bill of quantities - UNDP

bill of quantities - UNDP

bill of quantities - UNDP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

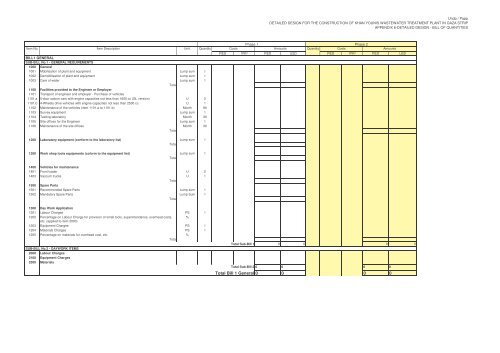

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

BILL1 GENERAL<br />

SUB-BILL No.1 - GENERAL REQUIREMENTS<br />

1000 General<br />

1001 Mobilisation <strong>of</strong> plant and equipment Lump sum 1<br />

1002 Demobilisation <strong>of</strong> plant and equipment Lump sum 1<br />

1003 Care <strong>of</strong> water Lump sum 1<br />

Total<br />

1100 Facilities provided to the Engineer or Employer<br />

1101 Transport <strong>of</strong> engineer and employer - Purchase <strong>of</strong> vehicles<br />

1101.a 5-door saloon cars with engine capacities not less than 1600 cc (GL version) U 2<br />

1101.b 4-Wheels drive vehicles with engine capacities not less than 2500 cc U 1<br />

1102 Maintenance <strong>of</strong> the vehicles (item 1101.a to 1101.b) Month 90<br />

1103 Survey equipment Lump sum 1<br />

1104 Testing laboratory Month 30<br />

1105 Site <strong>of</strong>fices for the Engineer Lump sum 1<br />

1106 Maintenance <strong>of</strong> the site <strong>of</strong>fices Month 30<br />

Total<br />

1200 Laboratory equipment (conform to the laboratory list) Lump sum 1<br />

Total<br />

1300 Work shop tools equipments (c<strong>of</strong>orm to the equipment list) Lump sum 1<br />

Total<br />

1400 Vehicles for maintenance<br />

1401 Front loader U 2<br />

1403 Vaccum trucks U 1<br />

Total<br />

1500 Spare Parts<br />

1501 Recommended Spare Parts Lump sum 1<br />

1502 Mandatory Spare Parts Lump Sum 1<br />

Total<br />

1300 Day Work Application<br />

1201 Labour Charges PS 1<br />

1202 Percentage on Labour Charge for provision <strong>of</strong> small tools, superintendance, overhead costs, %<br />

etc. (applied to item 2000)<br />

1203 Equipment Charges PS 1<br />

1204 Materials Charges PS 1<br />

1205 Percentage on materials for overhead cost, etc. %<br />

Total<br />

SUB-BILL No.2 - DAYWORK ITEMS<br />

2000 Labour Charges<br />

2100 Equipment Charges<br />

2500 Materials<br />

Total Sub-Bill 1<br />

0 0 0 0<br />

Total Sub-Bill 2 0 0 0 0<br />

Total Bill 1 General 0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

BILL 2 SCREENING AND PRETREATMENT<br />

SUB-BILL NO.1 - EARTHWORKS<br />

1000 Earthworks<br />

1001 Stripping <strong>of</strong> soil m² 700<br />

1002 Excavation in all materials after stripping topsoil not exceeding 5.0 m depth m³ 975<br />

1003 Extra-over for breaking up brickwork, concrete masonry and the like encountered in excavation m³ 50<br />

(provisional quantity)<br />

1004 Extra-over for excavation in rock (provisional quantity) m³ 30<br />

1005 Excavation for the removal <strong>of</strong> unsuitable material encountered below Permanent Works<br />

m³ 150<br />

(provisional quantity)<br />

1006 Backfill with selected excavated material m³ 650<br />

1007 Backfill with concrete class B as directed by the Engineer (provisional quantity) m³ 30<br />

1008 Dispose <strong>of</strong> surplus excavated material m³ 975<br />

1009 Backfill with granular material type 0/100 m³<br />

SUB-BILL NO.2 - CONCRETE INCLUDING FORMWORK AND REINFORCEMENT<br />

2000 Concrete<br />

Prices <strong>of</strong> all concrete items include shuttering, formwork, steel reinforcement, concrete,<br />

vibration, curing, striking, testing steel reinforcement and concrete, all material needed<br />

for expansion joints and workmanship, according to drawings, specifications, conditions<br />

and directed by the engineer.<br />

2001 Blinding 100 mm thick - Class E m² 365<br />

2002 Reinforced concrete class A in base slab, apron, ground, beams, pits, sumps, ground blocks, m³ 420<br />

on or below the ground level, whatever the position and elevation<br />

2003 Reinforced concrete class A in walls and columns m³ 315<br />

2004 Reinforced concrete class A in any others structures (stairs, weirs, blocks, balconnies, shafts, m³ 75<br />

channel, culverts … ) above ground level<br />

2005 Reinforced concrete class A in solid slab m³ 55<br />

2006 Reinforced concrete class A in ribbed slab m³ 95<br />

2007 Mass concrete class A in all position m³ 25<br />

SUB-BILL NO.5 - JOINTS<br />

5000 Movement joints<br />

5001 Supply and fix waterstop (sealing strip)-Type 1 ml 110<br />

SUB-BILL NO.6 - PROTECTIVES FINISHES<br />

6001 Bitumen ro<strong>of</strong> watertighess m² 310<br />

6002 Concrete or and concrete reinforcement masonry blocks (20cm in thickness);incl. Inside plaster<br />

render<br />

m² 480<br />

SUB-BILL NO.7 - FABRICATED ITEMS<br />

7001 Aluminium hand railing whatever the position including fixing ml 190<br />

7002 Galvanized steel door including industrial painting, frame, fixing, handle and lock m² 12<br />

7003 Aluminium windows whateever the position including fixing m² 16<br />

7004 Aluminium trap for future air-ducts with bars and frame m² 5<br />

7005 Galvanized steeel grating floors whatever the position including fixing m² 12<br />

7006 Aluminium covering domes to cover the ro<strong>of</strong> openings m² 8<br />

7007 Vehicles and lorries metallic doors, including vertical openning, 2 epoxy coats + 1 prime,<br />

motorization, lock, frame and fixing<br />

m² 32<br />

Total Sub-Bill 1 0 0 0 0<br />

Total Sub-Bill 2 0 0 0 0<br />

Total Sub-Bill 5 0 0 0 0<br />

Total Sub-Bill 6 0 0 0 0<br />

Total Sub-Bill 7 0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.11 - MECHANICAL EQUIPMENT<br />

11000 Raw water inlet inside building<br />

11001 Raw water inlet Pressure Pipe ND 700mm 316 stainless steel, counted 1 m outside the<br />

lm 14<br />

external wall<br />

11002 Raw water inlet pressure Pipe ND 450mm 316 stainless steel, counted 1 m outside the<br />

lm 14<br />

external wall<br />

11003 Electrical isolation joint ND 700 U 1<br />

11004 Electrical isolation joint ND 450 U 1<br />

11100 Fine screening<br />

11101 6 Frames and 4 Stop-logs for isolating fine screening channels 1.00m x 1,70m LS 1<br />

11102 Fine screens 1.00 X 1.70m including level probe, pressure measuring, proximity<br />

U 2 1<br />

detector,supply cable, brake motor,...<br />

11200 Transport and treatment <strong>of</strong> screenings<br />

11201 Screenings convoyer including accessories U 1<br />

11202 Screenings compactor including accessories U 1<br />

11203 Skip for Screenings storage including accessories U 2<br />

11300 Grit and grease removal<br />

11301 Penstocks for grit and grease removal feeding (1,50m x 0,45m) including frames and electrical actuators U 6<br />

11302 Turbine aerator including accessories U 6 3<br />

11303 Scraper bridge including truck, rails, wheels, motor, guidance system, scraping system (surface U 2 1<br />

and bottom), accessories …<br />

11304 Grit extraction pumps including pipes from sand pit up to sand classifier,valves, material handling, accessories U … 2 1<br />

11305 Grit extraction pumps in workshop U 1<br />

11306 Grit classifier 60 m3/h including pipes and valves, accessories U 1<br />

11307 Grease evacuation hoppers U 2 1<br />

11308 Skip 15 m3 for grit storage including accessories U 2<br />

11309 Pretreated water outlet Weirs on degritting chamber outlet U 12 6<br />

11310 Sprinklers for grease evacuation from collection channel to grease pit including pipes ND<br />

U 2 1<br />

20mm PVC counted 1 m outside the external wall up to collector channels<br />

11311 Solenoid valves on industrial water network U 2 1<br />

11400 Handling<br />

11401 Mobile crane for turbine aerator U 1<br />

11500 Ventilation<br />

11501 Aluminium fresh air inflow grille U 5<br />

11502 Aluminium foul air extraction grille U 5<br />

11503 Fiberglass-reinfroced polyester pipes, diameter 750 mm and all accessories lm 60<br />

Total Sub-Bill 11<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.12 - ELECTRICAL EQUIPMENT<br />

