News & Events - Institution of Engineers Singapore

News & Events - Institution of Engineers Singapore

News & Events - Institution of Engineers Singapore

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Lutron® | NEW Radio Powr SavrTM<br />

wireless occupancy and vacancy sensor<br />

A simple way to go green<br />

©2010 Lutron Electronics Co., Inc.

Contents<br />

Section 1: Engineering (General)<br />

2 IES Update<br />

Section 2: Engineering (Civil & Structural • Infrastructural<br />

• Environmental Focus)<br />

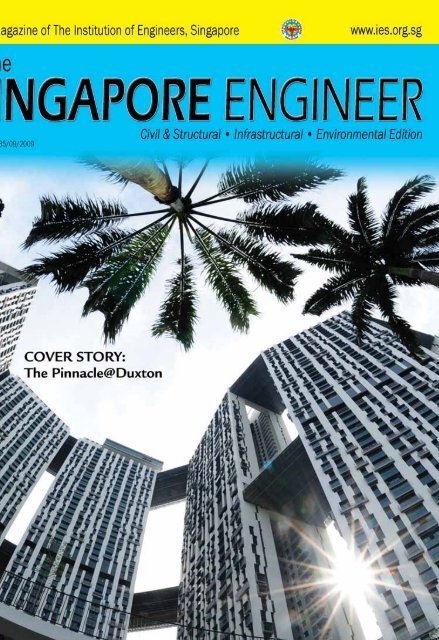

10 Cover Story: The Pinnacle@Duxton<br />

Published By<br />

The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong><br />

Director, Marketing<br />

Roland Ang<br />

Marketing & Publications Executive<br />

Jeremy Chia<br />

22 Structural Engineering: Burj Khalifa Tower<br />

30 Interview: Engineering urban transformation<br />

32 Products & Services<br />

38 Section 3: <strong>News</strong> & <strong>Events</strong><br />

Chief Editor<br />

T Bhaskaran<br />

Editorial Board<br />

Er. Dr Adhityan Appan<br />

Mr Lee Siew Wei<br />

Er. Siow Keng Cheng<br />

Mr Wong Chung Wan<br />

Manager, External Relations<br />

Valerie Neo<br />

Cover designed by Jeremy Chia<br />

Cover image by HDB<br />

The <strong>Singapore</strong> Engineer, The Magazine <strong>of</strong> the <strong>Institution</strong> <strong>of</strong><br />

<strong>Engineers</strong>, <strong>Singapore</strong> (IES) is published on a monthly basis,<br />

by the <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong>.<br />

The contents within the magazine, unless explicitly stated otherwise, do not reflect the opinions <strong>of</strong> the <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

<strong>Singapore</strong> (IES), and therefore have not received any endorsement from IES. The Editor reserves the right to amend, add to,<br />

condense, or rewrite, any editorial release or submission.<br />

The title The <strong>Singapore</strong> Engineer is the property <strong>of</strong> the<br />

<strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong> (IES).<br />

Although all efforts will be made to ensure that information is accurate at the time <strong>of</strong> going to print, the Publisher and Editor,<br />

as well as the <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong> (IES), will not accept any liability for errors within the magazine.<br />

© The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong>. The copyright<br />

<strong>of</strong> the contents <strong>of</strong> The <strong>Singapore</strong> Engineer is held by the<br />

Publisher. All rights reserved. Reproduction <strong>of</strong> information<br />

contained within the magazine, in its entirety, or in part, in<br />

any format, requires written permission from the Publisher.<br />

The publication is distributed free-<strong>of</strong>-charge. For enquiries on Editorial and Advertising, please contact the <strong>Institution</strong> <strong>of</strong><br />

<strong>Engineers</strong>, <strong>Singapore</strong>, 70 Bukit Tinggi Road, <strong>Singapore</strong> 289758. Tel: (65) 6469 5000 Fax: (65) 64671108.<br />

Printed in <strong>Singapore</strong> by SUN RISE Printing & Supplies Pte Ltd.<br />

THE SINGAPORE ENGINEER Jun 2010 · 1

IES Update<br />

Message from the President<br />

IES COUNCIL MEMBERS<br />

2010/2011<br />

President<br />

Er. Ho Siong Hin<br />

Vice Presidents<br />

Er. Chong Kee Sen<br />

Er. Pr<strong>of</strong> Chou Siaw Kiang<br />

Er. Edwin Khew<br />

Er. Lum Chong Chuen<br />

Er. Ong See Ho<br />

Pr<strong>of</strong> Yeoh Lean Weng<br />

Honorary Secretary<br />

Er. Ng Say Cheong<br />

Honorary Treasurer<br />

Assoc Pr<strong>of</strong> Daniel Lim<br />

Assistant Honorary Secretary<br />

Er. Jee Yi Yng<br />

Assistant Honorary Treasurer<br />

Mr Jeffrey Chua<br />

Immediate Past President<br />

Er. Lee Bee Wah<br />

Past Presidents<br />

Er. Tan Seng Chuan<br />

Er. A/Pr<strong>of</strong> Foo Say Wei<br />

Er. Ong Ser Huan<br />

Council Members<br />

Dr Boh Jaw Woei<br />

Pr<strong>of</strong> Er Meng Joo<br />

Er. Koh Beng Thong<br />

Mr Lim Shiyi<br />

Er. Low Wong Fook<br />

Mr Neo Kok Beng<br />

Er. Ong Geok Soo<br />

Er. Pr<strong>of</strong> Ong Say Leong<br />

Er. Pak Yew Hock, Lawrence<br />

Pr<strong>of</strong> Seeram Ramakrishna<br />

Mr Tan Kai Hong<br />

Er. Toh Siaw Hui, Joseph<br />

Mr Alfred Wong<br />

Dear Friends<br />

As the new President <strong>of</strong> IES, I welcome the opportunity to communicate with the<br />

readers <strong>of</strong> ‘The <strong>Singapore</strong> Engineer’ on a regular basis.<br />

In the last few weeks, we have seen how the blow-out <strong>of</strong> the oil well on the seabed<br />

in the Gulf <strong>of</strong> Mexico has played out for BP. The incident caused an explosion on<br />

the <strong>of</strong>fshore oil drilling platform, killing 11 workers and injuring 17 others. It also<br />

resulted in a massive oil spill that continues to threaten the east coast <strong>of</strong> the US, on an<br />

unprecedented scale. Efforts to cap the oil are ongoing but a lot <strong>of</strong> damage has already<br />

been done.<br />

This man-made disaster is an example <strong>of</strong> the consequences to human life, assets, and<br />

the environment (in this instance directly affecting the livelihoods <strong>of</strong> people), when<br />

production operations go wrong. A myriad <strong>of</strong> questions strike our minds: Why did the<br />

explosion happen? Were all the safety measures including those relating to materials,<br />

equipment, instrumentation, personnel and procedures etc, in place, that could have<br />

prevented it? Were scenarios for different kinds <strong>of</strong> abnormal situations visualised, and<br />

response measures developed, prioritised, and simulated?<br />

What we can say is that, as far as possible, such a situation should never be allowed<br />

to happen. The subject <strong>of</strong> safety should be given top priority, so that human beings,<br />

property, and the environment, are protected at all times.<br />

<strong>Engineers</strong> have a major role to play in the achievement <strong>of</strong> this objective. Backed by<br />

their technical knowledge and experience, they can take the lead in the development<br />

and implementation <strong>of</strong> safety measures and post-accident response programmes.<br />

This is why we place paramount importance on workplace safety in IES. The IES<br />

Academy has been organising training courses with an emphasis on safety to inculcate<br />

the ‘safety first’ mindset in our engineers. Lessons to be learnt from accidents in<br />

our recent memory, such as the Nicoll Highway collapse and the Marina Bay Sands<br />

fatality, are imparted to our engineers through relevant seminars and courses. Through<br />

education we hope that the safety mindset will be prevalent among our engineers.<br />

