You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> different configurations<br />

and technologies <strong>in</strong> <strong>ice</strong> mach<strong>in</strong>es<br />

An <strong>ice</strong> maker is an mach<strong>in</strong>e that uses the refrigeration technology<br />

to freeze water and turn it <strong>in</strong>to <strong>ice</strong>, with different sizes,<br />

shapes and humidity percentages. <strong>The</strong> refrigeration system of an<br />

<strong>ice</strong> mach<strong>in</strong>e is designed to absorb heat from water and transfer it<br />

to the surround<strong>in</strong>g environment, by means of a gas that is <strong>in</strong>itially<br />

compressed, then cooled-down until it condensates Into a liquid<br />

state (this heat exchange process takes place <strong>in</strong> the condenser),<br />

then allowed to boil, or evaporate, <strong>in</strong> a controlled way, return<strong>in</strong>g<br />

to its orig<strong>in</strong>al state by absorb<strong>in</strong>g the needed heat from the water<br />

that is brought <strong>in</strong> contact with it <strong>in</strong> the “evaporator”.<br />

<strong>The</strong> system consists of these ma<strong>in</strong> components:<br />

the Compressor: pumps-<strong>in</strong>, compresses and pushes-out the<br />

refrigerant gas, at a high temperature and pressure, therefore rich<br />

<strong>in</strong> energy, send<strong>in</strong>g it <strong>in</strong>to a closed circuit.<br />

Condenser: the place where the refrigerant gas condenses <strong>in</strong>to<br />

a liquid state as heat is removed and released to the surround<strong>in</strong>g<br />

environment. An <strong>in</strong>sufficient heat exchange <strong>in</strong> the condenser will<br />

result <strong>in</strong>to an <strong>in</strong>complete gas condensation, hence <strong>in</strong>to a less<br />

efficient <strong>ice</strong> mak<strong>in</strong>g process.<br />

Expansion valve: divides the first, high-pressure section of the<br />

circuit from the second, low-pressure one, and regulates the flow<br />

of liquid refrigerant that enters the evaporator to proceed and<br />

absorb heat from the water.<br />

Evaporator: here, the liquid refrigerant, due to the pressure<br />

drop, can go back (evaporate) to its orig<strong>in</strong>al state of gas. In order<br />

to complete this process, it needs heat– hence its subtraction<br />

from the water, which <strong>in</strong> turn starts freez<strong>in</strong>g and form<strong>in</strong>g <strong>ice</strong>.<br />

Once the <strong>ice</strong> is formed <strong>in</strong> whichever way we need it (cubes, flakes,<br />

etc) the freez<strong>in</strong>g cycle comes to a completion, and <strong>ice</strong> is detached<br />

from the evaporator. This may be achieved <strong>in</strong> different ways:<br />

mechanically (forced <strong>ice</strong> harvest), or by revers<strong>in</strong>g the refrigerant<br />

flow <strong>in</strong> the system by send<strong>in</strong>g it directly to the evaporator rather<br />

than to the condenser. Hot gas will start melt<strong>in</strong>g the <strong>ice</strong>, which<br />

will then fall-off by gravity. A comb<strong>in</strong>ation of the mechanical and<br />

thermal actions may be adopted to speed up the harvest<strong>in</strong>g<br />

process.<br />

Now, it should now be easier to understand that:<br />

• <strong>The</strong> refrigerant at high temperature can be cooled down <strong>in</strong> the<br />

condenser by the means of air circulation (forced air) or water<br />

circulation.<br />

• <strong>The</strong> two ma<strong>in</strong> parameters that may affect the production<br />

capacity of an <strong>ice</strong> mach<strong>in</strong>e are:<br />

• Room temperature (for units with air-cooled condenser)<br />

• Water Temperature (affects both condensation and <strong>ice</strong><br />

production capacity)<br />

As these parameters vary, so does the production capacity of an<br />

<strong>ice</strong> mach<strong>in</strong>e vs. the normal conditions. Also, <strong>in</strong>stall<strong>in</strong>g and<br />

commission<strong>in</strong>g the <strong>ice</strong> mach<strong>in</strong>e correctly, and a regular mach<strong>in</strong>e<br />

clean<strong>in</strong>g rout<strong>in</strong>e will ensure peak performance rather than a<br />

sluggish one.<br />

• <strong>The</strong> Air-Cooled Condenser (AS) looks like a car radiator,<br />

cooled down by the action of a fan which forces air through it.<br />

Both the griddle of the condenser and/or the air-filter that protects<br />

it, must be kept clean from the accumulation of clogg<strong>in</strong>g agents,<br />

such as dust and grease to ma<strong>in</strong>ta<strong>in</strong> their function. Designed to<br />

work best at a + 40° C ambient temperature, it will be adversely<br />

affected by an <strong>in</strong>crease of the ambient temperature and/or<br />

by a decrease <strong>in</strong> the air flow (which may also occur <strong>in</strong> case of<br />

poor built-<strong>in</strong> <strong>in</strong>stallations), with the consequent result of a<br />

decrease <strong>in</strong> the <strong>ice</strong> mach<strong>in</strong>e production capacity.<br />