12000 * Suppling, installing, testing and commission <strong>of</strong> the electrical works as per drawings,<br />

specifications, and engineer's instructions. The prices <strong>of</strong> the follwing items include all<br />

necessary junction boxes, wires, conduits, clamps, bolts, and connectors.<br />

* All installation shall be in accordance with The drawings , secifications and instructions<br />

and demands <strong>of</strong> the engineer and the electricity law and electrical code requirments <strong>of</strong><br />

the BRITISH standards.<br />

* The contractor should refer to the drawings , specifications and other Contract<br />

Documents .<br />

* The prices will be deemed to include for the full cost as described in all Documents.<br />

12100 Lighting Fittings<br />

12101 Supply, install, connect and test fluorescent lighting fixture 2x36w complete with lighting tubes<br />

36, chock, condensers, starters rigid PVC conduits, J.boxes, fixing screws (Galv.) and wiring.<br />

(provesional condition)<br />

U 1<br />

12102 Ditto , but water and dust pro<strong>of</strong> IP 65 U 18<br />

12103 Ditto,but with emergency back up power built in, for duration 3 hours. U 3<br />

12104 Supply, install, connect and test incandescence lighting fixture with 75W lamp, wires, conduits, U 4<br />

j. boxes and fixing screws for wall mounted. IP 65<br />

12105 Supply, install, connect and test lighting unit with 11w PL lamp with all needed part U 1<br />

and cables,(h=25cm) as per drawings (provesional condition)<br />

12106 Supply, install, connect and test emergency lighting fixture 8w, 3hrs. duration with self U 1<br />

adhesive PVC exit legend complete with all necessary accessories. (provesional<br />

condition)<br />

12200 Switches & sockets:<br />

12201 Supply, install connect and test single pole one way switch IP-55 watertight plate, U 1<br />

230V/13A complete with PVC conduite, junction box, wiring or (cables), cover and all<br />

necessery accessories (type is LEGRAND or equivalent). (provesional condition)<br />

12202 Ditto,but water pro<strong>of</strong> IP - 55 U 6<br />

12203 Ditto, but two way switch, one pole. (Type is LEGRAND or equivalent). U 1<br />

12204 Ditto, but water pro<strong>of</strong> U 8<br />

12205 supply, install connect and, testing single socket outlet 16A, 220v, 2p+E for flush or U 2<br />

surface mounting, complete with PVC conduits, J.boxes, wiring, and all necessary<br />

accessories. (Type is LEGRAND or equivalent).<br />

12206 Ditto, but water pro<strong>of</strong> (Type is LEGRAND or equivalent) U 1<br />

12207 IP - 55 W.P three phase socket outlet 3X16A, 380v, 3p+N+E for flush or surface U 2<br />

mounting, complete with PVC conduits, J.boxes, wiring, and all necessary<br />

accessories. (Type is LEGRAND or equivalent)<br />

12208 supply, install, connect and testing tuminaire IP-66 class I - 250W/230V, High U 6<br />

pressure Sodum, street lighting type, complete with PVC conduite, junction box,<br />

wiving or cabling and all necessery accessories type is (philips or equivalent)as per<br />

drawing see detail (A ) DD-PRE - E -003_B<br />

12209 Supply, install, connect and test testing reflector (high bay luminaires) IP-55<br />

12<br />

equipment with lamp 250W/230V H.P.S complete with PVC conduite, j.box wiring or<br />

cabling and all necessery accessories type in (philips or equivalent as per drawing<br />

detail B DD-PRE-E-003_B<br />

12300 Protection system<br />

12301 An earthing system including flat steel tapes (34*4mm), testing point, tap <strong>of</strong>f, LS 1<br />

equipotinal bus bars, 80un diam manhole, u bolted clamps and digging <strong>of</strong> three 19<br />

mm diam copper electrodes 3 m long. According to drawing DD- PRE- E- 001_B. the<br />

earthing resistance should not exceed 2 ohms.<br />

12302 Lightning protection system including pulsar lightning conductor, fixation brackets, LS 1<br />

connecting strips 30x2mm copper tape, interconnection box for equipotential bonding,<br />

inspection coupling manholes with 3 electrodes <strong>of</strong> 3mx19mm copper electrode with all<br />

accessories required.<br />

12400 Distribution panels<br />

12401 Supply install distribution Panel (DP/Pret) Consist <strong>of</strong> lockable panel Frames as per U 1<br />

specifications including 2mm Galv. Steel with anti static paint, bus bars for incoming<br />

cables, neutral and earthing terminal with all necessary accessoires needed as per<br />

drawing DD-PRE-E002-B

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

12402 Ditto, but lighting Panel (LP/Pret) as per drawing DD-PRE-E-002_B U 1<br />

12403 Control Box, consist <strong>of</strong> individual enclosure number <strong>of</strong> Bullons, IP-65, Surface U 4<br />

mounted, transparent door for operator access moeller type or equivalent as per<br />

drawing DD-PRE-E002_B<br />

Total Sub-Bill 12<br />

0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.14 - AUTOMATION AND INSTRUMENTATION<br />

14000 Raw waterflow measurement<br />

14001 Electromagnetic flow meter on pressure coming pipe ND 700, including convector and totalizer U 1<br />

14002 Electromagnetic flow meter on pressure coming pipe ND 450, including convector and totalizer U 1<br />

14003 pH sensor U 1<br />

14004 Temperature sensor U 1<br />

14100 Level measures for grit and grease removal<br />

14101 Level Switch Alarm High High (LSA HH) U 2 1<br />

14102 High level sensor U 2 1<br />

14103 Low level sensor U 2 1<br />

14104 Level Switch Alarme Low Low (LSA LL) U 2 1<br />

14200 Level measures for grit and grease removal<br />

14201 Low level U 2 1<br />

14300 Level measures for grease tank<br />

14301 High level controller U 1<br />

14400 Physico-chemical measurement<br />

14401 H2S detector U 1<br />

14500 Automation : PLC1 - Pretreatment<br />

14501 CPU U 1<br />

14502 Input TOR Modulate 32 Ways U 3 1<br />

14503 Output TOR Modulate 32 Ways U 1<br />

14504 Inpput Analogical Modulate 8 Ways U 2<br />

14505 Output Analogical Modulate 8 Ways U 2<br />

14506 Pr<strong>of</strong>ibus Cable U 1 1<br />

14507 Ethernet Switch U 1 1<br />

14508 Touch Panel U 1 1<br />

14509 PLC Cupboard U 1 1<br />

Total Sub-Bill 14<br />

Total Bill 2 Screening and Pretreatment<br />

0 0 0 0<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

BILL 3 MANHOLES AND DISTRIBUTORS<br />

SUB-BILL NO.1 - EARTHWORKS<br />

1000 Earthworks<br />

1001 Stripping <strong>of</strong> soil m² 130 30<br />

1002 Excavation in all materials after stripping topsoil not exceeding 5.0 m depth m³ 400 100<br />

1003 Extra-over for breaking up brickwork, concrete masonry and the like encountered in excavation m³<br />

(provisional quantity)<br />

1004 Extra-over for excavation in rock (provisional quantity) m³<br />

1005 Excavation for the removal <strong>of</strong> unsuitable material encountered below Permanent Works<br />

m³<br />

(provisional quantity)<br />

1006 Backfill with selected excavated material m³ 50 20<br />

1007 Backfill with concrete class B as directed by the Engineer (provisional quantity) m³<br />

1008 Dispose <strong>of</strong> surplus excavated material m³ 400 100<br />

1009 Backfill with granular material type 0/100 m³<br />

Total Sub-Bill 1 0 0 0 0<br />

SUB-BILL NO.2 - CONCRETE INCLUDING FORMWORK AND REINFORCEMENT<br />

2000 Concrete<br />

Prices <strong>of</strong> all concrete items include shuttering, formwork, steel reinforcement, concrete,<br />

vibration, curing, striking, testing steel reinforcement and concrete, all material needed<br />

for expansion joints and workmanship, according to drawings, specifications, conditions<br />

and directed by the engineer.<br />

2001 Blinding 100 mm thick - Class E m² 130 30<br />

2002 Reinforced concrete class A in base slab, apron, ground, beams, pits, sumps, ground blocks, m³ 180 25<br />

on or below the ground level, whatever the position and elevation<br />

2003 Reinforced concrete class A in walls and columns m³ 80 10<br />

2004 Reinforced concrete class A in any others structures (stairs, weirs, blocks, balconnies, shafts, m³ 5<br />

channel, culverts … ) above ground level<br />

2005 Reinforced concrete class A in solid slab m³<br />

2006 Reinforced concrete class A in ribbed slab m³<br />

2007 Mass concrete class A in all position m³<br />

Total Sub-Bill 2 0 0 0 0<br />

SUB-BILL NO.7 - FABRICATED ITEMS<br />

7001 Galvanized steel hand railing whatever the position including fixing ml 40 10<br />

7002 Galvanized steel door including industrial painting, frame, fixing, handle and lock m²<br />

7003 Aluminium windows whateever the position including fixing m²<br />

7007 Aluminium trap for future air-ducts with bars and frame m²<br />

7016 Vehicles and lorries metallic doors, including vertical openning, 2 epoxy coats + 1 prime,<br />

m²<br />

motorization, lock, frame and fixing<br />

Total Sub-Bill 7 0 0 0 0<br />

SUB-BILL NO.11 - MECHANICAL EQUIPMENT<br />

11000 Distribution well upstream aeration tanks<br />

11001 Weirs for distribution well DW1 (2,00 x 0.40) U 3<br />

11002 2 Stoplogs for isolation <strong>of</strong> channels (2,00 x 0,80) and 3 frames LS 3<br />