Er. Ho Siong Hin<br />

President<br />

The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong> (IES)<br />

2 · THE SINGAPORE ENGINEER Jun 2010

IES Update<br />

EAB workshop on ‘Developing Sustainable<br />

Program Assessment Processes’<br />

The workshop on ‘Developing<br />

Sustainable Program Assessment<br />

Processes’ by Dr Gloria Rogers, Managing<br />

Director, Pr<strong>of</strong>essional Services, ABET<br />

Inc, was organised by the Engineering<br />

Accreditation Board (EAB) <strong>of</strong> IES from<br />

10 May to 12 May 2010 at Furama<br />

Riverfront Hotel.<br />

The intention <strong>of</strong> the workshop was<br />

to prepare all local universities for the<br />

outcome-based accreditation which will<br />

be in place in Year 2012.<br />

The three-day workshop saw a total<br />

<strong>of</strong> 60 participants hailing from Nanyang<br />

Technological University (NTU),<br />

National University <strong>of</strong> <strong>Singapore</strong><br />

(NUS), and SIM University (UniSIM).<br />

All participants were actively involved in<br />

the programme lined up by Dr Rogers.<br />

At the end <strong>of</strong> the workshop, a<br />

majority <strong>of</strong> the participants (85%) gave<br />

the feedback that rubrics writing and<br />

designing good surveys are the most<br />

useful and meaningful lessons they have<br />

learnt.<br />

Many also commented that they<br />

enjoyed the activities i.e the table<br />

discussion and silent brainstorming, and<br />

the ‘toys’ provided by Dr Rogers.<br />

EAB workshop participants.<br />

Pr<strong>of</strong> Fung Tat Ching (NTU) explaining the<br />

written performance indicators to fellow group<br />

members.<br />

Dr Rogers examines the performance indicators<br />

written by A/Pr<strong>of</strong> Chen Zhong’s (NTU) group.<br />

Courtesy visit by IFEES<br />

On 17 May 2010, Dr Lueny Morell,<br />

President, International Federation<br />

<strong>of</strong> Engineering Education Societies<br />

(IFEES), paid a courtesy visit to IES.<br />

Accompanying her was Dr John<br />

Lamancusa, Pr<strong>of</strong>essor, Department <strong>of</strong><br />

Mechanical and Nuclear Engineering,<br />

The Pennsylvania State University, USA.<br />

The IFEES representatives were<br />

received by Er. Ng Say Cheong, IES<br />

Honorary Secretary; Er. Ong Ser Huan,<br />

IES Past President; A/Pr<strong>of</strong> Daniel Lim,<br />

IES Honorary Treasurer; and Er. Dr<br />

Chew Soon Hoe, Past Chairman <strong>of</strong> the<br />

National Committee <strong>of</strong> Engineering<br />

Organisations (NCEO).<br />

The parties exchanged updates on<br />

their respective institutions and how IES<br />

can play a role in the upcoming World<br />

Engineering Education Forum (WEEF)<br />

in October 2010. The meeting ended with<br />

a presentation <strong>of</strong> tokens and a dinner<br />

hosted by IES.<br />

From left to right: Dr Low Eicher, Acting Executive Director, IES; Er. Dr Chew Soon Hoe; Er. Ong<br />

Ser Huan; Dr Lueny Morell; Dr John Lamancusa; Er. Ng Say Cheong; and A/Pr<strong>of</strong> Daniel Lim.<br />

4 · THE SINGAPORE ENGINEER Jun 2010

IES Update<br />

H.K.U. Engineering Alumni Association’s<br />

(HKUEAA) Sustainable Development Study<br />

Tour to <strong>Singapore</strong><br />

On 2 June 2010, 17 delegates from the<br />

H.K.U. Engineering Alumni Association<br />

(HKUEAA) paid a courtesy visit to<br />

IES. The HKUEAA delegates were in<br />

<strong>Singapore</strong> for a three-day study tour with<br />

the theme ‘Sustainable City’. HKUEAA,<br />

founded to promote friendship amongst<br />

Engineering graduates from the University<br />

<strong>of</strong> Hong Kong (HKU) and to initiate<br />

and assist the pr<strong>of</strong>essional furtherance<br />

within and outside the campus, has<br />

been aggressively promoting sustainable<br />

development (SD) by having experiential<br />

projects for HKU engineering alumni and<br />

students to appreciate the examples <strong>of</strong> SD<br />

outside Hong Kong. The delegation has<br />

identified <strong>Singapore</strong> as a good example<br />

demonstrating the sustainable city<br />

development concepts.<br />

The HKUEAA delegation was received<br />

by Er. Ho Siong Hin, IES President;<br />

Er. Lawrence Pak, Chairman, Civil and<br />

Structural Technical Committee; Ms Titis<br />

Primita, Vice Chairman, Young Members<br />

Committee; Er. Dr Lim Ewe Chye,<br />

Chairman, IES Clean Energy Interest<br />

Group; and Dr Low Eicher, Acting<br />

Executive Director.<br />

Besides visiting IES, the delegation<br />

also visited the Urban Redevelopment<br />

Authority (URA) Gallery; ARUP<br />

<strong>Singapore</strong>’s <strong>of</strong>fice; Building and<br />

Construction Authority’s (BCA) Zero<br />

Energy Building; Solar Technology Centre<br />

at Ngee Ann Polytechnic; Gardens by the<br />

Bay Visitor Centre; NEWater Visitor<br />

Centre; Changi Water Reclamation Plant,<br />

and the Marina Barrage.<br />

Throughout the three-day study tour,<br />

the HKUEAA delegation were committed<br />

to the sharing <strong>of</strong> information and thoughts<br />

on the subjects / venues they visited. They<br />

were vocal and did not hesitate to make<br />

comments or seek additional information<br />

from the guides in the various places<br />

they visited. There was strong bonding<br />

between the students and alumni, where<br />

mentoring was not limited to sharing <strong>of</strong><br />

technical information but to general life<br />

aspects as well.<br />

Dr Lung commented that the trip was<br />

indeed inspirational to the students and<br />

praised the foresight <strong>of</strong> <strong>Singapore</strong> and its<br />

Government’s commitment on sustainable<br />

development. During the meeting, both<br />

sides exchanged information on the<br />

latest developments in their respective<br />

institutions and countries. The meeting<br />

ended with an exchange <strong>of</strong> tokens and a<br />

networking dinner.<br />

Er. Ho Siong Hin (on right) receiving a token <strong>of</strong> appreciation from Dr Francis Lung, Immediate Past<br />

President <strong>of</strong> HKUEAA.<br />

Visit to Solar Technology Centre @ Ngee Ann Polytechnic.<br />

Students admiring the barrage simulation at the Marina Barrage Gallery.<br />

6 · THE SINGAPORE ENGINEER Jun 2010

Intuitive design that<br />

saves you time<br />

Fastrak Building Designer is the ultimate design and drafting<br />

solution for steel structures. Used by 1000s <strong>of</strong> engineers<br />

worldwide, Fastrak will save you time when designing factories,<br />

commercial buildings, industrial facilities and even steel ro<strong>of</strong>s.<br />

Why choose Fastrak Building Designer?<br />

Fast, easy solution for designing both simple and complex buildings.<br />

Maximise productivity with powerful features such as automated<br />

wind loading, connection and composite design, and drawings.<br />

Manage changes easily and reduce your business overheads.<br />

Provide true Value Engineering for your client.<br />

Integrates with leading BIM and steel detailing s<strong>of</strong>tware including<br />

Revit Structure and Tekla Structures.<br />

Don’t just take<br />

our word for it…<br />

“Fastrak has increased<br />

our productivity tenfold.<br />

Designing refineries and<br />

plant structures only takes<br />

a day now, whereas they<br />

would have taken two weeks<br />

two years ago without<br />

Fastrak. Being able to work<br />

significantly faster has<br />

enabled our business to<br />

grow.“<br />

Ir Lim Keng Jit - Director<br />

Rekanan Jurutera<br />

Are you familiar<br />

with Orion?<br />

If you like our concrete design<br />

s<strong>of</strong>tware Orion, why not try<br />

Fastrak, our steel equivalent to<br />

Orion.<br />

Discover the benefits <strong>of</strong> Fastrak for yourself<br />

Call: 6258 3700 email: sales@cscworld.com or<br />

visit www.cscworld.com/fastrak/asia

“Fastrak has saved us time<br />

and money and allows us<br />

to Value Engineer each<br />

scheme to find the best<br />

option for our clients.”<br />

Er Soo Chee Sern, Managing Director - CS Consulting <strong>Engineers</strong> Pte Ltd<br />

“All our structural engineers use Fastrak Building Designer; it’s integral to our<br />

business,” says Er Soo Chee Sern, Managing Director <strong>of</strong> CS Consulting <strong>Engineers</strong> Pte<br />

Ltd. “It has saved us money, increased our productivity and improved the service we<br />

can provide to our clients. I am convinced that this has generated us more business.”<br />

