to uniaxial<br />

stress at a constant temperature. <strong>The</strong> creep test, <strong>for</strong> instance, is per<strong>for</strong>med<br />

by applying a constant <strong>for</strong>ce/stress <strong>and</strong> analyzing <strong>the</strong> strain response <strong>of</strong> <strong>the</strong><br />

system. In general, this curve usually shows three phases or periods <strong>of</strong><br />

behavior.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 27

Creep<br />

1. A primary creep stage, also known as transient creep, is <strong>the</strong> starting stage<br />

during which hardening <strong>of</strong> <strong>the</strong> material leads to a decrease in <strong>the</strong> rate <strong>of</strong> flow<br />

which is initially very high. (0 ≤ ε ≤ ε 1).<br />

2. <strong>The</strong> secondary creep stage, also known as <strong>the</strong> steady state, is where <strong>the</strong> strain<br />

rate is constant. (ε 1 ≤ ε ≤ ε 2).<br />

3. A tertiary creep phase in which <strong>the</strong>re is an increase in <strong>the</strong> strain rate up to <strong>the</strong><br />

fracture strain. (ε 2 ≤ ε ≤ ε R).<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 28

Relaxation<br />

A relaxation test is defined as <strong>the</strong> stress response due to a constant strain <strong>for</strong> a<br />

period <strong>of</strong> time. In viscoplastic materials, relaxation tests demonstrate <strong>the</strong> stress<br />

relaxation in uniaxial loading at a constant strain. <strong>The</strong> decompositon <strong>of</strong> strain<br />

rate is dε<br />

dt = dεe<br />

dt + dεvp<br />

dt<br />

<strong>The</strong> elastic part <strong>of</strong> <strong>the</strong> strain rate is given by dεe<br />

dt = dσ<br />

E−1<br />

dt<br />

For <strong>the</strong> flat region <strong>of</strong> <strong>the</strong> strain-time curve, <strong>the</strong> total strain rate is zero.<br />

Hence we have, dεvp dσ<br />

−1<br />

= −E<br />

dt<br />

dt<br />

<strong>The</strong>re<strong>for</strong>e <strong>the</strong> relaxation curve can be used to determine rate <strong>of</strong> viscoplastic strain<br />

<strong>and</strong> hence <strong>the</strong> viscosity <strong>of</strong> <strong>the</strong> dashpot in a 1D viscoplastic material model.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 29

Viscoplasticity<br />

Viscoplasticity describes <strong>the</strong> rate-dependent inelastic behavior <strong>of</strong><br />

solids. Rate-dependence in this context means that <strong>the</strong> de<strong>for</strong>mation<br />

<strong>of</strong> <strong>the</strong> material depends on <strong>the</strong> rate at which loads are applied[1].<br />

<strong>The</strong> inelastic behavior that is <strong>the</strong> subject <strong>of</strong> viscoplasticity is plastic<br />

de<strong>for</strong>mation which means that <strong>the</strong> material undergoes unrecoverable<br />

de<strong>for</strong>mations when a load level is reached. Rate-dependent plasticity<br />

is important <strong>for</strong> transient plasticity calculations.<br />

<strong>The</strong> main difference between rate-independent plastic <strong>and</strong><br />

viscoplastic material models is that <strong>the</strong> latter exhibit not only<br />

permanent de<strong>for</strong>mations after <strong>the</strong> application <strong>of</strong> loads but continue<br />

to undergo a creep flow as a function <strong>of</strong> time under <strong>the</strong> influence <strong>of</strong><br />

<strong>the</strong> applied load.<br />

Typical examples <strong>of</strong> such behavior are Polymers <strong>and</strong> Metals<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 30

Viscoplasticity<br />

<strong>The</strong> elastic response <strong>of</strong> viscoplastic materials can be represented in one-dimension<br />

by Hookean spring elements. Rate-dependence can be represented by nonlinear<br />

dashpot elements.<br />

Plasticity can be accounted <strong>for</strong> by<br />

adding sliding frictional elements. In <strong>the</strong><br />

figure E is <strong>the</strong> modulus <strong>of</strong> elasticity, λ is<br />

<strong>the</strong> viscosity parameter <strong>and</strong> N is a<br />

power-law type parameter that<br />

represents non-linear dashpot<br />

σ = λ dɛ 1/N<br />

. <strong>The</strong> sliding element can<br />

dt<br />

have a yield stress (σy) that is strain<br />

rate dependent, or even constant, as<br />

shown in Figure (c).<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 31

Viscoplasticity<br />

Stress-strain response <strong>of</strong> a<br />

viscoplastic material at different<br />

strain rates. <strong>The</strong> dotted lines<br />

show <strong>the</strong> response if <strong>the</strong><br />

strain-rate is held constant. <strong>The</strong><br />

blue line shows <strong>the</strong> response when<br />

<strong>the</strong> strain rate is changed<br />

suddenly.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 32

NL FE Special Considerations - <strong>The</strong> Contact Problem<br />

Difficult non linear behavior = contact between two or more<br />

bodies<br />

Contacts = From frictionless in small displacement to friction in<br />

general large strain conditions<br />

<strong>Non</strong>linearity <strong>of</strong> <strong>the</strong> analysis is not only geometric <strong>and</strong> material<br />

but also contact conditions<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 33