11100 Distribution well DW2<br />

11101 Overflow (1,50 m) for distribution well DW2 U 6<br />

11102 6 Frames (1,50x0,80) and 2 stop-log (1,50x0,50) for disribution well DW2 LS 1<br />

11200 Distribution well between degazing and clarifiers<br />

11201 Overflow (1,50 m) for distribution well between degazing and clarifiers U 8 4<br />

11202 2 Frames (1,50x0,80) and 2 stop-log (1,50x0,50) for disribution well between degazing and<br />

clarifiers<br />

LS 2 1<br />

Total Sub-Bill 11<br />

Total Bill 3 Manholes and distributors<br />

0 0 0 0<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

BILL 4 AERATION TANKS & BLOWERS ROOM<br />

SUB-BILL NO.1 - EARTHWORKS<br />

1000 Earthworks<br />

1001 Stripping <strong>of</strong> soil m² 5150 1 800<br />

1002 Excavation in all materials after stripping topsoil exceeding 5.0 m depth m³ 28280 10 000<br />

1003 Extra-over for breaking up brickwork, concrete masonry and the like encountered in excavation m³ 100 40<br />

(provisional quantity)<br />

1004 Extra-over for excavation in rock (provisional quantity) m³ 60 20<br />

1005 Excavation for the removal <strong>of</strong> unsuitable material encountered below Permanent Works<br />

m³ 300 100<br />

(provisional quantity)<br />

1006 Backfill with selected excavated material m³ 2000 800<br />

1007 Backfill with concrete class B as directed by the Engineer (provisional quantity) m³ 60 20<br />

1008 Dispose <strong>of</strong> surplus excavated material m³ 28280 10 000<br />

1009 Backfill with granular material type 0/100 m³<br />

Total Sub-Bill 1<br />

0 0 0 0<br />

SUB-BILL NO.2 - CONCRETE INCLUDING FORMWORK AND REINFORCEMENT<br />

2000 Concrete<br />

Prices <strong>of</strong> all concrete items include shuttering, formwork, steel reinforcement, concrete,<br />

vibration, curing, striking, testing steel reinforcement and concrete, all material needed<br />

for expansion joints and workmanship, according to drawings, specifications, conditions<br />

and directed by the engineer.<br />

2001 Blinding 100 mm thick - Class E m² 4880 1 700<br />

2002 Reinforced concrete class A in base slab, apron, ground, beams, pits, sumps, ground blocks, m³ 5900 2 200<br />

on or below the ground level, whatever the position and elevation<br />

2003 Reinforced concrete class A in walls and columns m³ 1490 380<br />

2004 Reinforced concrete class A in any others structures (stairs, weirs, blocks, balconnies, shafts, m³ 350 130<br />

channel, culverts … ) above ground level<br />

2005 Reinforced concrete class A in solid slab m³ 80 30<br />

2006 Reinforced concrete class A in ribbed slab m³ 245 90<br />

2007 Mass concrete class A in all position m³ 5 2<br />

Total Sub-Bill 2 0 0 0 0<br />

SUB-BILL NO.5 - JOINTS<br />

5000 Movement joints<br />

5001 Supply and fix waterstop (sealing strip)-Type 1 ml 660 230<br />

Total Sub-Bill 5<br />

0 0 0 0<br />

SUB-BILL NO.6 - PROTECTIVES FINISHES<br />

6001 Tyrolean finish coat (minimum 2 coats) for external wall m² 270<br />

6002 Paint finish coat (minimum 2 coats) for external wall m² 380<br />

6009 Concrete or and concrete reinforcement masonry blocks (20cm in thickness) m² 420<br />

Supply and execute external rendering 15mm to walls including galvanized metal lath angles<br />

and chicken wire at the intersection <strong>of</strong> concrete and block work's, pipes and including a<br />

rainwater isolation coat (Sand+Cement) according to Engineer approval and execute two coats<br />

<strong>of</strong> tyrolean finish with white cement for external rendering.<br />

m² 650<br />

6012 Supply and execute internal plastering 15mm thick (three coats) to walls, s<strong>of</strong>fits, side <strong>of</strong><br />

columns, jambs and reveals <strong>of</strong> openings, window sills, …etc. including galvanized metal lath<br />

angles for columns, edges and chicken wire at the intersection <strong>of</strong> concrete and block works,<br />

pipes.<br />

m² 500<br />

6008 Supply and execute internal plastering 13mm thick (three coats) for the ceiling m² 370<br />

6015 Supply and paint three coats policide for the ceiling including all the required materials as<br />

m² 370<br />

shown on the drawings, specifications and Engineer's instructions.<br />

6016 Supply and paint bondrol primer coat and three coats <strong>of</strong> emulsion paint (Supecryl) for internal<br />

walls including all the required materials as shown on the drawings, specifications and<br />

Engineer's instructions.<br />

m² 500

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

6019 Supply and cast in-place slopping foam concrete (150 kg/cm2) for ro<strong>of</strong> screeding <strong>of</strong> average<br />

thickness 7.0cm as shown in the drawings specifications and according to Engineer's<br />

instructions. Incl. Suppling and executing cement and sand angle fillets size 5c<br />

m² 300<br />

Supply and lay one layer <strong>of</strong> plasticised bitumen ro<strong>of</strong>ing membrane ( class 200gr/m2 Polyster)<br />

with chipping 4mm thick including priming concrete surface prior to laying, dressing into rain<br />

water outlets to form water pro<strong>of</strong>ing seal and cover angle fillets, a<br />

m² 300<br />

Total Sub-Bill 6<br />

0 0<br />

SUB-BILL NO.7 - FABRICATED ITEMS<br />

7001 Stainless steel 316 hand railing whatever the position including fixing ml 410 150 0 0 0<br />

7002 Galvanized steel grating floors whatever the position including fixing ( areation and blower) m² 130<br />

7003 Galvanized steel doors with lower louvers, incl. Industrial painting, frame, fixing, handle and<br />

lock<br />

7004 Galvanized steel doors with upper grating openings, incl. Industrial painting, frame, fixing,<br />

handle and lock<br />

m² 65<br />

m² 65<br />

7005 Galvanized steel grating windows, incl. Industrial painting, frame, fixing, handle and lock m² 35<br />

7006 Ditto but louver windows m² 3 0 0<br />

Total Sub-Bill 7<br />

0 0 0 0<br />

SUB-BILL NO.11 - MECHANICAL EQUIPMENT<br />

11000 Anoxic zone<br />

11001 Submersible stirrers for anoxic zone including motor, accessories U 4 2<br />

11002 Submersible stirrers for mixing/flow circulation in aeration tank including motor, accessories U 12 6<br />

11003 Air diffusers (4032) and 32 Support grids for air diffusers including connections, support legs<br />

condensate blow-down and all accessories<br />

11004 Air pressure distribution pipes ND600 , for air feeding from the ND 600 isolator valve to ND<br />

300, including complate installation <strong>of</strong> pipe, supports, elbows, reducers, joins, air release<br />

valves<br />

11005 Air pressure distribution pipes ND300 , for air diffuser from ND600 to ND 160, including<br />

complate installation <strong>of</strong> pipe, supports, elbows, reducers, joins, air release valves<br />

LS 1 0.5<br />

lm 90 30<br />

lm 30 15<br />

11004 Air pressure down pipes ND160 , for air feeding to diffusers grids, including complate<br />

lm 264 132<br />

installation <strong>of</strong> pipe, supports, elbows, reducers, joins, air release valves<br />

11006 Butterfly valves for connecting pipe ND 600 mm U 3 1<br />

11006 Butterfly valves for grid isolation ND 160 mm U 32 16<br />

11007 Mixed liquor recirculation pumps 350 m3/h including pipes, connections, valves, accessories U 4 2<br />

11005 Supply in ware house <strong>of</strong> 1 mixed liquer recirculation pump U 1<br />

11008 Effluent outlet weirs (3,00)stainless steel 304 L U 2 1<br />

11009 3 Blowers 19000 Nm3/h/u for process air (aeration tank) including air inlet, ducts for air<br />

exhaust,outlet tapper, air release valves, elbow, air flow meters, ND 600 check valve and ND<br />