The challenge<br />

Established in 1995, <strong>Singapore</strong><br />

based CS Consulting <strong>Engineers</strong> Pte<br />

Ltd provides structural engineering,<br />

industrial architecture and project<br />

management services.<br />

Providing innovative, design-led<br />

schemes was top <strong>of</strong> CS Consulting<br />

<strong>Engineers</strong> Pte Ltd’s list when it came<br />

to <strong>of</strong>fering their clients best value.<br />

To do this they needed to invest<br />

“CSC was confident that<br />

Fastrak Building Designer<br />

was the right solution<br />

as it would enable<br />

CS Consulting <strong>Engineers</strong><br />

Pte Ltd to design factories,<br />

commercial buildings,<br />

industrial facilities and even<br />

complex steel ro<strong>of</strong>s with<br />

ease.”<br />

in reliable, fast and flexible steel<br />

building design s<strong>of</strong>tware to help<br />

them engineer schemes quickly,<br />

while at the same time conform to<br />

complex design standards.<br />

A busy design <strong>of</strong>fice meant it was<br />

vital that changing design s<strong>of</strong>tware<br />

created minimal disruption. The new<br />

s<strong>of</strong>tware had to be easy to adopt<br />

and backed up by a competent<br />

technical team. With this in mind,<br />

CS Consulting <strong>Engineers</strong> Pte Ltd<br />

turned to CSC.<br />

The solution<br />

After reviewing the market,<br />

CS Consulting <strong>Engineers</strong> Pte Ltd<br />

opted for CSC’s Fastrak Building<br />

Designer, aware that this was<br />

the steel equivalent <strong>of</strong> Orion,<br />

CSC’s market leading concrete<br />

building design s<strong>of</strong>tware used by<br />

1000s <strong>of</strong> engineers worldwide.<br />

“Fastrak Building Designer<br />

integrates with leading BIM<br />

and steel detailing s<strong>of</strong>tware<br />

such as Revit Structure and<br />

Tekla Structures”<br />

Nigel Watts, Asia Pacific Regional<br />

Director for CSC, says, “Choosing a<br />

s<strong>of</strong>tware solution can be challenging.<br />

We eased the transition by providing<br />

a one-stop solution, <strong>of</strong>fering the<br />

s<strong>of</strong>tware, the training and the<br />

technical support.”<br />

CSC was confident that<br />

Fastrak Building Designer was<br />

the right solution as it would<br />

enable CS Consulting <strong>Engineers</strong> Pte<br />

Ltd to design factories, commercial<br />

buildings, industrial facilities and<br />

even complex steel ro<strong>of</strong>s with ease.<br />

Plus it would help them to quickly<br />

manage those inevitable variations<br />

that occur on every project.