Contact Conditions<br />

Usual term<br />

Contribution <strong>of</strong> contact<br />

<strong>for</strong>ces<br />

Consider N bodies that are in contact at<br />

time t:<br />

t S c is <strong>the</strong> complete area <strong>of</strong> contact<br />

t f c i : Components <strong>of</strong> <strong>the</strong> contact<br />

tractions t f S i : components <strong>of</strong> <strong>the</strong> known<br />

externally applied traction.<br />

<strong>The</strong>n <strong>the</strong> virtual work <strong>for</strong> <strong>the</strong> N bodies at time t is give by:<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 34

Contact Conditions<br />

Usual term<br />

Cont<br />

<strong>for</strong>ce<br />

We denote <strong>the</strong> two bodies as I <strong>and</strong> J. Each body is supported such that<br />

without contact no rigid motion is possible.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 35

Definitions used in Contact <strong>Analysis</strong><br />

Let t f IJ : vector <strong>of</strong> contact surface traction on body I due to contact with<br />

body J <strong>the</strong>n t f IJ = − t f JI . Hence, <strong>the</strong> virtual work due to <strong>the</strong> contact<br />

traction can be written:<br />

∫<br />

δu I<br />

S IJ i fi IJ dS IJ +<br />

∫<br />

δu J<br />

S IJ i fi JI dS JI =<br />

∫<br />

δu IJ<br />

S IJ i fi<br />

IJ dS IJ<br />

where<br />

where<br />

δu IJ<br />

i = δu I i − δu J i<br />

We call <strong>the</strong> pair <strong>of</strong> surfaces S IJ , S IJ a contact surface pair.<br />

S IJ is named <strong>the</strong> ”contactor surface” <strong>and</strong><br />

S JI is named <strong>the</strong> ”target surface”<br />

Hence, <strong>the</strong> right h<strong>and</strong> side <strong>of</strong> <strong>the</strong> previous eqn represents <strong>the</strong> virtual work<br />

<strong>of</strong> <strong>the</strong> contact tractions over <strong>the</strong> relative virtual displacements δu I i , δuJ i<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 36

Definitions used in Contact <strong>Analysis</strong><br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 37

Contact <strong>Analysis</strong>-Interface Conditions<br />

Normal Conditions<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 38

Contact <strong>Analysis</strong>-Interface Conditions<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 39

Contact <strong>Analysis</strong>-Interface Conditions<br />

Tangential Conditions<br />

Coulomb’s Law <strong>of</strong> friction States:<br />

Definitions Coulomb’s law <strong>of</strong> friction states :<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 40

Contact <strong>Analysis</strong><br />

Complexities<br />

In <strong>the</strong> previous we consider pseudo-static contact conditions<br />

In dynamic analysis:<br />

Body <strong>for</strong>ces include inertial <strong>for</strong>ce effects <strong>and</strong> <strong>the</strong> kinematic interface<br />

conditions must be satisfied at all instances <strong>of</strong> time, requiring<br />

displacement, velocity <strong>and</strong> acceleration compatibility between <strong>the</strong><br />

contacting bodies.<br />

<strong>The</strong> time integrations schemes (ex. trapezoidal rule) do not<br />

automatically satisfy compatibility which <strong>the</strong>re<strong>for</strong>e has to be imposed<br />

separately on <strong>the</strong> step by step solution<br />

Various algorithms have been proposed to solve contact problems in<br />

<strong>Finite</strong> <strong>Element</strong> analysis.<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 41

Contact <strong>Analysis</strong>-Solution Approach<br />

<strong>The</strong> Constraint Function <strong>Method</strong><br />

Let w be a function <strong>of</strong> λ <strong>and</strong> g such that <strong>the</strong> solutions <strong>of</strong> w(g, λ) = 0<br />

satisfy <strong>the</strong> Normal conditions<br />

Let v be a function <strong>of</strong> τ <strong>and</strong> ˙u such that <strong>the</strong> solutions v( ˙u, τ) = 0 satisfy<br />

<strong>the</strong> Tangential Conditions. <strong>The</strong>n, <strong>the</strong> contact conditions are given by:<br />

w(g, λ) = 0 v( ˙u, τ) = 0<br />

<strong>The</strong>se can now be imposed on <strong>the</strong> principle <strong>of</strong> virtual work using ei<strong>the</strong>r a<br />

penalty approach or a Lagrange Multiplier method. Variables λ <strong>and</strong> τ can<br />

be considered Lagrange multipliers, <strong>and</strong> so we consider <strong>the</strong>ir variations δλ,<br />

δτ. By multiplying by <strong>the</strong> variations <strong>and</strong> integrating in <strong>the</strong> domain we<br />

obtain <strong>the</strong> constraint equation:<br />

∫<br />

S IJ [δλ w(g, λ) + δτ u( ˙u, τ)]dS IJ = 0<br />

<strong>The</strong> governing equations <strong>of</strong> motion in this case are now both <strong>the</strong> principle<br />

<strong>of</strong> virtual work <strong>and</strong> <strong>the</strong> constraint equation<br />

Institute <strong>of</strong> Structural Engineering <strong>Method</strong> <strong>of</strong> <strong>Finite</strong> <strong>Element</strong>s II 42