600 butterly valve,connections, pipes, flanges and valves isolation, ventilation, insonorisation<br />

and accessories<br />

LS 1 0.33<br />

11100 Handling<br />

11101 Hoisting derrick 500 kg for submersible stirrers anoxic zone U 4 2<br />

11102 Hoisting derrick 500 kg for submersible stirrers mixing flow circulation U 12 6<br />

11103 Hoisting derrick 300 kg for mixed liquor recirculation pump U 1 1<br />

Total Sub-Bill 11<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.12 - ELECTRICAL EQUIPMENT<br />

12000 * Suppling, installing, testing and commission <strong>of</strong> the electrical works as per drawings,<br />

specifications, and engineer's instructions. The prices <strong>of</strong> the follwing items include all<br />

necessary junction boxes, wires, conduits, clamps, bolts, and connectors.<br />

* All installation shall be in accordance with The drawings , secifications and instructions<br />

and demands <strong>of</strong> the engineer and the electricity law and electrical code requirments <strong>of</strong><br />

the BRITISH standards.<br />

* The contractor should refer to the drawings , specifications and other Contract<br />

Documents .<br />

* The prices will be deemed to include for the full cost as described in all Documents.<br />

12100 Lighting Fittings<br />

12101 Supply, install, connect and test fluorescent lighting fixture 2x36w complete with lighting tubes<br />

36, chock, condensers, starters rigid PVC conduits, J.boxes, fixing screws (Galv.) and wiring.<br />

(provesional condition)<br />

U 1<br />

12102 Ditto, but water and dust pro<strong>of</strong> IP65. U 2<br />

12103 Supply, install, connect and test incandescence lighting fixture with 75W lamp, wires, conduits, U 8 8<br />

j. boxes and fixing screws for wall mounted IP 65.<br />

12104 Ditto, but with PL lamp U 2<br />

12105 Supply, install, connect and test lighting unit with 11w PL lamp with all needed part U 1<br />

and cables,(h=25cm) as per drawings (provesional condition)<br />

12105 Supply, install, connect and test emergency lighting fixture 8w, 3hrs. duration with self U 1<br />

adhesive PVC exit legend complete with all necessary accessories. (provesional<br />

condition)<br />

12106 Supply, install, connect and test rectangular projectors 45x50cm with lamp 250w U 16 8<br />

HPS.<br />

12200 Switches & sockets:<br />

12201 Supply, install connect and test single pole one way switch, 220v, 13A, complete with U 1<br />

PVC conduits, J.boxes, wiring,cover and all necessary accessories. (Type is<br />

LEGRAND or equivalent). (provesional condition)<br />

12202 Ditto, but water pro<strong>of</strong>. U 4 8<br />

12203 Ditto, but three phase socket outlet 3X16A, 380v, 3p+N+E for flush or surface U 1<br />

mounting, complete with PVC conduits, J.boxes, wiring, and all necessary<br />

accessories. (Type is LEGRAND or equivalent)<br />

12204 supply, install connect and, testing single socket outlet 16A, 220v, 2p+E for flush or U 1<br />

surface mounting, complete with PVC conduits, J.boxes, wiring, and all necessary<br />

accessories. (Type is LEGRAND or equivalent). (provesional condition)

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

12300 Protection system<br />

12300 An earthing system including flat steel tapes (34*4mm), testing point, tap <strong>of</strong>f, LS 1 1<br />

equipotinal bus bars, 80un diam manhole, u bolted clamps and digging <strong>of</strong> three 19<br />

mm diam copper electrodes 3 m long. According to drawing DD- AER- E-001-B . the<br />

earthing resistance should not exceed 2 ohms.<br />

12302 Lightning protection system including pulsar lightning conductor, fixation brackets, LS 1<br />

connecting strips 30x2mm copper tape, interconnection box for equipotential bonding,<br />

inspection coupling manholes with 3 electrodes <strong>of</strong> 3mx19mm copper electrode with all<br />

accessories required.<br />

12400 Distribution panels<br />

12401 Supply, install distribution Panel DP/thic consist <strong>of</strong> Lockable panel frames as per U 1 1<br />

specifications including 2 mm Galva. Steel sheets with anti-static paint, bus bars for<br />

incoming cables, neutral and earthing terminal with all necessary accessories needed<br />

as per drawing DD- AER-E-002_B/ for recirculation system<br />

12402 Ditto, but for stirrers 1 1<br />

12403 Ditto, but for lighting 1 1<br />

12404 Control Box as per drawing DD- AER-E-003_B U 4 2<br />

12405 Piping UPV OF 2" LM 80 20<br />

12406 Ditto, but 4'' LM 1500 350<br />

12407 Supply, install cable tray galvanized steel ( Perforeted ) <strong>of</strong> 200 x35mm LM 50<br />

12408 Ditto, but 150x35 mm LM 100 80<br />

12409 Ditto, but 100x35 mm LM 25 120<br />

12410 cables u1000 R02V 5X25mm2 LM 50 60<br />

12411 Ditto, but 5X10mm2 LM 40 60<br />

12412 Ditto, but 5X6mm2 LM 60 40<br />

12413 Ditto, but 5X4mm2 LM 100 80<br />

12414 Ditto, but 5X2.5mm2 LM 150 100<br />

Total Sub-Bill 12<br />

0 0 0<br />

SUB-BILL NO.14 - AUTOMATION AND INSTRUMENTATION<br />

14000 Physico-chemical measurements<br />

14001 O2 meter U 4 2<br />

14002 Rh sensor U 6 3<br />

14003 MES sensor U 2 1<br />

14004 NO3 sensor U 2 1<br />

14100 Mixed liquor recirculation measurement<br />

14101 Electromagnetic flow meter on pressure coming pipe ND400 including convertor and totalizer U 2 1<br />

14500 Automation : PLC2 - Aeration Treatment<br />

14501 CPU U 1 1<br />

14502 Input TOR Modulate 32 Ways U 7 3<br />

14503 Output TOR Modulate 32 Ways U 2 1<br />

14504 Input Analogical Modulate 8 Ways U 6 2<br />

14505 Output Analogical Modulate 8 Ways U 1 1<br />

14506 Pr<strong>of</strong>ibus Cable U 1<br />

14507 Ethernet Switch U 1 1<br />

14508 Touch Panel U 1 1<br />

14509 PLC Cupboard U 1 1<br />

Total Sub-Bill 14<br />

0 0 0 0<br />

Total Bill 4 Aeration tanks 0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

BILL 5 CLARIFIERS<br />

SUB-BILL NO.1 - EARTHWORKS<br />

1000 Earthworks<br />

1001 Stripping <strong>of</strong> soil m² 4030 1 400<br />

1002 Excavation in all materials after stripping topsoil not exceeding 5.0 m depth m³ 10770 3 600<br />

1003 Extra-over for breaking up brickwork, concrete masonry and the like encountered in excavation m³ 80 30<br />

(provisional quantity)<br />

1004 Extra-over for excavation in rock (provisional quantity) m³ 40 15<br />

1005 Excavation for the removal <strong>of</strong> unsuitable material encountered below Permanent Works<br />

m³ 225 80<br />

(provisional quantity)<br />

1006 Backfill with selected excavated material m³ 1120 380<br />

1007 Backfill with concrete class B as directed by the Engineer (provisional quantity) m³ 40 15<br />

1008 Dispose <strong>of</strong> surplus excavated material m³ 10770 3 600<br />

1009 Backfill with granular material type 0/100 m³<br />

Total Sub-Bill 1 0 0 0 0<br />

SUB-BILL NO.2 - CONCRETE INCLUDING FORMWORK AND REINFORCEMENT<br />

2000 Concrete<br />

Prices <strong>of</strong> all concrete items include shuttering, formwork, steel reinforcement, concrete,<br />

vibration, curing, striking, testing steel reinforcement and concrete, all material needed<br />

for expansion joints and workmanship, according to drawings, specifications, conditions<br />

and directed by the engineer.<br />

2001 Blinding 100 mm thick - Class E m² 4030 1 400<br />

2002 Reinforced concrete class A in base slab, apron, ground, beams, pits, sumps, ground blocks, m³ 2265 770<br />

on or below the ground level, whatever the position and elevation<br />

2003 Reinforced concrete class A in walls and columns m³ 335 120<br />

2004 Reinforced concrete class A in any others structures (stairs, weirs, blocks, balconnies, shafts, m³ 110 40<br />

channel, culverts … ) above ground level<br />

2005 Reinforced concrete class A in solid slab m³<br />

2006 Reinforced concrete class A in ribbed slab m³<br />

2007 Mass concrete class A in all position m³<br />

Total Sub-Bill 2 0 0 0 0<br />

SUB-BILL NO.7 - FABRICATED ITEMS<br />

7001 Aluminium hand railing whatever the position including fixing ml 140 50<br />

7002 Galvanized steel grating floors whatever the position including fixing m² 210 0 0<br />

Total Sub-Bill 7<br />

0 0 0 0<br />

SUB-BILL NO.11 - MECHANICAL EQUIPMENT<br />

11100 Degazing<br />

11101 Longitudinal skimmer for degazing U 2 1<br />

11102 Scum collection Hopper for degazing U 2 1<br />

11300 Scum pit<br />

11301 Pump 10 m3/h for scum including accessories U 4 2<br />

11302 Outlet pipes ND 65 HDPE from pumps to collector including accessories lm 2 1<br />

11303 Submersible agitators including accessories U 2 1<br />

11400 Clarifiers<br />

11401 Suction scraper bridge including accessories U 4 2<br />

11500 Sludge recirculation<br />

11501 4 Pumps for recirculation sludge 450 m3/h including accessories, pipes ND 300 up to the ND<br />