Er Soo comments, “It was essential<br />

that Fastrak could automatically<br />

design buildings quickly and in one<br />

go; we were delighted with the level<br />

<strong>of</strong> automation provided.”<br />

“Fastrak Building Designer also<br />

integrates with leading BIM and<br />

steel detailing s<strong>of</strong>tware such as Revit<br />

Structure and Tekla Structures”,<br />

comments Watts. “This gives<br />

ultimate flexibility as engineers<br />

and technicians can share and<br />

synchronise models during the<br />

complete design process.”<br />

Getting started with Fastrak Building<br />

Designer was easy. Er Soo explains,<br />

“Fastrak Building Designer<br />

is the steel equivalent <strong>of</strong><br />

Orion, CSC’s market leading<br />

concrete building design<br />

s<strong>of</strong>tware, used by 1000s <strong>of</strong><br />

engineers worldwide.”<br />

“We invested in training in-house<br />

so that all our engineers could<br />

benefit from the same level <strong>of</strong><br />

understanding. CSC’s training was<br />

real value for money.<br />

What’s more, CSC’s technical support<br />

team are all structural engineers, so<br />

they understand our business and<br />

the technical issues we face. They’re<br />

proactive and are always able to<br />

<strong>of</strong>fer us a practical solution to our<br />

query.”<br />

The result<br />

“Fastrak has saved us time and<br />

money and allows us to Value<br />

Engineer each scheme to find the<br />

best option for our clients, concludes<br />

Er Soo. “It is a market leading and<br />

well considered product that is<br />

going from strength to strength. I<br />

highly recommend Fastrak Building<br />

Designer to any forward thinking<br />

business that wants to <strong>of</strong>fer their<br />

clients the best service.”<br />

Fact file<br />

Name: CS Consulting <strong>Engineers</strong> Pte Ltd<br />

Area <strong>of</strong> operation: Structural<br />

Engineering , Industrial Architecture<br />

and Project Management<br />

Location: <strong>Singapore</strong><br />

Founded: 1995<br />

Number <strong>of</strong> employees: 15<br />

CSC products:<br />

Fastrak Building Designer<br />

TEDDS<br />

Orion<br />

S-Frame<br />

Key benefits <strong>of</strong> Fastrak:<br />

Increased productivity<br />

Time and cost savings<br />

Improved customer service<br />

Discover the benefits <strong>of</strong> Fastrak for yourself<br />

Call 6258 3700 or visit www.cscworld.com/fastrak/asia

Cover Story<br />

The Pinnacle@Duxton<br />

Over the last 50 years since its<br />

establishment in 1960, the Housing<br />

& Development Board (HDB) has<br />

chalked up an impressive array <strong>of</strong><br />

achievements. Extending the trackrecord<br />

further is the first 50-storey<br />

public housing project in <strong>Singapore</strong>,<br />

which is also, at 168 m, the tallest.<br />

Introduction<br />

The Pinnacle@Duxton comprises 1848<br />

residential units spread over seven<br />

blocks, and one multi-storey carpark. It<br />

is located on a site (Fig 1) on which, in<br />

1963, Blocks 1 and 2 Cantonment Road,<br />

the first two HDB blocks in the area,<br />

were built.<br />

An international architectural<br />

competition was organised by <strong>Singapore</strong>’s<br />

Urban Redevelopment Authority to<br />

obtain the best design ideas for high-rise<br />

living in the city, that would also take<br />

into account the historical significance<br />

<strong>of</strong> the site. The competition was won<br />

by architect Mr Khoo Peng Beng from<br />

ARC Studio Architecture + Urbanism, a<br />

<strong>Singapore</strong>-based firm.<br />

Important features <strong>of</strong> the project<br />

include sky bridges and sky gardens<br />

at the 26 th and 50 th storeys, linking all<br />

the seven blocks, as well as a variety <strong>of</strong><br />

façade elements. The circuit board-like<br />

arrangement <strong>of</strong> bay windows, planters,<br />

and balconies, helps to differentiate The<br />

Pinnacle@Duxton from other ‘regular’<br />

HDB projects (Fig 2).<br />

Project information<br />

Number <strong>of</strong> blocks<br />

and storey<br />

Total number <strong>of</strong><br />

units<br />

Type <strong>of</strong> unit S1<br />

Type <strong>of</strong> unit S2<br />

Facilities<br />

Basement<br />

7 blocks, each 50<br />

storeys high<br />

1,848<br />

1,232 units<br />

(93 m 2 - 97 m 2 )<br />

616 units<br />

(105 m 2 - 108 m 2 )<br />

Carpark below<br />

blocks 1A to 1E<br />

1 st Storey 1 food court,<br />

4 shops, and 1<br />

convenience store<br />

and carpark<br />

2 nd Storey Carpark at Blk 1A,<br />

1B and 1D<br />

3 rd Storey<br />

(Environmental<br />

deck)<br />

26 th Storey<br />

(Active Zone)<br />

50 th Storey<br />

(Contemplative<br />

Zone)<br />

1 childcare centre,<br />

1 education centre,<br />

playground, event<br />

plaza, basketball<br />

court, and pavilion<br />

jogging track, 840<br />

m long<br />

Viewing decks and<br />

themed garden<br />

Fig1: Site layout plan.<br />

Fig 2: Overall view <strong>of</strong> the completed The Pinnacle@Duxton.<br />

10 · THE SINGAPORE ENGINEER Jun 2010

Cover Story<br />

THE SINGAPORE ENGINEER Jun 2010 · 11

Cover Story<br />

Design <strong>of</strong> super-structure and substructure<br />

As The Pinnacle@Duxton was HDB’s<br />

first super high-rise development,<br />

rigorous design analyses were conducted<br />

to ensure structural stability. The<br />

structural system adopted is reinforced<br />

concrete construction coupled with a<br />

beam-column-slab rigid frame for the<br />

building. All column loads are transferred<br />

directly, floor to floor, down to the<br />

foundation. No transfer beams have been<br />

used. The design also responded to the<br />

need for robustness, with the provision<br />

<strong>of</strong> peripheral ties and internal ties, to<br />

ensure that the building is not vulnerable<br />

to progressive collapse.<br />

HDB collaborated with the National<br />

University <strong>of</strong> <strong>Singapore</strong> in the study<br />

<strong>of</strong> lightning protection and for wind<br />

tunnel analysis, during the design stage<br />

<strong>of</strong> the project. Numerous wind tunnel<br />

simulations were also conducted in the<br />

laboratory to analyse the effect <strong>of</strong> wind<br />

currents on the seven tall buildings and<br />

also their environmental impact on the<br />

neighbourhood. In addition, traffic<br />

impact modelling and analysis were also<br />

performed to ensure optimal travelling<br />

times along the two abutting major<br />

roads.<br />

HDB’s own in-house design and<br />

detailing s<strong>of</strong>tware, SE CAD, was used<br />

to model and design the tower blocks.<br />

SE CAD has been developed for highrise<br />

building analysis and design. Key<br />

performance parameters required for<br />

high-rise, reinforced concrete buildings,<br />

were computed automatically by the<br />

s<strong>of</strong>tware.<br />

Powered by a robust, finite element<br />

engine with a built-in precast components<br />

database, and incorporating a userfriendly<br />

interface, SE CAD provided<br />

solutions for tasks ranging from 3D<br />

structural analysis, computation, design,<br />

and detailing, to the production <strong>of</strong><br />

drawings (Fig 3).<br />

As the modelling and analysis process<br />

was fully integrated, feasibility studies<br />

were carried out on various possible<br />

structural configurations, to identify the<br />

most suitable design proposal.<br />

Once the shapes and layouts for the<br />

tall structures were established, their<br />

structural behaviour was simulated<br />

effortlessly. The design and analysis results<br />

(eg for bending moments and shear<br />

forces), structural drawings, and material<br />

quantities, were obtained instantly, once a<br />

building’s super-structure was modelled.<br />

Additional contributions from the SE<br />

CAD s<strong>of</strong>tware included auto-generation<br />

<strong>of</strong> the loading plan, 3D model rendering,<br />

and production <strong>of</strong> shop drawings for<br />

precast components and prefabricated<br />

reinforcements.<br />

For the sub-structure design,<br />

thorough investigations were conducted<br />

around the site, to ascertain the<br />

Fig 3: Typical workfl ow using SE CAD.<br />

properties <strong>of</strong> the soil. The Duxton site<br />

consists primarily <strong>of</strong> hard silty sandstone,<br />

and concrete bored piles have been used<br />

to support the foundation. A total <strong>of</strong><br />

1330 bored piles was designed with an<br />

average pile penetration length <strong>of</strong> 19 m.<br />

Each tower block was designed to sit on<br />

a 2.7 m thick raft foundation supported<br />

by 140 equally spaced bored piles <strong>of</strong> 1.5<br />

m diameter. The raft foundation system<br />

provides structural stability and rigidity<br />

for the high-rise tower block and prevents<br />

differential settlement.<br />

12 · THE SINGAPORE ENGINEER Jun 2010

Cover Story<br />

Precast technology<br />

For The Pinnacle@Duxton, conscientious<br />

efforts were made by the architects and<br />

engineers to make the project buildable,<br />

through the adoption <strong>of</strong> modularisation<br />

and standardisation concepts. The<br />

various options for the standard layouts<br />

(S1 and S2) <strong>of</strong> the units in the residential<br />

blocks, were obtained by configuring<br />

units as mirror images <strong>of</strong> one another<br />

and by rotation <strong>of</strong> these unit plans.<br />

The modularisation <strong>of</strong> the units was<br />

replicated to obtain the block design.<br />

The floor plans for a typical storey<br />

were also repeated for better efficiency<br />

in precast construction. The adoption<br />

<strong>of</strong> modularisation and standardisation<br />

also enabled prefabrication to be costeffective<br />

due to the high repetition <strong>of</strong> the<br />

precast components and prefabricated<br />

reinforcement.<br />

As a result, it was possible to<br />

incorporate a high proportion (about<br />

85% <strong>of</strong> the total volume <strong>of</strong> concrete) <strong>of</strong><br />

precast technology in the construction<br />

<strong>of</strong> the tower blocks. Precast components<br />

were utilised for various elements<br />

including prestressed plank, column,<br />

lift wall, household shelter wall, gable<br />

end wall, façade wall with bay window,<br />

façade wall with planters, façade wall<br />

with balcony, screen wall, refuse chute,<br />

staircase, and parapet.<br />

The use <strong>of</strong> large volumes <strong>of</strong> precast<br />

concrete in the project increased<br />

productivity by about 15%. In addition,<br />

it facilitated construction works in a<br />

tight, built-up, working environment,<br />

and reduced environmental impact on<br />

the existing area. In addition, precast<br />

concrete elements are <strong>of</strong> better quality as<br />

they are produced in a factory-controlled<br />

environment.<br />

To expedite construction works, a<br />

typical floor was divided into two segments<br />

(part A and part B) by a construction<br />

joint (Fig 4). The construction work<br />

was staggered, that is, a team <strong>of</strong> workers<br />

from a construction trade would work<br />

on part A and then move on to part B<br />

without having to stop for workers from<br />

the other trades to complete their tasks.<br />

With this, it was possible to achieve the<br />

anticipated 6-day construction cycle for<br />

each segment <strong>of</strong> a typical floor.<br />

The project team adopted the use <strong>of</strong><br />

large precast facade panels, measuring<br />

about 7 m in length (Fig 5) compared<br />

to the usual length <strong>of</strong> 3 m to 4 m. This<br />

enhanced tower crane utilisation and<br />

improved site productivity. The façades<br />

<strong>of</strong> planter boxes, sun-shaded louvred<br />

windows, and balconies, are arranged in<br />

different combinations, creating a series<br />

<strong>of</strong> vertical, zigzag lines that resemble<br />

Fig 4: Typical fl oor layout showing the construction joint which divides the fl oor into two segments.<br />

Fig 5: Large precast façade panels.<br />

Fig 6: Precast, volumetric hollow-cored wall.<br />

flowing water. In addition, the window<br />

frames were fixed to the facades before<br />

delivery to site. This will eliminate water<br />

seepage through the windows. The wall<br />

panels were designed to be hollow-cored<br />

(Fig 6) so as to reduce the weight <strong>of</strong> the<br />

components and minimise risk during<br />

hoisting and erection.<br />

THE SINGAPORE ENGINEER Jun 2010 · 13

Cover Story<br />

Design and installation <strong>of</strong> sky bridges<br />

The 12 sky bridges, connecting the seven<br />

blocks, at the 26 th and 50 th storeys, form<br />

part <strong>of</strong> outdoor sky gardens which are<br />

equipped with amenities for recreational<br />

purposes. The bridges are made <strong>of</strong> steel<br />

with concrete slabs on top. The lengths<br />

<strong>of</strong> the bridges vary, with the longest<br />

spanning 48 m and weighing 327 t. The<br />

widths and heights <strong>of</strong> the bridges are 20<br />

m and 3.9 m, respectively.<br />

The design <strong>of</strong> the sky bridges was<br />

carried out by T.Y.Lin International<br />

Pte Ltd, HDB’s consultant. The design<br />

adopted a 3-dimensional triangular<br />

truss layout which is stable without<br />

lateral support and could be erected<br />

independently. The bridges are designed<br />

to withstand wind forces in all directions.<br />

The side faces are tapered to reduce<br />

the obstruction to wind flow, thus<br />

minimising the wind pressure on the face.<br />

One end <strong>of</strong> each bridge was designed<br />

to be fixed to the building, to improve<br />

the natural frequency <strong>of</strong> the bridge and<br />

reduce vibrations from walking and<br />

jogging, thus enhancing comfort levels<br />

for people.<br />

Owing to the tight site conditions,<br />

there were many challenges in the<br />

erection <strong>of</strong> the bridges, relating to the<br />

installation method and procedures,<br />

availability <strong>of</strong> space at site, and duration<br />

<strong>of</strong> the installation. Owing to the sizes,<br />

the bridges were fabricated in segments<br />

<strong>of</strong>f-site, at a factory (Fig 7), transported<br />

to the site, and assembled onto the<br />

complete structure. To overcome the<br />

space constraints, the 50 th and 26 th storey<br />

bridges were stacked on top <strong>of</strong> each<br />

other (Fig 8). This also facilitated the<br />

subsequent lifting operation.<br />

In the factory, as well as during the onsite<br />

assembly <strong>of</strong> the sky bridge members,<br />

the fitting up, welding, testing, and trial<br />

assembly <strong>of</strong> the sky bridge trusses were<br />

supervised by an independent checker.<br />

The progress <strong>of</strong> the work was closely<br />

supervised by the Resident <strong>Engineers</strong> and<br />

Resident Technical Officers who were<br />

stationed on-site and at the fabrication<br />

yard.<br />

After fabrication, the sky bridges<br />

were lifted to their respective heights<br />

using the strand jack system which was<br />

used instead <strong>of</strong> cranes, due to the height<br />

<strong>of</strong> the buildings. In addition, this system<br />

Fig. 7: Welding, testing, and trial assembly, <strong>of</strong> sky bridge steel trusses at the factory.<br />