A water condenser consists of a coil made of two pipes welded<br />

together, where respectively water and refrigerant gas flow<br />

through. This system is less demand<strong>in</strong>g <strong>in</strong> terms of clean<strong>in</strong>g and<br />

ma<strong>in</strong>tenance and it is recommended <strong>in</strong> temperature-critical<br />

<strong>in</strong>stallations. Typically, water-cooled <strong>ice</strong> mach<strong>in</strong>es are used where<br />

the heat exchange is <strong>in</strong>sufficient, or where it may cause overheat<strong>in</strong>g,<br />

and best where the <strong>in</strong>let water-temperature is consistently<br />

around 18°-20°C. Examples of such situations, where water<br />

condens<strong>in</strong>g is highly recommended, are built-<strong>in</strong> <strong>in</strong>stallations<br />

with reduced air flow, or dusty environments, or where the<br />

noise factor must be kept to a m<strong>in</strong>imum (the water cooled<br />

condenser is virtually noiseless). <strong>The</strong> many advantages offered<br />

by the water cooled condensers must be weighed aga<strong>in</strong>st<br />

the <strong>in</strong>creased water consumption, with all the relevant issues <strong>in</strong><br />

terms of cost, availability and recycl<strong>in</strong>g of this precious element. In<br />

areas where water is rich <strong>in</strong> m<strong>in</strong>erals, the use of a correctly sized<br />

water-soften<strong>in</strong>g system is highly recommended.<br />

When specific local circumstances do not allow for the use of a<br />

water condensed unit, we may resort to variations on the standard<br />

air-condens<strong>in</strong>g system, such as:<br />

• Remote Condenser (ASR): allows for a remote <strong>in</strong>stallation of<br />

the condenser, away from the location of <strong>ice</strong> maker. It means<br />

remov<strong>in</strong>g all the heat-ejection and noise and plac<strong>in</strong>g them<br />

(usually) outside.<br />

Large units will also allow for SPLIT <strong>in</strong>stallations: here, not<br />

only the compressor is remotely <strong>in</strong>stalled, but also the<br />

refrigeration/ condens<strong>in</strong>g system (the compressor and so on),<br />

typically placed altogether outside of the <strong>ice</strong> production site. Both<br />

these systems grant an improved operation of <strong>ice</strong> mach<strong>in</strong>es that<br />

use air condensers <strong>in</strong> high-ambient conditions.<br />

General rule: a clean condenser will grant better energy<br />

efficiency and a longer work<strong>in</strong>g life of the refrigeration<br />

system components. Smaller <strong>ice</strong> mach<strong>in</strong>es, particularly affected<br />

by the opposite condition, are now equipped <strong>in</strong> the <strong>Scotsman</strong> 6<br />

Series with a “Clean Me!” light, positioned on the front panel side<br />

to the On-Off switch, which alerts the operator when the<br />

clean<strong>in</strong>g of the condenser air filter is due.<br />

Make the best<br />

of your bus<strong>in</strong>ess<br />

with <strong>Scotsman</strong> Ice!<br />

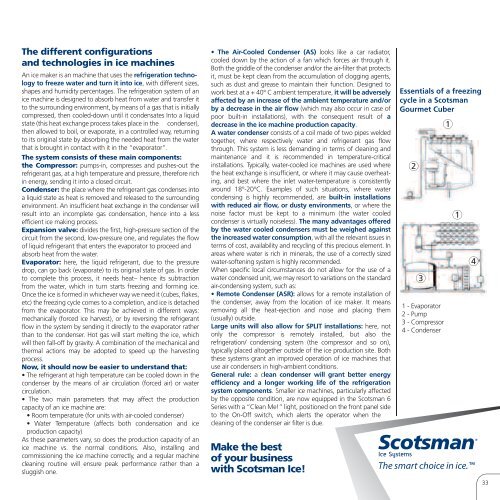

Essentials of a freez<strong>in</strong>g<br />

cycle <strong>in</strong> a <strong>Scotsman</strong><br />

Gourmet Cuber<br />

2<br />

3<br />

1 - Evaporator<br />

2 - Pump<br />

3 - Compressor<br />

4 - Condenser<br />

<strong>The</strong> <strong>smart</strong> <strong>cho<strong>ice</strong></strong> <strong>in</strong> <strong>ice</strong>.<br />

1<br />

1<br />

4<br />

33