600 manifold, valves and accessories<br />

11600 Excess sludge extraction<br />

11601 2 Pumps for excess sludge 80 m3/h including accessories, pipes ND 150 upto the ND 200<br />

manifold, valves and accessories<br />

LS 2 1<br />

LS 2 1<br />

11700 Handling<br />

11701 Hoisting derrick 300 kg for pump recirculation and extraction U 2 1<br />

11702 Hoisting derrick 300 kg for scum pump U 2 1<br />

11702 Hoisting derrick 500 kg for submersible agitators U 2 1<br />

Total Sub-Bill 11<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.12 - ELECTRICAL EQUIPMENT<br />

12000 * Suppling, installing, testing and commission <strong>of</strong> the electrical works as per drawings,<br />

specifications, and engineer's instructions. The prices <strong>of</strong> the follwing items include all<br />

necessary junction boxes, wires, conduits, clamps, bolts, and connectors.<br />

* All installation shall be in accordance with The drawings , secifications and instructions<br />

and demands <strong>of</strong> the engineer and the electricity law and electrical code requirments <strong>of</strong><br />

the BRITISH standards.<br />

* The contractor should refer to the drawings , specifications and other Contract<br />

Documents .<br />

* The prices will be deemed to include for the full cost as described in all Documents.<br />

12100 Lighting Fittings<br />

12101 12m long double armed lighting pole made <strong>of</strong> high static hot galvanised steel sheet with<br />

anodized aluminum street lighting fixture <strong>of</strong> 150W/HPS lamp, including concrete foundation<br />

with lattice base with L shape bolts, excavation, back filling, inlout pipes inspection opening<br />

with door, insulated fibre glass plate, earthing and any needed accessoires.<br />

U 4 2<br />

12200 Switches & sockets:<br />

12300 Protection system<br />

12301 An earthing system including flat steel tapes (34*4mm), testing point, tap <strong>of</strong>f, LS 2<br />

equipotinal bus bars, 80un diam manhole, u bolted clamps and digging <strong>of</strong> three 19<br />

mm diam copper electrodes 3 m long. According to drawing DD- CLA- E 001-B. the<br />

earthing resistance should not exceed 2 Ohms.<br />

12302 Lightning protection system including pulsar lightning conductor, fixation brackets, LS 1<br />

connecting strips 30x2mm copper tape, interconnection box for equipotential bonding,<br />

inspection coupling manholes with 3 electrodes <strong>of</strong> 3mx19mm copper electrode with all<br />

accessories required.<br />

12400 Distribution panels<br />

12401 Supply, install distribution Panel (DP/CLAR-G1)and (DP/CLAR-G2) consist <strong>of</strong> U 2 1<br />

Lockable panel frames as per specifications including 2 mm Galva. Steel sheets with<br />

anti-static paint, bus bars for incoming cables, neutral and earthing terminal with all<br />

necessary accessories needed as per drawing DD- CLA-E-004- B<br />

12402 u1000. R02V <strong>of</strong> section 3x6mm2 cable with HDPE 75mmflexible pipe. Price shall LM 95 30<br />

include trech excavation, earthworks, testing, transporting surplus soil, backfilling,<br />

sand bedding, magretic tape and restoration <strong>of</strong> surface, all as per specifications,<br />

drawings and as directed by the Engineer.<br />

Total Sub-Bill 12<br />

0 0 0 0<br />

SUB-BILL NO.14 - AUTOMATION AND INSTRUMENTATION<br />

14000 Clarifiers<br />

14101 Top level <strong>of</strong> sludge sensor U 4 2<br />

14100 Sludge recirculation measurement<br />

14102 Electromagnetic flow meter on pressure pipe ND 300 including converter and totalizer U 2 1<br />

14200 Excess sludge measurement<br />

14201 Electromagnetic flow meter on pressure pipe ND 150 including converter and totalizer U 2 1<br />

14300 Level measures for Sludge pit<br />

14301 Low level controller U 2 1<br />

14400 Level measures for Scum pit<br />

14401 Level Switch Alarm High High (LSA HH) U 2 1<br />

14402 High level controller U 2 1<br />

14403 Low level controller U 2 1<br />

14404 Level Switch Alarm Low Low (LSA LL) U 2 1<br />

14500 Automation : PLC2 - Clarifiers<br />

14501 Remote Input/Output Modulate U 1<br />

14502 Pr<strong>of</strong>ibus Cable U 1<br />

14503 Remote I/O Modulate Cupboard U 1<br />

Total Sub-Bill 14<br />

Total Bill 5 Clarifiers<br />

0 0 0 0<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

BILL 6 TERTIARY TREATMENT<br />

SUB-BILL NO.1 - EARTHWORKS<br />

1000 Earthworks<br />

1001 Stripping <strong>of</strong> soil m² 1000 200<br />

1002 Excavation in all materials after stripping topsoil not exceeding 5.0 m depth m³ 4560 920<br />

1003 Extra-over for breaking up brickwork, concrete masonry and the like encountered in excavation m³ 50 10<br />

(provisional quantity)<br />

1004 Extra-over for excavation in rock (provisional quantity) m³ 30 10<br />

1005 Excavation for the removal <strong>of</strong> unsuitable material encountered below Permanent Works<br />

m³ 150 30<br />

(provisional quantity)<br />

1006 Backfill with selected excavated material m³ 540 110<br />

1007 Backfill with concrete class B as directed by the Engineer (provisional quantity) m³ 30 10<br />

1008 Dispose <strong>of</strong> surplus excavated material m³ 4560 920<br />

1009 Backfill with granular material type 0/100 m³<br />

Total Sub-Bill 1<br />

0 0 0 0<br />

SUB-BILL NO.2 - CONCRETE INCLUDING FORMWORK AND REINFORCEMENT<br />

2000 Concrete<br />

Prices <strong>of</strong> all concrete items include shuttering, formwork, steel reinforcement, concrete,<br />

vibration, curing, striking, testing steel reinforcement and concrete, all material needed<br />

for expansion joints and workmanship, according to drawings, specifications, conditions<br />

and directed by the engineer.<br />

2001 Blinding 100 mm thick - Class E m² 920 190<br />

2002 Reinforced concrete class A in base slab, apron, ground, beams, pits, sumps, ground blocks, m³ 960 200<br />

on or below the ground level, whatever the position and elevation<br />

2003 Reinforced concrete class A in walls and columns m³ 330 70<br />

2004 Reinforced concrete class A in any others structures (stairs, weirs, blocks, balconnies, shafts, m³ 135 30<br />

channel, culverts … ) above ground level<br />

2005 Reinforced concrete class A in solid slab m³ 70 50<br />

2006 Reinforced concrete class A in ribbed slab m³ 20 5<br />

2007 Mass concrete class A in all position m³ 25 5<br />

2008 Precast concrete class A, as specified or directed by the Engineer m³ 30 10<br />

Total Sub-Bill 2<br />

0 0 0 0<br />

SUB-BILL NO.5 - JOINTS<br />

5000 Movement joints<br />

5001 Supply and fix waterstop (sealing strip)-Type 1 ml 160 45<br />

Total Sub-Bill 5<br />

0 0 0 0<br />

SUB-BILL NO.6 - PROTECTIVES FINISHES<br />

6001 Tyrolean finish coat (minimum 2 coats) for external wall m² 160<br />

6002 Supply and execute external rendering 15mm to walls including galvanized metal lath angles<br />

and chicken wire at the intersection <strong>of</strong> concrete and block work's, pipes and including a<br />

rainwater isolation coat (Sand+Cement) according to Engineer approval and execute two coats<br />

<strong>of</strong> tyrolean finish with white cement for external rendering.<br />

m² 160<br />

6003 Supply and paint three coats policide for the ceiling including all the required materials as<br />

m² 60<br />

shown on the drawings, specifications and Engineer's instructions.<br />

6004 Supply and execute internal plastering 13mm thick (three coats) for the ceiling m² 60<br />

6005 Supply and paint bondrol primer coat and three coats <strong>of</strong> emulsion paint (Supecryl) for internal<br />

walls including all the required materials as shown on the drawings, specifications and<br />