Fig 8: Assembly <strong>of</strong> the sky bridge steel trusses on site. The 50 th and 26 th sky bridges are stacked on top<br />

<strong>of</strong> each other.<br />

allowed the bridges to be assembled at<br />

a lower level before hoisting the whole<br />

assembly, thus enhancing safety on site.<br />

Four strand jacks were required for<br />

each lifting. The jacks were installed<br />

and positioned at four corners between<br />

the two buildings at the 50 th storey ro<strong>of</strong><br />

top position (Fig 9). Prior to the lifting,<br />

a trial jacking was done, that raised the<br />

skybridge 300 mm <strong>of</strong>f the ground, to<br />

ensure that the jacks were functioning<br />

properly.<br />

The bridges are fixed to the core<br />

walls <strong>of</strong> the residential buildings. To fix<br />

the bridges safely and securely to the core<br />

walls, base plates and sleeves for tension<br />

bars were cast together with the core<br />

walls. Great care was taken to ensure that<br />

the cast-in items aligned accurately with<br />

the tower blocks. When the bridges were<br />

lifted to their final positions at the 50 th<br />

and 26 th storeys, and adjusted, the main<br />

trusses were connected to the building by<br />

high strength bars and locked in-place by<br />

casting the concrete slab which forms the<br />

floor <strong>of</strong> the bridge.<br />

14 · THE SINGAPORE ENGINEER Jun 2010

Cover Story<br />

The sky bridge structural system<br />

Main<br />

structure<br />

Diaphragm<br />

Connecting<br />

member to<br />

member<br />

Connection<br />

to building<br />

core wall<br />

Main truss<br />

Three-dimensional steel<br />

truss.<br />

Concrete topping 125 mm<br />

thick.<br />

Full penetration butt weld.<br />

Using Macalloy posttensioned<br />

bars.<br />

Consists <strong>of</strong> 1 top chord<br />

and 2 bottom chords. The<br />

top chord has a 125 mm<br />

thick concrete topping.<br />

The combination acts as a<br />

composite.<br />

The concrete topping at the top deck<br />

level and mezzanine level ties with the<br />

building floor slab and, together with<br />

the tie beam between two core walls, acts<br />

as a diaphragm to resist the lateral and<br />

vertical loads.<br />

PROJECT CREDITS<br />

Client<br />

Housing & Development Board<br />

Project Management<br />

SIPM Consultants<br />

Design Architect<br />

ARC Studio Architecture + Urbanism<br />

Project Architect<br />

RSP Architects Planners & <strong>Engineers</strong><br />

C&S Consultant<br />

Surbana International<br />

Sky Bridge Consultant<br />

T.Y.Lin International<br />

M & E Consultant<br />

Surbana International<br />

Cost Management<br />

Surbana International<br />

Main Contractor<br />

Chip Eng Seng Contractors (1988) Pte<br />

Ltd.<br />

All images by HDB.<br />

Fig 9: Lifting <strong>of</strong> sky bridges to the 50 th storey using the strand jack system.<br />

THE SINGAPORE ENGINEER Jun 2010 · 15

Cover Story<br />

Panoramic view <strong>of</strong> the skyline from the viewing deck.<br />

The Pinnacle@Duxton is the tallest public housing development in <strong>Singapore</strong>.<br />

16 · THE SINGAPORE ENGINEER Jun 2010

RAISE YOUR BUILDING’S ECO-PROFILE<br />

Make your environmental statement, with a BIPV system.<br />

Harvest electricity, straight from the sun.<br />

Reduce your electricity bills, for years to come.<br />

Interested in architectural PV solutions?<br />

Contact Phoenix Solar - <strong>Singapore</strong>’s leading PV system integrator<br />

Phoenix Solar Pte Ltd<br />

209 Syed Alwi Road<br />

<strong>Singapore</strong> 207742<br />

Tel: 65-6511 9339<br />

Fax: 65-6511 9333<br />

info@phoenixsolar.sg<br />

www.phoenixsolar.com/sg<br />

Making energy together

Refreshing the GeoFEA’s User’s Interface<br />

By S.H. Hong, GeoS<strong>of</strong>t Pte Ltd<br />

In this article, we are <strong>of</strong>fering a glimpse at the<br />

user interface in the next version <strong>of</strong> GeoFEA. We<br />

had consolidated some feedbacks from users and<br />

prioritised the wish-list for our prototype.<br />

Introduction<br />

It had been two years since we started this column<br />

in 2008. A sneak into our new graphical user’s<br />

interface will conclude our series <strong>of</strong> articles in “The<br />

<strong>Singapore</strong> Engineer”. Much effort was put in to<br />

raise awareness <strong>of</strong> some key issues in geotechnical<br />

finite element modelling. It is also time for us to<br />

take a break and concentrate our effort on raising<br />

the bar in terms <strong>of</strong> user’s experience. We had made<br />

revamping the Graphical User Interface (GUI) our<br />

priority.<br />

Windows application that was written with<br />

Windows Presentation Foundation (WPF), Figure<br />

1(a) instead <strong>of</strong> Windows Forms, Figure 1(b). WPF<br />

is a graphical subsystem for rendering user<br />

interfaces in Windows-based applications. The core<br />

<strong>of</strong> pre- and post- processor will have to be build<br />

from the ground up, allowing easier development.<br />

GUI things that were previously not possible are<br />

now a possibility.<br />

Figure 2: Buttons for various stages <strong>of</strong> modelling.<br />

The user will be guided by the visible buttons<br />

(Figure 2) on what options are made available at<br />

each stage <strong>of</strong> modelling.<br />

(a)<br />

Workspace and tool panels<br />

Frequently used tool panels are opened by default.<br />

The users will have the freedom to move these<br />

panels from their default positions to a location that<br />

the users are comfortable with (Figure 3).<br />

Alternative placeholders are highlighted as shown<br />

in Figure 3 as arrow in a box ( ).<br />

(b)<br />

Figure 1: GeoFEA’s user interface. (a) Prototype<br />

new look. (b) Old look.<br />

We're considering revamping the GUI to a<br />

Figure 3: Placeholders for docking panels.

Another obvious change is the axes orientation<br />

indicator which is now coloured differently for each<br />

axis and resides on the workspace itself.<br />

GUI buttons<br />

The buttons are made larger with superfluous<br />

buttons removed for a clearer line <strong>of</strong> operation<br />

(Figure 4). For example, in a two-dimensional (2-<br />

D) project, buttons relating to 2-D work space are<br />

shown. The 3-D options are left out to give a<br />

cleaner look. This is a marked improvement from<br />

the previous GUI where the 3-D buttons are simply<br />

deactivated.<br />

You talk, we listen and respond. This change arises<br />

from feedbacks by our current user that the current<br />

interface has too many buttons to start with.<br />

Without proper hints and guidance, the old<br />

interface workflow is perplexing for beginners.<br />

Figure 5: Modified trackball control.<br />

(a)<br />

(b)<br />

Figure 4: Work space buttons. (a) 2D project.<br />

(b) 3D project.<br />

View controls<br />

We had also included easy 3D view change and<br />

intuitive 3 Button Mouse support. The trackball<br />

was modified to give user a better control over the<br />

view angles. Mouse over the view controls will<br />

bring them into focus and dimmed when not in use.<br />

This allows a larger screen estate to be tenanted by<br />

other essential controls.<br />

Maintaining an in-plane view rotation was quite a<br />

task in the old pre- and post-processors. The inplane<br />

rotation is decoupled from the out-<strong>of</strong>-plane<br />

rotation by the implementation <strong>of</strong> a circumferential<br />

ring control (Figure 5). The out-<strong>of</strong>-plane rotation<br />

can be realised by holding down the left mouse<br />

button in the preferred direction within the inner<br />

circular control (Figure 6).<br />

Figure 6: Inner circular control for out-<strong>of</strong>-plane<br />

rotation.<br />

View rotation using the centre mouse button is still<br />

available other than a minor tweak to the sensitivity<br />

level.<br />

A new zoom control was added for users without a<br />

scroll wheel mouse control.<br />

The panning operation, which was well tested by<br />

other computer aided design s<strong>of</strong>tware, was left<br />

largely unchanged by dragging the mouse keeping<br />

its right button depressed.<br />

Attributes <strong>of</strong> a model<br />

We had placed the attributes to a model as the<br />

default dock panel on screen to allow user’s access<br />

to various parameters defining geometry, analysis<br />

data and construction sequence as shown in (Figure<br />

7). The properties for each parameter will be<br />

reflected in another dock panel below the model<br />

attributes docking panel in the default layout.