Engineer's instructions.<br />

m² 185<br />

6006 Supply and execute internal plastering 15mm thick (three coats) to walls, s<strong>of</strong>fits, side <strong>of</strong><br />

columns, jambs and reveals <strong>of</strong> openings, window sills, …etc. including galvanized metal lath<br />

angles for columns, edges and chicken wire at the intersection <strong>of</strong> concrete and block works,<br />

pipes.<br />

6007 Supply and cast in-place slopping foam concrete (150 kg/cm2) for ro<strong>of</strong> screeding <strong>of</strong> average<br />

thickness 7.0cm as shown in the drawings specifications and according to Engineer's<br />

instructions. Incl. Suppling and executing cement and sand angle fillets size 5c<br />

6008 Supply and lay one layer <strong>of</strong> plasticised bitumen ro<strong>of</strong>ing membrane ( class 200gr/m2 Polyster)<br />

with chipping 4mm thick including priming concrete surface prior to laying, dressing into rain<br />

water outlets to form water pro<strong>of</strong>ing seal and cover angle fillets, a<br />

m² 185<br />

m² 60<br />

m² 60<br />

6009 Supply and execute cement and sand angle fillets size 5cm x 5cm as shown in the drawings ml 95<br />

and according to engineer's instructions.<br />

6010 Concrete or and concrete reinforcement masonry blocks (20cm in thickness) m² 130

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

6011 Double concrete or and concrete reinforcement masonry blocks with internal insulation layer ( m² 27<br />

kalkal) (10cm in thickness)<br />

Total Sub-Bill 6<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.7 - FABRICATED ITEMS<br />

7001 Aluminium handrailing whatever the position, incl fixing ml 485 162<br />

7002 Galvanized steel grating floor covering the ducts m² 125<br />

7003 Galvanized steel rolled door m² 8<br />

7004 Galvanized steel door including industrial painting, frame, fixing, handle and lock m² 5<br />

7005 Galvanized steel louver windows including industrial painting, frame, fixing, handle and lock m² 5<br />

Total Sub-Bill 7<br />

0 0 0 0<br />

SUB-BILL NO.11 - MECHANICAL EQUIPMENT<br />

11000 Pumping station Intermediate<br />

11001 Inlet PS pumps including accessories, unit flow : 1306 m3/h U 3 1<br />

11002 Pipe ND 500 steel with epoxy painting, including flanges, valves and elbows upto inlet channel lm 30 10<br />

filters<br />

11003 1 standard I-beam capable <strong>of</strong> carrying a 3500kg load at any point + hoist travelling trolley + LS 1<br />

hoist, max load : 5000kg<br />

11100 Sand filters<br />

11101 Overflow (1,50 m) U 4 2<br />

11102 4 Frames (1,50x1,70) and 1 stop-log (1,50x1,70) LS 1 1<br />

11103 Puddle pipe ND 450 (outlet filtred water or inlet wash water) U 4 2<br />

11104 Puddle pipe ND 250 (inlet air wash) U 4 2<br />

11105 Puddle pipe ND 200 (drainage filter) U 4 2<br />

11106 Butterfly valve motorised TOR ND 400 (inlet wash water) U 4 2<br />

11107 Butterfly valve motorised TOR ND 200 (inlet air wash) U 4 2<br />

11108 Butterfly valve motorised probe US ND 450 (outlet filtred water) U 4 2<br />

11109 Penstock motorised (outlet wash water) 400x400 U 4 2<br />

11110 Manual Gate valve ND 200 (filters drainage) U 4 2<br />

11111 Filter floor : all fitting equipment for : botts +nuts + slad attachement plate + sets <strong>of</strong> peripheral<br />

slad attachment brackeets, under-slab seals : natural rubber, dimensions :<br />

20 x 151 mm, hardness : 45 shores + sets <strong>of</strong> inter-slab seals<br />

LS 4 2<br />

11112 Filter long stem nozzles (220 mm) with embedding part, seal and installation fittings U 13300 6 600<br />

11113 Blowers air including all pipes, valves, accessories U 2<br />

11114 Delivery pipes as far as front-<strong>of</strong> filters, ND200, 304L stainless steel lm 30 6<br />

11115 Wash water pump including all pipes from pumps to all filters and valves, level probe, unit flow U 3<br />

455 m3/h<br />

11116 Dirty water pumps 135 m3/h including all valves, pipes from pumps to 1m after structure <strong>of</strong> the U 2<br />

PS, and all accessories<br />

11117 Sand (particle size 1,35 mm), C.U. < 1,5 _ 340m3 (Phase 1), 170m3 (Phase 2) T 340 170<br />

11118 Filter gravel 4/8 mm _ 25 m3 (Phase 1), 12m3 (Phase 2) T 25 12<br />

11119 Supply, install and commissioning up complete decorated split air conditioning unit<br />

OF CAPACITY 24000 BTU/Drywall mounted, including all valves,three speed fan<br />

control switch,drain pipe to be connected to the nearest drain pipe ,suspension<br />

accessories and all other accessories which are needed to complete the work as per<br />

U 1<br />

specification and drawings and as directed by the Engineer.<br />

11200 Desinfection U.V.<br />

11201 UV lamp including Regulation valves, electrical equipment, instrumentation LS 1 0.33<br />

11202 Frames for bulkhead gates (1,50 m x 1,98 m) U 4 2<br />

11203 Stop logs (1,50 m x 1,98) U 2 1<br />

11204 Sliding gate (1,50 m x 1,98), including motors, frames,… U 1

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

11300 Treated effluent PS<br />

11301 Variable speed pumps for treated effluent pumping station each equiped with variable<br />

frequency device (VFD) including all accessories, rates, pipes from pumps to 5 m outside<br />

building, level probes, including all accessories, unit flow : 1200m3/h …<br />

U 3 1<br />

11302 Outlet pipe ND 550 steel with epoxy painting, including electrical isolation joint, gate valves,<br />

check valves, air release valves, and all required fittings<br />

manifold pipe ND 920 steel with epoxy painting, including electrical isolation joint, gate valves,<br />

check valves, air release valves, and all required fittings<br />

11303 Supply and install stainless steel automatic air surge vessel (ARAA) dipping tube type for waste<br />

water use ( Vertical with volume <strong>of</strong> 35 m3) include complete installation <strong>of</strong> pipes, supports, all<br />

fittings such as: elbows , reducers , joints , valves .. Etc<br />

lm 30<br />

lm 20<br />

U 1<br />

11400 Industrial water<br />

11401 Variable-speed assembly consisting <strong>of</strong> three variable speed electropumps, total flow, 72 m3/h, U 1<br />

with chamber 500L and with all accessories …<br />

11402 Suction manifold from treated effluent PS, ND 125 steel with epoxy painting and HPDE lm 4<br />

11700 Manutention<br />

11701 Hoist and Hoisting derrick 5000 kg for inlet PS pump LS 1 1<br />

11702 Hoist and Hoisting derrick 5000 kg for blower air LS 1 1<br />

11703 Hoist and Hoisting derrick 5000 kg for wash water pump LS 1 1<br />

11704 Hoist and Hoisting derrick 5000 kg for wash water pump return inlet station LS 1 1<br />

11705 Hoisting derrick 500 kg for UV module U 2 1<br />

11706 Hoist and Hoisting derrick 5000 kg for treated effluent pumps LS 1 1<br />

Total sub-Bill 11<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.12 - ELECTRICAL EQUIPMENT<br />

12000 * Suppling, installing, testing and commission <strong>of</strong> the electrical works as per drawings,<br />

specifications, and engineer's instructions. The prices <strong>of</strong> the follwing items include all<br />

necessary junction boxes, wires, conduits, clamps, bolts, and connectors.<br />

* All installation shall be in accordance with The drawings , secifications and instructions<br />

and demands <strong>of</strong> the engineer and the electricity law and electrical code requirments <strong>of</strong><br />

the BRITISH standards.<br />

* The contractor should refer to the drawings , specifications and other Contract<br />

Documents .<br />

* The prices will be deemed to include for the full cost as described in all Documents.<br />

12100 Lighting Fittings<br />

12101 Supply, install, connect and test fluorescent lighting fixture 2x36w complete with lighting tubes<br />

36, chock, condensers, starters rigid PVC conduits, J.boxes, fixing screws (Galv.) and wiring.<br />

(provesional condition)<br />

U 1 1<br />

12102 Ditto, but water and dust pro<strong>of</strong> IP65. U 25 4<br />

12103 Ditto, but with emergency back up power built in, for duration 3 hours. U 4 6<br />

12104 Supply, install, connect and test incandescence lighting fixture with 75W lamp, wires, U 8 1<br />

conduits, j. boxes and fixing screws for ceiling mounted.<br />

12105 Supply, install, connect and testing ( Projector Rectangular) IP-55 equipment with<br />

lamp 250W/230V H.P.S complete with PVC conduite, j.box wiring or cabling and all<br />

necessery accessories type in (philips or equivalent as per drawing No DD-TER-E-<br />