Figure 9: Dimensions during basic shape creation.<br />

The coordinates <strong>of</strong> the cursor is also shown if the<br />

user is more comfortable with the old version’s way<br />

<strong>of</strong> input.<br />

Figure 7: Dock panel for model attributes.<br />

Stepping through the construction stages<br />

We have also made it easier to cycle through<br />

various construction stages by setting the stage<br />

view control as one <strong>of</strong> the default panels docked at<br />

the bottom right screen estate (Figure 8).<br />

Figure 10: Dimensions during extrusion operation.<br />

In Figure 10, the extrusion dimension from the<br />

basic shape is displayed so that the user can easily<br />

determine the third dimension in a 3-D view.<br />

Figure 8: Construction stage controls<br />

Dimensions indication feature<br />

One new feature that has successfully made its way<br />

into our prototype is the on-screen dimensioning<br />

function. The length and width <strong>of</strong> the rectangle is<br />

displayed on the screen to help user determine its<br />

size for the example shown in Figure 9.<br />

Reporting functions<br />

We hear you! In the pipeline, we are adding a<br />

report generation feature (Figures 11). The report<br />

wizard allows the user to quickly create a new text<br />

report. It includes features for filtering parameters<br />

to output, and also allows the user to easily create<br />

title box containing various information such as the<br />

date, time and page number (Figure 12). We aim to<br />

turn the tedious chore <strong>of</strong> drafting technical reports<br />

into something close to playing a video game.

Figure 11: Tree view <strong>of</strong> report generation user<br />

interface.<br />

Figure 13: Login page prototype for online<br />

engineering portal.<br />

Conclusion<br />

The graphical user interfaces revealed in this article<br />

is a prototype. This prototype will be used as part <strong>of</strong><br />

the s<strong>of</strong>tware design process to allow our engineers<br />

and designers the ability to explore design<br />

alternatives, test theories and confirm performance<br />

prior to our up-coming alpha test version release.<br />

Figure 12: Sample layout <strong>of</strong> image with title block.<br />

Going online<br />

Looking forward, GeoS<strong>of</strong>t is poised to take a giant<br />

leap forward with an exciting project - a dream <strong>of</strong><br />

an internet-based engineering platform on which a<br />

collaborative culture can be developed (Figure 13).<br />

The power <strong>of</strong> the Internet in the “Blue Ocean” is<br />

there for all to tap. This platform will be designed<br />

to facilitate communication, collaboration and<br />

content sharing across networks <strong>of</strong> contacts.<br />

The evolution <strong>of</strong> personal computer technologies<br />

will no doubt opens up exciting possibilities in the<br />

way engineers conduct finite element analyses.<br />

With the Internet no longer constrained by slow<br />

connections and computer processors and high<br />

costs for storage, it is time to rethink and revamp<br />

the way construction industry embraces these new<br />

technologies in terms <strong>of</strong> engineering services.<br />

S<strong>of</strong>tware should routinely be designed to make it<br />

easy for people to do what works and difficult to do<br />

what doesn’t. One important and powerful way that<br />

s<strong>of</strong>tware products can do this is through welldesigned<br />

defaults. Given the power <strong>of</strong> defaults, our<br />

designers could use them to nudge people in a<br />

direction that will enhance their work efficiency.<br />

According to Porter 2001, the greatest impact <strong>of</strong> the<br />

Internet is to enable the reconfiguration <strong>of</strong> existing<br />

industries that had been constrained by high cost<br />

for communicating, gathering information and<br />

accomplishing transactions. By integrating the<br />

internet into our overall strategy, GeoFEA will<br />

realise its potential as a powerful engineering tool.<br />

Reference<br />

Michael E. Porter. "Strategy and the Internet”,<br />

Harvard Business Review, Vol. 79, No. 3, March<br />

2001.<br />

About GeoS<strong>of</strong>t Pte Ltd<br />

GeoS<strong>of</strong>t Pte Ltd is registered in <strong>Singapore</strong>. GeoS<strong>of</strong>t<br />

focuses singularly on geotechnical products with<br />

unparalleled developments. We are the leader in the<br />

FEM mesh generation and solver technologies<br />

implemented on desktop PC platform.