002_B<br />

12106 Supply, install connect and test single pole one way switch IP-55 watertight plate,<br />

230V/13A complete with PVC conduite, junction box, wiring or (cables), cover and all<br />

necessery accessories (type is LEGRAND or equivalent)<br />

12107 Supply, install connect and testing pocket out-let IP-55 water tight plate A (2p+E)<br />

U 4 4<br />

U 6 3<br />

U 4 2<br />

230V/16A for surface or flush mounting, complete with PVC conduits, junction box,<br />

wiring or cabling and all necessery accessories (type is LEGRAND or equivalent)<br />

12108 Ditto, but (3p+E) 380V/16A socket U 4 2<br />

12109 Concret manhole (100x120x100cm), with 25 ton cover. U 3 2<br />

12200 Switches & sockets: 2<br />

12300 Protection system<br />

12301 An earthing system including flat steel tapes (34*4mm), testing point, tap <strong>of</strong>f,<br />

equipotinal bus bars, 80un diam manhole, u bolted clamps and digging <strong>of</strong> three 19<br />

mm diam copper electrodes 3 m long. According to drawing DD-TER – E-001_A . the<br />

earthing resistance should not exceed 2 ohms.<br />

12302 Lightning protection system including pulsar lightning conductor, fixation brackets,<br />

connecting strips 30x2mm copper tape, interconnection box for equipotential bonding,<br />

inspection coupling manholes with 3 electrodes <strong>of</strong> 3mx19mm copper electrode with all<br />

accessories required.<br />

LS 1<br />

LS 1

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

12400 Distribution boards and panels<br />

12401 Sub-distributionn board ( SDB/SF). Supply, install distribution board consist <strong>of</strong> LS 1<br />

Lockable panel frames as per specifications including 2 mm Galva. Steel sheets with<br />

anti-static paint, bus bars for incoming cables, neutral and earthing terminal with all<br />

necessary accessories needed as per drawing DD- TER-E-004_B<br />

12402 Ditto, but lighting Panel <strong>of</strong> Sand filter (L.P/S.F) according the drawing plan No DD- LS 1<br />

TER-E-005_A<br />

12403 Distribution Panel Backwah water and Control Valuer. ( DP/B.W-C.V). Supply, install LS 1<br />

distribution Panel consist <strong>of</strong> Lockable panel frames as per specifications including 2<br />

mm Galva. Steel sheets with anti-static paint, bus bars for incoming cables, neutral<br />

and earthing terminal with all necessary accessories needed as per drawing DD- TER-<br />

E-003_A<br />

12404 Isolating Box, consist <strong>of</strong> individual enclosure for M.C.B, IP-65, Surface mounted, U 4<br />

dimension 187x250mm tans parent door for operator access. Moeller type sefesence<br />

AE/123E/T as equivalent. As per drawing DD-TER-E-003_ A<br />

12405 Supply, isolating switches 450 A at junction box water pro<strong>of</strong> IP 65 with defferent U 4 2<br />

switching.<br />

12406 Ditto, but 100 A. 2<br />

12407 Ditto, but 70 A. 4 1<br />

12408 Ditto, but35 A. 2 1<br />

12409 Supply, INSTALLE CABLE TRAY GALIAMIZED STEEL ( Perforet ) <strong>of</strong> dinewusion LM 40<br />

200 x35mm<br />

12410 Ditto, but 150X35mm LM 35 10<br />

12411 Ditto, but 100X35mm LM 155 50<br />

12412 supply, installe R02V - u 1000 <strong>of</strong> section ( 3x 150+70 ) mm2 LM 100 20<br />

12413 Ditto - but section (4x35mm2) LM 150 50<br />

12414 Ditto - but section (4x16mm2) LM 40 15<br />

12415 Ditto- but section ( 4x10mm2) LM 35 10<br />

Total Sub-Bill 12<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.14 - AUTOMATION AND INSTRUMENTATION<br />

14000 Level measures for Intermediate pumping station<br />

14001 Level Switch Alarm High High (LSA HH) U 1<br />

14002 High level controller U 1<br />

14003 Low level controller U 1<br />

14004 Level Switch Alarm Low Low (LSA LL) U 1<br />

14100 Level measures for Sand filtration<br />

14101 Level sensor U 4 2<br />

14102 Fitters clogging measurement devices U 4 2<br />

14200 Level measures for filtered wash water PS<br />

14201 Level Switch Alarm High High (LSA HH) U 1<br />

14202 Level Switch Alarm Low Low (LSA LL) U 1<br />

14300 Level measures for Treated effluent pumping station<br />

14301 Level Switch Alarm High High (LSA HH) U 1<br />

14302 High level controller U 1<br />

14303 Low level controller U 1<br />

14304 Level Switch Alarm Low Low (LSA LL) U 1<br />

14400 Backwash water measurement<br />

14401 Electromagnetic flow meter on pressure pipe ND350 with converter and totalizer U 1<br />

14500 Dirty water measurement<br />

14501 Electromagnetic flow meter on pressure pipe ND200 with converter and totalizer U 1<br />

14600 Air flow measurement<br />

14601 Air flow measurement U 2<br />

14700 Physico-chemical measurements for treated effluent PS<br />

14701 pH sensor U 1<br />

14702 O2 sensor U 1<br />

14703 Temperature sensor U 1<br />

14704 NO3 sensor U 1 2<br />

14705 Turbidity sensor U 1<br />

14706 Ammonium sensor U 1<br />

14800 Automation : PLC3 - Tertiary Treatment<br />

14801 CPU U 1 2<br />

14802 Input TOR Modulate 32 Ways U 4<br />

14803 Output TOR Modulate 16 Ways U 1<br />

14804 Output TOR Modulate 8 Ways U 1<br />

14805 Inpput Analogical Modulate 8 Ways U 7 1<br />

14806 Output Analogical Modulate 8 Ways U 4 2<br />

14807 Pr<strong>of</strong>ibus Cable U 1<br />

14808 Ethernet Switch U 1 1<br />

14809 Touch Panel U 1 1<br />

14810 PLC Cupboard U 1 1<br />

Total sub-Bill 14<br />

0 0 0 0<br />

Total Bill 6 Sand filters<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

BILL 7 THICKENER<br />

SUB-BILL NO.1 - EARTHWORKS<br />

1000 Earthworks<br />

1001 Stripping <strong>of</strong> soil m² 580 200<br />

1002 Excavation in all materials after stripping topsoil not exceeding 5.0 m depth m³ 1575 530<br />

1003 Extra-over for breaking up brickwork, concrete masonry and the like encountered in excavation m³<br />

(provisional quantity)<br />

1004 Extra-over for excavation in rock (provisional quantity) m³<br />

1005 Excavation for the removal <strong>of</strong> unsuitable material encountered below Permanent Works<br />

m³<br />

(provisional quantity)<br />

1006 Backfill with selected excavated material m³ 900 300<br />

1007 Backfill with concrete class B as directed by the Engineer (provisional quantity) m³<br />

1008 Dispose <strong>of</strong> surplus excavated material m³ 1575 530<br />

1009 Backfill with granular material type 0/100 m³<br />

Total Sub-Bill 1<br />

0 0 0 0<br />

SUB-BILL NO.2 - CONCRETE INCLUDING FORMWORK AND REINFORCEMENT<br />

2000 Concrete<br />

Prices <strong>of</strong> all concrete items include shuttering, formwork, steel reinforcement, concrete,<br />

vibration, curing, striking, testing steel reinforcement and concrete, all material needed<br />

for expansion joints and workmanship, according to drawings, specifications, conditions<br />

and directed by the engineer.<br />

2001 Blinding 100 mm thick - Class E m² 530 180<br />

2002 Reinforced concrete class A in base slab, apron, ground, beams, pits, sumps, ground blocks, m³ 300 100<br />

on or below the ground level, whatever the position and elevation<br />

2003 Reinforced concrete class A in walls and columns m³ 110 40<br />

2004 Reinforced concrete class A in any others structures (stairs, weirs, blocks, balconnies, shafts, m³ 115 40<br />

channel, culverts … ) above ground level<br />

2005 Reinforced concrete class A in solid slab m³<br />

2006 Reinforced concrete class A in ribbed slab m³ 10<br />

2007 Mass concrete class A in all position m³ 2<br />

Total Sub-Bill 4<br />

0 0 0 0<br />

SUB-BILL NO.5 - JOINTS<br />

5000 Movement joints<br />

5001 Supply and fix waterstop (sealing strip)-Type 1 ml 55 20<br />

Total Sub-Bill 5<br />

0 0 0 0<br />

SUB-BILL NO.6 - PROTECTIVES FINISHES

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

6001 Tyrolean finish coat (minimum 2 coats) for external wall m² 92<br />

6002 Supply and execute external rendering 15mm to walls including galvanized metal lath angles m² 92<br />

6003 and Concrete chicken or and wire concrete at the intersection reinforcement <strong>of</strong> concrete masonry and blocks (20cm work's, in pipes thickness) and including a<br />

m² 75<br />

6004 Supply and paint three coats policide for the ceiling including all the required materials as<br />

m² 30<br />

6005<br />

shown on the drawings, specifications and Engineer's instructions.<br />

Inside plaster render for the ceiling m² 30<br />

6006 Supply and paint bondrol primer coat and three coats <strong>of</strong> emulsion paint (Supecryl) for internal<br />

walls including all the required materials as shown on the drawings, specifications and<br />

Engineer's instructions.<br />

6007 Supply and execute internal plastering 15mm thick (three coats) to walls, s<strong>of</strong>fits, side <strong>of</strong><br />

columns, jambs and reveals <strong>of</strong> openings, window sills, …etc. including galvanized metal lath<br />

angles for columns, edges and chicken wire at the intersection <strong>of</strong> concrete and block works,<br />

pipes.<br />

6008 Supply and cast in-place slopping foam concrete (150 kg/cm2) for ro<strong>of</strong> screeding <strong>of</strong> average<br />

thickness 7.0cm as shown in the drawings specifications and according to Engineer's<br />

instructions. Incl. Suppling and executing cement and sand angle fillets size 5c<br />

m² 70<br />

m² 70<br />

m² 30<br />

6009 Supply and lay one layer <strong>of</strong> plasticised bitumen ro<strong>of</strong>ing membrane ( class 200gr/m2 Polyster) m² 30<br />

6010<br />

with chipping 4mm thick including priming concrete surface prior to laying, dressing into rain<br />

water Supply outlets and execute to form cement water pro<strong>of</strong>ing and sand seal angle and fillets cover size angle 5cm fillets, x 5cm a as shown in the drawings ml 23<br />

and according to engineer's instructions.<br />

Total Sub-Bill 6<br />

0 0<br />

SUB-BILL NO.7 - FABRICATED ITEMS<br />

7001 Aluminium hand railing whatever the position, including fixing ml 40 20 0 0 0<br />

7002 Galvanized steel door with lower louvers including industrial painting, frame, fixing, handle and m² 9<br />

lock<br />

7003 Galvanized steel louver windows including industrial painting, frame, fixing, handle and lock m² 1.8<br />

Total Sub-Bill 7<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

SUB-BILL NO.11 - MECHANICAL EQUIPMENT<br />

11001 Surge skirt, diameter : 17 m,Picket fence, Floor scraper with all accessories U 2 1<br />

11002 Pump for supernatant installed in the pumping station including, all valves, all accessories,<br />

pipes from pumps to 1m outside the structure back flow<br />

Unit flow = 100 m3/h<br />

U 2 1<br />

11100 Thickened sludge pumping station<br />

11101 Pumps with variable speed (max flow:80 m3/h) for thickened sludge including all accessories,<br />

valves, pipes<br />

11700 Handling<br />

11701 Hoist and Hoisting derrick 500 kg for supernatant pump ls 2<br />

SUB-BILL NO.12 - ELECTRICAL EQUIPMENT<br />

12000 * Suppling, installing, testing and commission <strong>of</strong> the electrical works as per drawings,<br />

specifications, and engineer's instructions. The prices <strong>of</strong> the follwing items include all<br />

necessary junction boxes, wires, conduits, clamps, bolts, and connectors.<br />

* All installation shall be in accordance with The drawings , secifications and instructions<br />

and demands <strong>of</strong> the engineer and the electricity law and electrical code requirments <strong>of</strong><br />

the BRITISH standards.<br />

* The contractor should refer to the drawings , specifications and other Contract<br />

Documents .<br />

* The prices will be deemed to include for the full cost as described in all Documents.<br />

U 2 1<br />

Total sub-Bill 11<br />

0 0 0 0<br />

12100 Lighting Fittings<br />

12101 Supply, install, connect and test fluorescent lighting fixture 2x36w complete with lighting tubes<br />

36, chock, condensers, starters rigid PVC conduits, J.boxes, fixing screws (Galv.) and wiring.<br />

(provesional condition)<br />

U 1 1<br />

12102 Ditto, but water and dust pro<strong>of</strong> IP65. U 2 1<br />

12103 Supply, install, connect and test incandescence lighting fixture with 75W lamp, wires, conduits, U 4 2<br />

j. boxes and fixing screws for wall mounted IP 65.<br />

12104 Ditto, but with PL lamp U 2 1<br />

12105 Supply, install, connect and test lighting unit with 11w PL lamp with all needed part U 1 1<br />

and cables,(h=25cm) as per drawings (provesional condition)<br />

12106 Supply, install, connect and test emergency lighting fixture 8w, 3hrs. duration with self U 1 1<br />

adhesive PVC exit legend complete with all necessary accessories. (provesional<br />

condition)<br />

12200 Switches & sockets:<br />

12201 Supply, install connect and test single pole one way switch, 220v, 13A, complete with U 1 1<br />

PVC conduits, J.boxes, wiring,cover and all necessary accessories. (Type is<br />

LEGRAND or equivalent). (provesional condition)<br />

12202 Ditto, but water pro<strong>of</strong>. U 4 2<br />

supply, install connect and, testing single socket outlet 16A, 220v, 2p+E for flush or<br />

U 1 1<br />

surface mounting, complete with PVC conduits, J.boxes, wiring, and all necessary<br />

accessories. (Type is LEGRAND or equivalent). (provesional condition)<br />

Ditto, but water pro<strong>of</strong> (Type is LEGRAND or equivalent) U 2 1<br />

Ditto, but three phase socket outlet 3X16A, 380v, 3p+N+E for flush or surface U 2 1<br />

mounting, complete with PVC conduits, J.boxes, wiring, and all necessary<br />

accessories. (Type is LEGRAND or equivalent)

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />

Phase 1 Phase 2<br />

Item No. Item Description Unit. Quantity Costs Amounts Quantity Costs Amounts<br />

FEX USD FEX USD FEX USD FEX USD<br />

12300 Protection system<br />

12301 An earthing system including flat steel tapes (34*4mm), testing point, tap <strong>of</strong>f, LS 1<br />

equipotinal bus bars, 80un diam manhole, u bolted clamps and digging <strong>of</strong> three 19<br />

mm diam copper electrodes 3 m long. According to drawing DD- Thic- E-001-B . the<br />

earthing resistance should not exceed 2 ohms.<br />

12302 Lightning protection system including pulsar lightning conductor, fixation brackets, LS 1<br />

connecting strips 30x2mm copper tape, interconnection box for equipotential bonding,<br />

inspection coupling manholes with 3 electrodes <strong>of</strong> 3mx19mm copper electrode with all<br />

accessories required.<br />

12400 Distribution panels<br />

12401 Supply, Supply, install distribution Panel DP/thic consist <strong>of</strong> Lockable panel frames as U 1 1<br />

per specifications including 2 mm Galva. Steel sheets with anti-static paint, bus bars<br />

for incoming cables, neutral and earthing terminal with all necessary accessories<br />

needed as per drawing DD- THI-E-002_B<br />

12402 Ditto, but control Box U 2 1<br />

12403 Piping UPV OF 2" LM 80 30<br />

12404 Mahhole cd 60 un U 2 1<br />

12405 cables u1000 R02V 4X6mm2 MM 100 50<br />

SUB-BILL NO.14 - INSTRUMENTATION<br />

14000 Level measures for Thickened sludge pumping station<br />

14001 Level Switch Alarm High High (LSA HH) U 1<br />

14002 High level controller U 1<br />

14003 Low level controller U 1<br />

14004 Level Switch Alarm Low Low (LSA LL) U 1<br />

14100 Level measures for Backflow pumping station<br />

14101 Level Switch Alarm High High (LSA HH) U 1<br />

14102 High level controller U 1<br />

14103 Low level controller U 1<br />

14104 Level Switch Alarm Low Low (LSA LL) U 1<br />

14500 Automation : PLC4 - Backflow Pumping Station<br />

14501 CPU U 1<br />

14502 Input TOR Modulate 32 Ways U 1<br />

14503 Input TOR Modulate 8 Ways U 1<br />

14504 Output TOR Modulate 16 Ways U 1<br />

14505 Inpput Analogical Modulate 8 Ways U 1<br />

14506 Output Analogical Modulate 4 Ways U 1<br />

14507 Pr<strong>of</strong>ibus Cable U 1<br />

14508 Ethernet Switch U 1<br />

14509 Touch Panel U 1<br />

14510 PLC Cupboard U 1<br />

Total Sub-Bill 12<br />

Total Sub-Bill 14<br />

Total Bill 7 Thickeners<br />

0 0 0 0<br />

0 0 0 0<br />

0 0 0 0

Undp / Papp<br />

DETAILED DESIGN FOR THE CONSTRUCTION OF KHAN YOUNIS WASTEWATER TREATMENT PLANT IN GAZA STRIP<br />

APPENDIX 6-DETAILED DESIGN - BILL OF QUANTITIES<br />