Structural Engineering<br />

The design <strong>of</strong> Burj Khalifa Tower – the world’s<br />

tallest structure<br />

The objective in creating this building,<br />

besides setting a record, is to embody<br />

the highest aspirations <strong>of</strong> mankind.<br />

Such a project goal, by necessity,<br />

requires pushing current analysis, as<br />

well as materials and construction<br />

technologies, to literally new heights.<br />

However, as building to such a height<br />

had never been attempted before, it<br />

was also necessary to ensure that all<br />

technologies and methods utilised are<br />

<strong>of</strong> sound development and practice.<br />

Mr William F Baker, Partner,<br />

Mr James J Pawlikowski, Associate<br />

Director, and Mr Bradley S Young,<br />

Associate, from Skidmore, Owings &<br />

Merrill LLP (SOM), Chicago, Ilinois,<br />

USA, explain how the designers sought<br />

to use conventional systems, materials,<br />

and construction methods, modified<br />

and utilised in new capacities, to achieve<br />

this l<strong>of</strong>ty goal.<br />

Introduction<br />

The tower (Fig 1) opened to much fanfare<br />

on 4 January 2010 and was re-christened<br />

Burj Khalifa (it was previously known as<br />

Burj Dubai). Rising to a height <strong>of</strong> 828 m<br />

and with over 160 storeys, it is the world’s<br />

tallest building and the tallest man-made<br />

structure ever built.<br />

The Burj Khalifa Tower is the<br />

centrepiece <strong>of</strong> a US$ 20 billion<br />

development located just outside <strong>of</strong><br />

downtown Dubai. The project consists<br />

<strong>of</strong> the tower itself, as well as an adjacent<br />

podium structure, a separate 12-storey<br />

<strong>of</strong>fice annexe, a two-storey pool annexe,<br />

and four levels <strong>of</strong> sub-grade parking<br />

under the site. The 280,000 m 2 reinforced<br />

concrete multi-use tower comprises<br />

predominantly residential and <strong>of</strong>fice units,<br />

and it also houses retail establishments<br />

and a Giorgio Armani Hotel. Together,<br />

the tower and podium structures have a<br />

combined area <strong>of</strong> 465,000 m 2 .<br />

From the outset, the intention was<br />

to make Burj Khalifa the world’s tallest<br />

building (Fig 2 presents the world’s 10<br />

tallest buildings). The <strong>of</strong>ficial arbiter on<br />

heights is the Council on Tall Buildings and<br />

Urban Habitat (CTBUH). The CTBUH<br />

Fig 1: The Burj Khalifa Tower.<br />

22 · THE SINGAPORE ENGINEER Jun 2010

Structural Engineering<br />

Fig 2: Lineup <strong>of</strong> the world’s 10 tallest buildings.<br />

measures the heights <strong>of</strong> buildings using<br />

three criteria. Table 1 compares the values<br />

for Burj Khalifa with the corresponding<br />

values for the previous record holders.<br />

Architectural design<br />

The primary design concept for the tower<br />

took the form <strong>of</strong> an indigenous desert<br />

flower. The organic form, with tri-axial<br />

geometry and spiralling growth, can be<br />

easily seen in the final design.<br />

Additionally, traditional Islamic forms<br />

were utilised to enrich the tower’s design,<br />

and to incorporate visual references to the<br />

culture and history <strong>of</strong> the surrounding<br />

region. The floor plan has a tri-axial,<br />

Y-shaped configuration, formed by three<br />

separate wings connected to a central core<br />

(Fig 3). As the tower rises, one wing at<br />

each tier sets back in a spiralling pattern,<br />

further emphasising its height (Fig 4). The<br />

Y-shaped plan is ideal for residential and<br />

hotel usage, in that it allows the maximum<br />

views outward, without overlooking a<br />

neighbouring unit. The wings contain the<br />

residential units and hotel guest rooms,<br />

with the central core housing all <strong>of</strong> the<br />

elevatoring and mechanical closets.<br />

Additionally, the tower is serviced by<br />

five separate mechanical zones, located<br />

approximately 30 floors apart, over the<br />

height <strong>of</strong> the building. Located above the<br />

occupied reinforced concrete portion <strong>of</strong><br />

the building is the structural steel spire,<br />

housing communication and mechanical<br />

floors, completing the architectural form<br />

<strong>of</strong> the tower. The architects and engineers<br />

worked closely together from the<br />

beginning <strong>of</strong> the project to determine the<br />

shape <strong>of</strong> the tower, in order to provide an<br />

efficient building in terms <strong>of</strong> its structural<br />

system and in its response to wind, while<br />

still maintaining the integrity <strong>of</strong> the initial<br />

design concept.<br />

Structural system description<br />

In addition to its aesthetic and functional<br />

advantages, the spiralling Y-shaped plan<br />

was also utilised to shape the building,<br />

to reduce the wind forces on the tower,<br />

as well as to keep the structure simple,<br />

and foster constructability. The structural<br />

system can be described as a ‘buttressed’<br />

core, and consists <strong>of</strong> high-performance<br />

concrete wall construction.<br />

Each <strong>of</strong> the wings buttresses the others<br />

via a 6-sided central core or hexagonal hub.<br />

This central core provides the torsional<br />

resistance <strong>of</strong> the structure, similar to that<br />

Fig 3: Typical fl oor plan.<br />

for a closed pipe or axle. Corridor walls<br />

extend from the central core to near the<br />

end <strong>of</strong> each wing, terminating in thickened<br />

hammer-head walls. These corridor walls<br />

and hammer-head walls are similar to the<br />

webs and flanges <strong>of</strong> a beam in the way they<br />

resist wind shears and moments. Perimeter<br />

columns and flat plate floor construction<br />

complete the system. At mechanical<br />

Height to Architectural Top 828 m (Burj Khalifa) 508 m (Taipei 101)<br />

Highest Occupied Floor 535 m (Burj Khalifa) 474 m (Shanghai<br />

World Financial Center)<br />

Height to Tip 830 m (Burj Khalifa) 527 m (Sears Tower)<br />

Table 1: Comparison <strong>of</strong> height values for Burj Khalifa and those for previous record holders.<br />

THE SINGAPORE ENGINEER Jun 2010 · 23

Structural Engineering<br />

floors, outrigger walls are provided to link<br />

the perimeter columns to the interior wall<br />

system, allowing the perimeter columns<br />

to participate in the lateral load resistance<br />

<strong>of</strong> the structure. Hence, all <strong>of</strong> the vertical<br />

concrete is utilised to support both gravity<br />

and lateral loads. The result is a tower that<br />

is extremely stiff laterally and torsionally.<br />

It is also a very efficient structure in that<br />

the gravity load resisting system has<br />

been utilised so as to maximise its use in<br />

resisting lateral loads.<br />

As the building spirals in height, the<br />

wings set back to provide many different<br />

floor plates. The setbacks are organised<br />

with the tower’s grid, such that the<br />

building stepping is accomplished by<br />

aligning columns above with walls below,<br />

to provide a smooth load path. As such,<br />

the tower does not contain any structural<br />

transfers. These setbacks also have the<br />

advantage <strong>of</strong> providing a different width<br />

to the tower for each differing floor plate.<br />

This stepping and shaping <strong>of</strong> the tower<br />

has the effect <strong>of</strong> ‘confusing the wind’<br />

- wind vortices never get organised over<br />

the height <strong>of</strong> the building because at each<br />

new tier, the wind encounters a different<br />

building shape.<br />

Fig 4: Tower perspective.<br />

Structural analysis and superstructure<br />

design<br />

The reinforced concrete structure<br />

was designed in accordance with the<br />

requirements <strong>of</strong> ACI 318-02 Building<br />

Code Requirements for Structural<br />

Concrete. Wall and column concrete<br />

strengths range from C80 to C60 cube<br />

strength, and utilise Portland cement,<br />

fly ash, and local aggregates. The C80<br />

concrete has a maximum specified<br />

Young’s Elastic Modulus <strong>of</strong> 43,800 N/<br />

mm 2 at 90 days. Wall and column sizes<br />

were optimised using virtual work /<br />

LaGrange multiplier methods, resulting<br />

in a very efficient structure. Wall thickness<br />

and column sizes were also fine-tuned to<br />

reduce the effects <strong>of</strong> creep and shrinkage<br />

on the structure. To reduce the effects<br />

<strong>of</strong> differential column shortening due to<br />

creep between the perimeter columns and<br />

interior walls, the perimeter columns were<br />

sized such that the self-weight gravity<br />

stress on the perimeter columns was equal<br />

to the stress on the interior corridor walls.<br />

The outriggers at the five mechanical floors<br />

tie all the vertical load carrying elements<br />

24 · THE SINGAPORE ENGINEER Jun 2010

Structural Engineering<br />

together, further ensuring uniform<br />

gravity stress by essentially allowing the<br />

structure to redistribute gravity loads<br />

at five locations along the building’s<br />

height, thereby reducing differential creep<br />

movements. Additionally, the perimeter<br />

columns and corridor walls were given<br />

matching thicknesses, providing them<br />

with similar volume to surface ratios, to<br />

minimise differential shortening due to<br />

concrete shrinkage.<br />

The majority <strong>of</strong> the tower is a<br />

reinforced concrete structure. However,<br />

the top <strong>of</strong> the tower consists <strong>of</strong> a structural<br />

steel spire utilising a diagonally braced<br />

lateral system. The spire, which houses<br />

several mechanical and communication<br />

floors, and open void space, culminates<br />

in a pinnacle element. The structural<br />

steel spire was designed for gravity, wind,<br />

seismic loads, and fatigue, in accordance<br />

with the requirements <strong>of</strong> AISC Load and<br />

Resistance Factor Design Specification for<br />

Structural Steel Buildings (1999).<br />

The entire building structure was<br />

analysed for gravity (this included the<br />

performance <strong>of</strong> P-Delta analysis), wind,<br />

and seismic loadings, utilising ETABS<br />

version 8.4 (Fig 5). The three-dimensional<br />

analysis model consisted <strong>of</strong> the reinforced<br />

concrete walls, link beams, slabs, raft,<br />

piles, and the spire’s structural steel<br />

system. The full analysis model consisted<br />

<strong>of</strong> over 73,500 shells and 75,000 nodes.<br />

Under lateral wind loading, the building<br />

deflections were well below commonly<br />

used criteria. The dynamic analysis<br />

indicated that the first mode is lateral<br />

side-sway with a period <strong>of</strong> 11.3 seconds.<br />

The second mode is a perpendicular lateral<br />

side-sway with a period <strong>of</strong> 10.2 seconds.<br />

Torsion is the fifth mode with a period <strong>of</strong><br />

4.3 seconds.<br />

The Dubai Municipality specifies<br />

Dubai as a UBC97 Zone 2a seismic region<br />

(with a seismic zone factor Z = 0.15 and<br />

soil pr<strong>of</strong>ile Sc). The seismic analysis<br />

consisted <strong>of</strong> a site-specific response spectra<br />

analysis. Seismic loading typically did<br />

not govern the design <strong>of</strong> the reinforced<br />

concrete tower structure. However,<br />

seismic loading did govern the design <strong>of</strong><br />

the reinforced concrete podium buildings<br />

and the tower’s structural steel spire. Sitespecific<br />

seismic reports were developed<br />

for the project, including a seismic hazard<br />

analysis. The potential for liquefaction<br />

was investigated, based on several<br />

accepted methods. It was determined that<br />

liquefaction is not considered to have any<br />

structural implications for the deep-seated<br />

tower foundations.<br />

A comprehensive construction<br />

sequence analysis incorporating the effects<br />

<strong>of</strong> creep and shrinkage was performed to<br />

study the time-dependent behaviour <strong>of</strong><br />

the structure (Fig 6).<br />

Since the vertical concrete elements<br />

tend to have similar compression stress,<br />

the building performs well under the<br />

effects <strong>of</strong> creep and shrinkage. The results<br />

<strong>of</strong> this analysis were utilised to determine<br />

the horizontal and vertical compensation<br />

programmes. For horizontal compensation,<br />

the building is ‘re-centred’ with each<br />

successive centre core jump, correcting for<br />

gravity-induced side-sway effects which<br />

occur up to the casting <strong>of</strong> each storey.<br />

For vertical compensation, additional<br />

Fig 5: Three-dimensional analysis model dynamic mode shapes.<br />

Fig 6: Construction sequence analysis.<br />

height was added by increasing floorto-floor<br />

height, <strong>of</strong>fsetting the predicted<br />

vertical shortening <strong>of</strong> the column and wall<br />

elements.<br />

Wind engineering approach<br />

An extensive programme <strong>of</strong> wind tunnel<br />

tests and other studies was undertaken<br />

in RWDI’s 2.4 m x 1.9 m, and 4.9 m x<br />

2.4 m boundary layer wind tunnels in<br />

Guelph, Ontario, Canada. The wind<br />

tunnel testing programme included rigidmodel<br />

force balance tests, a full aeroelastic<br />

model study, cladding pressure studies,<br />

and pedestrian wind environment studies<br />

(Figs 7 and 8). These studies used models<br />

mostly at 1:500 scale. However, the<br />

pedestrian wind studies utilised a larger<br />

scale <strong>of</strong> 1:250 for the development <strong>of</strong><br />

aerodynamic solutions aimed at reducing<br />

wind speeds. Wind statistics played an<br />

important role in relating the predicted<br />

THE SINGAPORE ENGINEER Jun 2010 · 25

Structural Engineering<br />

levels <strong>of</strong> response to return period.<br />

Extensive use was made <strong>of</strong> groundbased<br />

wind data, balloon data, and<br />

computer simulations employing regional<br />

atmospheric modelling techniques, in<br />

order to establish the wind regime at the<br />

upper levels.<br />

To determine the wind loading on the<br />

main structure, wind tunnel tests were<br />

undertaken early in the design, using the<br />

high-frequency-force-balance technique.<br />

The wind tunnel data were then combined<br />

with the dynamic properties <strong>of</strong> the tower,<br />

in order to compute the tower’s dynamic<br />

response and the overall effective wind<br />

force distributions at full scale. For Burj<br />

Khalifa, the results <strong>of</strong> the force balance<br />

tests were used as early input for the<br />

structural design and allowed parametric<br />

studies to be undertaken on the effects<br />

<strong>of</strong> varying the tower’s stiffness and mass<br />

distribution.<br />

The building has essentially six<br />

important wind directions (Fig 9). Three<br />

<strong>of</strong> the directions are defined by the wind<br />

blowing directly into a wing. The wind<br />

blows into the ‘nose’ <strong>of</strong> each wing (Nose<br />

A, Nose B, and Nose C), creating the cutwater<br />

effect. The other three directions are<br />

defined by the wind blowing in between<br />

two wings, in the ‘tail’ directions (Tail A,<br />

Tail B, and Tail C). It was noticed that the<br />

force spectra for different wind directions<br />

showed less excitation in the important<br />

frequency range for winds impacting the<br />

pointed or nose end <strong>of</strong> a wing than from<br />

the opposite direction (tail). This was kept<br />

in mind when selecting the orientation <strong>of</strong><br />

the tower relative to the most frequent,<br />

strong wind directions for Dubai –<br />

northwest, south, and east.<br />

Several rounds <strong>of</strong> force balance tests<br />

were undertaken as the geometry <strong>of</strong><br />

the tower evolved, and as the tower was<br />

refined architecturally. The three wings<br />

are set back in a clockwise sequence with<br />

the ‘A’ wing setting back first. After each<br />

Fig 9: Plan view <strong>of</strong> tower.<br />

round <strong>of</strong> wind tunnel testing, the data was<br />

analysed and the building was reshaped to<br />

minimise wind effects and accommodate<br />

unrelated changes in the client’s<br />

programme. In general, the number and<br />

spacing <strong>of</strong> the setbacks changed as did<br />

the shape <strong>of</strong> wings. This process resulted<br />

in a substantial reduction in wind forces<br />

on the tower by ‘confusing’ the wind, by<br />

encouraging disorganised vortex shedding<br />

over the height <strong>of</strong> the tower (Fig 10).<br />

Towards the end <strong>of</strong> design, more<br />

accurate aeroelastic model tests were<br />

Fig 7: Aeroelastic wind tunnel model.<br />

Fig 8: Cladding wind tunnel model.<br />

Fig 10: Tower wind behaviour.<br />

26 · THE SINGAPORE ENGINEER Jun 2010

Structural Engineering<br />

initiated. An aeroelastic model is flexible<br />

in the same manner as the real building,<br />

with properly scaled stiffness, mass, and<br />

damping. The aeroelastic tests were able to<br />

model several <strong>of</strong> the higher translational<br />

modes <strong>of</strong> vibration. These higher modes<br />

dominated the structural response and<br />

design <strong>of</strong> the tower except at the very base<br />

where the fundamental modes controlled.<br />

Based on these results, the predicted<br />

building motions are within the ISO<br />

standard recommended values – there is<br />

no need for auxiliary damping.<br />

Tower foundations<br />

The tower is founded on a pile-supported<br />

raft foundation (Fig 11). The solid<br />

reinforced concrete raft is 3.7 m thick and<br />

was poured utilising 12,500 m 3 <strong>of</strong> C50<br />

(cube strength) self-consolidating concrete<br />

(SCC). The raft was constructed in four<br />

separate pours (for the three wings and the<br />

centre core). Each raft pour occurred over<br />

at least a 24-hour period. Reinforcement<br />

Fig 11: Tower raft under construction.<br />

was typically spaced at 300 mm in the<br />

raft, and arranged such that every 10 th bar<br />

in each direction was omitted, resulting<br />

in a series <strong>of</strong> ‘pour enhancement strips’<br />

throughout the raft. The intersections <strong>of</strong><br />

these strips created 600 mm x 600 mm<br />

openings at regular intervals, facilitating<br />

access and concrete placement.<br />

Owing to the thickness <strong>of</strong> the tower<br />

raft, limiting the peak and differential<br />

temperatures due to the heat <strong>of</strong> hydration<br />

was an important consideration in<br />

determining the raft concrete mix design<br />

and placement methods. The 50 MPa raft<br />

mix incorporated 40% fly ash and a watercement<br />

ratio <strong>of</strong> 0.34. The concrete mix<br />

was poured into large-scale test cubes with<br />

3.7 m side dimensions, prior to the raft<br />

construction, so as to verify the concrete<br />

placement procedures and monitor the<br />

concrete temperature performance.<br />

The tower raft is supported by 194<br />

bored, cast-in-place piles. The piles are<br />

1.5 m in diameter and approximately 43<br />

m long, with a capacity <strong>of</strong> 3,000 t each<br />

(the pile load is tested to 6000 tonnes).<br />

The diameter and length <strong>of</strong> the piles<br />

represent the largest and longest piles<br />

conventionally available in the region.<br />

Additionally, the 6000 tonne pile load<br />

test represented the largest magnitude pile<br />

load test performed to date within the<br />

region (Fig 12). The C60 (cube strength)<br />

SCC concrete was placed by the tremie<br />

method utilising polymer slurry. When the<br />

rebar cage was placed in the piles, special<br />

attention was paid to orient the rebar cage<br />

such that the raft bottom rebar could be<br />

threaded through the numerous pile rebar<br />

cages without interruption, which greatly<br />

simplified the raft construction.<br />

Another design challenge in the<br />

project arose from the existing site<br />

conditions. The ground water, which is<br />

quite high at approximately 2 m below<br />

the surface, is extremely corrosive,<br />

containing approximately three times<br />

the sulphates and chlorides present in sea<br />

water. As such, a rigorous programme <strong>of</strong><br />

anti-corrosion measures was followed<br />

to ensure the long-term integrity <strong>of</strong> the<br />

tower’s foundation system. Measures<br />

instituted included the implementation<br />

<strong>of</strong> specialised waterpro<strong>of</strong>ing systems<br />

and increased concrete cover for the<br />

reinforcement, addition <strong>of</strong> corrosion<br />

inhibitors to the concrete mix, applying<br />

stringent crack control raft design<br />

criteria, and the implementation <strong>of</strong> an<br />

impressed current cathodic protection<br />

system utilising titanium mesh (Fig13).<br />

Additionally, a controlled permeability<br />

formwork liner was utilised for the tower<br />

raft, which resulted in a higher strength /<br />

lower permeability concrete cover for the<br />

rebar. The concrete mix for the piles was<br />

also enhanced. It was designed as a fully<br />

self-consolidating concrete to limit the<br />

possibility <strong>of</strong> defects during construction.<br />

Fig 12: Tower pile load test.<br />

Fig 13: Cathodic protection below raft.<br />

THE SINGAPORE ENGINEER Jun 2010 · 27

Structural Engineering<br />

Tower construction methods<br />

The Burj Khalifa Tower utilised the latest<br />

advancements in construction techniques<br />

and materials technology. The walls were<br />

formed using Doka’s SKE 100 automatic<br />

self-climbing formwork system.<br />

The circular nose columns were<br />